Passive Butane Extractor and Reclaimer

What if you want to make your own BHO and reclaim your butane, but don't have the money to assemble a Terpenator? See: /projects/

What if you have lots of time, but limited financial resources?

A simple system like the Tamisium Essential Oils Extractor comes to mind, but while of quality design and manufacture, they certainly aren't cheap.

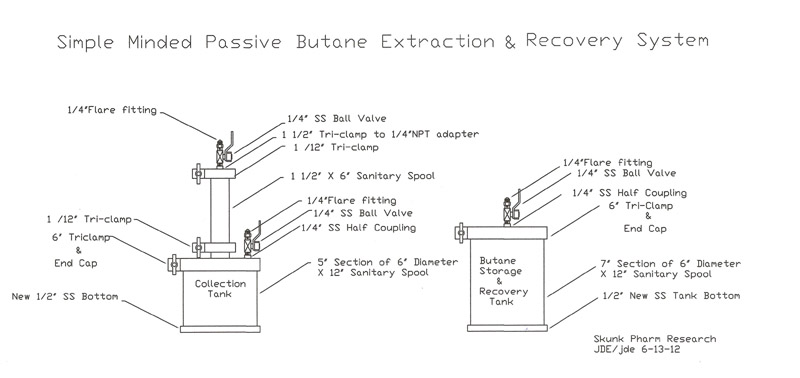

I started looking at passive butane recovery, which simply requires that the extraction pot be in hot water, and the recovery pot in an ice bath. I even designed a simple minded system from scratch, so as to get the price down, but alas, local machine shop costs still made it expensive and outside the resources of most maw and pa patients on fixed income.

Hee, hee, hee, a serendipitous order mistake at Glacier tank almost gave me a wet leg, because I had previously asked for 6" diameter sanitary spools, and was told that they were not available. As fate would have it, they did order a number of them on a special order, which fell through, and I was able to score four 6" X 12" 304 SS sanitary spools for $105 apiece. Ahwoooooooooooooooooooooooooo!!!!!!!!!!!!!!!!!!!

The spools are 12" long, so one is enough material to make the two tanks required, simply by cutting them in two pieces and welding on new bottoms.

I also grabbed two end plates, and tri-clamps, so that the two tanks will have tops, as well as a 1 1/2" tri-clamp ferrule, and a 1 1/2" tri-clamp to 1/4" female NPT adapter, plus the two 1 1/2" tri-clamps.

I grabbed a 1 1/2" spool 6" long for the column, which should hold about an ounce of dried prime bud, that has been sized and the sticks removed.

I picked up three 1/4" stainless ball valves at Paramount Supply, along with two 1/4" NPT 304 stainless half couplings.

For bottoms to the tanks, I ordered 1/2" X 6.5" diameter 304 blanks laser cut from plate, and dropped the parts off at a retired friends machine shop to have them machined to shape, as well as mill the holes in the 6" end plates for the 1 1/2" ferrule and the two 1/4" half couplings.

Pictures when those return, but until then, here is my simple minded conceptual:

Little Terp Parts List

|

No |

Item |

PN |

Qty |

Price |

Cost |

Source |

| 1 | 1/4 male flare to male NPT | JB-A31484 | 3 | $8.28/5 | $8.28 | RSD |

| 2 | 1/4" 304SS Ball valve 1000# | 34-92303 | 3 | $12.05 | $36.15 | www.paramountsupply.com |

| 3 | 1/4" 304SS close nipple | 34-06105 | 3 | $0.54 | $1.62 | Paramount Supply |

| 4 | 1/4" 304SS 1/2 coupling | 34-07136 | 2 | $0.71 | $1.42 | Paramount Supply |

| 5 | 1 1/2" End cap X 1/4" Fe NPT | NPT25-FM | 1 | $10.95 | $10.95 | www.GlacierTanks.com |

| 6 | 1 1/2" Tri-clamp | CSH-1500 | 2 | $5.90 | $11.80 | Glacier Tank |

| 7 | 1 1/2" X 6" Sanitary spool | SP-150-006 | 1 | $29.00 | $29 | Glacier Tank |

| 8 | 1 1/2" Tri-clamp weld ferrule | F150-28 | 1 | $3.90 ea | $3.90 | Glacier Tank |

| 9 | 6" Sanitary spool end cap | Cap-600 | 2 | $35/ea | $70 | Glacier Tank |

| 10 | 6" Tri-clamps | CSH-600 | 2 | $25.27 | $50.54 | Glacier Tank |

| 11 | 6" X 12" Sanitary spool | Sp-600-012 | 1 | $105 | $105 | Glacier Tank |

| 12 | Tank bottom blanks | N/A | 2 | $32 ea | $64 | Moody Machine |

| 13 | 1 1/2" Buna-N seals and 20 mesh screens | N/A | 2 | $15.90 | $31.80 | www.BreweryGaskets.com |

| 14 | 6" Buna-N seals | W181663 | 2 | $14.92 | $29.84 | SustainableSupply.com |

| 15 | 1/4" X 36" Refrigeration hose | 1 | $51 | $24.95 | Northwaysmachinery | |

| 16 | Total | $479.25 |

GW

Lu lu lu lu lu lu lu lu lu lu lu lu lu lu lu!!!!!!!!!!!!!!!! I picked up the parts for the new passive butane recovery system from the machine shop today and will drop them off at the welders tomorrow.

