skunkpharmresearch

Member since Jun 2016

This is the head cheese's account

Screen Name:

skunkpharmresearch

Gender:

City:

Portland

State:

Oregon

Country:

USA

Birthday:

Blog Articles Created

118 articles

-

-

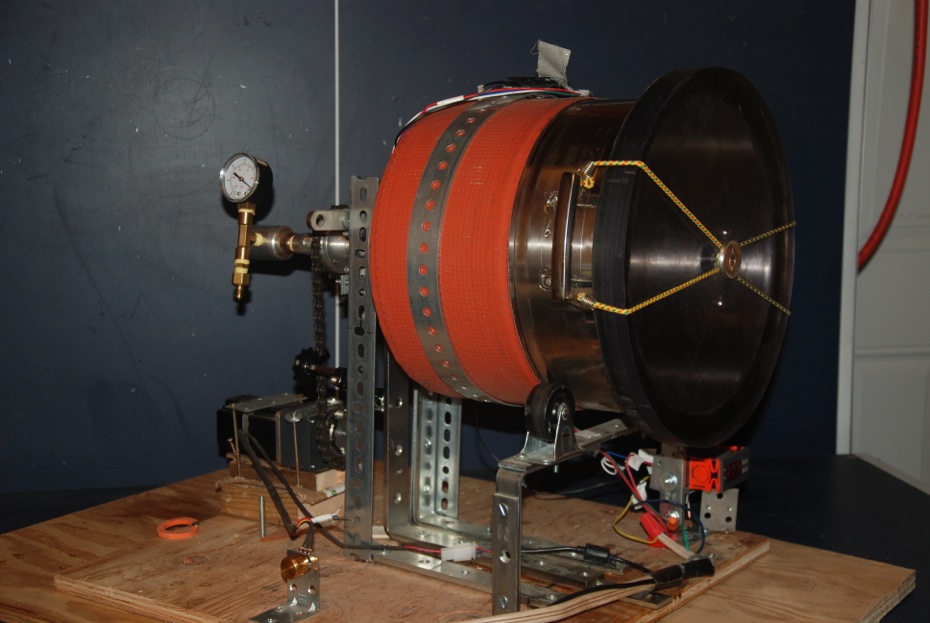

The Mk IA & automated Mk II Terpenator BHO Extractor

The Mk IA & automated Mk II Terpenator BHO Extractor

-

117 Comments

-

QWET Extraction With Ethanol

QWET Extraction With Ethanol

-

429 Comments

-

Cannabuttons

Cannabuttons

-

22 Comments

-

Alcohol Reclaim Still

Alcohol Reclaim Still

-

100 Comments

-

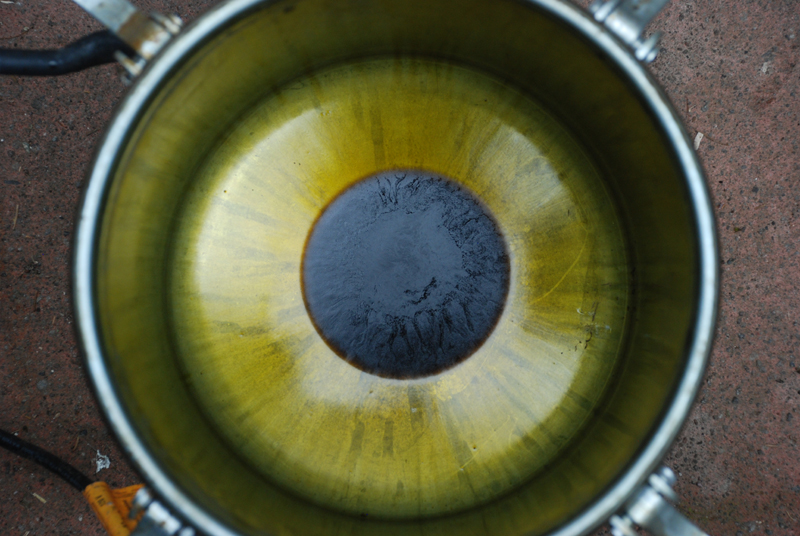

