How about those situations where the automated Mk II just isn't big enough, even running a 3" X 36" column, holding approximately 2 pounds of material?

I designed, but have yet to complete building a Mk IV Terpenator, because it was an attempt to gain more surface area than was available in a 6" diameter spool, by laying it on it's side, and Glacier Tank has since been able to arrange for 8", 10", and 12" X 12" sanitary spools.

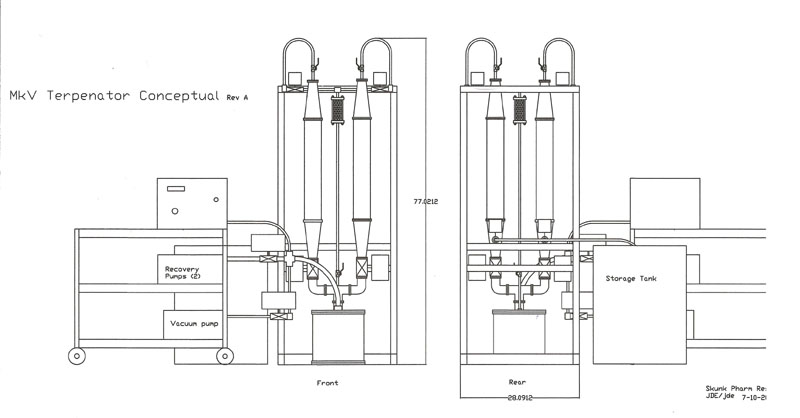

Hee, hee, hee, go big or go home! We are building two Mk V's based on the 12" X 12" sanitary spool, with 4" X 48" columns, holding approximately 5 pounds per run.

The Glacier Tank parts and prices are listed, and the Paramount Supply parts list will follow as soon as the bids are received.

Pacific Semiconductor, Inc (PSI) has agreed to build us another control system, and has designed one half the size of the original and estimated to cost about $840.

A Hoffman electrical enclosure will still be required, as will be the three pressure switches which control the process through the Panasonic programmable process controller.

As before, the valves will all be pneumatic, so that the enclosure containing the Mk V can be kept spark free.

It is our intent to run it with dual CPS TR-21 recovery pumps with after coolers, to keep speed up, and a CPS VP6S 6.2 cfm single stage vacuum pump for initial and final evacuation.

The following list shows two lower spools and an extra set of columns, though only one is required. They are included as extras to speed up operation and to keep the machine operating.

Mk V TERPENATOR PARTS LIST

|

NO |

ITEM |

DESCRIPTION |

REQ |

PRICE |

TOTAL |

|

1.0 |

Sanitary Steel |

|

|

|

|

|

1.1 |

16AMP-G200 |

1 |

$3.95 |

3.95 |

|

|

1.2 |

2" X 4" Concentric reducer |

B3114MP-G400-200 |

2 |

122.76 |

245.52 |

|

1.3 |

4" X 24" Sanitary Spool |

SP-400-024 |

4 |

113.00 |

452.00 |

|

1.4 |

40MPUS-200-20 |

2 |

22.95 |

45.90 |

|

|

1.5 |

13MHHM-DP200 |

3 |

7.95 |

23.85 |

|

|

1.6 |

40MP-SFY-200 |

2 |

1.95 |

3.90 |

|

|

1.7 |

40MP SFY-200 |

4 |

4.95 |

19.80 |

|

|

1.8 |

13MHP-400 |

5 |

21.95 |

87.80 |

|

|

1.9 |

2" Pneumatic ball valve |

BV2CV-200-air-2" |

1 |

448.00 |

448.00 |

|

1.10 |

2" X 24 Downspool |

SP-200-024 |

1 |

49.00 |

49.00 |

|

1.11 |

16AMP-G1200 |

3 |

94.95 |

284.85 |

|

|

1.12 |

SP-G1200-012 |

2 |

399.95 |

799.90 |

|

|

1.13 |

|

3 |

37.95 |

113.85 |

|

|

1.14 |

13MHM-1200 |

3 |

85.39 |

256.17 |

|

|

1.15 |

Total Sanitary Steel |

|

|

|

$3,080.37 |

7-26-13

An option to the Appion G-5 or the CPS-T-21, is the Caresaver Universal refrigerant recovery machine, which can be viewed at http://www.rda-eng.com/caresaver.html

They are designed to pump R-600 and R-600A refrigerants, which should gladden the hearts of the fire marshalls.

