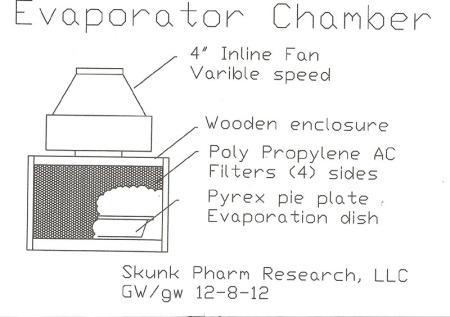

Here is one of next years back logged designs, intended to purge alcohol from shallow dishes, using rapid air exchange, with or without heat.

The attached design doesn't include space for a hot plate, as it is designed around existing filters, but it could be made taller to include one.

I've used fans to rapidly evaporate away Iso and Hexane, and it works well, but can introduce dust in a dusty environment.

It is but from two pieces of plywood, with wooden columns separating the two, and filters on all four sides.

Poly Propylene filters develop an electrostatic charge with air movement, which improves their efficiency, so I like to use them.

waiting to receive my first order of 3 Reptile Mats off auction/import for only $4 each. They even have a variable heat dial mounted 1/2 way up the cord. Alot thinner than a hotplate too!

Are the reptile mats warm enough? Hot plate on lowest setting was a little too warm, flavor loss. Cleared up cloudiness, though, and evaporated 90% volume EtOH in under an hour.

They worked, but not as well as silicone heat mats, which we switched to later. The mats do require better controls, as they are unregulated. GW

Which silicone mats? Trying hot plate with rheostat, but still feels hot.

We have ours made in China, but for this application I might suggest a 2.5 Watt/in2 silicone heat mat from Omega or Briskheat. Pharmgold has a few surplus that would be suitable, with or without the thermocouple molded in, and you could inquire at sales@Pharmgold.com for pricing. We typically used a PID controller, but have used a simple Variac variable transformer as well. GW

Old thread, but built one of these, and results may be similar to Mike W's. Evaporated 300 mls QWET to 20 mls in 6 hours at RT, but cloudy. Not filterable at 0.2 microns, re-dissolves in EtOH. Seems like moisture. Used 95% EtOH and freeze-dried material for QWET. Very dry - 49% RH, so must be absorbed from atmosphere. What to do? For evaporator chamber, used plastic file storage box and 4" duct fan. Cut out sides with hot knife. Easy.

try a cheap chicken incubator, they have adjustable heat and are designed to retain a constant heat.i got one from the local farm ranch supply for around $40. works great. keep it on 85° and let winterized oil set till clear and makes a great oil,just time consuming.

I am very curious is this design since i am trying to persevere terps with my winterizing. do you recommend running the fan on low? How long is the evaporation process? Could i use a 4 inch booster fan but for a longer amount of time?

A 4" will work. I would run it as fast as I could get away with, and keep the liquid confined to the dish. Evaporation is usually an hour or so.

Wouldn't the fan draw evaporating flammable fumes up and across an electric motor with some possible electrical arcing ? Maybe a fan with a pulley and motor in a slightly different position.than the exhaust fumes I have a question about this low and no heat process which I tried recently and in the past. back in the 80's I used 95 proof cane alcohol as a solvent and used a Pyrex baking dish placed in a metal cabinet with louvered doors and a light bulbs attached as close to the outside bottom as possible, for a little heat and within a few days I was satisfied with the resultant thick oil/tar to which I added some keif and rolled into small balls (pills) to be smoked.later. (I was not aware of the many medicinal properties at the time) A week or so ago I tried it a little different with Everclear and left the dish in a shed with a large open area with a good cross breeze. What I ended up with was some really sticky tar floating at the bottom of about an inch of water .. What happened and how ? I can't believe the herb had all that water so did it come from the night air ?? BTW .. Thanks for all your ideas, research and knowledge. ~ Keep on keepin on ~

The alcohol absorbs it from the plant material and atmosphere fast.

Unless you can keep the temperature of the solvent pool above ambient (using gentle heating), it won't help that the atmospheric water will be even more likely to condense into that mixture since the solvent pool will be cooled due to the evaporation. Greater evaporation rate = greater cooling rate = more water deposited (unless temperature is maintained). This is especially noticable when the atmospheric relative humidity is high and a large amount to solvent is to be evaporated.

I would love to talk to you GrayWolf. This Mike from Weed Country and CNR...

Judging from your link, I would no doubt enjoy talking to you too. I'll e-mail you contact information. GW

I'm very excited to see what you do with this design!