Cannabinoid and Terpene Info

Cannabinoid and Terpene Info

-

122 Comments

-

Grinning Reaper Dry Siever

Grinning Reaper Dry Siever

-

11 Comments

-

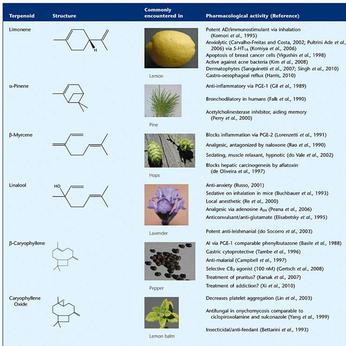

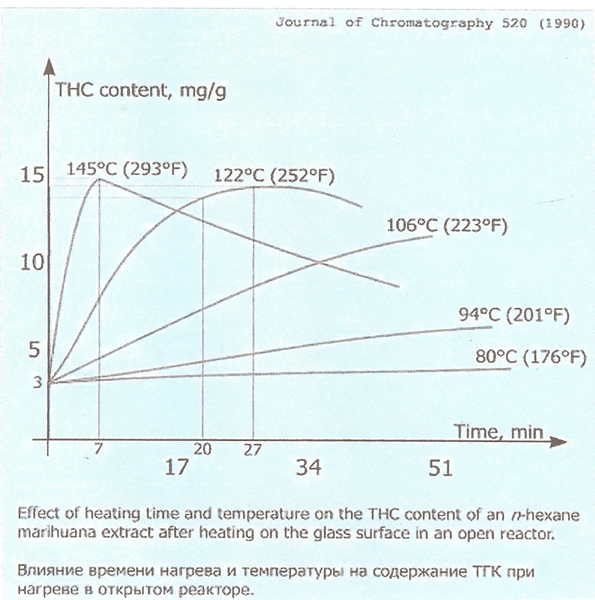

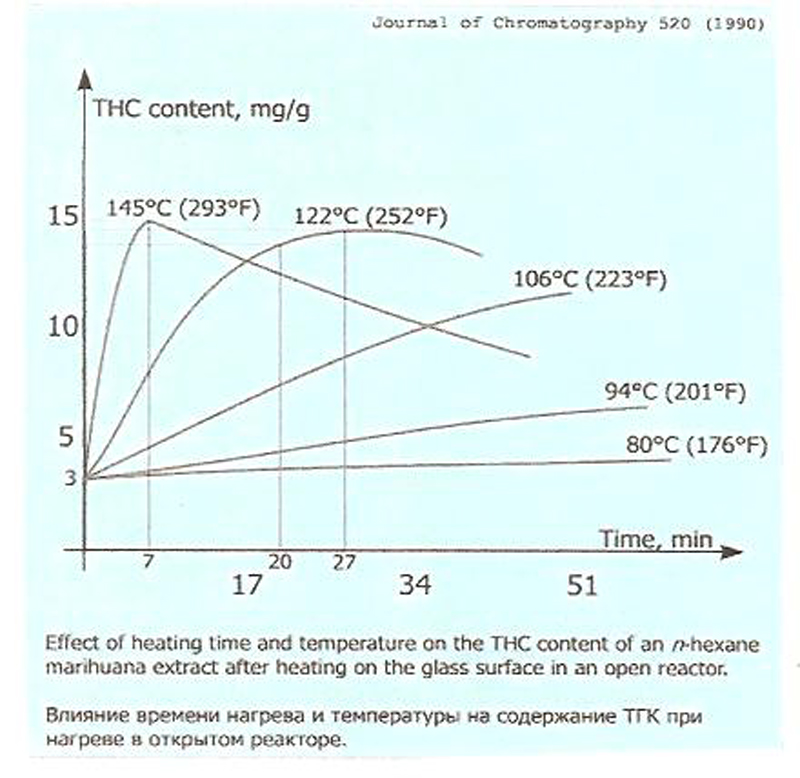

Decarboxylation

Decarboxylation

-

780 Comments

-

Butane Safety

Butane Safety

-

67 Comments

-

BHO Extraction

BHO Extraction

-

815 Comments

-

Cannapops

Cannapops

-

28 Comments

-

Glycerin Extraction

Glycerin Extraction

-

511 Comments

-

Holy Annointing Oil and Holy Shit.

Holy Annointing Oil and Holy Shit.

