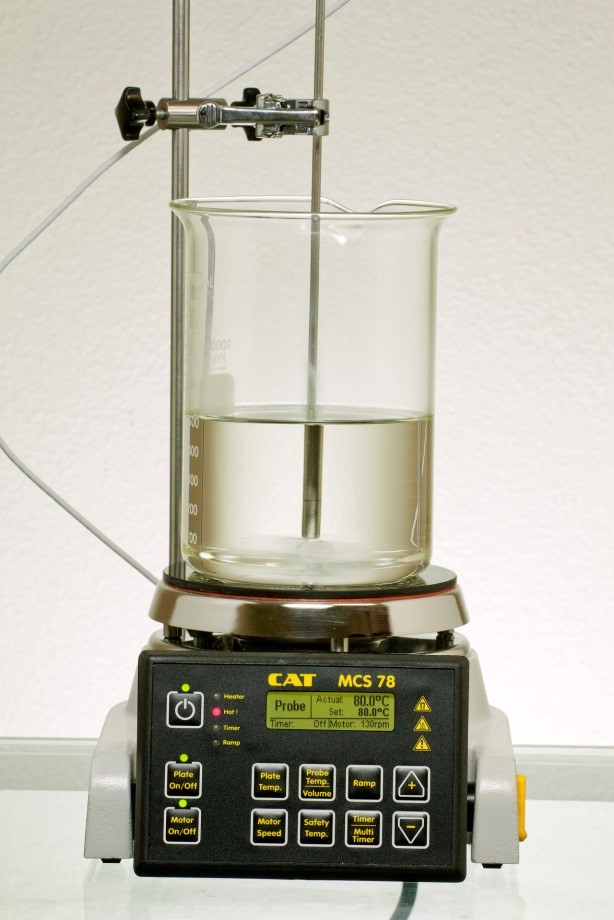

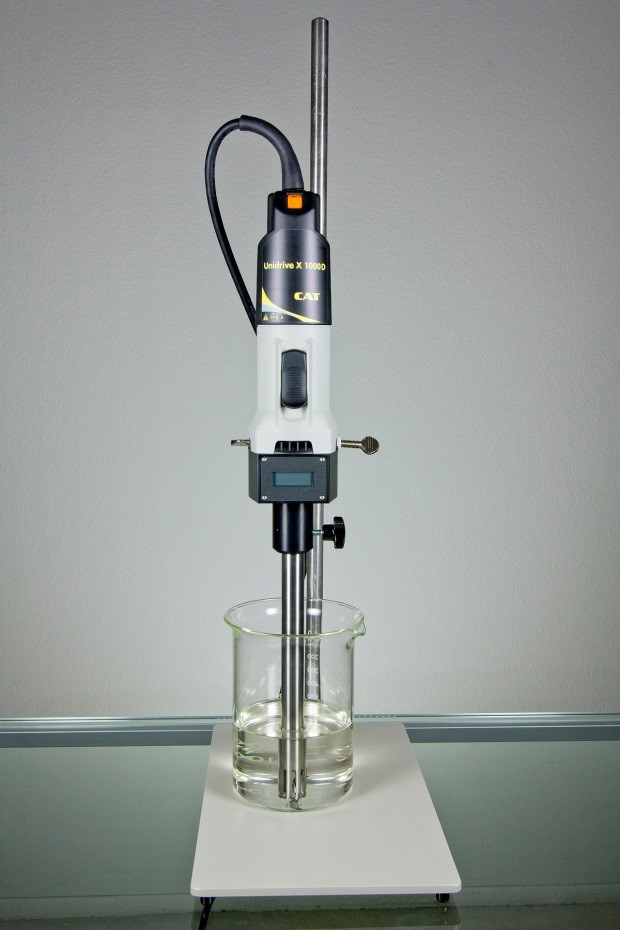

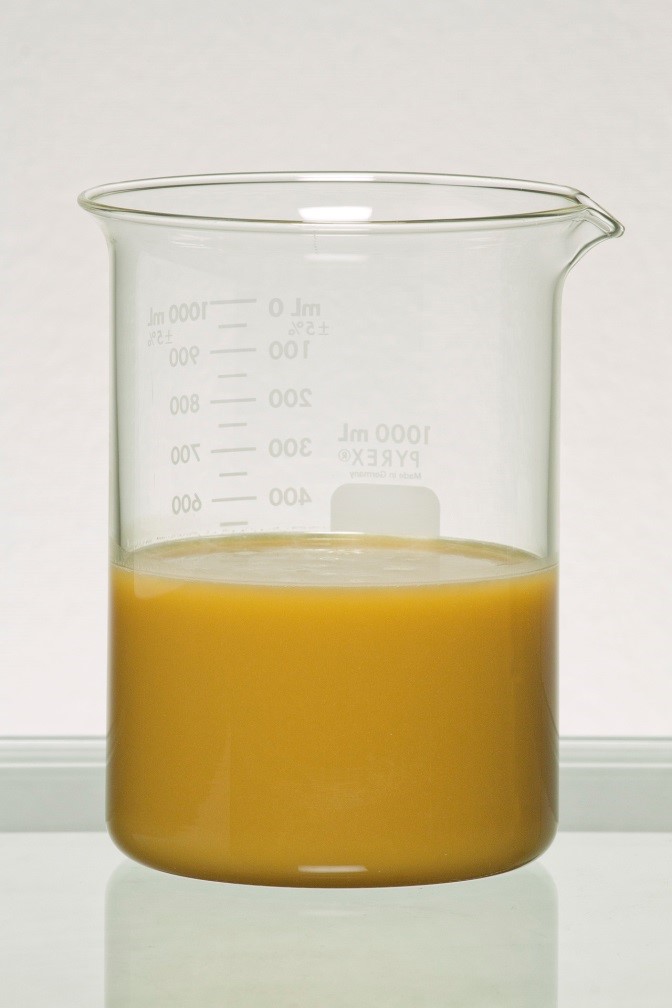

For those of you who’ve tried to mix vegetable glycerin and BHO for an e-juice or tincture know they don’t easily blend and separate quite rapidly. Whether you’re a large possessor or small, we at CAT Scientific have a method where the process can be completed in about two hours or less without using a surfactant, like lecithin. We were fortunate to have a company donate 25 grams of winterized and decarboxylated BHO absolute for this process. A CAT X1000D Homogenizer drive with a G-20 (N) Normal Generator Shaft Assembly is used to emulsify the BHO and Vegetable Glycerin. The X1000D Homogenizer Drive is needed to provide the torque to process the high viscosity of the glycerin and BHO. G-20 (N) Normal Generator shafts are sealed to prevent materials from being processed through the shaft tube, and the operator doesn’t have to be concerned about cross contamination or laborious cleaning. For the experiment, we placed 500ml of kosher vegetable glycerin in a one liter beaker, heated it to 80°C on the CAT MCS78 Magnetic Hotplate Stirrer. We also heated the 25 grams of BHO absolute in a separate vessel. After the vegetable glycerin has reached 80°C, the beaker is moved over to the CAT X1000D Homogenizer. The X1000D is clamped on its drive stand so the G-20 (N) Generator is immersed in the vegetable glycerin about a 1/16th of an inch from the bottom of the vessel. The device is powered on to the lowest setting; 4,000 rpm’s and increased to 8,000 rpm’s. The BHO is then poured into the vegetable glycerin and the vessel is moved around the shaft for about 45 seconds to one minute. The device is then powered off. The beaker is removed from the X1000D Homogenizer, placed back on the MCS78 Hotplate Stirrer. The VG-BHO