The Enabler Alcohol Fractionating Still

While messing around with passive butane essential oils extraction and recovery, it occurred to me that with very few extra pieces, the new Skunk Pharm Research passive butane extraction and recovery system could also be used to turn 80 proof drinking alcohol into 190 proof, for those of ya'll who are unable to get 190 proof for essential oil extractions.

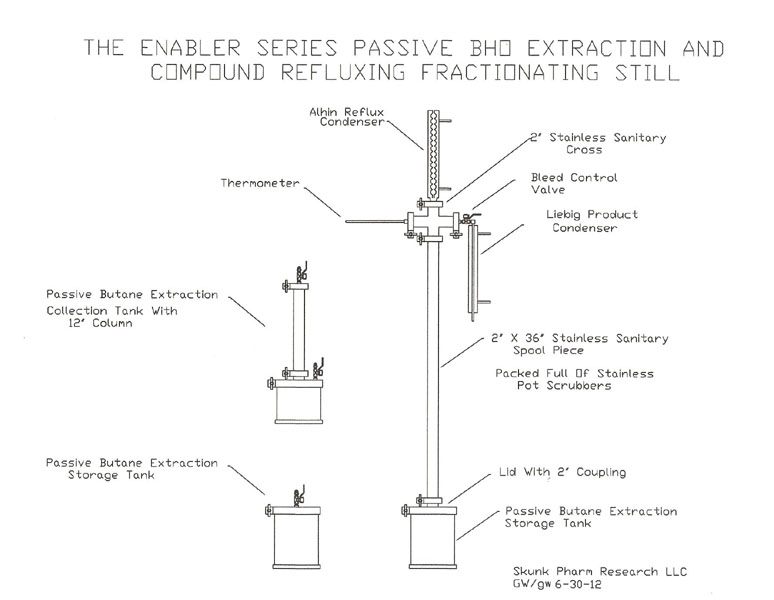

If we use the butane storage and recovery tank for the boiler, and the lid from the BHO recovery tank, we can install a 36" tall stainless sanitary spool for a refluxing column, packed with stainless steel pot scrubbers.

A sanitary cross at the top will provide ports for a thermometer, a refluxing condenser, and a product bleed. A product condenser on the product bleed port will condense the vapors bled off from the upper chamber, and the temperature of those vapors will tell you what they are.

Check with your personal attorney for their read on local laws, but by using the butane recovery tank, the volume of the boiler is under one gallon (.86), the taxes on the alcohol that you are condensing have been paid for, and it is used for extracting essential oils, not drinking.

In theory, the still could just as easily make 190 proof out of a ferment sugar wash, but that is illegal at least here locally, so we are not recommending it for that use where prohibited.

Here is a conceptual of how such a system might work, and here is a picture of what a 36" column with cross looks like. More when the parts come back from the welder and machine shop.

As with the passive extraction system, most parts are off the shelf.

Hee, hee, hee, ahwooooooooooooooooooooooooooooooooo

Enabler Configurations

Progress has been made. I picked up a dozen of the stainless pot scrubbers at Hongs Restaurant Supply for $5.99, and after I first pulled them apart, I rammed them firmly into the column, using a hard wood dowel.

They are held between the two combination Viton gasket/10 mesh screens at each end of the column, which I scored from brewerygaskets.com. I chose Viton because of its compatibility with hot ethanol.

I recommend this Cole Palmer site, for choosing alternate materials from what I have used here, should it be more readily available:

The science behind the 1 meter column packed with stainless ribbon, is that the large surface area of the ribbon continually cools the rising vapors until the point that they cool to a liquid and rain back down the column.

Eventually the vapors will heat up the insulated column, and they will rise higher and higher in the column, until the column and its contents reach thermal equilibrium.

Because of this continuous refluxing action, when it reaches equilibrium, the lowest boiling point vapors will be at the top of the column, and the heavier vapors below them in the column.

Because I would like to do this in a 1 meter column, I have elected to install an Alhin refluxing condenser above the column. This refluxing condenser condenses everything that rises above the packing, so that a shorter column can be used.

There is a digital thermometer in the cross below the refluxing condenser, with the probe far enough back, so as to not be affected by the temperature of raining condensate. It tells which constituent is at the top of the column, by the temperature of the vapors.

Bleeding off the fractions:

There are a couple of standard ways to bleed off the fractions, with one called liquid control, and one called vapor control.