More information can be had from Mathew Ellis at info@caresaverusa.com, or at 720.412.5194, and they sell for $2380 ea, plus applicable taxes and shipping, in units of one and $2240 for five or more.

9-11-2013

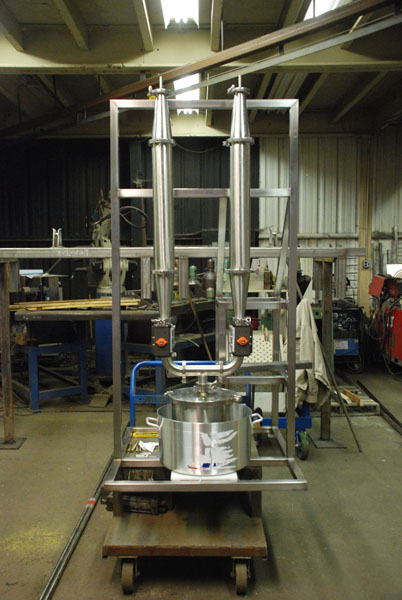

I got the machining and welding done, and assembled the Mk V tank for a pressure test using the new high pressure clamps. At 100 psi there were no leaks or excessive deflection, and the balance of the parts are rated at 150psi or above, so I'm proceeding to assemble the first prototype.

We continued with pneumatically operated automatic valves for explosion proofing, and they have also arrived.

The electronics are ready to mount in an enclosure and we made some upgrades, using an Arduino board to allow us to use a absolute pressure (PSIA) transducer to control the cycles, vis a vis three adjustable vacuum switches, as well as a read out announcing what is going on with the machine at that moment, instead of just indicator lights. That also allows us to more easily change the program parameters using the computer and software.

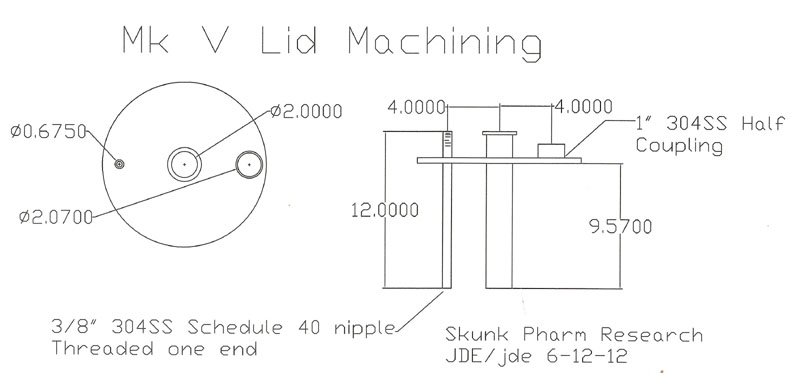

I'm picking up the 1 1/2" 16 gauge 304SS tubing for the roll around frame this morning, which is the last big chunk. Here are some prints, as well as a picture of the Mk V body components, without the valving:

10-13-13

I made some changes in the Mk V frame, so now it also supports the pumps and ancillaries. Here are a couple of pictures of it and its 304SS frame in final assembly.

All the machined brackets are made, so next we will hang the automated valves, so that we can start plumbing.

12-1-2013

Well, the first manual Mk V beta test sled was delivered and automatic is due completion next week. Here is a picture that the proud new owner sent of his second run, yielding 277 grams, or just over 12% on mixed trim.

First pilot run filling Johnny 5’s 12″ X 12″ collection pot with cotton candy shatter.

First cotton candy shatter run ever, filling a Mk III 6 X 6″ collection pot.

8-25-2014

Here are some Mk VB and automated Mk VA2’s pictures.

Mad Shatter Mk VB with tricore heat exchanger and nitrogen backfill.

Bertha MK VA2 automated

Mk VA2 control board from Pacific Semiconcuctor Inc

Haskel 59025-3 pneumatic recovery pump, plumbed for selective single or double stage operation.

Automated Mary & Bertha, dueling Mk VA2’s making money for their new owner.

