Cold Traps

So how do you keep the solvents that you are cold boiling from your oil, out of your vacuum pumps crankcase, so that it doesn't overflow, or dilute the oil and wipe out the pump?

The answer is that you really can't, but you can reduce it significantly and recover much of the solvent for reuse, by using a cold trap.

What is a cold trap? A cold trap is a container, through which the vapors are drawn, and which condenses them back to a liquid, trapping them in the container and keeping them from reaching the vacuum pump.

They range in design and complexity, some using dry ice or liquid nitrogen, but we wanted one simple and cheap to operate, besides being affordable.

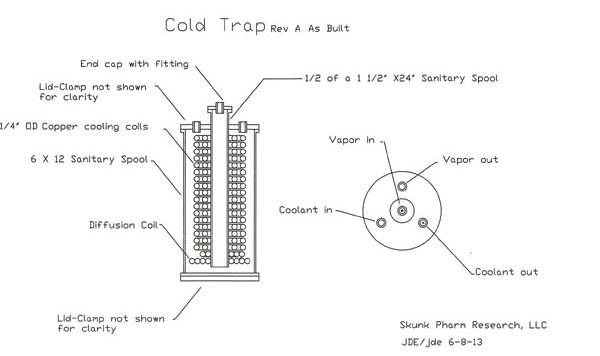

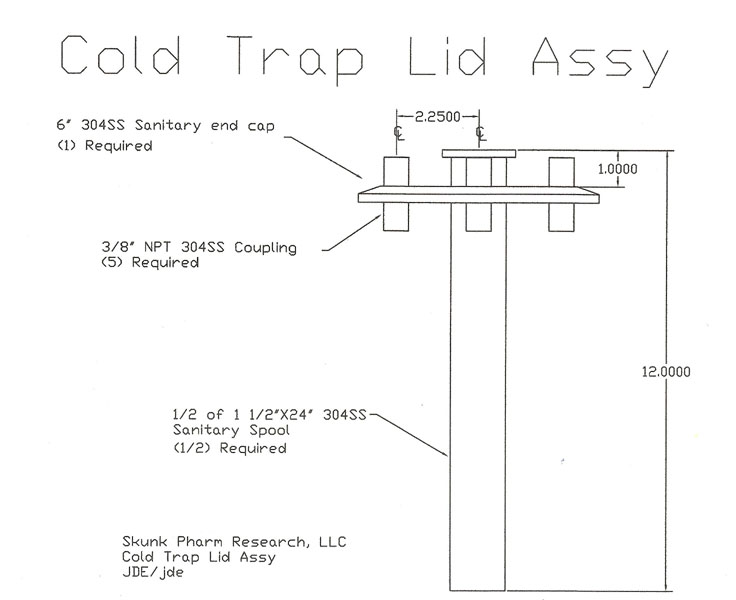

After experimentation with just a simple cold trap, and a simple cold trap with pre-cooler in front, I have a design which I am pursuing, which I feel will serve our needs. Copy of cad drawing attached:

It is based on a 6" X 12" stainless sanitary spool, with lids clamped on both ends and one lid modified to include five 3/8" couplings and a 1 1/2" center downsprew.

The 1 1/2" down tube is the inlet, that will reach within 1/4" of the bottom, and one of the 3/8" ports is the vapor port outlet to the pump.

The other four ports are the inlets and outlets of cooling coils, through which I will pump ice water or sub zero antifreeze from a freezer.

I will make an inner and outer layer of copper cooling coils, wrapped around the center downsprew, and put a diffuser at the bottom of the downsprew, so as to direct the bubbles.

As the chamber fills, the vapors are forced to bubble through the liquid present and the diffuser guides them between the double layer of cooling coils, as they make their way to the top of the liquid.

The cooling coils are copper, for the best heat transfer, and ice water or antifreeze can be circulated through them.

They can easily be taken below zero F, using a pump hooked to a tank of antifreeze, sitting in a chest freezer set on maximum cold, and even drop in dry ice, but any extreme cold, will require specialized pumps.

