I just hate to waste good numbers, so when circumstances changed, that there was no longer any motivation to build the half completed Mk IV Chimera, I decided to create the Mk IVA Phoenix rather than complete the Chimera just for show.

I dubbed the Mk IV the Chimera, because it was built from parts of several other systems, and was an attempt to get maximum surface area for vacuum evaporation, using available 6" sanitary spools. At that time, a 6" X 12" spool, was the largest that we could obtain.

Shortly before completion, 8", 10", and 12" X 12" sanitary spools became available, so I canceled the project.

Hee, hee, hee, behold the Mk IV Phoenix, risen from the ashes of the Chimera and embracing everything that we've learned to this point.

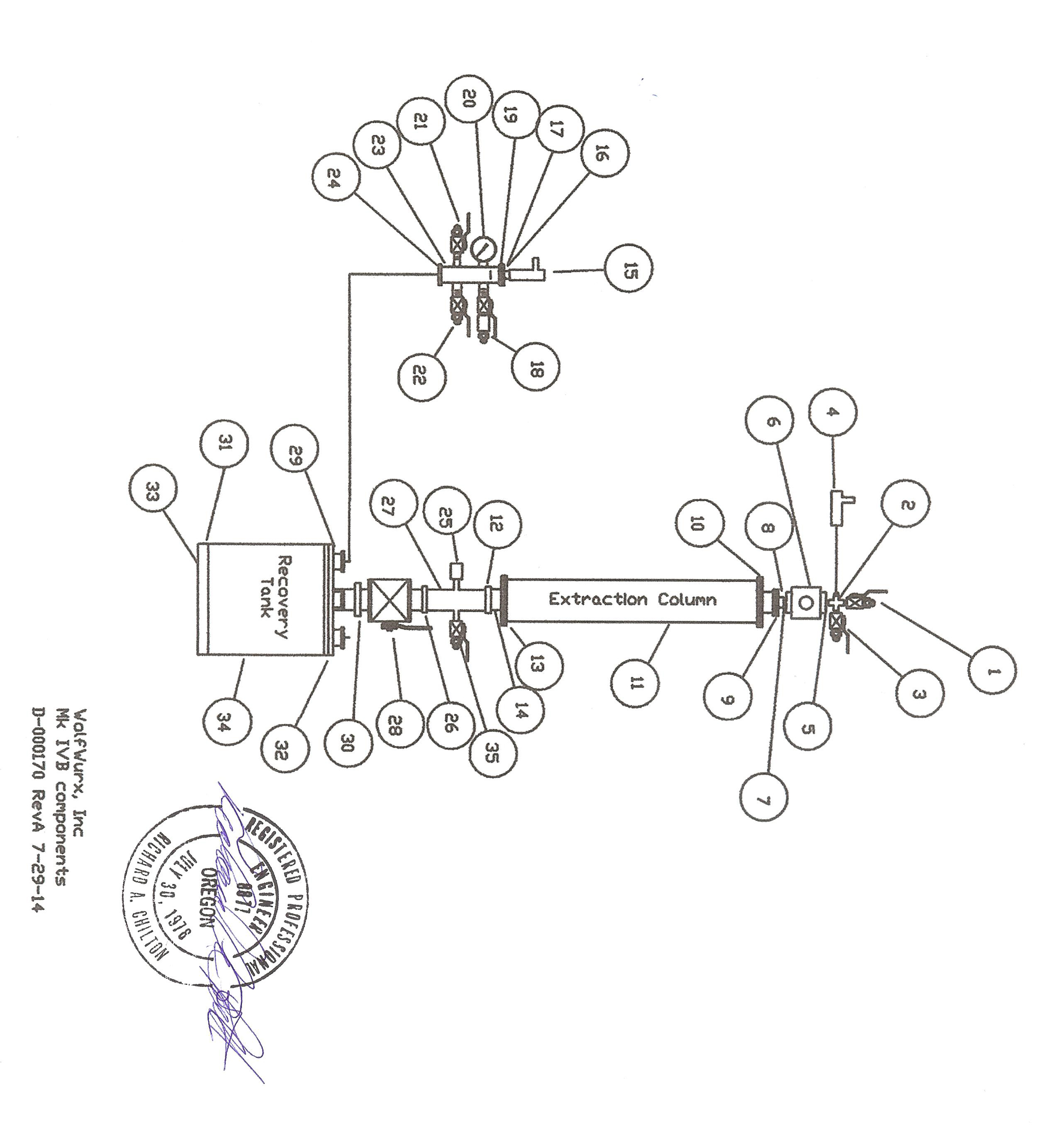

This prototype has a 10" X 12" lower spool and a 4" X 36" column. I put that size column on it for a January shoot out in Seattle, but it will accept anything from a 2" X 24" column up to a 4" X 36" column.

One of the things that we've learned and which has been addressed in the Mk IVA, and that is that stainless to stainless threaded fittings can be problematic, so the IVA uses welded manifolds, rather than manifolds assembled out of pipe fittings.

It has two sight glasses to monitor what is going on, and has a thermocouple in the tank, to monitor the internal temperature during processing, in addition to a JB compound pressure gauge.

While this is about the largest practical unit that can be horsed around, we will be adding a 304SS cart anyway, to carry the pumps and 100# recovery tank, as well as the Mk IVA on casters.

A Haskel Model 59025 pneumatic refrigerant pump is on order for our prototype, and due in January, so timing will be close. We chose the Model 59025 because the pumping chamber is separated from the air piston by enough space, so that if a seal blows, dirty air can't contaminate the butane stream, with the meds in it.

The system has ports to either recover or vacuum the columns separate from the chamber, and can accept up to three recovery pumps, as well as a separate vacuum pump port, so multiple electric pumps can be run instead of the pneumatic Haskel, which takes a 10 hp screw compressor to run.

Sooooo, here tis!

what's between component #23 and #29 it is also between #29 and the hose to #1, it is in pictures not diagram. where might one find manifold #23. Ive checked glacier tanks, terpextractors accessories,

Typically a Viton sanitary gasket, between the two flanges. If operating significantly subzero, it is usually PTFE or a PTFE sandwich sanitary gasket. GW

