We developed Cannabuttons as a way to produce super potent smokable MMJ from scrap and trim, during the annual period right before outdoor harvest, when numerous new patients were posting for donations and surplus bud supplies were exhausted.

The process cools and further smoothes prime bud, makes an unbelievably smooth smoke out of even iron lung grade leaf trim and makes even harsh fan leaves smokable, though sedative and not tasty.

A Cannabutton can be turned into an Improved Cannabutton by mixing in Kif, or a Super Cannabutton by soaking it with cannabis oil extracted from trim, prior to compressing into a button.

Depending on the strain and type of material the button is based on, a hash oil soaked Cannabutton can produce everything from an intense high to couch locked slack jawed sedated stupor.

Of course you can also use prime bud and hash oil from prime bud, and even throw some kif into the mix, and make Super Duper Cannabuttons. Let your imagination be your guide!

As a bonus, the same home made 12, 000 psi press and dies needed to produce Cannabuttons will also make peachy keen hash buttons out of bubble or kief in a heartbeat.

Details

Manufacturing basic cannabuttons is extremely simple, but requires equipment, which fortunately is also extremely simple to purchase or make.

Part of the manufacturing process is oriented toward producing the button itself and there is a second process if hash oil is to also be used.

To make the button, we may use bubble hash, kief, bud, or bloom cycle leaf. They are made by finely dividing the material and pressing it into a pellet under about 12,000 psi of hydraulic pressure.

If the material is hash or kief, no preparation is necessary prior to pressing, but bud and bloom cycle leaf must first be reduced to powder in an electric coffee grinder. We break up and remove the stems from bud first, but no other preparation is necessary before tossing them in the grinder.

Bloom cycle leaf material first needs the wood taken out, which we do by drying it in a 200F oven on a cookie sheet until it is just frangible when rolled between our finger and thumb.

We then manually scrub it through a pasta strainer to both pulverize the leaf material and separate it from the woody stems and leaf veins. After straining, it goes directly in the coffee grinder as well.

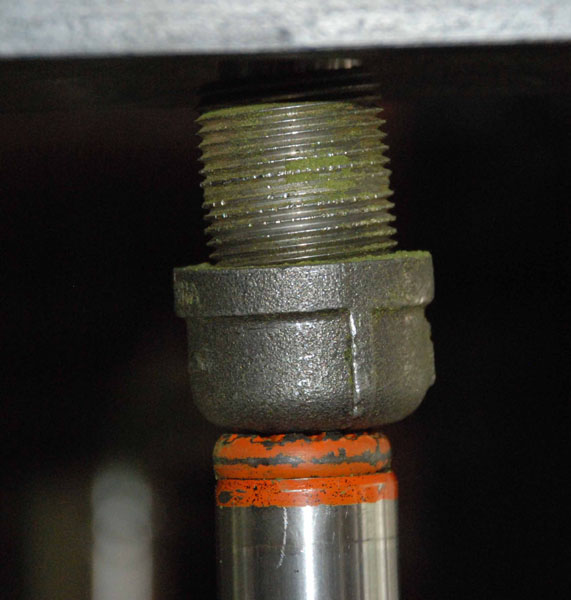

We grind the material to a fine powder using a pulsing technique, and then simply load it into a die made out of a 1” pipe nipple, a 1” pipe cap, and two short lengths of 1” hardened steel dowel rod. See attached picture:

The cap is screwed on the nipple and a length of dowel just long enough to sit on the inside of the pipe cap and reach 1/8” or so into the pipe nipple is inserted so as to seal off the bottom.

The interior of the pipe is then filled with material, and another length of dowel rod set on top of it. The assembly is then put in a hydraulic press and the top length of dowel rod is forced into the pipe full of material as deeply as 12,000 pounds of pressure will force it.

When the material is removed from the die, it is a formed button. Depending on the material it was formed from, it may be gummy, oily, or hard like high density fiber board.

Bloom cycle leaf material contains cannabinoids, just like the cannabis flowers. They are just less concentrated and the ratio of plant material to resin content makes it just too harsh to smoke long term without having iron lungs.

The leaf material is also rumored to be higher, ratio wise, in CBDs than bud, which is the source of much of cannabis’s analgesic pain relieving properties, as well its anti-inflammatory abilities.

The press that we use is actually a glycerin tincture press that we built from an $18.00 six ton hydraulic jack from Harbor Freight and some 6” X 13# wide flange for platens and 1 ½” X ¼” A-36 MS angle iron horizontal stays I picked up as scrap. Picture attached:

To remove the button from the die, we unscrew the bottom cap and remove the bottom dowel pin and replace the cap. We then return the die to the press and set the dowel pin that we just removed on top of the one pressing the button. When we force it into the pipe, it forces the newly formed button into the pipe cap, where it is easily removed by just shaking.