Here are pictures of my test sled using an original prototype butane tank for the Mk III, before I switched to a 50# tank for speed. It was a perfect design for either, as it was set up with both a dip tube (now a down sprew) and a vapor port.

For the test pre-cooler, I used a CPS refrigeration M-69 after cooler, which we purchased for their M-21 pump that we are testing on the automated Mk II Terpenator.

More as progress is made:

Trap in ice bath

Trap in ice bath Cold trap with precooler

Cold trap with precooler

6-8-13

Hee, hee, hee, all designs start in heaven and no plan with very many details ever remains unchanged, leading us to the "as builts."

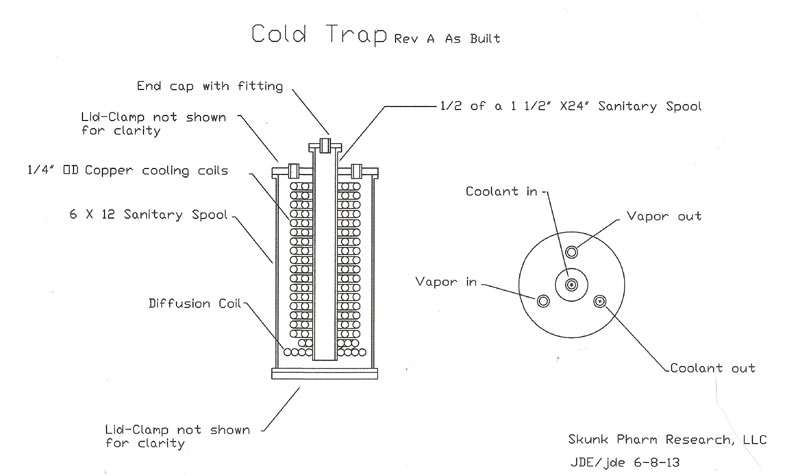

Regardless of what the first print, here is what I built and why.

I discovered two things as I assembled the parts for this puppy and the first is that it was over complicated by having two separate cooling coils, so I changed it to one and reduced the number of lid connections.

The second was that despite the utility of having the coils out of 3/8" copper, I was unsuccessful after four tries, to wrap the 3/8" condensing coil around a 1 1/2" mandrel without kinking it or freezing up the over coil coil I was using for bending.

I therefore went to 1/4" tubing, which increases my back pressure and now requires a higher pressure pump. One step at a time...........

Otherwise, the trap turned out well and awaits more pressure than the exiting 1/6 hp submersible affords. Now looking for a replacement............

Here are some pictures of the unit, and I replaced the lid layout print above to reflect three ports instead of five. You will notice that the bottom diffuser plate has also been replaced by a diffuser coil, made by making extra loops of copper tubing at the bottom of the first wrap, before continuing with the second layer coil wrap.

COLD TRAP COMPONENTS

|

NO |

Item |

Req |

Cost |

Price |

|

1 |

6" Lid |

2 |

$42 |

$82 |

|

2 |

12" Downtube |

1/2 |

$45 |

$22.50 |

|

3 |

6" X 12" Column |

1 |

$120 |

$120 |

|

4 |

3/8" Union |

3 |

$1.49 |

$4.47 |

|

5 |

1 1/2" X 1/4" NPT Lid |

1 |

$10.95 |

$10.95 |

|

6 |

1/4" NPT X 1/4" flare fitting |

1 |

$3 |

$3 |

|

7 |

1 1/2" Triclamp |

1 |

$5.90 |

$5.90 |

|

8 |

6" Triclamp |

2 |

$29 |

$58 |

|

9 |

3/8X 1/4" bushing |

2 |

$1.16 |

$2.32 |

|

10 |

1/4" NPT X 1/4" Compression elbow |

2 |

$2.83 |

$5.66 |

|

11 |

1/4" Copper tubing |

1 roll |

$37 |

$37 |

|

12 |

Machining |

1 lot |

$50 |

$50 |

|

13 |

Welding |

1 |

$30 |

$30 |

|

14 |

Total |

|

|

$431.80 |

[…] Cold Traps | Skunk Pharm Research LLC – Cold Traps. So how do you keep the solvents that you are cold boiling from your oil, out of your vacuum pumps crankcase, so that it doesn’t overflow, or dilute the … […]