what is the purpose of the yellow valve located across from the injection valve?

It allows you to recover the column separately, which comes in handy once the recovery pressure is below ~12/15" Hg, so as to be able to heat the column and drive out the LPG, without sending heated LPG down through the collection pot, where you may be making "Cotton Candy", and need more precise temperature control. GW

Is there any other information you would be willing to provide on creating a "cotton candy" consistency. I have a Mk III and MkIV both with biflow but currently without the necessary duel port shown on your machine. Assuming I did have one, what conditions/ process is necessary to create a cotton candy consistency.

Once the visible butane is gone, and only random bubbles are seen, turn on the high vacuum pump and inflate the remaining oil and butane mixture into a foam. Continue to pump with it inflated, until it solidifies in that state and stays rigid when you back fill. GW

I'm thinking about assembling one of these using a 4"x36" column, and an 8"x20" collection pot topped a special end cap reducer lid from glacier that is 8" in diameter, with tubing that extends 8" down into the collection pot. I was wondering if the combination of the pot diameter and the length of the lid tubes would allow for smooth operation without flooding the recover pump. Let me know thanks!

EDIT: combination of the pot dimensions* (Not diameter)

Also, at what size point is it necessary to switch from single hinge clamps to high pressure clamps? (Sorry for multiple posts)

I would suggest longer down tubes. Port velocities are pretty high when the pot is still under positive pressure, and dropping the liquid in the rapidly moving vapor stream, is likely to entrain some of it. I design my tubes to reach within about 2.5" of the bottom, with a gas vent opposite the pump port, so the column can dump when the pot covers the bottom. GW

Hi guys lovely product i was wondering if you had enough room height could you build this to strip 10 pound at a time . Would you need a bigger collector/bottom spool i am a small time fabricator /fitter and a customer wants me to build one of these systems Cheers ben

Your limitation is the lower pot size. A 10" pot with 8" of liquid in it, would be about 628 cubic inches of working space. A 10 lb column would ostensibly be around 1107 cubic inches and a three volume flood and flush would be around 3321 cubic inches.