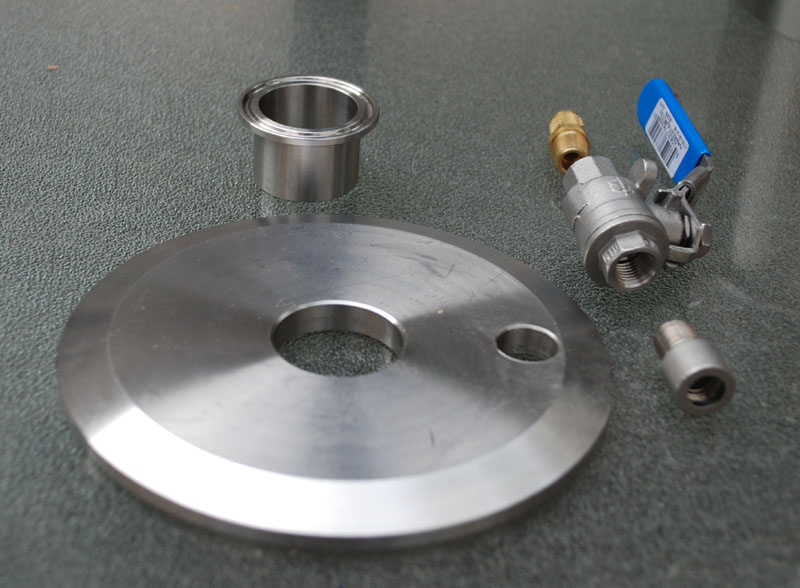

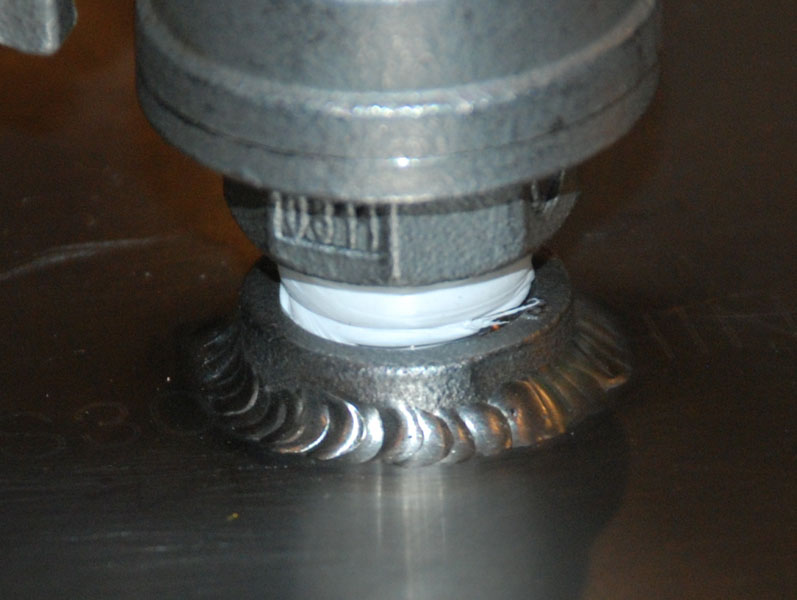

Couldn't resist mocking up some shots of the components stuck together, before actual welding. As you can see from the pictures, the tanks are both made from the same 6" X 12" sanitary spool, which I scored from Glacier Tank. I had them cut into two pieces, to make the wrappers and triclamp closures for both tanks.  The bottoms were laser cut from 1/2" 304SS By BBC Steel in Canby, and were machined by Moody Machining in Milwaukie. Besides a clean up cut on all exposed surfaces, the bottoms were grooved to accept the tank wrappers.

The bottoms were laser cut from 1/2" 304SS By BBC Steel in Canby, and were machined by Moody Machining in Milwaukie. Besides a clean up cut on all exposed surfaces, the bottoms were grooved to accept the tank wrappers.  The collection tank lid has two holes cut in it, to receive a 1/4" 304SS half coupling and a 1 1/2" Triclamp weld coupling.

The collection tank lid has two holes cut in it, to receive a 1/4" 304SS half coupling and a 1 1/2" Triclamp weld coupling.  The butane recovery tank lid was machined to receive a 1/4" 304SS half coupling.

The butane recovery tank lid was machined to receive a 1/4" 304SS half coupling.  The rest are all screw together parts! Hee, hee, hee....................

The rest are all screw together parts! Hee, hee, hee....................

More after welding and a test run! Ahwooooooooooooooooooooooooooo!!!!!

More after welding and a test run! Ahwooooooooooooooooooooooooooo!!!!!

6-3-12

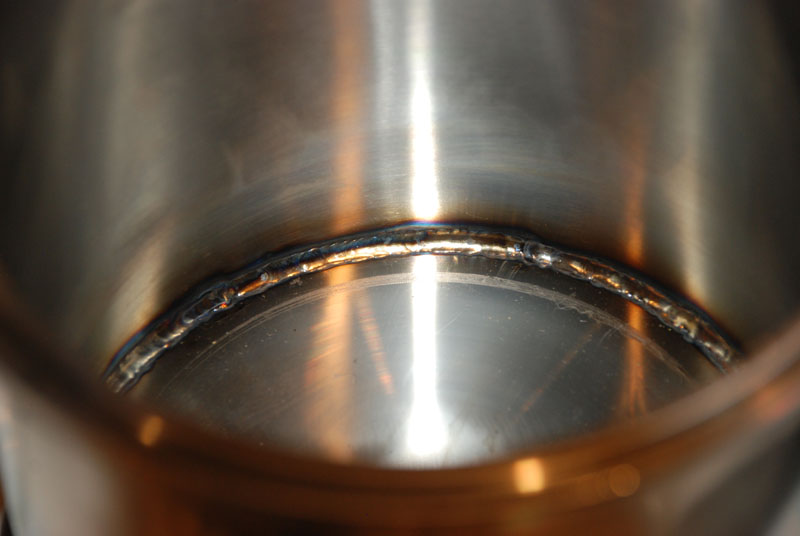

Lu lu lu lu lu lu lu lu lu lu lu lu!!!!!!!!!! Hee, hee, hee, the welded parts are back and Gibson aerospace welding did a gorgeous job as usual!

