Hey Pharmers, welcome to Part 2 of the FlackTek SpeedMixer series: Extractions.

It’s been amazing to see the landscape of different types of extraction evolve exponentially since the inception of legalization. Sub/Super-critical CO2, Hydrocarbon, Alcohol, Rosin, Thermodynamic, Lipid, Water, Microwave, Electrostatic, Refrigerant, Distillation, Ultrasound, and now Dual Asymmetric Centrifuge (SpeedMixer) Extraction. Cannabis extractions come in many forms with each having their own specific benefit and/or detriment. The debate will rage on for what is best for what. Today we will be covering how the SpeedMixer can be used for making common extractions like water bubble hash, olive oil, butter, or ethanol extracts.

The SpeedMixer assisted extraction is a concept many will be easily familiar with. As it takes the fundamentals of making water bubble hash, alcohol, or lipid (oil) extraction and “speeds” up the process by applying immense force.

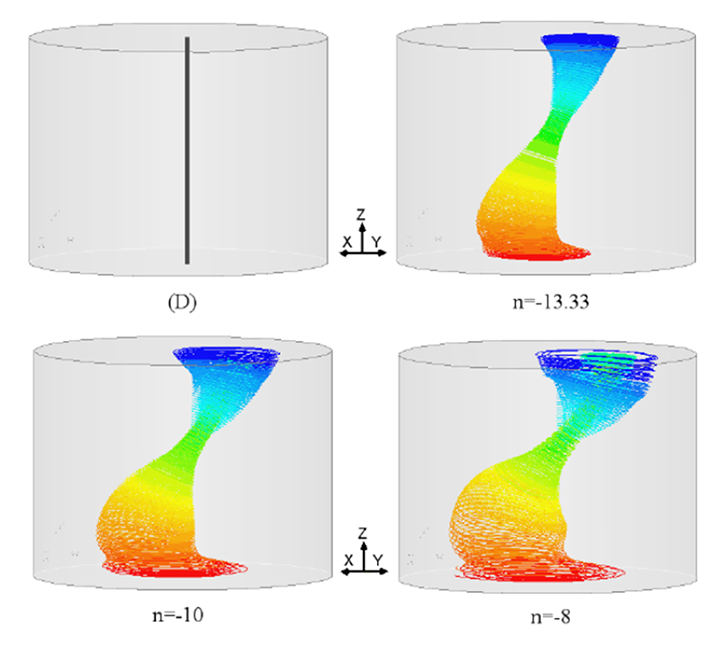

If you are coming here from part 1 Grinding/Milling you will notice a similarity in all of the seven processes described. The reason for that is quite simple, all 7 processes this 1 machine can do are achieved by the dual asymmetric centrifugal vortex the SpeedMixer creates. As a quick reminder- SpeedMixer is the originator of the Dual Asymmetric Centrifuge technology patented over 30 years ago. Originally designed to mix high viscosity dental impression materials without blades and no bubbles. It’s bladeless design uses opposing centrifugal forces on the outside to push the material against itself in a vortex pattern.

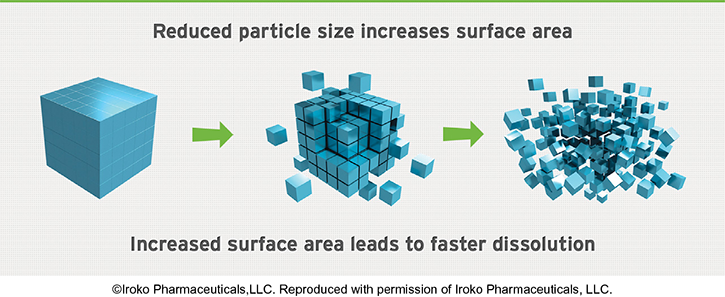

In respect to extractions, this vortex applies shear force while simultaneously cycling all the material through the focal point. This means that all of your plant material will be exposed to the solvent rapidly and with force. This process effectively increases the available surface area of plant material to solvent especially when combined with milling beforehand.

Compared to other methods of mixing solvents the SpeedMixer applies magnitudes higher amounts of power than a washing machine, propeller, mag stir bar, disperser, or overhead stirrer.

With that high power comes thorough homogenization, maximizing the Cannabinoid saturation possible in your carrier/solvent.

Step 1) Introduce the solvent over the plant material (or vice versa)

Step 2) Mix the solvent and plant material in the SpeedMixer etc.

Step 3) Strain it/Filter it

Step 4) Remove the solvent, or in the case of lipid extraction leave it in and use. (Might want to decarb before use)

How the SpeedMixer is different in respect to other methods is the speed and cleanliness at which saturation can be achieved. Due to the vortex motion each particle of plant material will have shear forces applied and solvent exposure in seconds. If the speed and repeatability of the process weren’t great enough- there’s no cleanup of the machine after! This means 100% yields of what went into your container. Since there is no cleaning (remember, there are no blades!), you can jump directly into your next processing without any down time between batches.

Using this method, it is possible to process up to 100lbs of plant material in a 1kg capacity DAC1100 in an 8hr day, assuming a very long 5-minute mix/process time. At an assumed 10% yield (depending on the plant material and solvent) It is possible to arrive at 10lbs of extract (after purging) per day. If using a lipid solvent like olive oil, it becomes an immediate “tincture”.

A few pointers below to consider for extractions using water, alcohol, or oils:

Particle size considerations:

Extraction of phenolics and essential oil from dried sage (Salvia officinalis) using ethanol–water mixtures (Durling et al 2007)

https://www.sciencedirect.com/science/article/pii/S0308814606002913

Solvent/Carrier Consideration:

Cannabis Oil: chemical evaluation of an upcoming cannabis-based medicine

LL Romano, A Hazekamp

Stay tuned for Part 3 as we explore how the SpeedMixer can be used to Purge solvents like Butane, Propane, and Co2 in just a few minutes.