-

222 Comments

-

Acoustical Dry Sieving

Acoustical Dry Sieving

-

32 Comments

-

Granny Storm Crows 2014 list

Granny Storm Crows 2014 list

-

2 Comments

-

Stem Oil Extraction

Stem Oil Extraction

-

28 Comments

-

QWISO Extraction with Isopropyl

QWISO Extraction with Isopropyl

-

326 Comments

-

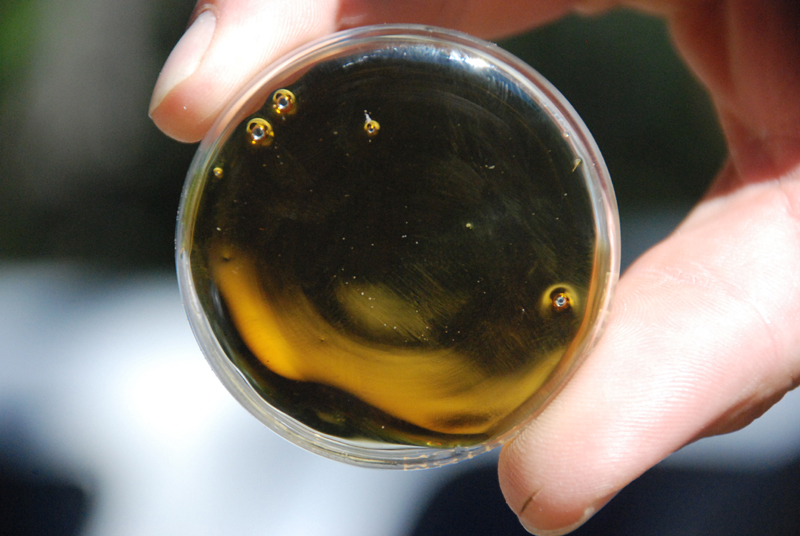

Hexane Honey Oil

Hexane Honey Oil

-

202 Comments

-

Extracting With Oils

Extracting With Oils

-

246 Comments

-

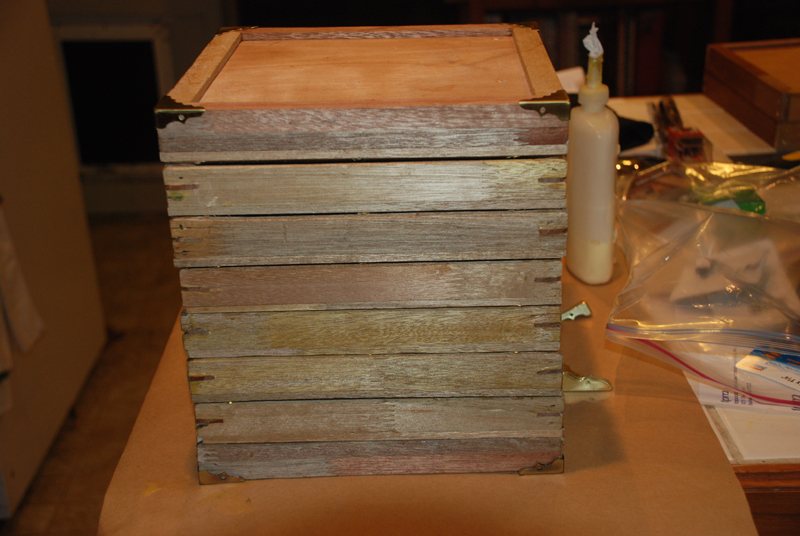

DIY Sieving Frames

DIY Sieving Frames

-

26 Comments

-

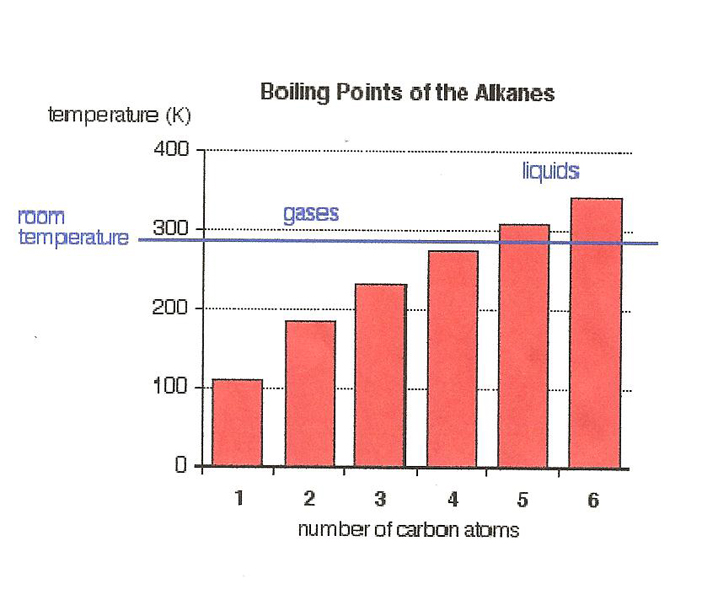

Alkanes, Alcohols, and Ethers

Alkanes, Alcohols, and Ethers

-

51 Comments

-

Vaporizing Oil

Vaporizing Oil

-

75 Comments

-

Salvaging Moldy Material

Salvaging Moldy Material

-

53 Comments

-

Alzheimer’s, Mom and Cannabis

Alzheimer’s, Mom and Cannabis

-

159 Comments

-

Anna the dog and Alzheimer's

Anna the dog and Alzheimer's

-

45 Comments

-

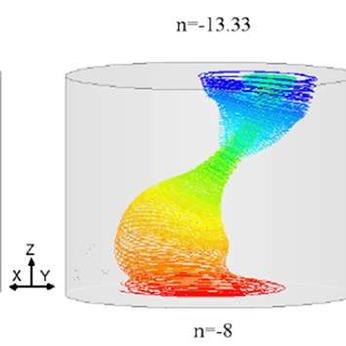

DIY CO2 Extraction?

DIY CO2 Extraction?