emulsion is heated to 80°C for ½ an hour. During that time, whatever BHO falls out of solution will appear in the center of the vessel. The vessel is then moved over to the X1000D Homogenizer and emulsified again, as described above. The beaker is again placed on the MCS78 Hotplate Stirrer and the solution heated to 80°C for ½ an hour. If any BHO falls out of solution, emulsify again with the X1000D. This completes the process and you’ll have a stable VG-BHO Emulsion for about 90 days. If you’re processing the solution to be taken orally, do not use a dropper because rubber causes polarization, the vegetable glycerin BHO emulsion will separate.

After 1st emulsion run, reheat VG-BHO to 80°C for ½ hour. If any BHO falls out of solution it will appear in the center of the vessel, homogenize again.

After 1st emulsion run, reheat VG-BHO to 80°C for ½ hour. If any BHO falls out of solution it will appear in the center of the vessel, homogenize again.

Whatsapp: +195.464.18238 Open link https://sites.google.com/view/nembutal-pentobarbital-sodiums Buy Xanax bars , Lean syrup , Oxycodone , Adderall , Percocet , Methadone , Ecstasy , Lsd and acid , Actavis Promethazine Cough Syrup , Viagra , Vyvanse , Klonopin , Fentanyl , Rohypnol (Roofies) , Ketamine , Hydrocodone 10/325, MDMA (molly) crystal and pill form , Crack Cocaine , Heroin (white, brown and tar) Weed , Marijuana , Cannabis buy in Switzerland , Germany , Spain , Italy , Strawberry , Sour Diesel , Jack Herer , Durban Poison , Haze, Pineapple Express , Blue Dream , Purple Haze , AK-47 , Grapefruit , White widow , OG Kush , Purple Kush , Black weed , CBD Oil , Hemp oil , Moonrock for sale in Switzerland , Germany , Spain , Italy ,E-mail: danny@ doctor. com https://onlinecannamedshop.com

How many hours logged on the CMEP-OL HC refrigerant recovery machine before the bearing failed?