With liquid control, you capture some of the liquid raining down from the reflux condenser at the top of the column and bleed it off.

Instead of liquid control, I will be using two different vapor control techniques with this fractionating still. I will detail them below, but the principle with both liquid and vapor control, is that if you provide a means to extract the liquid or vapor at the top of the column at a slow enough rate, the column will continually reestablish equilibrium, and you can bleed off that constituent.

The rising temperature tells you that the next constituent, or an azeotrope of that constituent has reached the still head.

Providing a bleed path using vapor control:

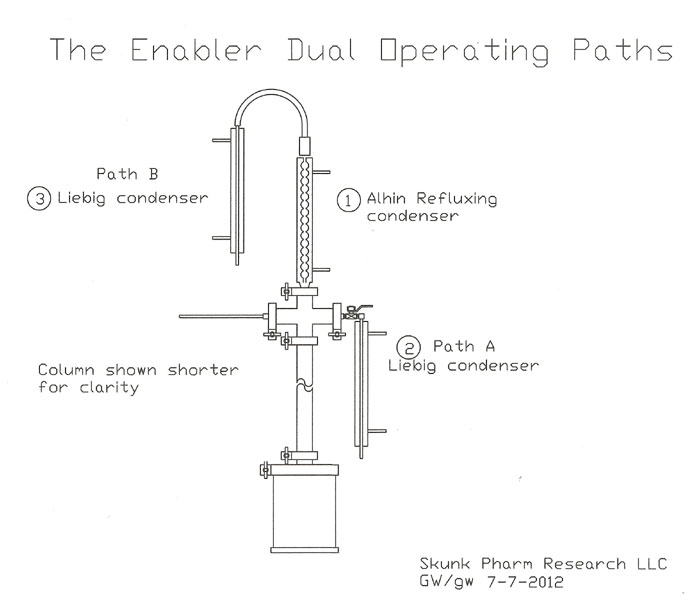

You will notice that besides the Alhin reflux condenser at the top of the column, there are two Liebig product condensers that come into play, depending on where the vapor stream is coming from.

Path A is created by cracking the valve on one leg of the cross, which allows some of the vapors at the top of the reflux column to exit through the Liebig condenser, where it is cooled to a liquid.

This technique relies on the fact that water steam is lighter than air, at 0.6 its density, while ethanol vapors are 1.6 times as dense. That means that given an opportunity, that the steam will rise and the ethanol vapors will sink, until their concentration falls below about 41% by volume in the top of the column.

This is a handy feature if you are making ethanol from scratch, as you can strip the wash with the valve wide open, and the product will drop off as the critical temperature for tails is reached, making the separation easy.

Usually the first constituent to reach the head of the still will be the Ethyl Acetate, and Methanol, which are bled off and discarded, followed by their azeotropes with ethanol, called the heads.

After the heads, comes the purified ethanol, until it reaches about 41%, at which time the tails arrive, with fusil oils and other cogens.

The advantage of this type of vapor control, is that the temperature and flow of the incoming water to the condensers isn't as critical, and it is self regulating on shut off. The temperature will not only rise, but product through the Liebig condenser will dwindle.

Path B, provides even finer separation of the constituents, but does rely on regulating both the flow and temperature of the water to the Alhin refluxing condenser, because we will be using it as the control point.

The way we operate it, is to run it in full reflux mode until it reaches equilibrium, and then start cutting back the flow to the Alhin condenser. That will permit the very lowest boiling point constituents to flow up and out the top of the Alhin, where it is directed through a Liebig product condenser and cooled into a liquid.

The advantage is very fine control, but it has to be monitored more closely and cooling water pressure, temperature, and flow are more critical.

You can also achieve the same effect by leaving the flow through the Alhin reflux condenser constant, and cranking up the boiler heat. Less system losses, the amount of heat added by the boiler, has to be removed by the reflux condenser to stay in balance. Increasing the heat will drive the vapors out the top of a finely balanced heat exchanger, just like reducing the cooling capacity.

Pot still:

For those applications where a simple pot still is just the ticket, with the Enabler's modular design, the head cross can easily be attached directly to the boiler itself, eliminating the column altogether. Hee, hee, hee, what could be sweeter?

