About the Author

Pharmer Ted Reynolds, Cannabis Specialist, FlackTek

Pharmer Ted is from Denver, CO and has several years of experience within the cannabis industry, focusing both on CBD and THC. Pharmer Ted began his career in Exercise Science and after a few years he switched gears to enter the cannabis industry where he started his career in cannabis as a Supercritical co2 Extraction Tech. He then moved upward to the role of Quality Engineer where he assisted in ensuring safety of products and compliance with GMP/ISO. Next, Pharmer Ted took on multiple roles within Research and Development where he focused on water solubility, nanoparticle deliveries, and targeted effect formulations. He is now working as a Cannabis Specialist with FlackTek as well as launching a new Cannabinoid Biotech company called CannaComplete.

Pharmer Ted has been a long time reader of SkunkPharmResearch.com and asked for the opportunity to contribute content and valuable information to all of its readers like himself. Of course we couldn’t say no! This is part one in a seven part series and we want to hear your feedback. Let us know if you’re enjoying the content, if you have any personal experience with the techniques being discussed, all feedback is welcome and we hope you enjoy!

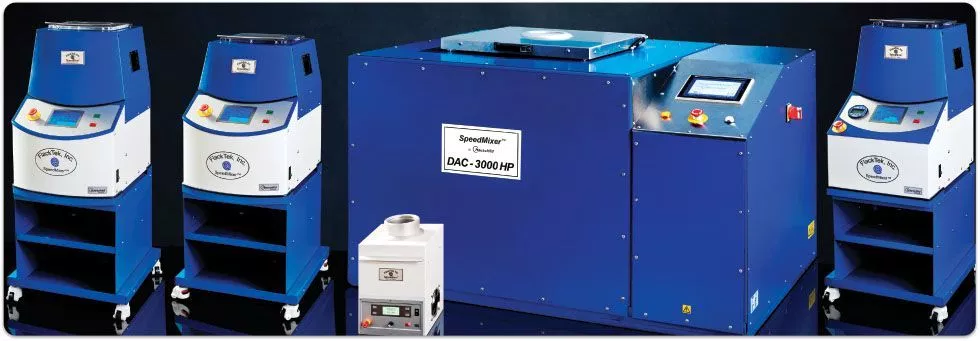

First in our FlackTek SpeedMixer series we will be outlining the fundamentals of how the technology works, its history and its applications in other industries. Next, we will discuss how to utilize the SpeedMixer in seven different ways to start your next level Cannabis creations with this all-in-one processor.

SpeedMixer is the originator of the Dual Asymmetric Centrifuge (DAC) technology, patented over 30 years ago. Originally designed to mix high viscosity dental impression materials without blades or bubbles. The bladeless design uses opposing centrifugal forces on the outside to push the material against itself in a vortex pattern. For example, imagine two hurricanes colliding at a 90 degree angle at their eyes. This design creates a focal point where, at top speeds, it can apply 800g’s to material inside the machine. Yeah, 800g’s. That’s about 266 x the g-force produced from a space shuttle at take off.

All mixing is performed inside closed containers so there is no chance of contamination or need for cleanup. Standard machine sizes range from less than 1 gram (in DAC 150 SpeedMixer) all the way up to a ~5 gallon bucket of material / 10kg capacity (DAC10000 SpeedMixer).

As you can imagine, with that amount of force, you can start to do some crazy cool mixing, formulations and experiments quite fast. How fast do you say? Most applications mix times are typically 90 seconds or less. Yes SECONDS. We like to say ‘most people think about their processes in terms of minutes and hours - we think in terms of seconds'. The amount of force over just a few minutes can make room temperature asphalt flowable without adding any external heat.

It is this tremendous amount of power that has made this technology the standard of mixing in over 30 different industries like high tech sectors, medical devices, to high energetics and pharmaceuticals. Not only is the power and time impressive, but there is no cleanup, no bubbles and the process is highly repeatable. Many items and materials you interact with each and every day started their life in a SpeedMixer. Have you flown in an airplane lately? There is a good chance the adhesive holding that plane together was developed and perfected in a SpeedMixer.

Ok PharmerTed I get it, the SpeedMixer is great and all but what’s it got to do with weed dude? Well remember those crazy cool experiments and formulations I mentioned? The same applies for all things Cannabis my friend. This article series will cover seven uses that we have found with this creators tool called SpeedMixer.

- Grinding/Milling

- Extracting

- Purging

- Terpene/Distillate Reintroduction

- Infusing

- Emulsions

- Whipping.

Today we will be starting off with a use that analytical labs are particularly interested in: Grinding and Milling. Typically when grinding or milling, one uses a blade or crushing process, these options often result in material loss and excess time in clean up. SpeedMixers utilize a one-time use disposable container which keeps everything sealed up and virtually eliminates loss of product or sources of contamination while simultaneously homogenizing what's inside to perfection each and every time. When it comes to testing results; accuracy, repeatability and contamination free is the name of the game.

We will be using our smallest model, the DAC 150, with 100g capacity for the following grinding example.