I built the reclaim still I saw on your site. It works great but I want to cold boil instead. I am going to use the vacuum chamber > cold trap > vacuum pump system you describe here. Is there a pump that you recommend? I have a Gast DOA-P704-AA, but it says not to run flammable vapors through it.

I would like to purchase one of your cold traps. Will that be possible? 650 308 6160

Just thought I'd point out that bhogart sells a "cold condenser" for $285. http://bhogart.com/product/bhogart-cold-condenser/ I've been quite happy with my $30 amazon purchase of "Wort Chiller,stainless, Aprox 20', 1/4" Flare Fittings, Nut and Sealing Washer" sold by Smallwares and Parts LLC, though currently unavailable.

Hi, Not sure if you're already beyond this project or not but I'll pass along a tip for wrapping 3/8in copper tubing around a mandrel as small as 1/2 inch. Just fill the tubing with salt prior to wrapping, pressure and soak in H2O will clear the salt, a finer grain is better for less tube deformation, course salt is easier to clear but will result in more overall deformation. I've built a half dozen coils using this method without fail. What are you folks using for clamps on the 12in lids? 2 bolt high pressure? Thanks for the great site and making the information available!

Could a filter-drier reduce the amount of oil changes?

Hey Grey Wolf!! Quick question, looking at utilizing a cold still to play around with some of the mono and sisqueterpenes that may get trapped along with the alcohol. What I was wondering is if you guys utilize ethanol as a transfer solvent while running the mkiii or similar active units. I have always been concerned with the vapors back feeding and mixing in the lp50 with the butane, but some companies go as far as to include its use in their instructions on how to use their passive units. The other option we utilize in processing is to just dissolve the concrete extracted initially that we have in the collection chamber into the ethanol after the butane process has been completed...but that takes up a bit of time that we could be using to get another run going. Thanks for any insight you can lend!

Could you please elaborate on this setup? Decarboxylate in oven 200 for 17-20 minutes Place in frozen jar and put in freezer along with bottle of 99.9 iso, freeze until 32f/0 filter thru mesh screen then thru coffee filter into Pyrex bowl Put bowl into water bath, cover pot with 3 mil plastic, press downwards in centre, seal top with rubber bands, place a bowl of ice on top of plastic and heat at 212 and wait until alcohol has condensed? I've been successful without the plastic and ice, just allowed the hot water bath to evaporate the alcohol. I've heard and seen(Internet) the process. Just need a knowledgable understanding of the process. I've read and read and read skunkpharm's methods amongst many other methods , and confident I came to the right place for quality answers. Thanks a million skunkpharm. Fantastic information

Hi there i'm very interested in building one of these cold traps but i fear messing it up... would you ever sell a cold trap on ebay or amazon? if so, im willing to pay you for labor and whatever costs for trap. Also wanted to say thanks for all the information you share, its greatly appreciated!

and whatever costs for the cold trap***

WolfWurz might contract having one built on your behalf. Try WolfWurx at wolfwurx@gmail.com

Thank you very much!

Ok now i am getting really getting confused.

Is there any particular reason why the design uses 3/8 unions into 1/4 bushings instead of just 1/4 unions? Also, I believe there is a small typo on the parts list where you indicated the quantity of 1/4" NPT x 1/4" flare fittings :)

So it can also be made with 3/8" tubing for less back pressure

The pre cooler, what brand is it x where might one be able to source that item, thx in advance

That is a CPS Mt-68 Transformer.