-

529 Comments

-

Portable Pen Vaporizers

Portable Pen Vaporizers

-

86 Comments

-

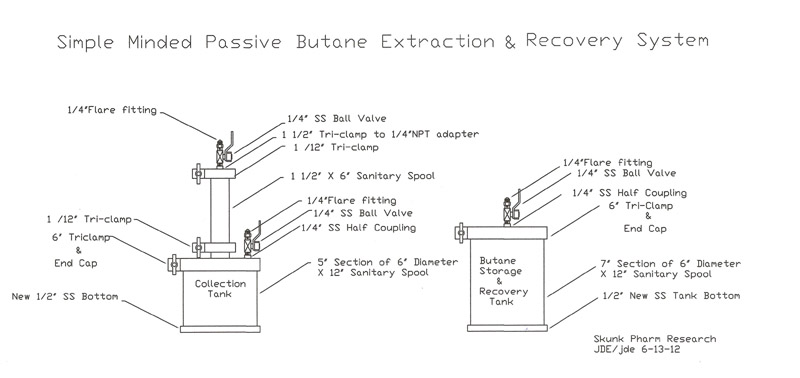

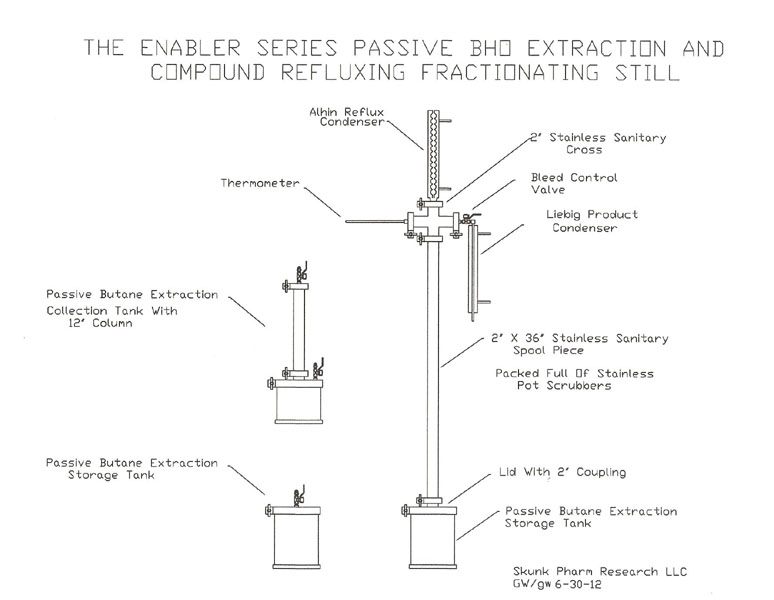

Lil' Terp Passive BHO Extractor

Lil' Terp Passive BHO Extractor

-

246 Comments

-

Plant Turnover and Dipping Fixture

Plant Turnover and Dipping Fixture

-

13 Comments

-

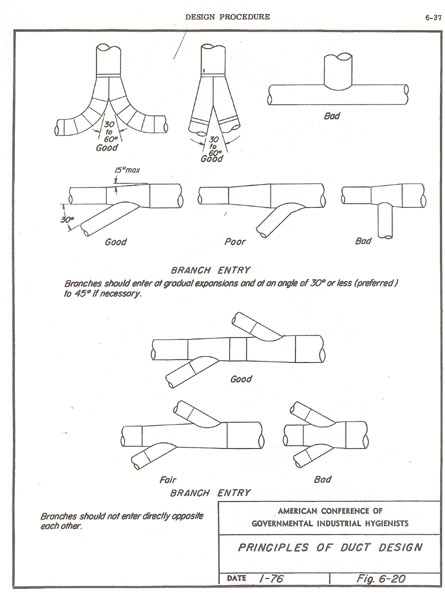

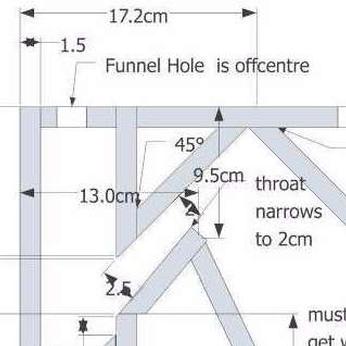

Ventilation System Design

Ventilation System Design

-

5 Comments

-

Alcohol Fractionating Still

Alcohol Fractionating Still

-

44 Comments

-

Opiate Withdrawal

Opiate Withdrawal

-

73 Comments

-

The Mk III Terpenator

The Mk III Terpenator

-

663 Comments

-

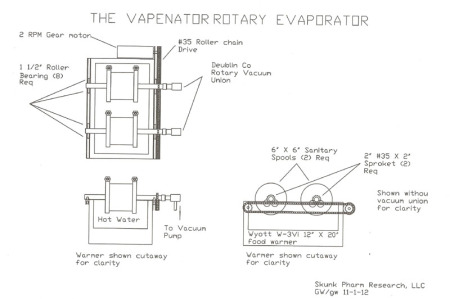

The Evapanator Rotary Thin Film Evaporator

The Evapanator Rotary Thin Film Evaporator

-

40 Comments

