Some MMJ applications require greater purity and potency, so it is desirable to remove inactive ingredients like fats, lipids, and plant waxes, as well as any chlorophyll and other water solubles.

When I class chlorophyll with the water solubles, it is not in the same vein as the term is used in inorganic chemistry and is more involved. Chlorophyll itself has a polar head and hydrophobic tail, so it is mostly non soluble in polar water, but can be removed from the plant and conveyed by water as micelle.

Water also dissolves and washes away the Chlorophyll binding proteins and exposes the Chlorophyll to the solvent used. Chlorophyll is highly soluble in alcohol and slightly soluble in butane.

For further discussion of that subject, please see: /chlorophyll-pickup-in-extractions/

Processes that use a polar solvent and reflux or soxhlet to maximize extraction, also maximize and concentrate chlorophyll, which can be a problem for some people. The poison is in the dosage, so even for a salubrious ingredients like chlorophyll, some people can get too much of a good thing, producing digestive tract upsets, with attendant vomiting, cramps, and diarrhea.

See: http://www.nlm.nih.gov/medlineplus/ency/article/002893.htm for details.

In a nutshell, many water soluble non cannabinoid ingredients come along for the ride when a polar solvent is used and water is present. While it is easier to use a process that minimizes their extraction in the first place, if that is a moot point, because you already have an extraction with excessive non-active ingredients, here are some ways to clean them up:

Filtering:

After re-dissolving the extract in ethanol or hexane, it may simply be filtered to remove the material that is insoluble. We usually use coffee filters for this purpose, or if we have a larger amount, we use a Whatman # 1 lab filter, with a vacuum assist.

If we wish to filter it further, we run it through 0.45 or 0.2 micron syringe filters, which takes out any remaining plant material, as well as any bacteria present.

Winterizing:

When using non polar solvents like butane and hexane, some non-polar waxes, fats, and lipids are extracted as well. An easy way to get rid of them is to simply re-dissolve the non-polar extraction in 190 proof (~95.5% azeotropic) polar ethanol and stick it in the freezer for about 48 hours at -18C/0F, for the waxes to coagulate.

The waxes will precipitate out of solution as the temperature drops and clump together so that they are easily filtered out with a standard coffee filter, or a Whatman #1 lab filter.

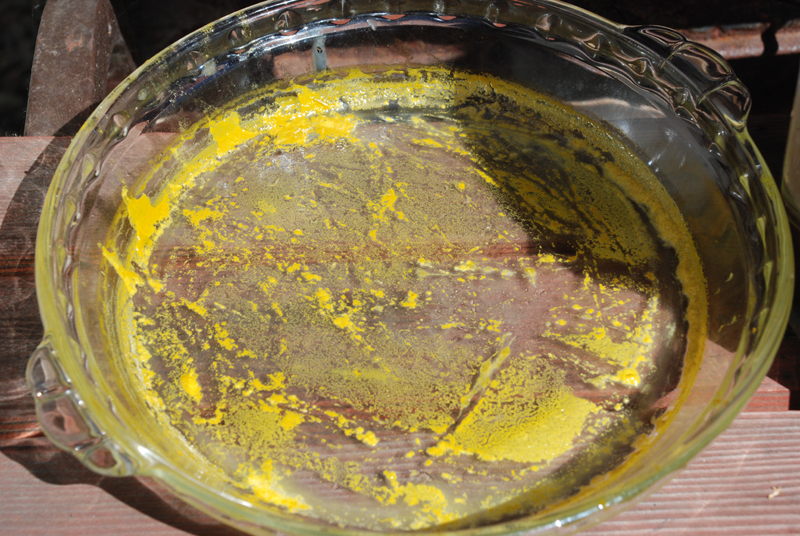

Here is what a winterizing filter cake looks like, while still wet.  After filtering, the alcohol is evaporated or vacuumed off, to leave a pristine Absolute.

After filtering, the alcohol is evaporated or vacuumed off, to leave a pristine Absolute.

Winterizing ISO, Methanol, and Denatured alcohol extractions:

Even though Ethanol is polar itself, it can still be used to remove some of the undesirables they pick up, because it is not as aggressive a solvent as Isopropyl and Methanol. By re-dissolving their extracts in hot ethanol and then placing that in the freezer overnight, some of the undesirables will precipitate out and may be filtered out.