SPR, is the MT69 precooler needed for butane extraction? -If not NEEDED is it however better/make recovery quicker/more efficient?

Depends on what recovery pump you have, as to how much effect it has, but it isn't strictly required. It does make things faster, especially if you are running an uncooled TR-21

Hey SPR, yeah I am using a Tr-21, so I will def get the precooler than. Lastly, would a burnout filter ttached to the tr-21 also be good/help? -as long as theres no issues hooking the precooler and burnout together? Thanks for all the help!!!

Hey Skunk pharm, I was curious if the Mt-69 precooler is needed for butane extraction? (IE mk 3-5) -or if not "needed" if it would help/improve recovery time?

It sure helps if you are running a TR-21 recovery pump.

GW Once again a great concept and eloquently delivered. I have a question about the drawing "Cold Trap revision A as built": could you have mixed up the labels for coolant in and vapor in, or alternatively I'm just confused? I'm still trying finalize the design for my cold trap. Here is my thinking. On the 6" lid, instead of the 1.5" x 12" downspew, use a NPT-NPS TriClamp Adapter (Glacier Tank 22MP-G100-NPS - NPS 1" female to 1.5" TriClamp). By then using a 1" x 12" threaded pipe it could be screwed in to make a full length downspew or removed to use the cold trap as the distillation tank for removing mystery oil from butane. Set it up as above for the cold trap (minus the downspew extension; plus the zeolite column). Go from can tapper through the m-69 aftercooler, into the cold trap, out the top of the column into recovery pump and into 30# recovery tank.The cold trap and its pump along with M-69 would sit in 85 F water. Your thoughts? Doug

You are absolutely right, thanks, I must have been brain dead when I drew that. I've corrected it now. A couple of ways to go. The cold trap pictured, uses the center sprue to deliver the butane at low pressure underneath the cooling coils, so it bubbles up around them, and they are kept cold by pumping coolant through the coils and setting the whole thing in coolant.. The trap that I designed for butane fractional distillation, uses the center sprue for a post distillation filtration column. The butane is introduced into the lower chamber through a side down sprue, which contains copper wool to remove sulfur compounds, and drawn out as a vapor from the center sprue, through filter medium. Adding a M69 is probably overkill, as the can discharges butane at about 31.5F and it has to be warmed to reach 85F. Sounds like you are on the right track.

Hi Guys, Am getting very close to collecting all the parts I need for the MKIIIA and the cold trap. However, it seems you left the 3/8" couplings out of the parts list here. Am I missing something?

Looks like I called them a union, instead of a coupling. My mistake!

I heard K from Trichome Technologies speak of a design he's working on w/AI, that is meant to capture terpenes lost during the vac purge, and reintroduce them to the product. Any ideas?

Ken and I discussed his design at the Seattle Cup last week, and will be comparing notes hence forth. Both of us are working on that process.

Good luck with it, sir!

Thank-you for the wonderful advice, Grey Wolf; and the detailed instructions, too. Your willingness to be open with your information puts you at risk in many ways; this is why the cannabis community is greatly indebted to you and this site. Thank-you for sharing!

Once the butane has been trapped into the cold trap how are you safely returning the butane to the supply take to recover it? My interest in these forms of bho extraction is to recover as much butane as possible.

The cold traps are for alcohol, not Butane. You just open them up and pour out the liquid.

So basically unless your gone go thru the trouble of tryin to make this shit just get a cheap pump that can hit 29hg cuz it's gonna poop out lol

Our relatively cheap CPS VP6S withstood a lot of cold boiling, with us just changing the oil as needed, so you can live without a cold trap. They just save time and recover alcohol for reuse.

for small runs, is there any reason one couldn't just put the cps precooler in an ice bath by itself and blow it out with a compressor from time to time?

I've actually used it for that, in front of a simple cold trap, to improve the efficiency.