-

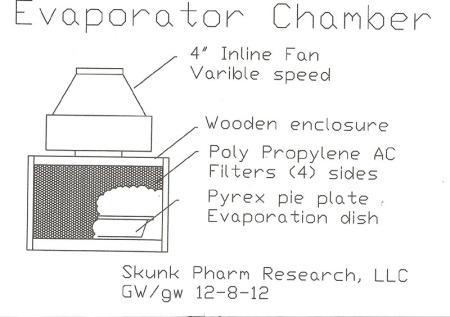

Evaporator Chamber

Evaporator Chamber

-

15 Comments

-

Skunk Pharm Research 2013 Classes

Skunk Pharm Research 2013 Classes

-

172 Comments

-

2013 Class Schedules Posted

2013 Class Schedules Posted

-

83 Comments

-

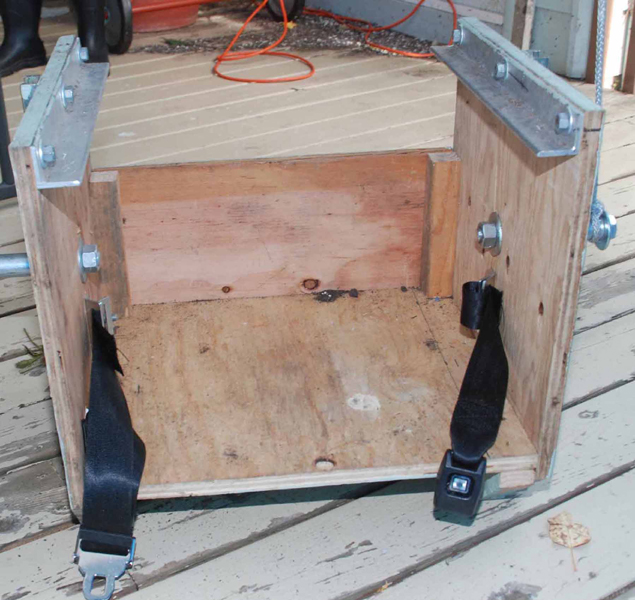

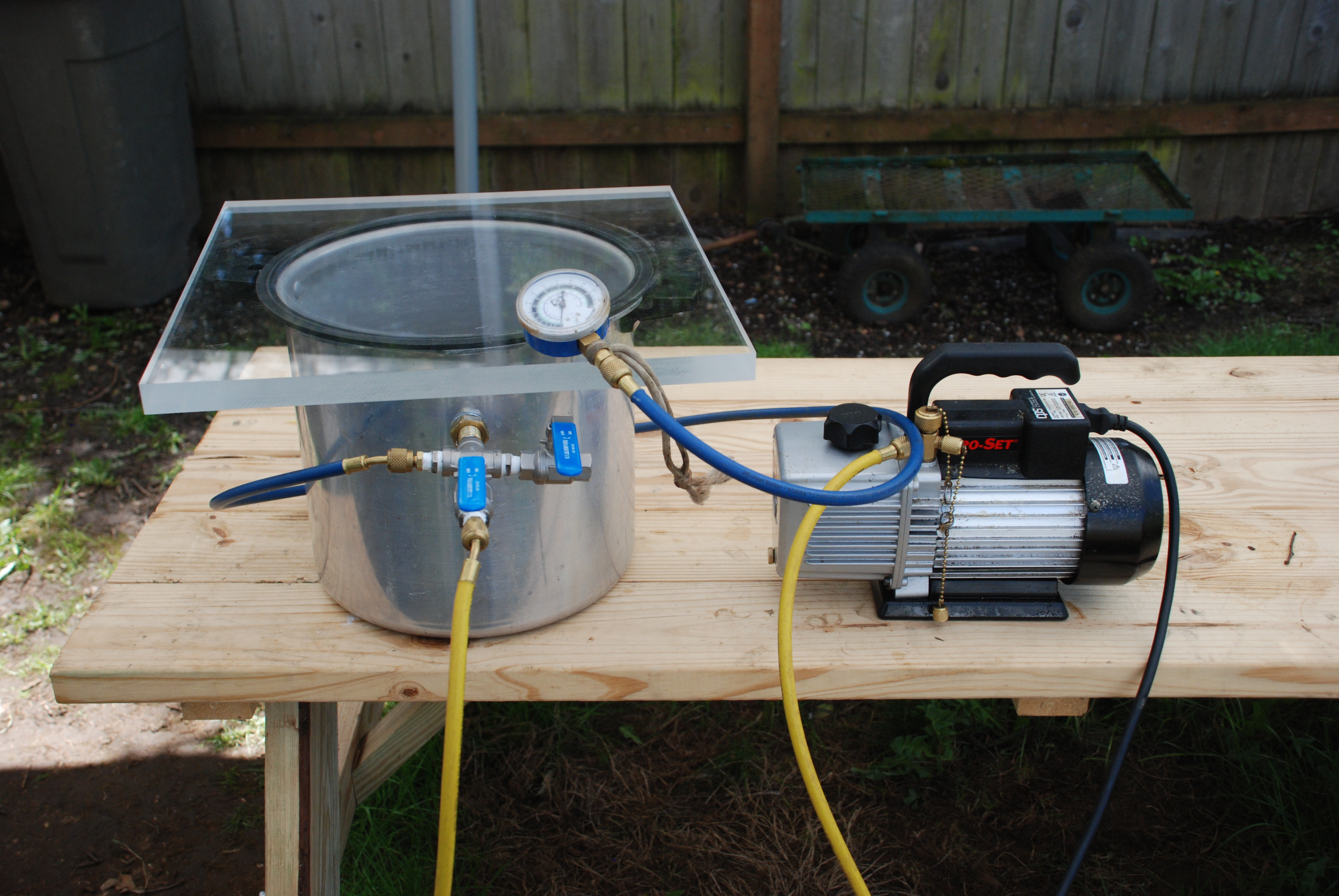

DIY Vacuum Purging Chamber

DIY Vacuum Purging Chamber

-

175 Comments

-

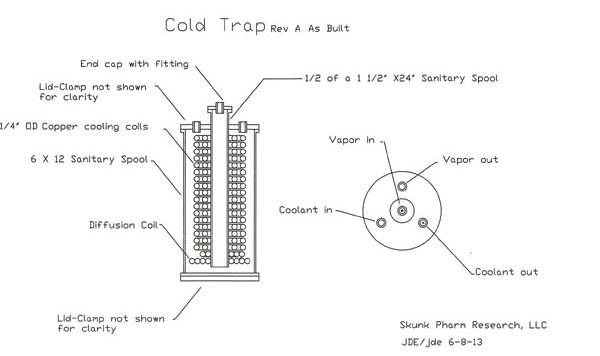

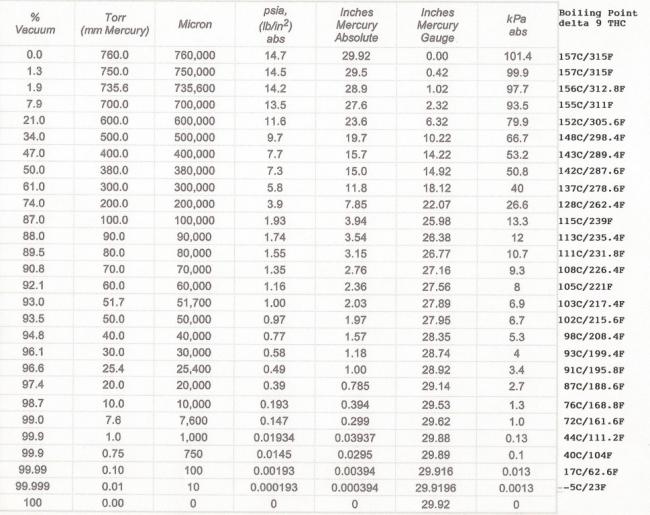

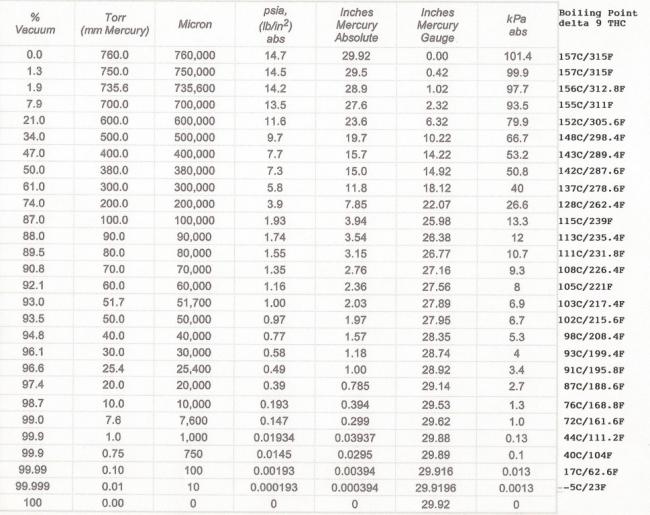

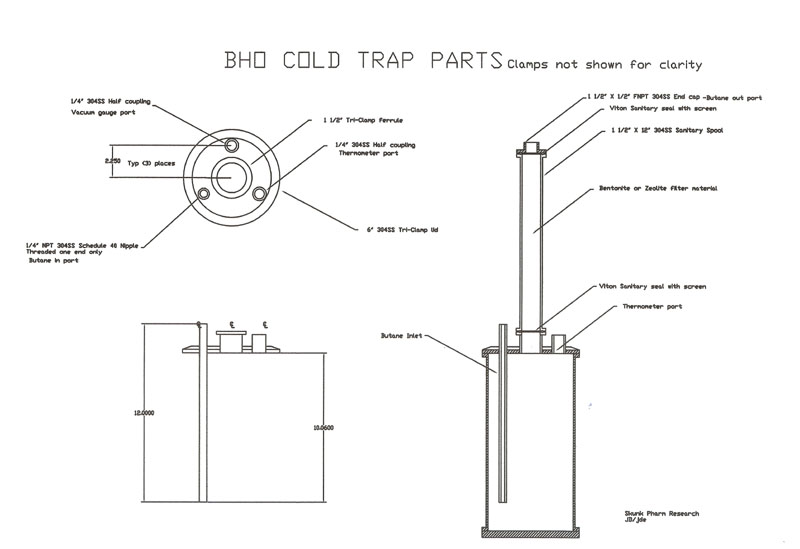

Cold Traps

Cold Traps

-

53 Comments

-

The Mk V Terpenator

The Mk V Terpenator

-

134 Comments

-

Spraying Butane Directly on Silicone Mats

Spraying Butane Directly on Silicone Mats

-

45 Comments

-

Refurbishing a Used Vacuum Oven