Removing minor green coloration:

Because butane is non polar and considered insoluble in water, it is the longest chain alkane that is still slightly water soluble at 0.0325 vol/vol (3.25%). That means that a liter of n-butane will actually hold as much as 32.5 ml or mgs of water (1000ml X 0.0325).

3.25% by volume is also enough water to bring along some water solubles like chlorophyll and leave an otherwise pristine extraction with a green tint, usually light and sometimes a gorgeous electric hue.

These light green hues are easily removed without the more involved and extreme measures that I will follow up with, and is as simple as putting a jar of the oil suspended in an ethanol tincture, in sunlight or a light from a high UV source, like a grow lamp.

The UV radiation in the sunlight will quickly break down the chlorophyll and the breakdown products are amber, so the green color disappears. Alas, UV radiation also destroys cannabinoids, but fortunately at a much slower rate, and three or four hours in the sun is usually enough.

OH MAH GAWD:

Oops! Soooo, what if the extraction is really, really messed up, or if you just want to see how purdy you can make an extract?

Sometimes bad things happens to good oil, and evil spirits need to be exorcised, or sometimes the most economical process, or indeed the only available extraction process, extracts undesirables. Fortunately there are ways to remove undesirables, though at the expense of yield and some of the other terpenes, so there is compromise involved.

Alcohol/Hexane wash:

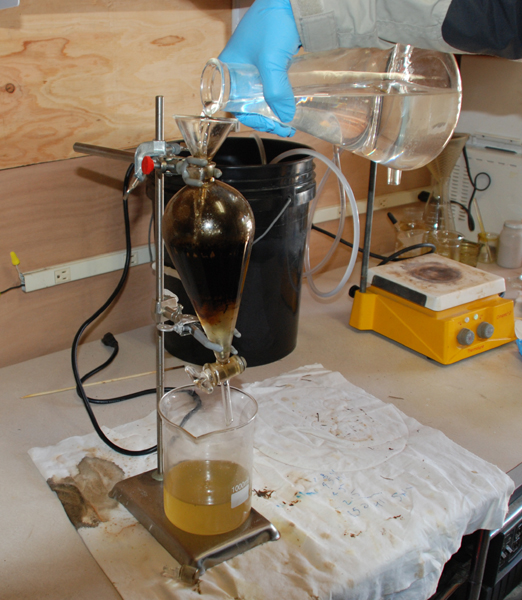

One way to clean up an alcohol extraction, is to reduce its volume to a manageable level given your resources, and pour it in a separatory funnel to about the one third level, followed by the same volume of n-Hexane and then of water.

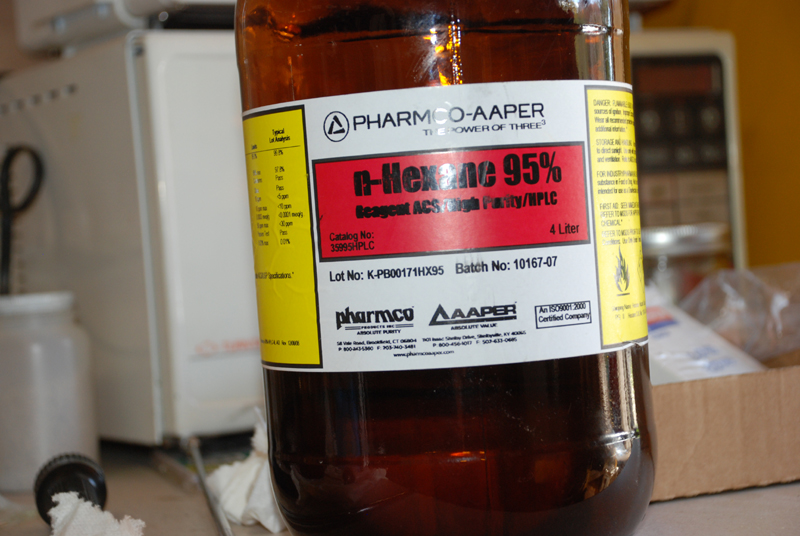

We use an HPLC Reagent grade for this purpose, which we get from the local scientific supply store.  Shake well and then lift the lid long enough to burp any pressure, before setting it in a stand to stratify into layers. After it has separated, bleed off the water and emulsion layer. They contain both the undesirables, and the alcohol as well, with the cannabinoids left with the hexane.

Shake well and then lift the lid long enough to burp any pressure, before setting it in a stand to stratify into layers. After it has separated, bleed off the water and emulsion layer. They contain both the undesirables, and the alcohol as well, with the cannabinoids left with the hexane.

