Hee, hee, hee, don't you just love synergism?

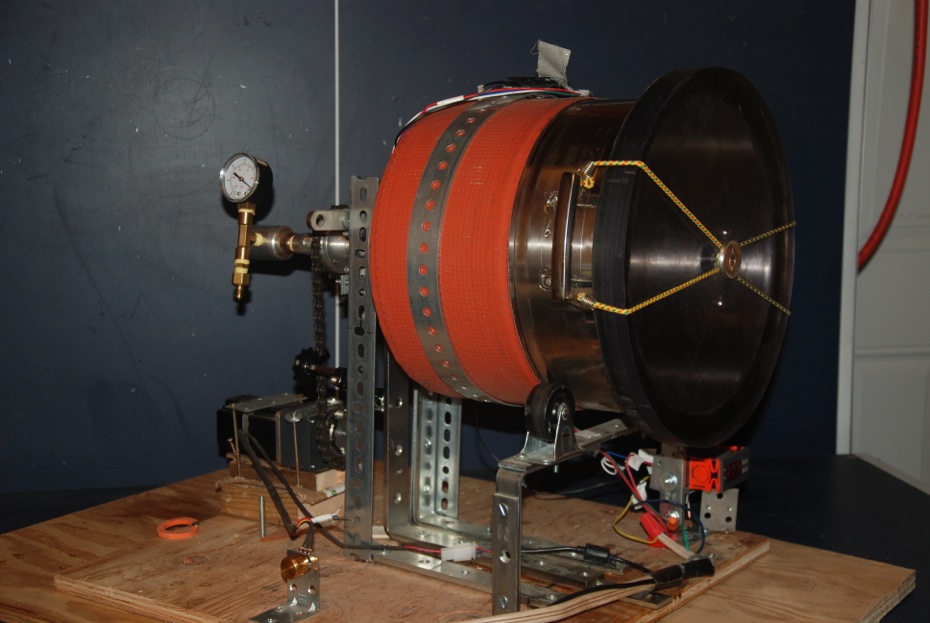

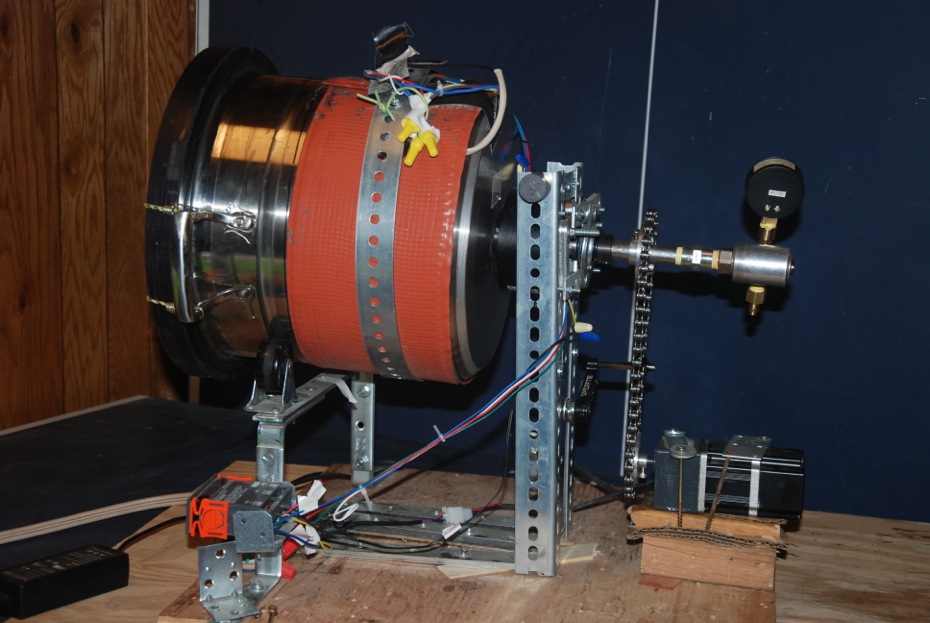

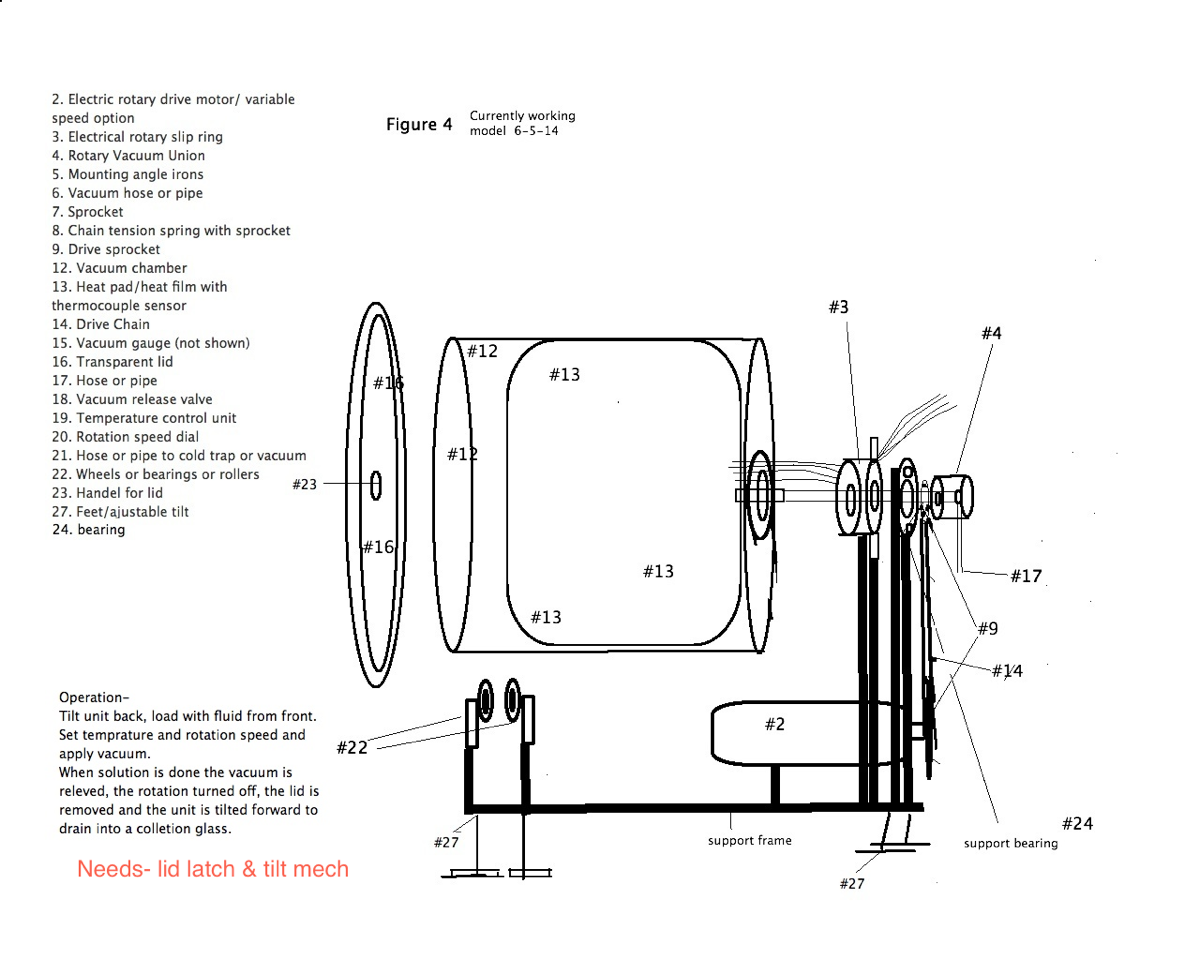

I posted a rotary evaporator design based on available sanitary spools at the time, but didn't build it because better options were becoming available, and Siskiyou Sam took the challenge and built one of his own design.

He has consented to share, so here tis:

Howdy!

*

Several lifetimes ago, your wizardly host, Greywolf, posted a challenge @ /the-evapanator-rotary-thin-film-evaporator/

*

He said and I quote, "Here is my conceptual of the purdy thang! For those of ya’ll who understand it at a glance and are off to do it one better, ah hope you will share.“ Inspired by the thought of doing "one better” I headed off to the shop to see if I could pay it forward.

*

Well here it is folks, took me over a year and now I’m sharing with the hope that…1. All you tinkers out there will build your own, enjoy it’s use, improve on the design and share. 2. I can crowd source a manufacturing partner. (Contact: laboregon@gmail.com)

*

The Rotovap Maximus is a thin film evaporator that will currently remove and recapture (when used with a cold trap) 1 liter of alcohol in 4 hours. The entire process can be viewed through the polycarbonate lid. From cold start to 110 F. in less than 60 seconds. Variable rotation speed to 40 RMP. Thermocouple controlled.