Refurbishing a Used Vacuum Oven

-

28 Comments

-

Vacuum Oven Controls Upgrades

Vacuum Oven Controls Upgrades

-

18 Comments

-

Vacuum Purging and Processing Tips

Vacuum Purging and Processing Tips

-

191 Comments

-

Vacuum Equipment and Process Tips

Vacuum Equipment and Process Tips

-

122 Comments

-

Resources

Resources

-

5 Comments

-

BHO Mystery Oil

BHO Mystery Oil

-

246 Comments

-

Removing Butane Mystery Oil using a Terpenator.

Removing Butane Mystery Oil using a Terpenator.

-

45 Comments

-

Vacuum distilling Butane

Vacuum distilling Butane

-

26 Comments

-

The Mk IVA Phoenix Terpenator

The Mk IVA Phoenix Terpenator

-

63 Comments

-

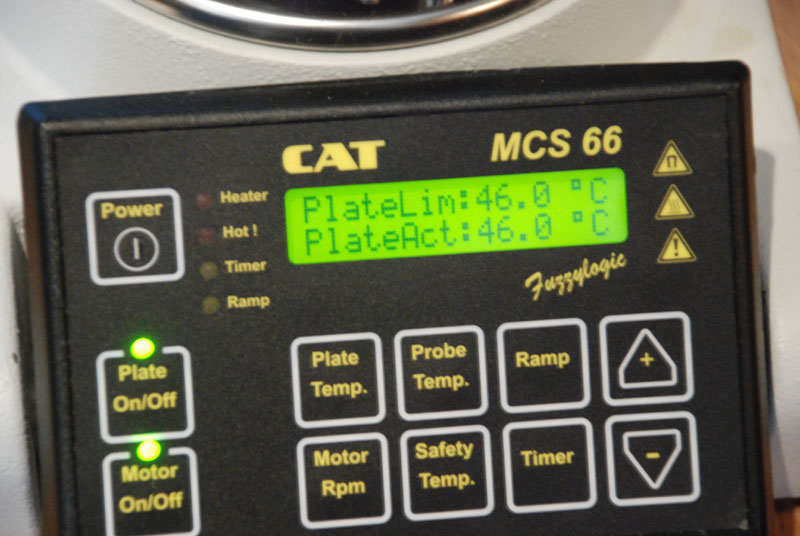

CAT Scientific MCS 66 Stirring Hotplate Test

CAT Scientific MCS 66 Stirring Hotplate Test

-

16 Comments

-

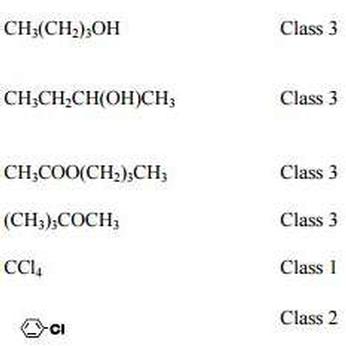