Add water again and repeat the wash step until you are satisfied with the clarity, before evaporating off the hexane, to yield the pristine oil. More on hexane purging in the subsequent process description for serious scrubbing:

To put this process into perspective, I once collected all of my pipe bowl scrapings and roaches until I had about a pint of them, and dumped that into the container of black denatured alcohol, that I had been cleaning my pipes in.

I shook the mixture well and let it soak for a day to extract the material from the roaches and scrapings, before straining it through a wire strainer and then a coffee filter.

Because I didn't want to mess up a separatory funnel with the black foul smelling mess, I poured the solution in a 1 gallon Ziploc bag, to which I added equal amounts of water and hexane.

After shaking it well, I hung it from one corner, to let it stratify, and after it had, I clipped off the lower corner of the Ziploc bag, and by pinching it, and controlling the bleed rate, I was able to bleed off the water, alcohol, and emulsion layer, so that only the now gold hexane solution remained.

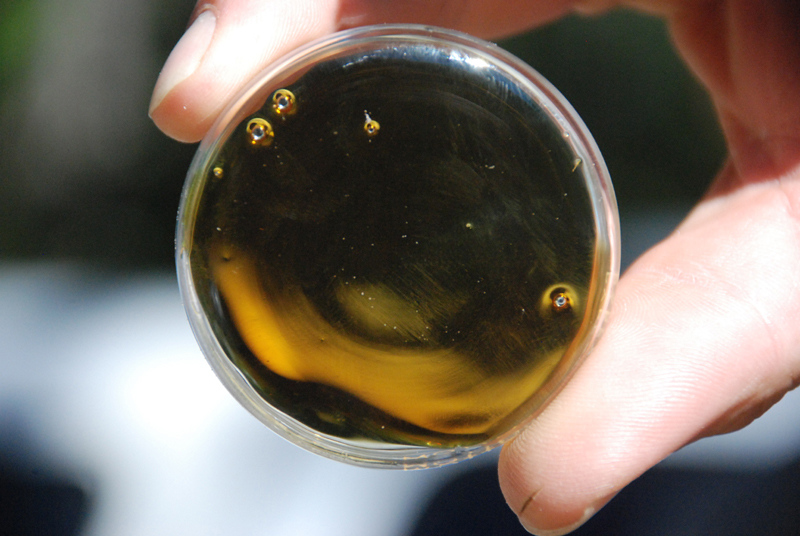

I filtered the hexane and poured that into a Pyrex pie plate, which I blew air over with a fan to evaporate off. Attached are pictures of the amber oil that I extracted.

While the black color was gone, slight ashtray undertones could still be tasted, so further refining was necessary with activated charcoal, but we will cover that as a separate subject.

I am not suggesting this process for reclaiming ashtrays, but simply to make a point.

Hexane/Saline water wash:

Joe came up with this process, which has produced our most pristine creations. It involves re-dissolving the oil in a hot highly non-polar solvent such as hexane and repeatedly washing the solution with saturated salt water until it is mint quality.

Salt water washing uses a separatory funnel as above, but we start out dissolving the extraction to be cleaned directly into hot n-Hexane, and then washing the hexane solution with saturated salt water.

The magic trick is two fold. The saline exposes any proteins hydrophobic surfaces, making them insoluble in water, so that they precipitate out, and the saturated water has no room for anything but the alcohol, which aids that process.

We start out by making four or five liters of saturated salt water in a glass (or ceramic) container, by mixing sodium chloride (table salt) in hot tap water with a hand mixer until no more will dissolve. We buy the salt cheap by the bag, using salt intended for water softener use.

We perform the salt water wash of the hexane mixture, by simply pouring the salt water and hexane into the separatory funnel together in about equal parts and shaking well and burping, before allowing the mixture to separate out into layers.

After carefully bleeding off the bottom layer of water, we continue to replace it and repeat the wash process of both the emulsion layer and the hexane solution, until the emulsion layer disappears and the hexane has bell clear clarity.

At that point we stop washing and evaporate off the hexane. While we use HPLC grade hexane, light naphtha containing only Pentane & Hexane will also work for this process. Check the MSDS because the word light naphtha only means it boils between 30C and 100C, so it can contain Benzene..

Purging Hexane:

While n-Hexane is a delightfully non polar solvent, that enables us to do some amazing things, it has two more carbons and four more hydrogen atoms in the chain than Butane, and so due to the greater Van der Waal forces involved, is not as easy to get rid of as Butane.