GW

I haven't quite understood from the below information. But using an air still or any pot still for that matter to recover the ethanol, I understand it picks up water. So if it's 95% to begin it's likely to end up recovered at about 93% so i can continue to use it a few more times for oil extraction? After which it will have diluted too much? Or will it stop picking up water at a certain %? Or can I distill it once through the pot still to increase the proof again? Thanks

I would like to mention that there could be a layer of oil on the stainless steel ribbon so it's always prudent to wash it beforehand with a degreaser or clean solvent (Pharmaceutical Grade). Also besides the the benefit of a easier cleanup why would you not saturate your ethanol with sodium chloride and then decant the newly formed water later? Then just a simple distillation and you have your 185+ proof clean ethanol. I don't know the exact numbers but also the residual salt in the ethanol solution boosts the efficiency of distillation over plain ethanol and water.

If you are lucky enough to have a recirculating chiller laying around (or big bucket of ice water) you could use a 1.5" jacketed dewax column as your condenser...maybe stuff it full of SS pot scrubbers, to slow the condensate down and help cooling, then put the 90 degree sweep on the end and drain into collection vessel...

If you're finding it hard to source pure alcohol try using Shellac Thinner from your local hardware store. It's usually denatured ethyl alcohol so it's perfect for alcohol extractions. ;-P

I believe the very reason for sharing the information is safety and to educate individuals as to the proper ways to do this and the EXTREME need for safety precautions. Let me say that again "THE EXTREME NEED FOR SAFETY PRECAUTIONS" because people are going to do this anyways and if their going to do it its our civil duty to see they don't blow themselves up in the process. Not to mention it it provides references to the proper types of materials to use. Again, people are going to do this regardless and if this information saves one life (which it is doing) its paying big dividends into another account, but by making a comment about profits it appears clear that you don't really get it. Life is not about having the most toys its about experiencing the most joys and helping people without expectation is one of the greatest, add saving lives to that and your making bank.This plant has been here a lot longer then we have and will be here a lot longer after we are gone. The fact that it is viewed as a means to massive profits by many was only created by its prohibition.The fact that your A** hurt over knowledge being shared that actually educates those with an interest is a rather half witted approach to thinking...Were you born with the knowledge you possess on this subject matter or did you have to learn from someone? We don't need bad media and press on any of this movement, If we are going to further this cause for society as a whole profits are not where an advocate places there focus. If I remember correctly compassion is how this started. KNOWLEDGE IS POWER AND POWER IS SOMETHING WE THE PEOPLE ARE IN SHORT SUPPLY ...EMPOWER ALL THAT YOU CAN. Aidin

Don't you need a license to distill alcohol in Oregon? Not that a person producing for their self only should care about that since a competent operator that keeps to themselves would never get caught.

Nicely done.

Great website! Thanks for all the info. I am currently trying to come up with a way to concentrate CBD from trimmings. My wife and several friends have cancer and I want them to be able to get as large a dose of cannabinoids as possible and still be able to function without getting too high. I read about using a controlled temperature vaporizer to extract the THC and other cannabinoids by vaporizing at about 175-180C, then they could be discarded (or used for some other purpose, he, he). Then a second vaporization at about 215C would extract the CBD, CBG, and CBN which could be used to create the desired medicine. I am considering first extracting the trichomes using a dry ice extraction method to eliminate most of the plant material. My thoughts on the next step would be to vaporize the hash in a two step process discussed above but instead of collecting in a balloon, to bubble the hot air and vapor through a chilled ethanol bath and use a vacuum pump to remove the air (at about 100-200 mmHg to avoid losing too much alcohol). I then would have two alcohol based tinctures presumably one high in THC and CBC, already decarboxylated by the hot air and vaporization, and a second high in CDB, CBG, and CBN. Next I would use a distillation process to concentrate the cannabinoids and recover as much ethanol a possible for the next batch. This still unfortunately uses a flammable solvent (flash point < 100F), which is considered illegal here in Colorado. Perhaps I could substitute a temperature controlled glycerin bath to collect the vapors instead? Am I missing something here, or could this be a viable process?

Further research seems to allow use of alcohol in Colorado, but not butane, propane, ether, or high pressure gas like CO2 without a state license.

You do not need fancy equipment to put sieve hash in some oil. A 1g cap can supply 200mg of CBD easy with just hash and oil. Of course, it will not make you look cool though

Makasih atas infonya , Adria

What does this method extract?