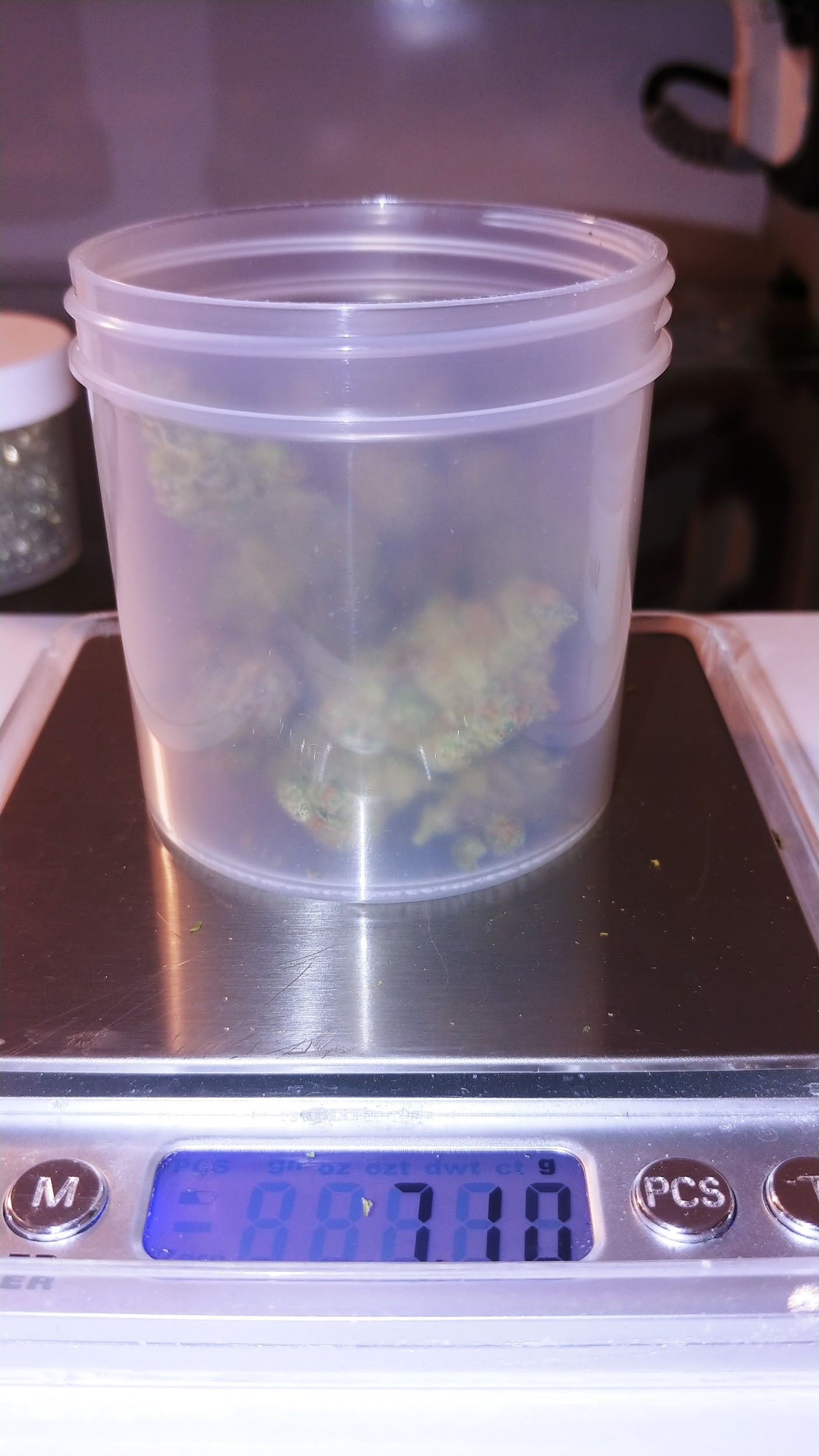

Dispensary bought flower and grinding media:

Grinding:

Place your buds wet or dry in an appropriately sized cup packed snug, but not too tight. The density of buds is quite low, with only ~10g of material, it takes up nearly 200mL of volume before grinding.

Set the timer on the SpeedMixer and hit “start” for a quick burst. Now for some applications, a simple quick burst of DAC forces will get the level of grind to exactly where you need it. However, this process could yield materials to be too fine, or too large for other applications. Simple process optimization is easy in the SpeedMixer

(After quick burst)

For a smaller particle size we can add a little amount of time.

(After a few more seconds)

To go even finer we can use this ceramic grinding media (or other types) to add additional shear. Many materials work for this, but these ceramics are specifically made with FDA food safe material.

After a quick burst with the grinding media:

The final product: Ultrafine.

The blade free process of the SpeedMixer works for grinding or milling a plethora of dry materials, but for advanced applications you can also perform cryomilling with liquid nitrogen (LN2) which cools your materials as you grind.

Perhaps you want your gummy material in powder form to work or test with, you can flash freeze the material with LN2 inside the container and then grind using the steps above.

These same milling practices are utilized in a variety of industries every day. One example would be milling hard ceramics into a very small particulate size for advanced energy applications.

Once you grind/mill down flower into a fine particulate, you increase the surface area potential for the next processes in our series: extraction!

For more information on the SpeedMixer head over to www.SpeedMixer.com