The most effective way that we've found to remove the residual hexane, is either with multiple ethanol washes, usually around three, or thin film vacuum.

To wash with ethanol, redissolve the hexane honey oil in ethanol at a ration of about 10 to one and boil off the alcohol. When it is almost all gone, do it again, and repeat, until there is no decernable hexane odor.

For thin film evaporation, we place about .200 inch of it in a six inch Petri dish, which we place in a vacuum chamber and evacuate down to 29.5 mm Hg and ~80F for 30 minutes.

N-Hexane boils at about 69 °C/ 156 °F and has a high vapor pressure, so it is easy to evaporate, but harder to completely purge. Given our 30ppm taste sensory threshold and our 130 ppm odor threshold, we can detect its presence, long before we reach levels of concern.

Because it is a simple Alkane and relatively non toxic, hexane is used extensively in food extraction, but should not be viewed as being as salubrious as mother's milk.

The first clue of course, is that it doesn't come in nearly as attractive a container, and the second is the MSDS information which tells us, that in excess, N-Hexane attacks our nervous system. The following is a typical MSDS Section 8:

http://www.sciencelab.com/msds.php?msdsId=9927187

Section 8: Exposure Controls/Personal Protection

Engineering Controls:

Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of vapors below their respective threshold limit value. Ensure that eyewash stations and safety showers are proximal to the work-station location.

Personal Protection:

Safety glasses. Lab coat. Vapor respirator. Be sure to use an approved/certified respirator or equivalent. Gloves (impervious).

Exposure Limits:

TWA: 500 (ppm) from OSHA (PEL) [United States] Inhalation

TWA: 1800 (mg/m3) from OSHA (PEL) [United States] Inhalation TWA: 176 (mg/m3) from ACGIH (TLV) [United States] SKIN TWA: 50 (ppm) from ACGIH (TLV) [United States] SKIN TWA:

500 STEL: 1000 (ppm) from ACGIH (TLV) [United States] Inhalation TWA: 1760 STEL: 3500 (mg/m3) from ACGIH (TLV)

Section 11: Toxicological Information

Routes of Entry: Absorbed through skin. Dermal contact. Inhalation. Ingestion.

Toxicity to Animals:

WARNING: THE LC50 VALUES HEREUNDER ARE ESTIMATED ON THE BASIS OF A 4-HOUR EXPOSURE.

Acute oral toxicity (LD50): 25000 mg/kg [Rat]. Acute toxicity of the gas (LC50): 48000 ppm 4 hours [Rat].

As the saying goes, the poison is in the dosage, so leave us please keep N-Hexane's potential nature in perspective, which includes never losing sight of it. Note also that oxygen in a breathing atmosphere greater than 75% pure will kill us dead!

A review of the hexane Material Safety Data Sheet shows that the oral rat LD50: is relatively high at 25000 mg/kg.

Acute toxicity of the gas (LC50 rat): was 48000 ppm using 4 hours exposure data and the Threshold Limit Value for an 8 hour weighted average in breathing air is 500 ppm with a Permitted Exposure Limit of 1800 mg/M3 (~ppm).

Studies of shoe repair folks suggest that long term chronic exposure at lower limits can have long term effects, because the liver converts n-hexane to Hexane 2.5 dione. Their chronic exposure was many times what you would encounter in purging residuals left in oil that is below sensory threshold.

Besides NIOSH, we also have U.S. Department of Health and Human Services, Food and Drug Administration, Center for Drug Evaluation and Research (CDER), Center for Biologics Evaluation and Research (CBER) regulating what you can use and what you can leave behind:

They list n-Hexane as a class two solvent with 290 ppm concentration limits, and a total PDE of 290 mg/day.

The good news is that if you are out of the stink or taste, you are less than about .01% of TLV, but the bad news (?) is that although it is relatively non toxic, hexane still tastes like lighter fluid below toxicity levels, with our 130 ppm sensory threshold far below the Threshold Limit Value.

Hello Mr Gold, Thank you for your book, it must have been hard work publishing a book of this nature back then. If you have time to talk I am keen to learn more and would love to start a rappor with one of my idols.