First Post, Thank you so very much for your blog, I couldn't have gotten as far as I have without it. I'm extracting HHO to help my wife fight Stage 4 Breast Cancer. I built a refluxing distillation extractor but it has the following problems: All refluxing stops when it reaches thermal equilibrium and releasing the pressure build up (2psi) causes it to flash boil and flood the whole column and shotgun condenser with material. I added a couple viton screen gaskets to stop the material blow back. I do not have any opening to atmosphere after the condenser so I am considering designing one in to keep the pressure from building up. I am also interested in learning more so I can build and run a fractional distiller to pull off the various canabinols to create custom meds. I am a SW Engineer so missing the knowledge to resolve these, but not the motivation. Sincerely focused on safety and quality!

Dear Brother You might want to also check out www.fungiperfecti.com for Turkeytail mushroom capsules! And or utube as Paul Stamets Has Indeed Helped Cure his Mother from stage 4 breast cancer using Trametes Versicolor ie Turkeytail mushrooms and i think maby Red Reishei mushroms! He is shown on utube like 5 yrs After his mother was given 3 months to live and she started using said mushrooms & was 100% cancer free 5-6 yrs later!! Im a Believer in MMJ but this is something you migt also consider!! Im also a huge advocate of informed choices!! May God Bless 1 Love

Great info guys! Fun science. We have seen runs as low as -15f. Keeping it cold long enough is always a challenge. We aren't having problems getting ethanol, though there is a huge range in cost on it. I am MedMike, I'm an educator and activist. I'm the Executive Producer of the Jack Herer Awards show. I helped Jack for 20 years. I'd love to discuss binding unlike constituents/ liquids such as oil and water. Also any thoughts on thc removal to get cbd rich oil from extracted oils such as fractionation? Decarboxilation and it's use and need outside of oral consumption? Thanks for teaching, learning and sharing, MedMike

Greetings. Thank you so much for the amazing posts and information here GW. (I understand you are in the NW? I am here and would LOVE to meet you guys). I wanted to know your thoughts on a modification I thought about for a still I have. The still is quite modular. A simple pot / element which holds a qwet, enters through a column of copper mesh, condenses and recovers the ethanol. My modification would be to place the material in a thimble / filter (in place of the copper mesh) with a stainless t cross as you described between the pot and the column which would divert the vapor out a different path to another short column which sits between the condenser and the column with the thimble / material. The vapors would condense and bathe the material as liquid, once through the material and divert out to a site glass which would fill up and then siphon back down into the pot. (This is basically an attempt to turn the still into a soxhlet, and it would have reasonable capacity as soxhlet’s go.). I have photos and a sketch I could e-mail if there is an address. Again, thank you for all the great information.

Yup, we're in Portland. Swing by sometime for tea and crumpets! Soxhleting with EtOH picks up a lot of chlorophyll. We do QWET frozen, so as to tie up the water and water soluble chlorophyll binding proteins in ice, because water and chlorophyll are both highly soluble in alcohols.