I picked up the provisional patent, so it’s "Patent Pending" at the moment. While this thing works very well for removing and recapturing alcohol it also can be used by chefs and bartenders for low temperature flavor capture, extractions, reductions, infusions and who knows what else. Siskiyou Sam

Nice build! Featured in our HomemadeTools.net newsletter: http://mailchi.mp/buildthreads/classic-workbench-load-rollers-bandsaw-support-post-342773

That's rad I like it have you ran product through it yet?

Siskiyou Sam ran significant product through it and as far as I know, still uses it. GW

I died laughing reading this. It reads like the teacher comments on my high school chemistry lab reports. A lot of things like " Mhmm and did you consider that you were venting a flammable gas and not under the hood" HAHAHAHAHA this took me back. SkunkPharms keeping it real as always.

You're one to talk GrewWolf!Lol! If your so smart why does your passive system take 2 or 3 hours to operate? You also say your device are asme certified by building together a bunch of asme certified parts. That's like saying you can make an fda certified device by welding together a bunch of fda certified parts. And you leave that up amateurs. Sounds like you feathers got ruffled and you didn't like it. You know the responses were posted out there and you need to posst them up instead of pretended they don't exist.. Maybe it's because you didn't like the answers you got.its easy to tell a one sided story to your friends in private, post up the answers unless your just hosting your private shit talking forum. Easy to sound smart when you only say your half of the conversation. I wouldn't buy an 8 ounce system, but I sure the hell wouldn't buy your slow fake certified devices either.. Thanks for taking down your open blasting stuff too, glad to see you finally took a dose of the safety shit you keep talking about everyone else.

Our Design's are stamped by a professional engineer; so we aren't just slapping together parts.

Which passive system takes 2 to 3 hours to operate, and under what conditions? I ignore most of the hubris on line by those who are ill informed or have a secondary agenda, because they aren't about facts, they are personal attacks like this one, which I have little patience and no time for. If you were better informed, you would know that long ago I submitted my designs for third party peer review and certification that they met ANSI/ASME, to lead the industry in that direction. If you didn't have a secondary agenda and were not in collision with the standards that I've outlined, I'm not sure what the purpose of this conversation is, beyond a personal attack? If you can't meet those standards, I suggest you get out of the game now, because regulation will put you out of any legitimate business. GW

Thank you for taking the time to illustrate the issues properly. The worst thing about a bad closed loop system is the danger posed by an operator who *thinks* he is safe. False advertisingt and an open dare to jeopardize your life and our industry are very different. Mr Extractor is going to get a case law named after them at some point if this shit keeps showing up at tradeshows.

This 8 oz unit is joke ..I would never inject tane into atmosphere ..or 'hot' solvent into my extraction ..nor pay 6 grand for an 8oz mr. Coffee ..they gonna rip a bunch of patients who want to extract for themselves off .. and probably facilitate several injuring themselves..

DAMN!!! That was like yo momma jokes for the well educated! Well done article guys. Points to inconsistencies. Defines why. Throw on a little heat (shame on them) to boot. Now that's some good coffee, lol. P.s. I admire your efforts to stop human fireballs and progress much safer societal practices in this area. Your like total heroes, and thanks for helping progress mankind, where others are afraid to. Period.

Good questions, apparently they are a fly by night outfit. They will get someone injured badly if they don't take butane as seriously as they should; butane is a real life changer when it explodes, the fireball is over 3000 degrees and will melt steel and burn the fat off of your body.

thanks for this, some of these companies are completely embarrassing. what a joke... smh

Thanks! The truth is best!

I contacted y'all about a year ago about how I have a rotovap. I was curious if you knew if you did a high proof alcohol extraction and ran through rotovap, if the end product that is left in the collection flask still has plant properties, such as the TCH in it post distillation? Is there a setting you suggest? My equipment is advanced, so I can remove, say just the ethanol from the maceration/tincture and it will distill through low temp and low pressure (tricking the boiling point for said setting) which then does not "cook" the plant material during the process. Does the ethanol that is pulled off from the tincture and remains in the collection flask have THC in it AND does the water left with the plant material in the rotary flask also still have the THC in it? Thank you.

[…] The DIY Rotary Evaporator by Siskiyou Sam […]