I have a caresaver universal refrigerant recovery unit that I do not use any more, & am looking to get off of it for a good price. mr.coryriddle6@gmail.com is my email. Get at me if interested.

Where is the best current forum for ongoing terpenator discussions?

Fantastic work you're doing here GW! A friend came back from Glacier Tank recently with a prefabbed 12" lid with appropriate outlets and fittings specifically for extraction. I can't find it on their site though. I"m not even sure what they call it. Any ideas on how to order one?

http://www.glaciertanks.com/TriClamp_Product_304_316-Special_End_Caps.html

I love this place! GW you are the man and do so much for the community. I have a sweetleaf extractor but am looking at upsizing from 1lb of meterial per run to about 5lbs per run. The sweetleaf uses a "dewaxing chamber"...a spool with a sleeve. it also keeps the solvent from existing the material chamber and dexaxing chamber with a ball valve. To move extract laden solvent from the dewaxing chamber to the collection chamber you are supposed to have vacuumed the collection chamber and rely on that. I see some flaws and am very interested in your design. Some questions i cant seem to ascertain from the pictures...with dual tubes, are these ran simultaneously? If so how is the solvent tank and lines configured to accommodate this? In your system do you keep the solvent in the material chamber or does it drain straight into collection chamber? i know in your smaller designs you said it went straight into the collection chamber and them you turned it upside down to re soak the material. Just seeing how to do it now with a much larger material tube that you cant turn upside down and stuff like that...

Also want to know your thoughts on using a cmep ol pump in all facets of transferring solvent. Like from solvent tank to material tube as well as from collection chamber back to solvent tank.

Hi, what is the reason for single and two stage setup on the Haskell, thanks

Greywolf, Thanks for all that you do. I love to learn and share the wealth, its the best.

Thanks! It is heartwarming to see closed loop systems catch on and reduce the amount of open blasting going on.

Where can i buy these? I am a very serious customer. I would like 2 of these units.

The only Mk v's that I'm aware of, are custom built by WolfWurx, Inc engineering program management. You can contact Todd, the owner, at wolfwurx1@gmail.com Peace, GW

Ha ha funny, if Abbott labs showed pill makers with filthy hands, would you trust their pills? If Bayer made aspirins with muddy hands, would you still take their aspirins? If the most wonderful medicine on the earth, the sacred Cannabis, is to be shown in this manner, is that going to convince the average person to accept Cannabis extract. NO, the average person would avoid it. Please, consider the effect of showing filthy hands in the manufacture of extract. Use gloves if the extract is so sticky and hard to clean. What part of cleanliness so hard to understand. Doesn't it make sense.

They pour ethanol in, dissolve it, and pour it into jars for winterizing. Even if his hands are dirty, his hands don't touch the oil. If you're this passionate about cleanliness that you'll come back months later to comment the same shit then lead by example. Go make your own oil and wear gloves and masks and lab coats, and post pictures for us to see. GreyWolf is a legend, I would refrain from trying to belittle him. <3

A good point and one we relayed to the elated new owner sending us the picture, as have a plethora of others, who apologized for his exuberance at finding the pot of gold on his first pilot run, after a morning of moving and reassembly. He did have gloves on hand and assured me that he was gloved when he harvested and processed the material. I did replace the photo with one without his hand for scale, as well as a few more photos you might find interesting. GW

That. Is insane.

Easy for us'ns that already bay at the moon, hayuk, hayuk, awhooooooooooooooooooo.............

Has anyone experimented with solvent recovery by reverse osmosis? Or dewaxing by micro filtration?

We haven't here. The "brine" from either would ostensibly be hard to pump and I would guess it would be prone to foul the membranes. If any of ya'll have, I would be delighted in knowing more about your process too.

Hi, love the site. I was wondering what the second smaller recovery tank is used for in the mkva pics. Thnx

That photo shows a test sled using a Gast diaphram pump and a Promax 6000 supplied by owner. The Gast pumps into the secondary tank, and the Promax recovers the butane from that tank to the storage tank. Pressure switches keep the Promax from ever running dry, so as to preserve its life between piston seal replacement.