The Poor Mans Closed System Vapor Extractor, or, SOXHLET With additional commentary. . . . . . I have built and use a simple Soxhleter. I run it it with 190 proof. Copper screen basket, 13 Qt. double boiler arrangement, using a heated water bath. Simple canning setup with the jar tray basket handles inverted and bent to support the basket above the solvent bath about 2 inches. The lid is inverted, a 27" bicycle tube (air fill cut out and entire tube sectioned to make a long band) is used to tie off to 1 handle, wrap tightly around lid/pot edge 2 wraps & ties off to opposing handle. The fine copper screen is sectioned and lays seamlessly into basket, holding up to 2 lbs of plant materiel. The heat source to heat the water bath (a galvanized tub for automotive fluid drains) is a 3-legged propane camp stove. Consistent sized ceramic pebbles/marbles serve to keep the extraction vessel evenly in the water bath. Setup using a short level. I monitor the temperature with a canning thermometer & hold at @185 deg. Vaporization point of ethanol is 173 deg, thus internal vessel temp is locked near 170 deg. The inverted cap of the vessel is filled with ice to condense the rising vapor, dripping the condensate profusely down through the plant materiel, which is well loosened up by the arising hot vapors. I made a Styrofoam cap for the vessel to help preserve the ice from rapid melt. Other than siphon off the water, refresh the ice and monitor the temperature, I get a complete extraction virtually to cellulose of the materiel in under 4 hrs. A typical run uses about 1 1/2 gals organic ethanol 190 proof. With cleanup operations/transfers etc @ 2 gallons total per batch. The most efficient and practical method I am aware of for producing a fine oil in which the chlorophyll, tar and waxes are easily isolated is using a Di-ethyl ether wash. Problem being is unless one has a license to purchase this volatile solvent it may only otherwise be prepared from certain automotive starting fluids based on Di-ehtyl ether. It requires super chilling of liquid, opening of cans, transfer of cold contents to cold container (outdoors), addition of equal volume of cold distilled purified water, soap, and mixing to wash, pressure release from vessel (large french mason jar with rubber seal and metal clamp). Return to freezer and repetitive mixing with pressure release. Finally, the other petroleum solvents are dissolved, the remaining soap/water/pet solvents are separated out by siphoning the ether layer or draining through a cold separatory funnel. It is then ready for use after an additional wash using cold double distilled water. A lot of friqqin trouble, very dangerous and likely considered as an illegal activity as well. Honestly though, other than for clarification useful in certain medications, cosmetics and simply for the joys of pure clear extracts, I must admit the following; This simple soxhleter produces a full spectrum extract, when the partially isomerized product (extract) is placed in a reduction vessel and heat reduced to take the alcohol down to about 5-7%, a fully isomerized full spectrum syrup is produced. This is real medicine with no frills and no BS. It is easier to control the dosage for cancer and other patients as you literally count drops (3 to 6). Additionally the medication is preserved more readily whereas with a complete reduction to a tar-like 'grease', it is subject to spoiling and harder to control the dose, not to mention the substance itself, as it is notorious for sticking to teeth & esp. dentures! Either way I find this superior to the Rick Simpson method (using naptha, well purged) which I have also done and patients definitely benefited from. The full spectrum alcohol extract, fully isomerized using heat reduction of alcohol, is superior due to the solvent being clean and complete "purging" is not desirable, as the alcohol is a wonderful natural preservative. The cost of not recovering alcohol is of little significance considering this "poor mans" setup has saved so many lives. From there it is know the genetics, organic clean status, the strain, its virtues, and you are good to go. The 'heat isomerization method' yields a 3 to 6 time increase in CBD value, depending on your base working materiel, because you can only "get what you got". Testing is certainly desirable and not too terribly expensive. Either way. Real medicine, that works, for a change. Safe and affordable. The ether preparation and washes portion of the above information are for educational purposes only, are in no way suggested, are dangerous and, in fact, in most jurisdictions and minus certain licensing, illegal.

Diethyl ether costs something like $200-300/gal. Buying it in cans and refining it will not be cheaper unless your time is worthless and you steal the starting product. You do not need a license for it as photography supply. There is no way you had clean extract using Naptha unless you used certified light Naptha and you purged it several times with Ethanol. You did not increase CBD with isomerization. Isomerization is for converting CBD to THC and is not worth the time if you can actually get pot to begin with. Heat reducing Ethanol is not "isomerization"

OMG!!!! $200-300/gal???? It is Sooo easy to make!!! Check-out youtube for instructions!!

Greetings, I do believe your site mmay be having browser compatibility issues. When I look at your web site iin Safari, it looks fine however, if oening in Internett Explorer, it has some overlapping issues. I just wanted to provbide you wth a quick heads up! Aside from that, great blog!

Hurrah! Finally I got a weblog from where I can in fact take useful information concerning my study and knowledge.

Can this be used to fraction BHO? Could you load it with bho in a carrier oil with higher boiling point and then isolate different Cannabinoids by their vaporization points

Unfortunately, no!

All the more reason for me to built the little terp. 10/10. brilliant post. Anyone interested in recipes for fine liquors and more still plans should check out http://homedistiller.org. I'll enjoy making absinthe with this...kinda want to use cannabis as an infusion herb in the coloration procedure

how cold is to cold for winterizing? would it beneficial to get colder I'm having problems of it warming up too fast. Thinking about using dry ice under the mason jar in the freezer. the coldest I can get to is -8 it flexes for -1 to -8.

We've had good luck with an alcohol and dry ice mixture to speed up wax precipitation.

He asked what is "too cold" Correct answer: there is not a "too cold" unless you freeze the stuff solid

Greeting, Im new to the discussion and passionate to assist others, I recently purchased a Coldfinger extractor from edenlabs and feel that there are steps missing with this piece of equipment in regards to creating a pure smokable essential oil, are there any ways to modify this unit to better utilize it, or use it in conjunction with another apparatus to reach the desired outcome

Which cold finger did you get?

Has this been built and tested yet?