FDA Rating and limits on various solvents

FDA Rating and limits on various solvents

-

7 Comments

-

Booming BHOtards The Explosion of Explosions

Booming BHOtards The Explosion of Explosions

-

109 Comments

-

The Generic Terpenator Operators Manual

The Generic Terpenator Operators Manual

-

22 Comments

-

The DIY Rotary Evaporator by Siskiyou Sam

The DIY Rotary Evaporator by Siskiyou Sam

-

15 Comments

-

Centuria Foods CBDA Decarboxylation Research

Centuria Foods CBDA Decarboxylation Research

-

2 Comments

-

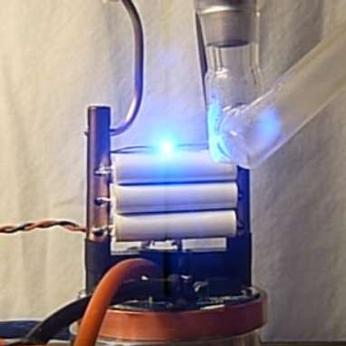

DIY - Induction Heating your Titanium Nail

DIY - Induction Heating your Titanium Nail

-

0 Comments

-

The Bad Boy is in Town

The Bad Boy is in Town

-

0 Comments

-

Royal Jelly

Royal Jelly

-

0 Comments

-

Tattered Old Graywolf Retires Again????