What's the best way to get all solvent back into the tank from the hoses once the extraction is finished, there is still residual solvent in the lines that must be purged

We set the Mk V plumbing up, so that we can recover the butane between the pump and the tank, using the recovery pump to pump it a separate tank, so as to not lose the butane in the hoses, drier and heat exchanger coils.

Please don't defend the fact that you have dirty hands. It happens to all of us. What is crucial here is that the pictures shows dirty hands with medical grade marijuana tincture. The two don't mix in the minds of those who oppose marijuana. or even to those who love pot. That picture could set back the medical marijuana movement. Think about a cancer patient who views that picture and swears that MMJ is unsanitary, unclean and dangerous, look at the hands of the producer. Think what bad effect it will have when FOX news sees that picture and blatantly states that MMJ is a hoax and unsanitary. That picture is bad karma and needs to be removed for the sake of MMJ's acceptance in this crazy, unbalanced society. Remember, if Nancy Grace gets a hold of that picture, she will set MMJ back many years. For the sake of MMJ, please remove that picture. Be proud that you get your hands dirty doing honest hard work, just don't show it with the golden tincture.

You're high If you think that is unsanitary. Go eat at McDonald's and tell me this is unsanitary.

Do you stare at Cindy Crawford and only see her mole? When you work with bulk material, sifting BULK material for processing you discover things you don't encounter on the smaller scales. Since this was literally the first run of the first ever mk5 and that's my hand in the picture lemme explain exactly the events that lead to that as well as what isn't in the picture. On a smaller scale you don't have to worry about all the keef that collects on the underside of your gloves and after some time makes its way into them. If you've ever tried to clean one of these machines out bare handed that's a terrible idea as you will end up contaminating them as well as having an ungodly mess, or scream in pain as you brush your hair to the side to realize you just ripped your hair out cause your hands are superglue. I took my gloves off to be able to open the spool lid cause its realllllly difficult to do with rubber gloves, gave it a quick thumbs up for scale, moved it to the table to reglove and empty it. It was only days later that I realized all the residual keef had found its way from my wrist and into the gloves. theres things u can't learn until u try it, and when u start working with these machines at this scaled you'll find keef and trim everywhere lol. See the forest thru the trees, people's nagging a are the reason that no more pictures of Johnny 5 and Jenny are uploaded anymore. people complaining about fingernails would freak if they saw people at dispensaries with oil made from pvc tube open blasters made with moldy mildew infested material, wait till nancy grace sees that and shuts down mmj completely lol. See the forest through the trees man. Keep the pic removed GW, boggles my mind. It's like if you broke the speed record in your car and people complain u didn't use a blinker when u turned into the pits, seriously this was the first ever test of this machine and it worked your opinion of my fingernails is irrelevant to the fact that that picture was the culmination of months of hard work, GW tearing his shoulder out on this thing, and my all of my eggs in one basket or spool as it were. I'm proud as hell if that picture, it afforded me to get a manicure if I ever so desire lol.

Couple of questions... Why are there two ports on each of the lower concentric reducers? Are their better drawing or routing diagrams for the piping and hoses. Why does the smaller 1/2 " pipe extend down into the 12" spool.

Where are you getting the silicone heater pads?

We order them custom made from China.

The picture of the golden tincture had a problem. That man had the dirtiest fingernails of anyone dealing with medicine destined to go to sick people. What happened to hygiene, how can he forget to wear gloves or not wash his hands. The golden tincture though was the finest thing I have ever seen. The metal gold has nothing, is nothing compared to the golden tincture. Please post another picture in its place before the media and the law find it and start blasting the whole MMJ industry as unsanitary and filthy and MMJ should be eliminated or further regulated. Please, at least remove that picture. Thank You

If you have worked with cannabis resins. Just harvesting gets resins all over your hands scrape it off ( and or wash hands w/iso filter and freeze) its finger hash ok to smoke. After filtering with lab filter the dirt and debris come out and you know it's not good to eat. My floors are covered with little bits of wax, shatter etc. the resin will not all come off with alcohol and detergent so it stays under fingernails and around the edges of them. I leave this residue on my hands to prevent the alcohol from drying my hands. after all I HAVE CLEANED THEM W / ISO AND DETERGENT. I'm pretty sure trisodium phosphate would do the job but it's really sucks all oils from the skin. my hands may look dirty but I'll live with it.