Whatsapp: +195.464.18238 Open link https://sites.google.com/view/nembutal-pentobarbital-sodiums Buy Xanax bars , Lean syrup , Oxycodone , Adderall , Percocet , Methadone , Ecstasy , Lsd and acid , Actavis Promethazine Cough Syrup , Viagra , Vyvanse , Klonopin , Fentanyl , Rohypnol (Roofies) , Ketamine , Hydrocodone 10/325, MDMA (molly) crystal and pill form , Crack Cocaine , Heroin (white, brown and tar) Weed , Marijuana , Cannabis buy in Switzerland , Germany , Spain , Italy , Strawberry , Sour Diesel , Jack Herer , Durban Poison , Haze, Pineapple Express , Blue Dream , Purple Haze , AK-47 , Grapefruit , White widow , OG Kush , Purple Kush , Black weed , CBD Oil , Hemp oil , Moonrock for sale in Switzerland , Germany , Spain , Italy ,E-mail: danny@ doctor. com https://onlinecannamedshop.com

can I put a butane extraction straight into the ethanol for polishing or do I need to put it in my purge oven first?

Hi, I'm wondering in regards to using UV light, if Sylvania UV-Lamp 400W E-40 would be of choice or is it too powerful? or just that less time is needed? Cheers

After winterizing and seprating the wax, would it be wise to keep oil solution cold like very cold? And filtering through AC and DE?

Thank you so much! We still have just one question - does the Hexane/Saline water wash impact the yield? We've got a bulk quantity of medicine that we would like to polish.

It doesn't have to be a lot. What you are removing is not that much by volume or weight, and the miscibility of pentane or hexane is low, though not zero. Pentane is about .004% water soluble and Hexane is about .001%, so not a lot goes out with the water wash. https://erowid.org/archive/rhodium/pdf/solvent.miscibility.pdf Where the yield is most affected is when you make the final cut with the separatory funnel, as long as you never cut quite to the emulsion layer until the last wash/cut. It also takes longer to work the emulsion layer with subsequent washes, and each wash leaves with some, so at some point need to make the call. I suggest that you start with a small sample and see how it works for you! GW

We did our first experiment and the most unexpected thing ever happened - it didn't work out as expected, haha. Let me go through everything in more detail. We are working with oil extracted through warm methanol extraction. We used 20 grams of oil and around 200ml of Pentane & Hexane mix. We warmed the oil and solvent in a pyrex dish in water bath. It didn't dilute very easily (???). We poured the soution in the separatory funnel along with 1 liter of saturated saline water. We let it settlte and drained, it looked as if it was going as planned, the water was colored (but no percipitation). The second time we washed, the water was lighter. The third time it was even lighter, but the hexane/oil was still dark. At this point, after draining, we added 300ml of saline water and 300ml of methanol. This time, a lot of stuff percipitated. Drained again. Washed 5 more times with just saline water. The hexane/oil remained dark, but though we must have done it right already... We purged - the oil was still black. Part two. We redissolved the same oil in pentane/hexane. This time we decided to wash with methanol and saline water every second time. Everytime we added methanol there was a lot of green cream settling to the bottom (of course it was getting less and less, but slightly so). And everytime we washed with only saline water, the water remained rather clear. We must have repeated this at least 10 times. We used around 8 liters of water and 3 liters of methanol. Finally, after 5 hours of washing and waiting for the layers to separate well, we gave up. Purged the pentane/hexane, the oil hasn't changed its color, it was still black. Very interesting. We wonder how we could make this process work for us...

The reason we are trying to yield pristine oil is so we could advise accurate dosage to our patients as the medicine is illegal here and no lab testing is available. GW, could you by any chance assist in us getting in touch with a lab that would accept a sample and cash payment via mail?

What state are you in? If the sample crosses state lines, it ostensibly falls under the aegis of the Feds. For our in house information, we picked up our own gas chromatograph used for $12K. The manufacturer also provides classes on how to use it accurately for about $400. That might be another solution. We were able to justify the cost based on the number of samples we ran and the cost to have a lab run them for us. We still send out samples for others material to test for pesticide, but if you know the history of material that you've grown yourself, you should know what you used. GW

I've asked our chemistry brain trust Pharmer Joe to also share his thoughts, but my first thought is that a warm methanol extraction would be chock full of extra stuff, that as you've noted is difficult and time consuming to remove. Before delving into how to make that process work, may I ask why you've chosen to extract with warm methanol. GW