Ours didn't fail, but the pump got side tracked at a lab over the hill and far away, where it sits and we haven't had the opportunity to finish running it to failure. We expect to get the pump back and finish that test here locally, but it drags on.

If it did not fail does this copy paste refer to some other pump? Ripped apart my cmep ol and it was the bearings that blew out on one of the Pistons crankshaft.

Not sure what you are looking at brother, but the only pump we've tested to destruction was a VaporHawg test sled. I've read reports about bearing failure and a ceramic replacement, so you might check back with your supplier. Check out this thread: https://www.icmag.com/ic/showthread.php?t=302855 GW

Thanks, very informative

greetings! great work! i was wondering if you could supply more info (pics, diagram parts etc) on converting the 59025-3 Haskel (or ext-420 or aa5-d etc) to two stage? thank you!

I added a schematic to better explain the picture of our conversion. GW

WHERE CAN I BUY ONE OF THOSE NEMA 7 Pumps from??? have a haskel and a huge air compressor now and would absolutely LOVE to switch to one of those!

Any word on the cmep-ol from he's testing? Also wondering about the cmep-6000 3hp unit?

hello. if you're interested I can solve the problem with pumping pure butane. And prolong life. In my experimentation with the TR21, when replacing native piston rings, on the other their life increased by 10 times. Sorry for the bad english.

Hello everybody. As I understood from the CMEP-OL there is a problem with the piston rings and they do not work for a long time with a pure butane. Correctly?

I'm looking to purchase a knf double diaphram explosion proof recovery pumps for a precision extractor and was wondering if there was any testing by you guys here . Thanks

Just got one, we will be testing it in the next week or so...if you can control the back pressure I hear it works efficiently.

so i just received mine aswell and was hoping to see if you had possibly done any testing yet ? havent had any time quite yet to do any testing myself.

I was wondering if your precision extractor had the -50 chiller and how quickly it recovers. I'm doing my first runs with one tomorrow and they have claimed 45 minutes recovery without a mechanical pump.

How is the cmep ol testing coming along? Im looking to pick one up. Is a cold trap needed after the pump to cool down the gas before returning to the recovery tank?

Our CMEP OL test has gone well to date, and it continues to run without incident, so we will next tear it down and look inside for a look see.

Thats awesome to hear. Im ordering mine this friday.

I have a cmep-ol that I've been running since July 2015. I run it a min Aug of 10 hours a day some days longer. I've had very few problems. Recently the fan blade came disconnected.......I think the cmep-ol is the pump for this industry. Another thing I'd like to point out is that I run a very custom extractor and the distance from the bottom of your base and the pump output line and the length of hose on your vacuum side make a difference. I have a tall base and long lines. I've been cycling through 15 pound runs with 32 to 36 pounds of solvent in 2.5-3 hours a run.....

The haskel gas boosters have some blow by on every stroke. I don't think it would be wise to run a gas booster indoors with anything explosive solvent. I can lose 10 pounds of Co2 in 2 hours through my haskel, and as it wears it will get worse. I run a Co2 safety alarms in my lab which will warn me when the PPM's reach 1500, gives a visual alarm @1800 and a audible alarm @2000. Is there such a safety device that could be used in a Butane lab? In my other work with explosive solvents we had to have nitrogen purges hooked to the machine that would automatically purge the system with nitrogen if any safety parameter were to fall out of a normal range. The machine would not run if it could not get a positive flow from the nitrogen bottle on startup. That is a true safety, one that will not allow a operator to run fast and loose for even one cycle. With that being said people still burn down there business with explosive solvents because they use the solvents outside of their safe machine. All because it is quicker and easier to vent that to recover....... and then a spark! I hurts me to see people suffer needlessly. I also hurts to see a grass roots movement erode away as the mainstream adopt the ideas and use the products in masses. The days of small labs are numbered, the money is pouring in and there is no catching up. All of the industries that once turned a blind eye to the needs of the few in a passionate movement will "roll out the red carpet" for a legal cannabis industry. This will leave little room for the small guy to compete, some will survive but most won't.

CO2 is a much smaller molecule than Butane and thus far we are not getting any discharge from the fail safe port between the two seals on the EXT-420. When we do, we will rebuild the pump. Good point on indoor leaks. We recommend indoor running, only in a properly set up extraction room, which has an HC alarm and ventilation capable of keeping any leaks below 25% of LEL.

Just have to say, thank you GW for your wealth of knowledge, and being my "go to" when I need to resolve an issue, or solve a problem, with my day to day work flow. That being said, I've had experience with just about all the available electric pumps, available, that we as an industry utilize. The latest is the CMEPOl, I utilize home made dry sieve (4a) filters (made with sanitary fittings/spools) one pre CMEPOL to catch and hopefully clean any moisture pre pump, and then another post pump, for the same, and to clean gas pre recovery tank. After a day's use, it's astonishing all the carbon/articulate this filter catches, and if I wasn't utilizing it, all this "crap" would end up in my recovery tank, to contaminate all Future runs... Have you come across this? Thoughts?