90% complete, and not tested.

Dam look at that old grey wolf hand hahaha ;)

Hee, hee, hee, snicker, snark, snort.......My hands have always looked ancient. When I was a kid, my mom used to tell me that my hands looked like they had worn out a dozen bodies, so I guess it must now look like at least thirteen worn out bodies.

Most excellent Skunk Pharm Research,LLC , Thanks for keeping us apprised of this new data.

I appreciate the design, what adapters or fittings are you using to reduce from the 2" sanitary cross to the glassware? My glassware has a diameter of just under an inch. Also have you thought of doing a distillation under vacuum?

Solly to fall behind bro! Excellent question, and yes I've considered vacuum as a way to tilt the azetrope toward the alcohol again. The issue I am trying to resolve at this point, is my abysmal recovery percentage under vacuum compared to a simple compound fractionating or even a pot still. I am still losing too much through the pump, so I need to go to a colder trap, lower flow, or to more surface area. Dry ice and acetone would resolve the colder cold trap issue, but would be an added hazard to deal with. We picked up a small liquid nitrogen Dewar and plan to run some experiments using a liquid nitrogen cold finger, but the whole purpose of our Enabler design, is something that most ma and pa patients can whomp together, with few modified parts, to make or condense ethanol for extracting their meds, where it is legal to do so. The added complication of vacuum distillation would be a push for many, so perhaps there needs to be a Mk I ma and pa version, and a Mk II professional version. Hee, hee, hee.........

DIY don't need anything but QWET. People are making extract way more complicated than it needs to be. Medical doesn't need to be anything but effective. I can't see any complicated process being more medically effective than a good QWET. ...or people can support qualified professionals by actually paying money for things they value

I am not Sure if this would apply here, and the stainless scrubbers are easy enough to find most Anywhere. I have a buddy who built a still that he used for various applications including essences for candy, baking, being a chef in general. It was also used for alcohol. Instead of the scrubbers, he had glass marbles in what I guess would have been the column of the still. Worked a treat for him. Thanks for all you do!

Yes, glass marbles will work as well and are easy to clean, but don't have as much surface area as the stainless ribbon, so it takes more of them to accomplish the same effects. You can also use commercial Raching rings, which ostensibly would work even better than ribbon. GW

Hello, I'm in the cannabizness in CO, and also made a living doing industrial design for a few decades, now working on making better canna-extractions. My current goals are in building or buying an affordable CO2 extractor, and also a much bigger bho recovery-type extractor than the current Tamisium unit I have (and have a lot of issues with, notably recovery time too long). I like your open format, and may have something to contribute too, with an idea to build on what you've done. I would be interested in fabricating your latest iteration if that's ok with you? I don't do my own machining but apart from that I do have a good fabrication shop, and good machinists including cryo. Also curious if you have a favorite supplier for the stainless klein fittings? I would really appreciate a chat if you have the time.

Hi Tom, please feel free to build anything I have published, and improve upon it for your own purposes as you see fit. I am delighted at how many folks world wide have been doing so, and how the idea has caught on. I will update the Mk III page, to add part numbers, and so that the landscaped parts list that I posted is reduced small enough for you to see the complete page showing resources. Currently the whole right side of the spread sheet is not visible. All of my sanitary fittings came from Glacier Tank here in Portland, and I have provided Rochelle at that location, with a complete parts list, which they will assign a part number to. They have also agreed to start stocking the specialty sanitary seals that we use, so that it narrows the number of vendors required down to Glacier Tank and Paramount Supply. I am in the process of making similar arrangements with Bob at our local Portland Paramount supply, so that all that will be necessary for builders to pick up a complete kit, is to ask for it by part number. Good job on having good machining resources. Good technical support makes things easy and building a Mk III could hardly be simpler with a good machinist and TIG welder, as there is only the lid assembly and injection tee to build. The rest just screws or clamps together. I deleted your phone number from this post, but will try it about mid morning today and if I miss you, I will leave you a contact number. Peace, GW

I don't see how you giving profits to less insightful and creative people is a good thing. If they deserve the profits, they won't need a contribution from you.

Oh, btw, I read your work for entertainment. I am familiar with most of this stuff and am not interested in advancing extracts because it really benefits low skilled producers with shit tons of capital. Enabling half wits to make their own is not a proper compromise for the situation. But thanks for publishing anyways. I can't find much good entertainment due to most people preferring cave man type stuff.