Hello im Rob. I'm trying to build one of these but im having trouble finding the lid and a few other parts on glacier tanks site?I've also seen two site online with modified versions of your master piece. Emerald science and terpp extractors.is their anything I should know or change before ordering parts?or do you have any new designs coming out soon I should wait for?

check out sanitarysteel.com under "end caps(custom)"

Have you guys done any studying or experiments with a thermal extraction?

Welcome Dr. Mark

We are starting to sell the Mk IV's and have been working with them for a while. We have upgraded the vent lines to SS PTFE hose, and our 10" gaskets are flanged (which save a lot of hassle.) We find a 1" dump valve to be faster than a 2" valve. Really there is a bunch of configurations that can help you achieve different results. We will be opening a store in Redding, CA this August. In the mean time you can order or schedule an appointment at www.emeraldscience.org

Whoop whoop!!!

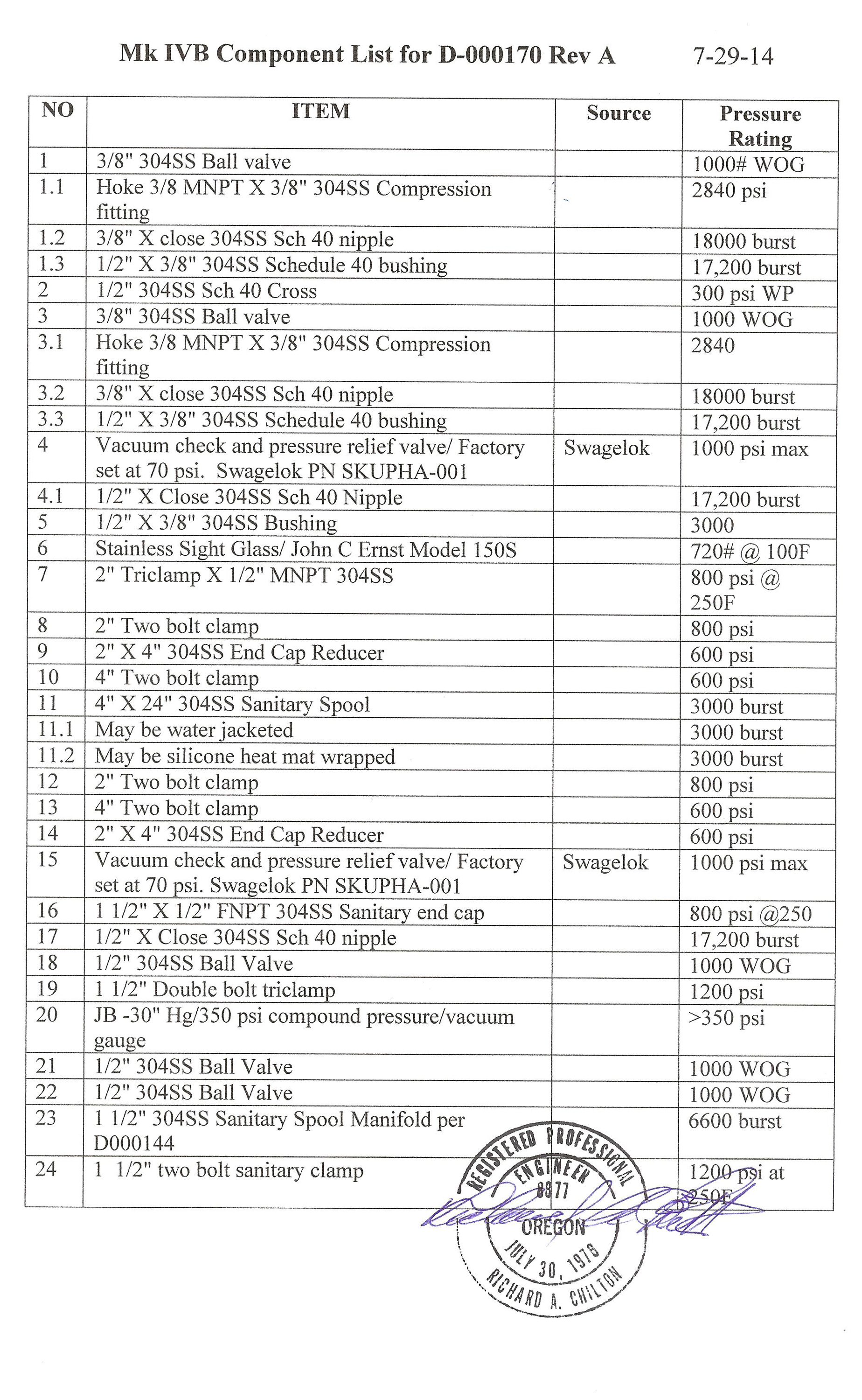

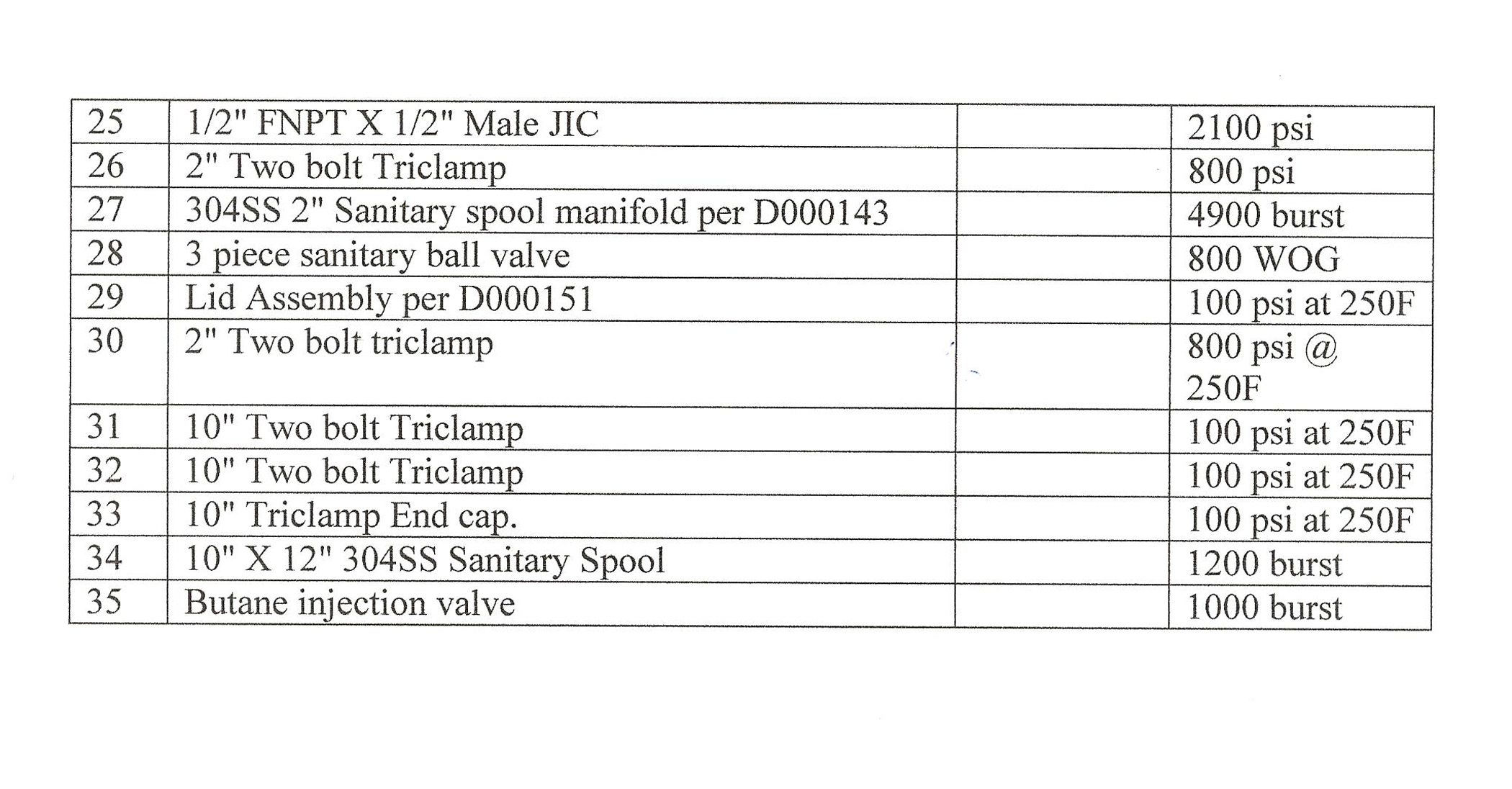

Is there a parts list available for this unit yet? I really want to take a swing at making this thing a reality

Does the Haskell replace both the recovery and high pressure pumps? Haskel literature appears to infer that it does. Checked Haskel (http://www.haskel.com/Haskel/en/Products/Pneumatic-Pumps/Refrigerant-Pumps) website and wondering if you are using buna seals option? Also curious on the cost a one a those babies... Thanks for all the great work, ~M