Once a weld engineer for a metal fabrication company, I was certified as an ASTME Section IX boiler code welder, but with a cataract on one eye, I have no fine depth perception, and eschew welding until I get it fixed.

Even though Gibson's is not certified to Section IX boiler code, he is certified to numerous aerospace welding specifications that are as restrictive, or more so, and one of the best TIG welders that I met in my professional career.

He sure does purdy work too and noted that the material welded exceedingly clean and was a pleasure joining the two 304 SS components using 309SS wire.

The collection tank is welded inside and outside, so there are no internal seams or cracks, but the butane recovery tank is welded only on the outside. None of the other welds actually required outside welds, but we welded both sides, to give them a more finished appearance.

Lookee:

I bolted it all together and will boil the system in hot water and detergent today, to get it ready for when the backordered 6" clamp arrives, so I can try it out. Probably play with the extractor half using a pump until then, snicker, snark, snort.............

I bolted it all together and will boil the system in hot water and detergent today, to get it ready for when the backordered 6" clamp arrives, so I can try it out. Probably play with the extractor half using a pump until then, snicker, snark, snort.............

|

No |

Item |

PN |

Qty |

Price |

Cost |

Source |

| 1 | 1/4 male flare to male NPT | JB-A31484 | 3 | $8.28/5 | $8.28 | RSD |

| 2 | 1/4" 304SS Ball valve 1000# | 34-92303 | 3 | $12.05 | $36.15 | www.paramountsupply.com |

| 3 | 1/4" 304SS close nipple | 34-06105 | 3 | $0.54 | $1.62 | Paramount Supply |

| 4 | 1/4" 304SS half coupling | 34-07136 | 2 | $0.71 | $1.42 | Paramount Supply |

| 5 | 1 1/2" End cap X 1/4" Fe NPT | NPT25-FM | 1 | $10.95 | $10.95 | www.GlacierTanks.com |

| 6 | 1 1/2" Tri-clamp | CSH-1500 | 2 | $5.90 | $11.80 | Glacier Tank |

| 7 | 1 1/2" X 6" Sanitary spool | SP-150-006 | 1 | $29.00 | $29 | Glacier Tank |

| 8 | 1 1/2" Tri-clamp weld ferrule | F150-28 | 1 | $3.90 ea | $3.90 | Glacier Tank |

| 9 | 6" Sanitary spool end cap | Cap-600 | 2 | $35/ea | $70 | Glacier Tank |

| 10 | 6" Tri-clamps | CSH-600 | 2 | $25.27 | $50.54 | Glacier Tank |

| 11 | 6" X 12" Sanitary spool | Sp-600-012 | 1 | $105 | $105 | Glacier Tank |

| 12 | Laser cut 304SS tank bottom blanks | N/A | 2 | $33.50 | $67 | BBC Steel |

| 13 | 1 1/2" Buna-N seals and 20 mesh screens | N/A | 2 | $15.90 | $31.80 | www.BreweryGaskets.com |

| 14 | 6" Buna-N seals | W181663 | 2 | $14.92 | $29.84 | SustainableSupply.com |

| 15 | 1/4" X 36" Refrigeration hose | 1 | $24.95 | $24.95 | Northwaysmachinery | |

| 16 | Sub Total parts | $482.25 | ||||

| 17 | Machine tank bottoms 30 minute | 2 | $60 | J Moody & Co | ||

| Part spool | 1 | $15 | ||||

| Port top plates | 2 | $45 | ||||

| $120 | ||||||

| 18 | Weld and blend components | $75.00 | Gibson Welding | |||

| 19 | Total parts and outside labor | $727.25 | ||||

| 20 | 5% Contingency | $36.36 | ||||

| 21 | Grand total est. cost for Little Terp | $763.61 |

Lu lu lu lu lu lu lu lu lu lu!!!!!!!!!!!!!!

I just learned that Glacier Tank has some 6" diameter X 6" long sanitary spools due in this month, which you could make a tank out of just by using another end plate and a clamp for the bottom. The only welding would be for the plumbing fittings. Hee, hee, hee, snicker, snark, snort!!!!!!!!!!

GW

7-20-12

Hee, hee, hee, snicker, snark, snort, awhooooooooooooooooooooooooooo!!!!! Ah just loves it when a plan comes together.

Here is the first cleaning run on the Lil Terp, and as you can see, it works slick! I wish I could say I pulled this one out of my nether regions, but alas, I did not. Hats off to the inventor of the Tamisium, for his insight in using passive recovery in this application!

Since this was a cleaning run, after I washed everything in denatured alcohol and then boiled it out in hot water and detergent, we ran donated mixed trim destined for topical application.