There is absolutely nothing to the process beyond reducing it to a powder and then recombining it under pressure, but the surface area is reduced, which reduces the area that can react with oxygen at any given time, which cools the smoke down and reduces harshness.

It works regardless of whether it is dry kief, bubble hash, prime bud, or leaf. It is all a matter of how much head and body medicinal effect each method has.

Using it is as easy as breaking or carving off a piece, and rolling it between the finger and thumb to pulverize. Placed on a screen and smoked like hash, it makes a pleasant smoke whose efficaciousness can be controlled by content.

For those requirements that dictate also adding hash oil to the buttons, it is as easy as saturating the powdered material with the hash oil tincture, made by mixing cannabis oil with just enough warm ethanol to make it fluid.

We then dry it in a 200F oven, while stirring frequently with a scientific grade bamboo chopstick. When it is dry, it is loaded in the die, just like the untreated material and pressed.

Depending on the extraction process used for the hash oil, the puck may be stiff or crumbly.

Hash oil: Manufacture of the hash oil has a number of directions to go, but any of the processes may be used. I usually use QWET, BHO, or Hexane extraction protocol. Please check those threads for details.

Summary: Cannabuttons offer an effective way to directly convert leaf scrap to aspiratable material and infusing them with hash oil extracted from leaf scrap, produces a highly potent medication at a lower unit cost than bud given the present pricing structure.

Reducing the plant material to powder and pressing it at high pressure reduced the harshness of all of the materials tested, both making even prime material easier on the lungs, and allowing the use of material previously too harsh to smoke or vaporize.

While compressing ground up bud and passing it off for hash is an old practice, as may be doctoring it up with hash oil, doing so at high pressure seems to produce a product that is unique and desirable.

Locally we have made our point by passing out samples, but since that isn’t possible on an international scale, may I heartily recommend that some of ya’ll other curious risk taking types make a few and I welcome your input.

Note that you don’t even need a press if you have a bottle jack, because you can find a convenient truck and use its frame as the upper platen and the ground for the jack base.

The die is simple Schedule 40 BIP plumbing fittings, with a couple of sections of dowel pin. What could be simpler? You can even use MS round bar.

May I suggest that you use a dedicated coffee grinder to maintain marital bliss as grinding cannabis in one pretty much over rides any later flavor subtleties in coffee beans? GW

Hey there folks @ Skunk, much respect- I really enjoyed this. Being a machinist, I went to the shop and grabbed some 1" ID chrome moly tubing and some 1" OD cold rolled steel and 30 min later, had a nice pressing device for our 20 ton press. Followed your guidance, I was making nice 1/4" slugs of canna-buttons shortly after. Going to try making the various versions to test and pass around. This was a nice discovery as I have not really thought about why trim and leaf was harsh, the analogy makes perfect sense. Thanks for taking the time to present this us. Warm regards, The Captain

wonderful idea guys... love it.... now as far as trim bho goes... have yall found it works well with cooking?

Have you tried crumbling them up and adding them to food products? Seems like a half dozen in some cornbread would be delicious.

Interesting that your rooting formula only contains IBA. The study I read (on hemp) said they had better results with 0.1ppm IBA and 0.05ppm NAA. http://www.pakbs.org/pjbot/PDFs/41(2)/PJB41(2)603.pdf

marijuana from test tubes is now available on the kindle through amazon

Be sure to stop by the Skunk Pharm Research Facebook page and your likes.:) https://www.facebook.com/SkunkPharm

Great ideas, but... Not sure that I'd be keen on tasting the product from those pic's, since it looks like you're using a high LEAD content steel cap end (Lead added to prevent sparks I think, like your petrol/gas pump fittings at the petrol/gas stations). If this is the case it would be virtually impossible to avoid traces of lead containing metal shavings/dust entering your product and then probably entering your body (yes its volatile with many cases of poisoning being documented from lead fumes). Not good considering lead builds up in your body, though the traces (so far) PROBABLY wouldn't have added more lead into your system than you had gained during those bad ol' days of leaded petrol/gas resulting in lead being spewed into the air we breath and its surrounds. At least times are improving and we learn from our mistakes (if we're smart & lead dints our I.Q.!). It's worth noting here too that lead is found in high concentrations in plastic electrical insulation surrounding wires (up to 4% w/w) and in even higher concentrations in many common flexible wires and metals (it's added to make them softer), and that this lead is absorble through skin and lungs as well as things like acidic nutrient solutions, acid rain (which it always is) etc. - the less lead near you the better!

Neither the Black Iron Pipe, The carbon steel pin, nor the 304 SS used for this purpose is high in lead. Where did you get the idea that it was?