Graywolf or anyone ever seen river rock colorados rock budder, it looks like flakey yellow crystals, they claim it’s bho purge at cold temps, it’s not stable and when touched it gets very sticky and it starts to clump together Into crystal shards if it stays at room temp long enough. I have to barely heat up my dabber to get it to stick without dripping off, it doesn’t bubble when it touches my heated skillet just melts, and it’s literally so packed with flavor it unbelievable. When I first got it, my first thought was yellow sugar, it looked like the heads of the trichs but extremely vibrant yellow and pretty positive that if it was set in a hot car for a day it would turn to shatter, but it seems to be fully purged at the state it's in. I'm no expert just basing my guess off taste compared to poorly purged oil, and bubbling of poorly purged oil. Would be pretty grateful if someone knew. Anyone of the hash masters on this site might know what I’m talking about or how this extraction would be done? Love what you guys are doing, keep up the research! Big fan Ive read post from most of you guys on toke city

Hi Brandon! I've never seen Colorado rock butter, but we can get flakey blonde to yellow crystals extracting and purging under vacuum at low temperature. It comes out of the Terpenator as paper thin sheets of cotton candy shatter, that can be reduced to a powder. It is dry to the touch, but if you hold it, it will warm up and stick to you. It however fizzes when heated, because it is still in carboxylic acid shatter form.

hello GreyWolf just don't understand where will solvent be collected?the vapor in vapor out makes sense ,so does the pump circulate thru unit using coolent that's in the blue vessel? Im putting together my shopping list and just gotta say this is a slick unit well done again(smile) looking forword to hearing back thank you very much frank

The solvent collects in the cold trap, before making it to the vacuum pump. You open the cold trap and pour it out afterwards. It sets in its own ice bath and has coolant pumped through it from the ice bath, or antifreeze from a tank in a deep freezer.

Is this available through specialized formulations? This post made me realize I'm screwing my vac pump. I've seen my vac oil increase by half the total volume after a few consecutive runs. sometimes I drain it on the spot and add fresh. I have noticed a drop in performance when the oil is diluted. Makes me think about the oil in it now... off to change my vac oil. Thanks for sharing, well laid out as always GW.

When we finish beta testing, we will make the cold traps available through Specialized Formulations or other source. Good idea on changing the vacuum oil regularly. Without a cold trap, we change it several times a day when cold boiling.

Any progress on the AI terpene collector? If I put my fresh cut buds in a vac chamber and use a cold trap can I basically remove and collect the majority of the terps? The I could dry the buds and run them through my extractor and then when I purge my end product there is no reason to worry about destroying the terps. I simply purge the final product and then add my previously collected terpenes back in. Any thoughts? Thank You.

I'm starting to construct a vacuum still for a QWET extraction. Should I connect the vacuum trap between the collection pot and the vacuum pump since most of the the alcohol vapor has already been condensed passing through the coil? Or could I simply replace the condensing coil and the collection pot with vacuum trap that you've designed?

The vacuum trap works without a still. You just put it between the vacuum chamber and the pump, to condense out the solvent before it reaches the pump.

That's awesome is this the idea that allows butane to be evaporated and recovered in the terpentor and other advanced BHO extraction machines?

No, this goes between the vacuum pump and vacuum chamber, to condense out the alcohol or hexane when cold boiling off the solvent, so that it doesn't dilute the pump crankcase.

This is important if you want to run multiple colums in a row, good work SPR!

Why is this important if you want to run multiple columns in a row?

Ummmm, could you elaborate on the question?

Just wondering about Kgb William's comment that a cold trap is important for running multiple columns in a row (presumably referring to terpenator columns). I run multiple terpenator columns without a cold trap and was just wondering if there is a compelling reason to include a cold trap. Thanks!

Not sureI understand the context that KW's comment was in, because we don't use a cold trap in the Terpenator system itself and run multiple columns. We have found that the butane tank will eventually pick up water and has to be inverted and flushed through the vent valve periodically.

[…] our project at: http://skunkpharmresearch.com/1845-2/ , where we are making one out of copper tubing and a stainless sanitary […]