I installed the 1 1/2" X 12" column, which held approximately 2 ounces of material, after first packing in two wadded up coffee filters, against the 20 mesh screen at the end of the column, and two more on top of the material, between it and the top 20 mesh screen.

I started out by weighing the collection vessel, which weighed 15 pounds 3 ounces. I then calculated the internal capacity of the 6" diameter X 5" tall collection tank as 141 cubic inches.

I calculated that 141 cubic inches of water at .0361 lbs/inch cubed, times the .601 specific gravity of butane, would weigh about 3 pounds, so an 80% fill would weigh about 2.4 pounds. That means that 2 pounds 7 ounces is a maxim fill, to allow for hydraulics with temperature changes.

Next I pumped the supply tank down to -29.9hg and after soaking it in an ice water bath for about thirty minutes, sat it on a refrigerant scale to establish the 15 pound, 3 ounce tare.

I then connected it by hose to the dip tube of a butane supply tank and filled it to a total weight of 17.1 pounds.

Next I connected the collection vessel to the supply tank by hose, and sat the collection vessel and column in ice water. I held the supply tank upside down and opened both valves, so that the butane flowed through the material in the column, and collected in the collection vessel.

After a couple of minutes, I weighed the supply tank, and it again weighed 15 pounds, 3 ounces, so I shut all the valves and disconnected the hose. A minimal amount of butane was lost when I disconnected the hose.

Next I turned the collection tank upside down, so that the butane again saturated the material in the column, and flipped it about four or five times for about 30 minutes, including the final setting the column upright and letting it drain.

I then connected the recovery vessel and the supply tank by hose, and sat the recovery vessel in a 109.4F hot water bath in an electric soup pot, and the supply tank in an ice water bath.

I kept track of the temperature of the fittings on top of the recovery tank and the supply tank with a laser pyrometer, and when the temperature of the fitting on top of the collection tank was 98F and the fitting at the top of the supply tank was 31.1F, I again weighed the supply tank, and found it again weighed 17.1 pounds.

Except for the losses when we disconnected hoses, recovery was 100%, and the losses were not measurable by weight. I disconnected the system and opened up the collection vessel, to find the attached scene.

Even though I used trim set aside for topical and it was a cleaning run, after inspecting it for petrochemical contaminants with a black light, I still had to taste some and though the material it was extracted from was aged and dried enough to have little floral undertones, it still had a clean crisp hashy flavor.

There were no contaminants revealed under black light, so looks like the system is clean and tomorrow we will have to get serious with some bud! Hee, hee, hee………………

9-24-12

Lu lu lu lu lu lu lu lu lu lu lu lu!!!!!!!!!!!!!!!!!!!!!!!!!!! The 6″ X 6″ sanitary spools came in, so here is a new parts list, as well as a picture of the Mk III prototype construction underway using one.