This information is invaluable. Where can I find out more?

I would suggest contacting joeoakes@skunkpharmresearch.com and picking his brain or attending one of our classes http://skunkpharmresearch.com/skunk-pharm-research-classes/

soylent green ?

Hee, hee, hee........... Cannabuttons and Super Cannabuttons are certainly green and a way to medicate more people with less. Not unlike the movie using recycle to feed the masses.

Heeeheee.... you read my mind! GMTA!

This is what I was referring to. Identification of candidate genes affecting Δ9-tetrahydrocannabinol biosynthesis in Cannabis sativa http://jxb.oxfordjournals.org/content/60/13/3715.full

This is quite fantastic and right down my alley (im a senior year biotech major). I am also part of the largest NORML chapter (UCF), how should i go about getting funding for you all? also, cannabulent could you link me to the site discussing the mRNA profiles?

Hey Ryan, We are not a registered nonprofit nor are we looking to sell any ownership stake. So any funding would have to be an in kind gift. I believe the study that cannabulent referred to can be found at the nih.gov site. There you can find the est's related to your search. Joe

Yup, qRT-PCR would work really well, in a 96 well or 384 well format, you could look at transcript levels for every gene in the pathway at once! It would be super interesting to see how distinct chemotypes (CBD vs. THC rich for example) would differ. And as deep sequencing gets cheaper, it will get easier and more quantifiable to get this type of data. With regards to mutations that affect flower morphology, as a proof of principle for the genetic transformation, it could be interesting to make GFP flowers. As the marketplace saturates, one could make quite a splash with glow in the dark flowers. Also doing traditional forward genetics with chemical mutagens could be a lot of fun.

I will leave the genome sequence to Medicinal Genomics since they already have an Ion Torrent sequencer and I don't have an extra 50k. Gfp is a fun marker to use and its not the only glowing gene. Check out Invitrogens living rainbow collection. You could use them in concert with different promoters for different localized expression, like green trichomes and red flowers. Joe

Yes, I am familiar with the latter study, but it was my understanding that once transformed, the researchers were unable to fully differentiate the plant into a vegetative state. To that point, do you have any pictures of older clones, ie. ones that look more well differentiated? In regards to the mRNA expression profiling. This has been done for cannabis trichomes, so the protocol and sequences are out there, using academic resources one could do this pretty easily. I like your idea of looking at this as a function of development, it would also be interesting to look across sub-types. These are experiments that would be foundational to any attempts to engineer and/or disrupt the cannabinoid biosynthetic pathway. One might also want to look at the GC-MS at the same time and then try to correlate the transcriptional changes with the chemical changes. until next time!

I know that they have done some Mrna studies and that they have found the specific genes I'm interested in. I was thinking120 clones and analyzing one at each change in the photoperiod. 120 because I would destroy each specimen to do the analysis. I would really like an rtpcr for Christmas but alas I'm not that good of a boy. That would be more interesting to me than the current studies. I'm also interested in mutations that affect flower morphology. I look forward to your comments. Joe

I am really impressed with the site and was very excited by this page. Are you mostly pursuing this type of work so that you can store genetic copies/clones of a given strain? It is my understanding that there are no publicly documented cases for the genetic transformation of cannabis. I fantasize about doing so. One could use trichome specific promoters to manipulate terpene and cannabinoid diversity and concentration. But what I would really like to do, is to play with the genes in the trichome development pathway. Work in Arabidopsis has led to the discovery of genes that dictate size, concentration and cellularity of trichome structure. Knocking out homologous repressors of trichome growth in cannabis could be very interesting and could serve as a model system for the use of a plant as a factory for the production of novel/difficult to synthesize natural products. Keep up the good work! You guys rock! (PS: I do not work for Monsanto, nor would I endorse the industrialization of said engineered strains)

Hello Cannabulent, In response to your knowlegeable comment: We are using TC to store clones for future genetic comparison. Our DNA project is currently on back burner status because it’s expensive. We aren't currently doing any in vitro DNA assays; that doesn’t mean we aren't paying attention to literature published that helps our on paper project outline. In the future we hope to be able link mutations in the cannabinoid biosynthetic pathway to GC analysis of the trichomes. I am particularly interested in gene expression analysis of the floral bracts and trichomes as they develop. Soon we will be adding a page about our DNA aspirations so keep an eye out for it. http://www.medicinalgenomics.com (Whole Genome Sequencing) There is one published report of transformation that I am aware of (see link) I think they would have been more successful obtaining transgenic plants with a floral dip while the seeds are still immature. Transformation http://www.jstor.org/discover/10.2307/4293671?uid=3739856&uid=2129&uid=2&uid=70&uid=4&uid=3739256&sid=47698763684267 Joe