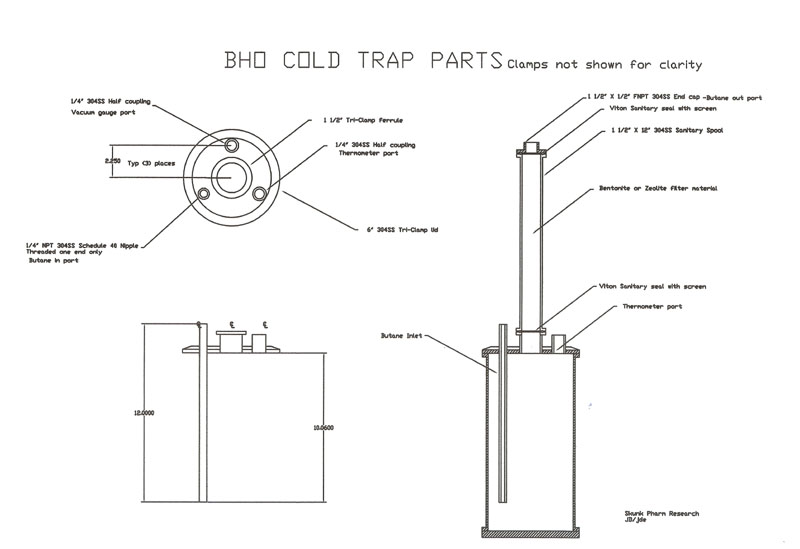

For those of ya'll wishing to vacuum distill your butane to remove any heavier components, before using it for extraction, here is a design for the cold trap that we will be using as a test sled, to not only vacuum distill the butane, for further polish filtering it through a Bentonite, zeolite, etc, column.

The way it works, is that the butane is injected into the cold trap as a liquid and pumped off as a vapor, leaving behind those things with a higher boiling point.

I set my cold trap in 85F water. You can do it without setting the trap in warm water, but as the butane boils off under vacuum, the transition from liquid to vapor, liberates the heat of vaporization, and plunges the temperature of the pool of butane to below its boiling point, so the process moves in starts and stops.

The next Alkane boils at about 36.1C/98.6F, at atmospheric pressure, so it is important to not heat the pot much beyond about 85F. The thermometer in the cold trap lid will tell you at what temperature your butane pool is during the cycle.

It is also important to not recover the butane below where the compound pressure gauge reads zero pressure, zero vacuum, or 14.7 PSIA.

PSIA is pounds per square inch absolute, which starts at absolute zero, without the weight of the atmosphere (at full vacuum). The atmosphere weighs 14.7 pounds per square inch, which is what a 1" column of mercury 29.92" tall weighs.

We do this operation outside and recommend that everyone do the same. Even though it is ostensibly a fully enclosed system, what if there is a leak or something goes wrong, goes wrong, goes wrong..........?

I recommend that you read and heed the thread on Butane Safety, before embarking on this journey. /butane-safety/

Pull a full vacuum on the empty 50# refrigerant recovery tank for the first time, and valve it off.

Attach the pressure gauge to the cold trap via 1/4" refrigerant hose and pull a full vacuum on the trap, and valve it off, before assembling the system.

To vacuum distill using the cold trap, attach a 1/4" refrigerant hose to the inlet of the cold trap, and the other end to either an LP-5 tank of n-Butane, or to a can tapper, preferably with a ball valve attached at the tapper.

Attach the 1/2" outlet hose to the top of the filter section and the other end goes to the inlet of a refrigerant recovery pump.

We've used a couple of inexpensive brands for this purpose, namely the Appion G-5 twin and the CPS T-21, but neither are rated by the manufacturer for butane, because they are not explosion proof should a leak occur.

Our larger commercial sized Mk V Terpenator will have the more expensive Caresaver Universal, or a Haskell pneumatic refrigerant recovery pump as an option, that are rated for flammable refrigerants, such as R-600 (n-Butane).

Depending on your situation, you should pick an option that fits your needs and safety needs.

The other hose goes to the red liquid dip tube valve on the 50# refrigerant recovery tank, which is sitting in an ice bath. If you really want to fly, set it in a denatured alcohol bath, with chunks of dry ice dropping the temperature to -70F or so.

Start the refrigerant recovery pump and the open the red valve on the refrigerant recovery tank, as well as the outlet valve on the cold trap.

If you are using an LP-5 tank of n-Butane, set the tank on a refrigerant scale and weigh it. Record the weight and push tare on the scale.

Open the inlet valve on the cold trap slowly and transfer about two liters of butane, or about 1146 grams, 2.5 lbs. Close the inlet valve.

The pressure gauge will have gone from -29.92" Hg vacuum, to positive pressure in the range of 10 to 30 psi. Watch until the pressure gauge drops to zero pressure, zero vacuum, and then load another 2 liters for distillation.

If you are using canned butane and a can tapper, close the valve at the can tapper, and open the inlet valve on the trap fully.