|

No |

Item |

PN |

Qty |

Price |

Cost |

Source |

|

1 |

1/4 male flare to male NPT |

JB-A31484 |

3 |

$8.28/5 |

$8.28 |

RSD |

|

2 |

1/4″ 304SS Ball valve 1000# |

34-92303 |

3 |

$12.05 |

$36.15 |

|

|

3 |

1/4″ 304SS close nipple |

34-06105 |

3 |

$0.54 |

$1.62 |

Paramount Supply |

|

4 |

1/4″ 304SS 1/2 coupling |

34-07136 |

2 |

$0.71 |

$1.42 |

Paramount Supply |

|

5 |

1 1/2″ End cap X 1/4″ Fe NPT |

NPT25-FM |

1 |

$10.95 |

$10.95 |

|

|

6 |

1 1/2″ Tri-clamp |

CSH-1500 |

2 |

$5.90 |

$11.80 |

Glacier Tank |

|

7 |

1 1/2″ X 6″ Sanitary spool |

SP-150-006 |

1 |

$29.00 |

$29 |

Glacier Tank |

|

8 |

1 1/2″ Tri-clamp weld ferrule |

F150-28 |

1 |

$3.90 ea |

$3.90 |

Glacier Tank |

|

9 |

6″ Sanitary spool end cap |

Cap-600 |

4 |

$35/ea |

$140 |

Glacier Tank |

|

10 |

6″ Tri-clamps |

CSH-600 |

4 |

$25.27 |

$101 |

Glacier Tank |

|

11 |

6″ X 6″ Sanitary spool |

Sp-600-012 |

2 |

$97 |

$194 |

Glacier Tank |

|

12 |

1 1/2″ Buna-N seals and 20 mesh screens |

N/A |

2 |

$15.90 |

$31.80 |

|

|

13 |

6″ Buna-N seals |

W181663 |

2 |

$14.92 |

$29.84 |

SustainableSupply.com |

|

14 |

1/4″ X 36″ Refrigeration hose |

|

1 |

$51 |

$24.95 |

Northwaysmachinery |

|

15 |

Total |

|

|

|

$624.71 |

|

GW

8-3-15

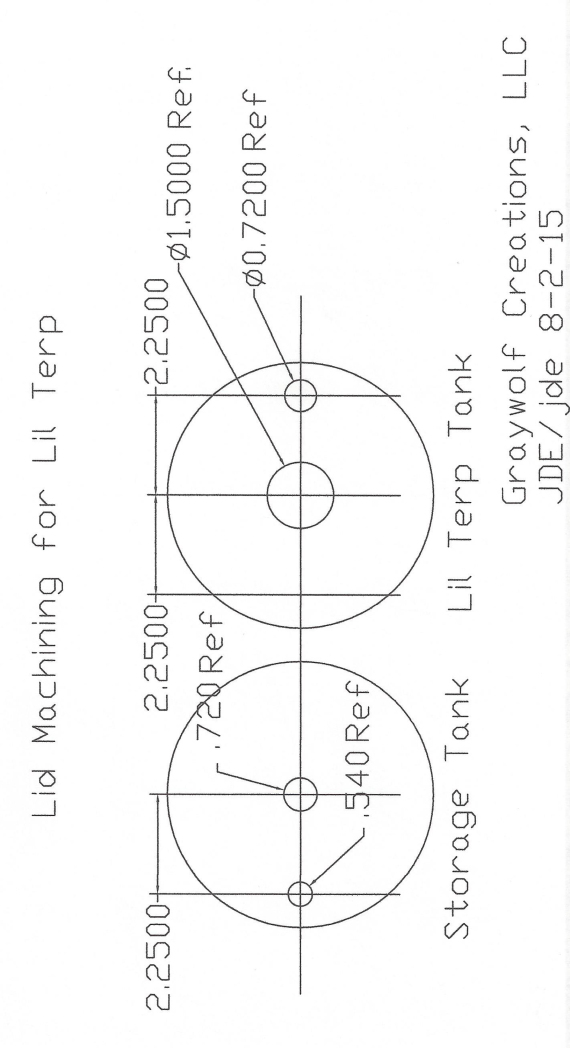

Here is a Mk III lid print, which I modified to show the Lil Terp dimensions.

Note that the lid penetrations are given as reference dimensions. That is because there is dimensional tolerance and variability like out of roundness to consider, so I give the machinists the dimensions of what is ostensibly required, along with the actual parts used and the requirement that the parts mate snugly snugly.

GW

Hey there GW. I am planning a build for a solvent tank with designs here, just for a slightly bigger one. I'm wondering how big of a spool would be needed for around 5-8 pounds of solvent? If yours is 6 by 12 and holds 2.7 pounds, would say a 6x24, 8x12, or 10x 10 be sufficient? Thanks GW!!

n-Butane weighs aproximately .0217 lbs/cubic inch. You can only safely fill to 80%. 8lbs/.80 divided by .0217= 460 cubic inches A six inch column has a face area of around 28.3 square inches, so 460/28.3= 16.25 inches of column. A 6 X 18" column would work. 10" moves you from ASME piping to ASME pressure vessel, which as an LPG storage tank, would be required to meet 350 psi minimum, so it would be a bad move if you wish to certify. GW

Thank you for the quick reply!! You've been a wonder for years now. I appreciate how humble you are too share wisdom. This set up is going to be in the Michigan. Where until nov. 2017 there aren't certification regulations. But it is just for personal use anyways. I just want to be as safe as possibly, and know all the numbers! Thanks again Aton GW! Also going to be using one of your MK's :)

Thanks for the good thoughts brother! Be safe, good luck, and bon appetite! GW

When I built mine I didn't spend the extra on asme cert8fied. If you read the specs there 8s no reason to spend the exyra. If your kicking pressures up that high to be concerned there's something wrong. GT was a great resource but on the splatter platter, TV LIDS, and clamps you can find comparable cheaper elsewhere.GT made the spools valves etc. easy until they charge you for making payments

So you used the ASME certified SS spools from Glacier Tanks not their regular SS spools right?

ASME rated spools are typically ASME BPE, a polishing specification. http://www.harrisonep.com/electropolishing-asme-bpe.html Spools 6" and under fall under ASME piping, and above pressure vessels. The standard 6" spool will work, but you need to use an C060.4.SSH high pressure clamp from LJ Star to get the required 350 psi rating. GW

nice work, nice welding, how is it with a splatter plater, easy for cleaning

Thanks for the good thoughts! That welding was by Gibson. Either Gibson or Josh can make aerospace quality TIG welds like a purdy stack of new dimes. Check them out under resources: https://skunkpharmresearch.com/resources/ You could use a 6 X 6" spool with shatter platter, instead of the welded bottom. GW

If I played for the parts could you have it welded together for me? Or build me a mkII and I'll pay for it . I'm disabled and not capable of that sort of work but I need to upgrade my system. Please help

If you give Josh a call from https://skunkpharmresearch.com/resources/ page, he can do both the machining and welding. He is at 503-758-4625 WWW.joshspair.com GW

my boss was searching for AK Employment App earlier this week and discovered a great service that hosts lots of form templates . If people are wanting AK Employment App also , here's a

http://goo.gl/tzhjjJI've been looking for a cheap, cheerful and SAFE way of butane washing a variety of volumes and quality of materials, with a view to making oil for cancer treatment. I get given sticks, and schwag mainly, and I have become a dab hand (excuse the pun) at turning the schwag into a very useful dark oil that can be used for the mind or the tumour as neccesary. I've had what I think is a new idea.. Can anyone see whats wrong with this idea? Take a large sealable openable pot (one of two) rated to 100 psi and load it with your schwag. Open valve number 1 and pull a vacccum in the pot, using a surplus fridge compressor, then close valve. Put it in the table top freezer till it's cold. Connect your super clean butane tin to valve number 1 and fill. Repeat for as much butane as you believe will be needed to at least half cover the schwag before putting it back into the freezer, (where I might not have mentioned you have made a tumbling apparatus) so as the schwag butane mix can be tumbled for a few hours in the cold. After a period of time long enough to absolutely dissolve anything that will dissolve into the butane, we need to remove the cold tank, invert it and drain the butane/oil mix off into our seond tank (which of course we have pulled down to vacuum, and then frozen) We can now clean out the first tank, throw away the denuded schwag, freeze and evacuate it, ready to receive the butane that we will now be evaporating from the tank with the mix in it... At the end one should have one tank full of clean butane (which you store in the freezer ready for next time, and one tank with a goodly amount of oil in the bottom waiting for you to extract it. whatever oil gets left behind will be reclaimed on the next run, of course. At no point are we using positive pressure, or elevated temperatures which should improve safety, no end, and the cost of the aparatus is one table top freezer (second user is fine) one surplus fridge pump and the two "pressure" vessels. I'll check back from time to time and see if anyone raises any points or adds any ideas I haven't thought of. I have a secondary version I am trying to work up that uses alcohol and one of those tabletop stills, but I've picked up the idea that the butane is a better solvent for the job.