I'm interested in building a modified version of this. I'd like to go with a 6" x 36" column, and same recovery tank as the MKV. Or double up on the 12" x 12" spools, just stack them. Gonna fill the 4 concentric reducers (2 x 6" to 4" and 2 x 4" to 2") as well. I'm 6'5", not too tall for me. Ordering parts now. Going with the Haskel pump too. Been doing a lot of one solvent winterization. Butane only, as our patients complain about the vodka like taste of the two solvent absolute. We'd been distilling and re distilling ethanol, and doing lots of winterization. In fact one of our freezers is dedicated to it. But lately we've been using butane only. just using vacuum assisted filtration, bacterial filters, butane and oil in solution. I was trying to figure out a way of super chilling the butane in process. So we could do the whole thing with the terp and our vacuum ovens. Any thoughts or advice would be greatly appreciated. Thanks in advance, ~M

That is a good question and one that I posed to a cryogenic equipment manufacturer associate and am currently awaiting his thoughts.

Yes Buna and ptfe options. They cost about 2k plus a 40scfm air compressor. I would still use a regular vacuum pump to remove atmosphere prior to operating.

I am very interested to build this one out... When will you have the parts list and plans ready?

So is this design basically the same as the mkiiia but with a different size column and recovery tank? Are the rest of the parts the same? Or have more changes been made than just column size and recovery tank?

Same principle, but a more evolved design.

just wondering if you have parts list on this bad boy......I can't wait to give it a shot....have you ran yours yet....

what size air compressor will you be using to run the haskel?

40 scfm