Rub olive oil on your hands before you wash with soap and it will come off and leave your hands soft.

Very good point John! Any vegetable oil will work and I usually use coconut oil. Besides washing it off, you can also rub it in.

What is the safest way to use the CPS TR-21. I noticed it has no gauges or valves, do I need to purchase a Manifold Kit to control it?? Also do you think it will overheat if it is recovering 10Lbs of solvent without the MT69 cooling accessory? I ask because I just got one in the mail, and the MT69 doesn't arrive for 5days. Will I be alright running the CPS TR-21 inside of a controlled temp environment (72degrees).... The last thing I want is to ruin this brand new unit. Our Appion stopped working after about 2 months of abuse.

We used the TR-21 in conjunction with our own heat exchangers made from 50' of 3/8" stainless tubing, because they definitely need heat exchangers after them, to keep tank temperature and pressure low.

My friend purchased a double column system from Emerald Science. He spent almost 10k and is able to purge 3 lbs of shatter a day. He plans on buying 5 more collection chambers to purge 5 lbs a day. but he was told to use 2"×48" columns only fitting 600 grams . I am thinking of getting a similar setup accept I want to run more at a time. What's the fastest machine and purging method you know of? Has anyone had success with the Haskel? Lastly do 3" and 4" tubes empty with a air compressor still. Thank you for all your help.

hello all, i have finished my experimenting in oil, and have 3 of both the mark iii and v (w/ 1 3' section, not 2x2) setups, along with literally 10-20 of every part needed to make either (reducers, endcaps with npt, 6 or 12 spools, etc). i won't be selling the appions because of concerns and problems with used ones. if anyone is interested in buying please contact me at terpenatorparts@gmail.com, i know glacier is sold out pretty much 24/7 so hopefully this brings parts to those who need them. i also have lots of improved parts (ie: 3/8 npt -1/4 flare, eliminating the need for bushings, etc) i can send pics.

Do you guys really have a reddit I saw this on reddit

Hi Graywolf, I built myself a MkV terp with only one 4" x 24" column instead of two tee'd together. I've operated it about 4 times now, and I ran into an issue on this last run that just finished. It seems that oil got sucked up through the recovery intake port and up into the mega-flow hose as well. I checked and it didn't look like it made it all the way to the filter drier that's connected between the appion intake and mega flow hose. It slowed down recovery infinitely. Took almost 5 hours to recover all the solvent with the oil blocking its way. I'm scratching my head wondering why this happened, since I made sure to carefully calculate how high the puddle could be and still give it 5 inches from the recovery intake port, since thats what you said to another person above would be an appropriate amount of room. I tapped exactly 40 300ml cans of butane into the refrigerant recovery tank, since that would be exactly enough to fill the 12" x 12" collection pot 7 inches high, leaving 5 inches of head room for the boiling puddle to not do exactly what it just did. I've been heating the collection pot with a 55 gallon trash can cut in half to accomodate the collection tank inside and I just pour in 90F degree water. It cools down quickly though. Just adding that in case it happens to have any affect on why this is happening. Any input at all would be appreciated. Thanks Gray.

I'm not 100% sure where you isolated your hoses with valves, so my ideas may be worthless, but try insulating the trash can to keep it from cooling too quickly, and if your hose is clogged, try warming it up with a heating pad to loosen up the congealed oil in the hose and configure the system to enable you to pull a vacuum & clear it. I think.

Nice work on the Terp V ! I hope to start building a manual one as soon as you update the parts list with the hoses and other parts. I wasn't able to make an adequate comparison between the recovery pumps your listed. Would this Refrigerant Recovery unit be able to handle the flow? FM3700 Bacharach Heavy Duty Commercial Recovery Unit (http://www.centurytool.net/FM3700_Bacharach_Commercial_Recovery_Unit_p/2000- 3701.htm) It seems to be pretty powerful especially when coupled with a Subcooler (http://www.centurytool.net/MT69_CPS_Recovery_Submersible_Subcooler_p/cpsmt69.htm).