Sticks and stems have trichomes, but they're sparse, so you have to put the same amount of work into a lot of material for a low yield. What it does yield, doesn't require long soaks, or tumbling. Long soaks and tumbling will increase the extraction rate of molecules longer than C-21, producing a dark oil, high in plant waxes. Sticking containers of LPG gas into a freezer is iffy, as you are relying on zero leakage to remain safe, and polymer seals lose their resilience at low temperatues. We've found that stem and fan leaf oil does make a killer topical for pain relief, but not so good for dabbing, giving more of a Charley horse between the ears, than a high. As far as your equipment technique, that is similar to the original process FOAF used, that started the rest of us down the closed loop recycle path. GW

Hmmm. Well first thing one must find a place to do suchhiclads welding, isn't it.. Great resource, great info, great read

Does the passive extractor system require 3 tanks or 2 ? You use collection vessel, recovery tank and supply tank? Thank you

Your welder should have used 308 wire to weld 304 to 304.... 309 is for stainless to carbon mild steel!! Thanks for the awesome blog tho

309 is perfectly fine for this especially if you have some laying around. It can weld stainless to regular steel but can also be used for 304 to 304. Source: I'm a tig welder.

I'm a ticketed TIG welder and 309 works very well because it will wells a variety of stainless grades to each other as well as to steel.

308 is certainly most commonly used with 304 with electrodes, but 309 has enough additional chromium so as to be less corrosion prone if the assembly isn't subsequently solution annealed. I've also welded 304 with 310, 316, 321, and 347. In aerospace we welded 304 with 304 and re-heat treated afterwards.

I thought that you couldn't heat treat 300 series stainless as its austinetic grain structure at room temperature? Source: I'm also a gig welder

So while waiting for the spool and cap I am practicing closed blasting ALL DONE OUTSIDE. I have yet to load good nugs in there but with good trim 28g its yielding about 4.5 g+ of good oil. I do not have vac chamber yet and it is stable at room temp. My issue is how do I get that nice golden clear color. Mine is darker than I would like but good in all other ways. What can I do. I vac out tube, s/s line and tap prior to fill. I dump the liquid into and vent a bit to work the full can into the tube. I have a process robot that keeps it moving for 10 minutes prior to blasting it into the pyrex. Comes out tasty, clean potent but the color is off. Also GW can you please send a link or post vid of when you ran the lil terp set up as above. the 6" base and cap will be here soon so I guess that helps but have more questions about that process. Again this is for personal use and am in need of making this medicine because locally patients are allowed to make it and hat is there is sub standard black, think reclaim with texture.

Load good nugs. I hypothesize that amounts of chlorophyll make it through the run, especially when using trim. The coloration is inevitable with trim and some bud. To get the clear colors you need herb that has been flushed very well at the end of the grow cycle with as little leaves as possible. All the trim run bho I've done is dark. But thb I don't care! Lol

Hi Greywolf I am looking to build one of these units and was wondering if you had any tech drawings of the various custom parts. My Fabricator needs ID and OD, wall thicknesses for certain parts. to quote me. Thanks for all you have given us already. Cheers

I couldn't find the original Lil Terp prints, so I modified a Mk III print to show the lid dimensions. Note that the machining shows reference dimensions. I supply them to the machinist for quotation and layout purposes, but also supply him with the parts and the requirement that they fit snugly. The reason for that is dimensional tolerance and out of roundness, etc. If we dimension the holes to insure that every possible dimensional variable is covered, we would have a sloppy fit. Snugly means that they can easily be inserted and removed, but without slop. The reason for that, is to make life easy for the welder on the .065 wall sanitary tubes.

OK thanks for that. Ill send this off to him and see what he tunes. I was also wondering a few more things: -The tank bottoms.. are they 12.7mm (1/2") custom laser cut? -On the lid design, is it necessary to have a vacuum gauge? and an emergency pressure release? -If I wanted the above additions, is there anywhere specific on the lid where it should be placed? -I In the pictures I see that there is a mesh filter between the collection tank and the "material tube", is that a Gasket Mesh screen? Thats all for now. Thanks

The tank bottoms are 1/2" 304SS water jet cut. You need a vacuum gauge to tell that you have fully evacuated the atmosphere from a Lil Terp, before introducing butane. ASME requires a pressure relief valve over 15 psi. Not much room on a 6" lid, and you don't want it in the water, so you might consider just a port and the gauge and pressure relief on the end of a hose. Yes, that is a sanitary gasket screen

I built a closed column extractor no collection vessel at 1.5"x6" it holds 1 ounce stuffed but only half a can of N tane and only yields 1g on good trim what am i missing. I vacuum the column after filling it and then shoot from can tap into but like I said wil not accept a full can unless I crack the valve to release some butane and let the rest fill. i let it marinate in the cold for 30 minutes r so moving it to move the butane around but such a low yield from good trim. I am afraid to use bud and get a bad yield. It is potent and tasty, contaminant free but still not as much as expected

It has no way to vent vapor.

so while waiting for collection tank open drain valve a little until full then let marinate? Also why such a low yield this is very frosty trim like I said its clean potent even tasted good just not a lot also dark

Most likely from your use of only 1/2 a can of butane. The Lil Terp uses about two pounds for its extraction.