Thanks for getting back to me, I will get what ever size you call for, I have the Tami 700 now and it works great but it won't keep up with the patients in our collective so I need something bigger....I paid 7500 for the 700 but that was a lot and the 3000 they have which runs apx 2lbs is 27k which is crazy and way out of our reach. I have been following the info on your website and can see you have as good or a better product and I can get the welders and machine shop set up no problem. And if you can speed up the recovery time that would be awesome. Please let me know what I need to get started and if parts list is available, and again thanks for taking the time to get back to me. Don

It is a thing of beauty. Do you think that pump will be accepted as hydrocarbon compliant? I have been looking at similar pumps, but also other mechanically driven and intrinsically safe vac pumps that might do the job.

The air driven Haskel is "explosion proof" and flammable hydrocarbon compliant.

Are the dimensions/lengths of the 2"x12" downtube (into the recovery chamber) and the threaded pipe cut/still the same length as in the mk5? - I dont want to have asperation issues

They are both 12" long, so extend about 9.6" into the 12" depth and away from the pump intake.

Hey skunk pharm, -Im pretty sure but wanted to check with you to be sure-----all the ball valves/npt fittings MUST be SS right? -I dont want to have metals being stripped by the solvent.

I keep all the metal that the medications themselves touch stainless, but the butane comes in a carbon steel tank and has brass fittings. Butane itself is a simple fully saturated Alkane, so it is pretty inert, but some of the plant terpenes will strip paint.

SPR, is the 2inch x 6" spool necessary for the 2 lines coming out? or can i weld these 2 lines into the reducer, thus not needing the 2" x 6"?