Tap the can and open the ball valve at the tapper. The pressure will rise from zero, to positive pressure. When the recovery pump lowers the pressure back to zero pressure, zero vacuum, close the valve at the tapper and tap a new can.

Open the valve to drain that can as well, and continue this cycle until all cans are empty.

Once you have emptied the LP-5 or the cans, when the pressure reaches zero again, close all valves and turn off the recovery pump.

Disconnect the hoses from the trap and open all valves to let it breath.

Remove the lid to the cold trap to remove the materials removed from the butane, and clean the trap with denatured alcohol for the next batch of butane.

Could i use zeolite from the pet store for fish tank ammonia removal to dry butane? Im assuming that if it will adsorb ammonia that its around 3a or 4a otherwise it would just go around it correct? Im looking to use it to dry for any water and or mercap or other contaminants around that size, butane is about 4.9a so I would assume it would be left alone from adsorption in the crystals if it catches ammonia because of the gap from ammonias size (which it is advertised to be adsorbing) to the size of butane which is roughly 1.5-1.9 angstroms larger so it should be fine right?am I correct in this thinking? A second or third opinion on this would be awesome thanks

I've read several excellent stuff here. Certainly price bookmarking for revisiting. I surprise how much attempt you set to create one of these great informative site.|

Just wondering, when extraction companies say 5(9) Butane what does that mean exactly?

If I would like to Distill 21 pounds of butane, do I need to wipe my cold trap clean after every recovery or can I just refill it over and over again for a longer period of time to avoid constantly dismantling and rebuilding my machine? I'm using an Oreo obie and a caresaver

We clean when we finish the batch, typically 24 to 48 lbs. GW

How long does it take condensate 2 liter of butane? And does butane stays transfer line after butane vaporizes?

Can charcoal be used to filter in the cold trap?

I am a chemist. I admire you guys for trying but I must say that your research is comparable to that of an Apollo monkey on cannabis. You shame my profession. You share bad information.

If you're a chemist...... do be specific about what information Johnny Chimpo has wrong ?

Well enlighten us then if you have such good information? Last time I checked, the info that is posted here, was not posted by anyone claiming to be a chemist or scientist but instead a group of people who are in this venture together. So enlighten us please by letting us know what information is incorrect

Yup I wonder where the money comes from that keeps skunk farm going. The .org dont fool me Oil companies?

Nope, looks like someone beat us to it. May I suggest a good laxative for what ails you? GW

Yup I wonder where the money comes from that keeps skunk farm going. The .org dont fool me Oil companies?

Out of our personal pockets and it is a matter of public tax record that it has been a money hole. We've gotten free gas samples and equipment to test and report, which we've done as a public service pro bono. No need to fool you brother, you are so full of it, that you're doing a good job yourself! May I ask what have you done recently to make the world a better place??? GW

There is so much debate regarding refrigerant pumps. Has anybody put enough hours on a haskell to recommend a part number? I don't really want to discuss Appion as safety is my main concern. Kind regards, QZ, Safety Officer

A fair number of folks running the single/dual stage 59025-3 Haskel, and Haskel is now coming out with a single stage EXT-420 stainless version, geared to our industry. Check out this thread for more insight into the pump. https://www.icmag.com/ic/showthread.php?t=297278

How about posting a PDF reprint of the article? Thanks!

any possibility this can be accomplished with a lil terp?

Dumb question maybe. Is it possible to use a small glass vacuum distilling apparatus to recapture butane from an extraction? Collecting the butane solution from an open run, and distilling the butane off, leaving a small amount as a carrier for the concentrates left in the bottom of one flask, and pure butane on the other?

Yes, the right thickness glass or borosilicate would work.

I made a glass CLE out of 1.5" tubes that came out of a milk sterilizer. It works good, but heating the liquor to get it to distill makes the dab really dark. Still 82% THC, and shatters... anyway I'm going to drop the temp to 98.6F and see if I get the yellow stuff I do when I waste the butane. And I'm going to buy a pump haha. One of those cheap Robinairs.

I found the same by trial on new terp. Excellent post. Worrkshop was great training.

I am just getting my order together with Glacier Tank and I have a question about the butane distillation apparatus. Can you provide more details on the piece that should be ordered to fulfill the 12" input port? Also a spec on the thermometer and maybe a source for it as well. Many thanks for your efforts to share this information on your site. You are true Samaritans..

I cut a 24" 1 1/2" sanitary spool in half to make two of those pieces. I had a Type K 1/4" tubular thermocouple made by Branom Instruments and use a cheap Mypin temperature controller off E-Bay http://www.ebay.com/itm/New-Dual-Digital-F-C-PID-Temperature-Controller-Control-TA4-SNR-K-thermocouple/280840220156?_trksid=p2045573.m2042&_trkparms=aid%3D111000%26algo%3DREC.CURRENT%26ao%3D1%26asc%3D27%26meid%3D3094846578978645992%26pid%3D100033%26prg%3D1011%26rk%3D3%26rkt%3D3%26sd%3D141126338876%26, and use it as read only.

[…] http://skunkpharmresearch.com/vacuum-distilling-butane/ […]