Hey Skunk!! If I were to amend this design to be done with 4"x6" recovery and collection tanks, and 1.5"x6" column, what would I have to worry about as far as pressure? I want the total size of both tanks to be a little less than the lil terp. I really only ever want to run 1/2 - 1 oz. I just feel like it'll explode on me, and well you know we don't want that. So would I end up having to 4"x9" instead if I have the option? Should I also add a high pressure release valve? I'm doing gauges for sure. Thanks!!

I'm unaware of a 4" tall x 6" sanitary spool, but it would have the same pressure rating as the Lil Terp. If you are talking about a 4" diameter X 6" sanitary spool, then the pressure rating would be higher, and recovery rates slower. Theoretical burst for a 4" sanitary spool is 3000 psi and 2000 psi for a 6". Pressure limitations are not the spools, but the clamping system, which is 800 psi for the high pressure 4" clamps and 300 psi for the 6" at 70F, and 600 psi and 200 psi respectively at 250F. The valve is rated at 1000 psi. Operating temperature of a Lil Terp is 110F maximum, and at 110F 100% n-Butane is at 47 psi. ANSI/ASME requires a 3X safety factor, so 150 psi is adequate to meet those requirements. As far as a safety relief valve, ASME rules apply on containers above 15 psi, and the fire marshals will most likely refer to NFPA 58, which states in 5.7.2.1: ASME containers shall be equipped with one or more pressure relief valves that are designed to relieve vapor.

insurancewhisper.com I value the post.Really thank you! Great. I loved your post.Thanks Again. Really Cool.

Hey Skunk, I was looking into making a solvent/recovery tank that could hold 8 300 ml cans for a 1/2lb run. Thinking 6"x6" sanitary spool is correct, true? Whats up with the hole on the bottom tank plates? Also if you know of somewhere I could just buy it so I wouldnt have to go through the welding thatd be awesome. I cant seem to find em. Thanks a bunch

I know waxmax sells them but they do not advertise them here is the link http://www.mywaxmax.com/terp-kit/

I was wondering when purchasing a refrigerant storage tank do i purchase one with or without a float switch and is there a specific brand you recommend? Also does the pressure guage need to reach specific requirements aswell as the hoses? Sorry if you answered this before theres alot of comments to read through. It would be cool if you had a list of specifics that are overlooked or requirements of the equipment thats overlooked. Ive been to your sight on many seperate ocassions and keep finding new bits of important information, such as the double sided welds on the tanks. Mabey a list of key things to think about or standards you need to discuss with the machinist and welders begining your project. Thank you for your dedication to safety and spreading helpfull information without regards to gaining financially.

Could this extractor be used with refrigerants such as r134a?

I would love to see your ideas on making this into an active closed loop. Nice job!

Check out the Mk IIIA, which is one way to use the parts to build an active system.

Could you in theory use the lil terp for alternative solvents like liquid O2, CO2, propane and or acetone?

Can I use (RBCUZN-C) brazing rod on extraction equipment for making joints in contact with the butane and product? 59% Copper 40% Zinc 1% Iron

Thanks for the links to our site! I just wanted you to know we also carry the 6" clamps and the 6" gaskets both cheaper than what you have listed above.

can brazing rod be used instead of welding?

I'm by far no expert on the units we are talkimg about, but I worked with explosive's of all kinds, shapes, sizes and styles. RC Det., Motion, pressure plates just anything conventional and a lot of IED's. Morenod the! Than anything. So my point is this, you're looking for a short cut to a very volitile area, lots of Pressure! When you use butane, its Highly flammable. With weak seals and pressure joints or welding joints designed to withstand high pressure and rapid drops in heat and temps that will degrade the weld over time. If you're ntryimg to save a few bucks and just want to have an explosion, I can give you some ways that You can blow the fuck up and just destroy yourself. If you want to use high pressure and flammable expansion gasses you Must Use the highest quality welds or you are building a bomb sir. But, I'm no Expert on this device, the manufacturer may have some other ideas on it for you. BTW, Beautiful SS welds! Impressive!

This design failed and blew up

I infer you are speaking of the as built design, versus the original third party certified ASME design. Most certainly the one involved in an explosion shows visible design flaws, excluded from the original design, starting with the sight glass.

How do you regain a full recovery of butane into your solvent vessel? It would seem like the recovery vessel would want to equalize with the collection vessel during recovery and prevent a full passive recovery.

yeah unless the pressures created is due to volatile gases that in turn decrease pressure when chilled. temp change combined with pressure inert to the gas being used.. Even a 5 degree temp drop will condense due to pressure helping that condensing effect. But it would take a long time. Basic laws of physics. We are looking for a relative temp drop to pressures. In other words. at 70F you should have a temp of ___? in a closed tank with a given solvent. it should be lower than that to keep boiling and condensing in two tanks of varying temps opened to each other. Right from the lips of the guy that holds the patents. Hope you are safe with it.