Tattered Old Graywolf Retires Again????

-

0 Comments

-

How to Purge Ethanol from Cannabis Oil Using the CAT MCS78 Hotplate Stirrer by CAT Scientific

How to Purge Ethanol from Cannabis Oil Using the CAT MCS78 Hotplate Stirrer by CAT Scientific

-

3 Comments

-

Spam Not

Spam Not

-

0 Comments

-

Normal and Isobutane Rated GRAS by FDA

Normal and Isobutane Rated GRAS by FDA

-

0 Comments

-

ISO-3 By D. Gold

ISO-3 By D. Gold

-

7 Comments

-

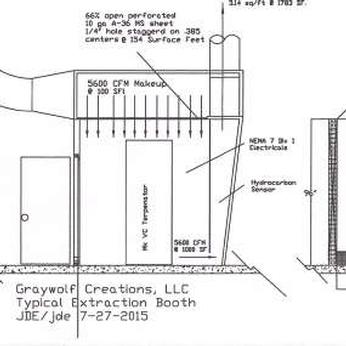

BHO Extraction Booth Design

BHO Extraction Booth Design

-

0 Comments

-

BHO Extraction Equipment Certification

BHO Extraction Equipment Certification

-

0 Comments

-

Cannabis Hyperemesis

Cannabis Hyperemesis

-

0 Comments

-

From Russia with Love!

From Russia with Love!

-

0 Comments

-

DIY Seed Separator

DIY Seed Separator

-

1 Comments

-

Vacuum pump evaluation

Vacuum pump evaluation

-

6 Comments

-

OMMP Card Renewal

OMMP Card Renewal

-

2 Comments

-

Adabadoyas

Adabadoyas

-

2 Comments

-

Changes are Coming...

Changes are Coming...

-

0 Comments

-

To Grow or To Buy, That is the Question.

To Grow or To Buy, That is the Question.

-

0 Comments

-

Should You Medicate your Pet with Cannabis?

Should You Medicate your Pet with Cannabis?

-

0 Comments

-

Making Rosin Step-by-Step

Making Rosin Step-by-Step

-

0 Comments

-

Marijuana in the Workplace

Marijuana in the Workplace

-

0 Comments

-

Rosin Press Experiment

Rosin Press Experiment

-

0 Comments

-

Cannabis: Just the Facts

Cannabis: Just the Facts

-

0 Comments

-

Willamette Week: Andrew Jones vs. Gray Wolf

Willamette Week: Andrew Jones vs. Gray Wolf

-

0 Comments

-

5 Essentials Every Stoner Needs

5 Essentials Every Stoner Needs

-

0 Comments

-

Pharmer's Market is Now Open!

Pharmer's Market is Now Open!

-

0 Comments

-

How Cannabis Affects the Digestive System

How Cannabis Affects the Digestive System

-

3 Comments

-

The City of Los Angeles Passes Regulations!

The City of Los Angeles Passes Regulations!

-

0 Comments

-

Product Review with Vapeur Terp

Product Review with Vapeur Terp

-

2 Comments

-

Canna Chocolate Truffles

Canna Chocolate Truffles

-

1 Comments

-

Events, Trade Shows, and Festivals Oh My!

Events, Trade Shows, and Festivals Oh My!

-

0 Comments

-

Chalice Farms: A Gem Among the Weeds

Chalice Farms: A Gem Among the Weeds

-

0 Comments

-

Skunk Pharm Apparel: GET YOURS

Skunk Pharm Apparel: GET YOURS

-

0 Comments

-

Cannabis Banking, an Appeal to Congress

Cannabis Banking, an Appeal to Congress

-

0 Comments

-

Starting a Vape Shop?

Starting a Vape Shop?

-

2 Comments

-

Induction Nail Videos

Induction Nail Videos

-

0 Comments

-

Health Benefits of Vaping Cannabis

Health Benefits of Vaping Cannabis

-

0 Comments

-

FlackTek SpeedMixer: Extractions

FlackTek SpeedMixer: Extractions

-

0 Comments

-

Certification with a Smile

Certification with a Smile

-

0 Comments

-

CBD Producers Wanted

CBD Producers Wanted

-

4 Comments

-

SPR Reviews: SteamCloud Micro

SPR Reviews: SteamCloud Micro

-

0 Comments

-

CBD and COVID-19

CBD and COVID-19

-

2 Comments

-

Beginners Guide to Safely Trying CBD Edibles

Beginners Guide to Safely Trying CBD Edibles

-

1 Comments

-

Find out how CBD can Help with Stress

Find out how CBD can Help with Stress

-

1 Comments

-

What is Delta-8 Cannabis & Does it Have THC?

What is Delta-8 Cannabis & Does it Have THC?

-

2 Comments

-

Blog Comments I've Made

2548 comments

Replies To My Comments

0 articles

Favorites

0 favorites