Looks interesting! It says it is an oil less and suitable for all refrigerants other than R-11, R-113 and R-123. Only goes down to 13" Hg, so greater losses on final.

fantastic picture of the mkV prototype woking! whoop whoop! the one i'm building has everything machined and welded. Alas, I must confess to being befuzzeld by the parts i need from paramont and rds. any chance you could help me out with a list of what to get in terms of valves and hoses and such. I've tried looking at the part lists for the mk3 but i know youve changed some specs, and i dont want to order a bunch of the wrong parts. I'm will not be able to add pneuamatic valving for this model :( but hopefully in the future! I know the holidays are super busy for everyone, so any help is appreciated. either way HAPPY HOLIDAYS!!!

I'll update the parts list shortly. I didn't keep track during shakedown and have to go back and dig out records. The hoses were custom made from stainless braided PTFE hose custom made from: MOTION & FLOW CONTROL PRODUCTS INC 3342 NW 26TH AVE PORTLAND, OR 97210-1854 | view map (503) 228-0190www.colvillecapital.com

Love your site, so mmuch great info! I am wondering, is this intended to be a bottom flood, similar to the ultra?

Not sure what an ultra is, but all of the Terpenators are bottom flood. Only the Lil Terp is top flood.

is there a diagram for the bottom reducer?

It uses the same bottom reducer as the Mk IVA, and I will send you a copy attached to an email. It has two ports, one for butane injection and one for evacuating the columns separately from the lower tank.

Could you please send me a copy of that diagram too,?

Hello GW thanks for your work. would you happen to have a updated parts list?

Yeah, I'm working on that, but have been focusing on completing and shaking out the two, so haven't made much progress. I expect to complete that shortly, as soon as I dig out of the 60 or so comments I am behind on. I also have made some changes to the original prints that need incorporating, and make progress slower than I once did, so I beg your patience.

You use 2 recovery pumps. How are they configured in the system? Are they in series or parallel?

In parallel. They both have 1/2" ports on a 1" ID manifold on the intake and tee in with a simple 1/4" Schedule 40 tee on the discharge.

Hi GW and Team SPR, If I had a son I would name him Gray Wolf. Thank you from the bottom of my heart for all of your hard work that you have blessed us with. You have inspired me to emulate you and try to "pay it forward." I see you have added concentric reducers to the tops of the Mk V columns. What purpose do they serve? Would adding a concentric reducer to the top of the Mk III be a good upgrade?

I added the concentric reducer to the top of the 4" columns, to bring the steam back together without missing the upper corners, as would happen with just a blanking plate and vent port. A 1 1/2" column doesn't really need that.

Hey GW, I'm a longtime fan and anonymous contributor. I have some extra 12" x 12" spools, lids, and concentric reducers that I'm liquidating on eBay. My machinist accidentally made too many lids and reducers...only a handful were supposed to have holes. I hope it's not too out of bounds to post the links here with the caveat that you and skunkpharm are not related to this? If you think you could use these I would be glad to donate 'em them provided that you pay shipping =D. http://www.ebay.com/itm/111189965092

Also, what is this filter I read people using to prevent oil getting into they're refrigerant pump? Thanks again for all your wonderful work!

We are currently using a filter dryer by Emerson EK-032MF which we get from RSD refrigeration supply.

Absolutely fabulous! Quick question. Is it necessary to have both the after cooler and the condenser? Perhaps I'm not fully understanding the design? Do they run in line? Or separately?

You need something to cool down the compressed butane and the air cooled heat exchanger on the Appion or the fluid cooled after cooler are ways to do that. You can also stick your recovery tank in denatured alcohol and dry ice to speed up recovery.

Thanks for EVERYTHING as usual.... after reading this.... I have a question.... Would it be safe to put my LP5 tank in a tub with Denatured Alcohol and Dry Ice? and would that stay cold longer than just Ice? What is the advantage of doing that over regular ice?

We put our 50# refrigerant recovery tank in denatured alcohol and it works fine. It speed up recovery, extracts less plant waxes, and extracts lighter colored extracts.

That sure is a beautiful machine.

Skunk Pharm Research LLC Facebook https://www.facebook.com/SkunkPharm

Nice work dad. Although I use the word "work" loosely....

Watch this closely son! If you are going to carry on the family tradition, you need to be solid on all the details................

Will do... & I'll see you in Nov.

So any winterized entries and if so how we're they finished and how did they place?

Some, but only three entries placed and they weren't one.