And you all are working with flammable's? Please research, ALL info/angles of manufacturing, and troubleshooting! NO SHORTCUTS! Remember, it's what you CANNOT see, will hurt/kill you! THINK 5 STEPS AHEAD ON WHAT COULD GO WRONG? A little common sence, goes a long way!

Wtf? Why the thumbs down? It's so simple a fucking chicken would cross the road to show you the right answer! LOL! Only for a laugh! I'm not hateing on anyone, he's just got extremely valid points, sometimes the simple info gets left out! You gotta read everything on the subjects you want to tackle in life. Thanks, Charlie

I'm pretty new to CLS but not to BHO. I'm getting this unit http://www.bestvaluevacs.com/extractorkit.html and wanted your opinion on any accessories, valves or whatever I can get to make this a better system? This is being given to me so buying a different one isn't an option lol, gotta work with what I got. Thanks for the help.

I want one

I want one.

having trouble finding this as on the one on there website under the product number does not look like yours 1/4 male flare to male NPT JB-A31484 3 $8.28/5 $8.28 RSD. Also which hose are you using having trouble finding it on there website 1/4″ X 36″ Refrigeration hose?

Would there be any negative drawback if I were to use 2 6x12 sanitary spools and adjust the length of the 1.5x12 column to a 1.5x24 with the goal of running 4oz. ?

i understand that the stainless to stainless threads can be problematic. is there any reason that a brass 1/4" close nipple couldn't be used in place of the 304ss counterpart? would making the threads brass to stainless solve the issue. all my parts are going to be delivered tomorrow and i can't wait to get it all set up. i just want to sidestep as many problems as possible. thanks.

Lead free brass is fine.

Hi all just a quick question, I know that when you fill your supply tank you need to pull a vacuum. Do you also need to pull vacuum on the collection vessel before you use it? I am assuming that you do but I didn't see it mentioned in the directions. Also is there any difference in the speed or quality of extraction between running butane gas through the product or butane in liquid form?

Vacuum all parts before introduction of butane.

Liquid only through material.

Hey gw In the process of building lil terp , would like to make one with two recovery tanks so I can pull a vacuum. Thinking of using two mastercool 30lb recovery tanks . Do you think this will work ? Would like to do two oz runs what size column should be used and how much butane?

hey gw in the process of building a lil terp , I want to use 2 recovery tanks so I can pull a vacuum , plan on useing 2 mastercool 30lb recovery tanks . I want to run 6"x1.5" and 12"x1.5" coloums , with a 6"x6" collecting chamber. -Do you think this will work , worried about the tanks being to big. Do you think I can acheve yeilds / qualitys compared to a tamisium or a terpenator with a set up like this? -How much butane should be in the system with a 6"x1.5" coloum? How many cans is that 300ml? -How much butane should be in the system with a 12"x1.5" coloum? -I noticed for the terpenator mk 111 the coloum goes into collection chamber and on your lil terp it is flush with the lid . which one would be better for my application ? -plan on puting 3 hole in lid of collection chamber and haveing tee in it with pressure gauge and high pressure release valve to outside , is there a type of gauge you recomend ? what pressure is somthing like this good for? - What type of hose would you recomend thanks and sorry if you already anserwed my questions.

Hi Greywolf, rereading my question from last night I realized it was not very clear. The question should be,if a pump was being used to recover the butane,could the extraction tank be kept cool enough to make a lighter coloured product.With the tamisium I can do a complete recovery at 104F, but it very dark oil. There seems to be a misconception that dark BHO is a flawed product.

Dark is more nutritious. Check out a youtube video under the keyword saw palmetto documentaries part 4 as it pertains to large high level extractions. I know it is not the same thing but the info crosses over. To get light extractions, it is a matter of what is called delipidation, not dewaxing. There are dozens of ways to do that but you generally dont want to do it in a solvent that the lipids or waxes are very soluble in especially if using a filter. That would require a very low temp to get them to cluster if filtering out. AC is the best way to lighten but remember to lighten also decreases the variety. You should choose a lightening method that allows you to harness capture and save what is removed. I see a lot of questions posed to greywolf about tamisium extractors. Thanks for answer them but I would appreciate it if I was asked directly. Purely for accuracy reasons alone. I think there is a misconception that users in the MMJ field cannot talk to tamisium extractors. Laws are changing and states are making up their own minds. We have changed our views a lot in the last 5 years. Although i dont invite blatant talk about extracting federally controlled substances, and there are many, I dont ignore request for help a person that operates legally in their state or dont state otherwise. So ask away. Thanks Greywolf for taking up some slack for me this long.

I should have said low viscosity extractions rather than light. But that also can be used to lighten depending on the compounds being filtered.

Hi Greywolf, I have a 8oz tamisium and would like to both speed up recovery time and produce a lighter colour oil.I was wondering what is the lowest temperature you could run the extraction tank at and still recover the butane. Many thanks for this and all the other great info. ery

as long as the recovery tank is colder it will passively work. so even room temp should work but if you going for the blond keep it under 100f

temps during extraction are independent of temps during recovery. This is why using a loading ratio is superior to loop processes. Actually there are many reasons but controlling temp during extraction is one of them. To send the correct amount of solvent through the plant material one time and then recover it all allows this separation of parameters for both extraction and recovery processes.