Not sure I understand what you mean, but if you mean adding them to the concentric reducer, then no it won't work the same.

Will you be posting a parts list and lid machining diagram for this unit?

Yes

Where can I find this? Thanks GW

WolfWurx1@gmail.com is in the process of setting up supply lines and already has the manufacturing network set up. I would check with them.

I'd like to build one. Does it need the 2 sight glasses? Looking to a parts list. Is there a list showing how much material each different size column uses?

It doesn't need two sight glasses, but they make it easier to tell when you have extracted enough, and when you are in danger of aspirating liquid into your recovery pump. No chart, but it is based on 4.1 grams per cubic inch for best case scenario.

GW does the MKIV need the high pressure clamps or will the 10" single clamps work ok?

High pressure clamps

also how much will a 4" X 36" hold? -is there a equation to figure

So there is a anchor point to calculate from, we set our standard at 4.1 grams per cubic inch, for 10/15% water content prime bud, reduced to 10 mesh, and all the stems removed. We use that process for our cancer meds, which are subsequently decarboxylated and formulated, so appearance and monoterpene retention aren't of prime concern. Prepared mixed trim is closer to 3.8 grams/cubic inch, because it has less oil. 10/15% water content is about where them material is no longer leathery, and just frangible when rolled between the finger and thumb firmly. Stuffing whole buds for bragging rights extractions, packs even less, so you have to just experiment. We use a ram close to the diameter of the tube, or in the case of 3 and 4 inch tubes, about a 2" ram. We pack about every 6" and press firmly until the material stops moving, but don't use hammer or percussion to pack it more firmly.

I Know that you use a #50 for your butane storage tank right.? Would a 12" x 12" spool tank (storage tank) work/be big enough? -for no pressure issues. I pressume as long as im not doing multiple column runs before emtpying the storage tank, that ill be fine. Would I be ok with this or no?

The wrapper would be strong enough, but a 12" X 12" lid deflects enough to lift off the seal above about 100 psi, even with high pressure clamps. The pressures inside a storage tank can rise above that level.

So your basically/highly recommending a 30 or 50lb tank for safety?

For the Mk IVA I plan to use a 100# tank, with about 30 to 50 pounds of butane in it.

Are the transitions between the 2 sight glasses NPT 1/4 female to on both ends? or is it a bigger size?

The FNPT threaded 1 1/2" sanitary end caps are 1/2". The vent down tube in the tank is also 1/2" NPT, but the vent tube itself is 3/8". It is bushed to 3/8" at the valve.

Ok thank you SP. Im seemingly doing this 'Phoneix' build, but with a 12" x 12" recovery tank and a 4" x 36" material tube. Ill keep you updated

Also is your recovery tank/spool the same schematics as in the mk5? - I mean as far as the 2" x 12" and how much its sunken down/away from the bottom of the tank.

The spool sticks about 2" from the top of the lid and about 9.5" below.

Im also curious if the 2" x 12" spool in the middle of the recovery tank, is it the same as in the mk5? as far as it being 2.5" from the bottom of the inside of the tank.. I just dont want to have asperation issues

At 12" long, it is about 9.56" from the bottom of the tank and extends about two inches above the lid.

why not use 1/2 inch steel tubing?

It needs to be stainless steel tubing, but you could use 1/2" throughout. This is pharmaceutical and food grade product, so the equipment needs to be corrosion resistant and easily cleaned. The WW Mk IVC uses 3/8"X.035 wall and 1/2"X.049 wall 304SS tubing on LPG circuits, and 1/2" X .035 wall 304SS tubing for chiller circuits. The heavier wall thickness is required for 1/2" LPG piping, not because it isn't strong enough, but because it is thin and more likely to have a through wall manufacturing flaw. 3/8" is still at .035 wall. We used coiled 3/8"X.035 316 SS tubing on the liquid N2 circuits, instead of hose. GW

Looks fantastic. Can't wait to hear how it runs. Keep up all the great work.

[…] Read more at http://skunkpharmresearch.com/the-mk-iva-phoenix-terpenator/: […]