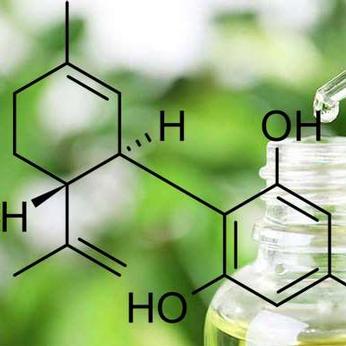

Chemically, these are very similar. They both bind with CB1 and CB2 receptors to have an impact on the way you feel and cause that “high” feeling. Both have a double bond, which scientists think is what makes you feel high and euphoric. Read More...

-

-

CBD helps alleviate possible medical problems causing stress. More and more people suffer from an anxiety disorder at some point in their life, such as panic disorder, social phobia, OCD, among many others. The calming effects of CBD oil are beneficial for all of them. Read More...

-

CBD can also influence non-cannabinoid receptors. CBD modulates the 5ht serotonin receptor... Read More...

-

Today I’m excited to share my insights from working with my favorite engineer, Tom Sage from Sage Machine Design. A few years ago one of my extraction lab clients needed to reclaim large volumes of solvent (ethanol) used for cannabis extraction. Read More...

-

I’m a middle-aged marijuana enthusiast who lived and worked in the “Emerald Triangle” of northern California and Southern Oregon during the drug wars of the 90’s without (fortunately) wearing handcuffs. I left Humboldt County and landed in Portland as medical cannabis became a thing for Oregon. Read More...

-

Let’s have a look at some tips for successfully growing cannabis in your very own greenhouse. Read More...

-

There are several factors to growing healthy marijuana plants. Air circulation is the most essential system involved. Here are a few tips for improving the air circulation in your cannabis grow room. Read More...

-

Today, we’ll break down everything we need to understand about marijuana. Read More...

-

With a quick search of "COVID-19 and CBD" more than half a dozen articles come up stating that CBD can help fight off the Corona Virus... There are no legitimate medical studies to find this true. We want eve Read More...

-

This has become my favorite little vape pen, easy to keep in the pocket due to its short size and oval sh Read More...

-

Is your supply for US grown hemp solid? Is it the highest quality hemp, grown by America’s best farmers, to produce the Read More...

-

"We work with manufacturers to ensure safe equipment and facility sites for all cannabis extraction processes. When equipment or facilities are ready for inspection, our 3P Certz team goes to the location..." Read More...