First of all GW , youre the man! Thank you for sharing your knowledge. Can you recommend the most economical compressor that will work for the Haskel EXT420 . I just dropped 3k on one so every dollar counts!

If you have three phase power, get a three phase motor, but Eaton makes a 7 1/2 hp rotary screw compressor with tank and dryer for under $7K that keeps up, and Chicago Pneumatic makes an economical one. We've had good luck with Portland Compressor off Sandy in Portland. Despite needing 40 SCFM at 100 psi, in our application, you only need about 25 scfm at 50 psi to run our process, so a 7 1/2 hp screw compressor should work. The 7 1/2 hp Eaton that we ran, kept the air at 81 psi, and the 10 hp Chicago Pneumatic kept it at 110 psi, while running unloaded part of the time.

That after running their CM-OL for a few hours it has blown the piston seals and sent black material into their product. They also said they've gone thru 3 units and even had an engineer look at one and he determined that the pump was designed with the intentions that the solvent would be carrying lubrication through the pistons helping lubricate them. Now I know everyone has different experiences and I'm still gonna do my due diligence and run the CM-OL and see how much use I get out of it. I am very interested in your continued updates of your testing and I will also share my experiences. Thank you all very much and stay safe!

I saw the pictures posted, and it is hard to do an analysis from a distance, so am only offering observations and guesses until I do an analysis. The glazed cylinders and deposits look exactly like some of the pumps I've seen that ingested cannabis oil and had been run hot and dry. No oil less piston pump will tolerate that. We just moved our test unit to the fifth lab for trials without any complications, and before passing it on, I alcohol swabbed the intake and discharge ports between three and four, to see if it had been compromised. So far none of ours labs have done so. We will tear ours down when it does fail, and do both a personal failure analysis, as well as use a certified forensic lab to identify any accumulated substances. At that point I will be in a better point to comment.

PS: That does however bring up an excellent point! The CM EP OL is faster than dual TR-21's, which means the port velocities are higher and more likely to aspirate oil that is too close to the pump intake.

First I just want to say thank you to every one of you that has put so much dedication and effort into our beloved industry. Information that you provide is one of the most valuable resources that we have and you continue to help in so many ways. I run an mk4c from terrp extractors and I had a CM-EP and stopped use immediately after my first recovery and realized it had been contaminated by the hemp seed oil in the CM-EP. I just finally received my long awaited CM-OL only to hear from a local industry leader

Yeah, we tried the CM EP to test equipment as well, but never extracted with it because of the oil pickup.

Morning Tim! An Apion G-5 works, but isn't rated for flammable refrigerants and Apion management has made it clear that they want no part of our market. We are still in the middle of seeing how long it takes us to break our CM EP OL test pump, so its longevity has yet to be determined, but the CM EP OL is the only electric oil less pump that I am aware of, rated for our purpose today. With such a huge market window, that will no doubt change with more off shore offerings, as well as domestic manufacturers looking for ways to tap into the demand. The only time proven oil less pump that I'm aware of this gorgeous morning, is still the Haskel pneumatic, but it is an even larger investment bite to swallow. Peace, GW

GW, Thanks so much for the info, as always you are precise and honest, I think I will buy the Appion for a temp unit , and wait to save my pennies for the Haskell or CMEP when you guys finish your test runs please post. Thanks so much for all you do Tim

GW, thank you for all of your hard work and reliable data, in this business it is hard to come by such clear and reliable information. I am to be at the 6/26 tranformintor class, stepping up from a terp III (wonderful machine)yesterday I toasted my promax 6000. I would love an explosion proof pump but I cannot afford the additional expense right now. would I be wasting my money on an Apion G5 ? Or should I just step up and buy the CMEP ?

What's your thoughts on the cmep-6000

if you need to recover 100lbs of solvent in one go then its great, otherwise it is way overkill. its basically three or four CMEP-OL's in series in one housing (i cant exactly remember how many)

I haven't tried the four cylinder CMEP-6000, but understand that the CMEP-OL was designed after it. So far we are pleased with its performance, but haven't crashed it yet and pulled a head to see what it looks like inside after a summer in the field, with multiple operators. If it is the same design and quality as the pump we are CMEP-OL we're testing, its worth investigating further, and if someone will send us one to use and abuse, we will be happy to put it through its paces and report back.

So my cmep-ol just died! Tried restarting and it just sounds like it's seized up. Ordered the rebuild kit and beginning the tear down as soon as it arrives. It was chugging merrily along and then made a strange noise and quickly stopped.

Ripped apart my cmep ol and it was the bearings that blew out on one of the Pistons crankshaft.