We tried a third time, it seems that no matter how we approach it, it looks like, the water only washes off the chlorophyll, but other dark colored stuff that methanol pulls initially stay in the hexane along with the goodies. The reasons we use warm methanol are the following... Quick washes resulted in very unsatisfactory yields. We are way over budget and we thought this would be the cheapest way to achieve high yield with one wash. So far, a third of our flowers are processed like this. We are willing to consider changing the solvent, however, even with lab grade methanol at this price (cheapest solvent) we are struggling financially... Time is an additional constraint in that sense. Also, we need to process our entire batch before proceeding further... We are outside the States. We feel the purity of our medicine would be irrelevant considering there are no alternatives due to tyranical laws. We use premium flowers - the quality is certainly there, still, we are hung upon being able to advise accurate dosage. We are considering using ethanol instead and attempting the hexane/water wash again... If it works out (it should) and we go that route, we'll need to preserve half of our flowers in some way, enabling us to store them away securely... so we could process one halve now and rest later. We haven't figured that one yet. We deeply appreciate your support and what you do! Ideas are more than welcome!

The darker colors are typically the C-30 size molecules like anthro cyanin plant pigments, which are also glucosides (plant sugars) and can darken with caramelization. Extracting frozen with subzero alcohol is intended to avoid extracting those molecules, but as you note does reduce yield on the first wash. We address that with two extractions, one higher quality than the other. Either ethanol or methanol have the same issues, though the dielectric constant of methanol at 32.7, is higher than either isopropanol at 17.9 or ethanol at 24.5, so is more prone to extract polar molecules like chlorophyll. As you may know, anything above 15 is considered polar, with water at about 80. Once extracted, the only way I know to remove them is carbon and Bensonite clay filtration, with attendant losses of targeted elements, column chromatography, or fractional distillation yielding somewhere in the neighborhood of 30% center cannabinoid fraction and discarding the balance. You can reduce the pickup of water, water solubles, and other polar elements, by soaking in a non polar solvent, but if you do so at ambient temperatures you will still pick up the non targeted C-30 elements, and is more prone to pick up the ~C-30 non polar plant waxes. Have you considered extracting with something like Pentane, which you can recycle, and winterizing with ethanol? Ostensibly Methanol would do an even better job winterizing, but would require tighter purging standards. FDA lists Hexane and Methanol as Class II solvents, while Ethanol and Pentane are Class III. GW

...However, methanol and ethanol being chemically almost identical, shouldn't differ at all as solvent, do you agree? They differ a lot in price though. What would your recommendation for maximizing the yield be, without doing a warm extraction? It is likely that the warmth is what causes the extraction of the uncleanable stuff... On another note, we are not that sure anymore about complicating the situation further with additional processes. We would be happy enough If we found a way to test the potency of our extract. This is our main concern. The effectiveness of the medicine is what is really important...

The reduced yield is not as much as you might think, once you eliminate the non targeted element pickup. I would suggest chilling both the material and the alcohol to below -18C/0F and doing multiple quick washes, keeping them separate, or switching to a non polar solvent at the same temperatures. GW

There is a SURE fire way to remove the polar substances from your extract, and furthermore purify your compound to either a pure cannabinoid product or nearly pure. I have done this several times and it works but is not activated carbon. The process is known generally as Dry Column Vacuum Chromatograph (DCVC) although the only references I find online relate to the method as used with silica gel as the stationary phase. I use aluminum oxide as the stationary phase and the solvent system I use is water/iso mix. Silica would likely work great but comes with a few problems regarding toxicity when inhaled, plus very tiny percentage will disolve in isopropyl alcohol and end up in our sample. Alumina is basically the grit on sandpaper and is as toxic as sand. I only have one video which only shows one step and how effective the process works just as a pure filtration method rather than seperation. Next month I plan to do a vid from start to finish and present the results in a video to show it. Here is how it works as a general background; You fill a Buchner funnel equipped with the aluminum oxide on top of the frit. About 2-3 inches. You dry load your sample on top of the aluminum oxide column. Then the idea behind DCVC is that a continuos solvent gradient is fed through the system starting with an extremely polar solvent. I use isopropyl alcohol and water as a solvent system because it is inexpensive and much safer from a fire hazard and fume point of view than systems that use hexane. In column chromatography, which takes HOURS for even small samples and simply cannot handle larger samples, a solvent gradient works by passing a solvent through the column that has very little or no ability to disolve the sample and carry it through the stationary phase. With each solvent gradient the column progressively elutes the less polar compounds. Then the person begins to adjust the solvent (called the mobile phase) as he adds it to the column in progressive increments which slowly makes the mobile phase more and more non polar. at a certain point the polarity will become just right for the cannabinoids to pass through the column. Fractions are collected as the process proceeds and the ones identified by the right color (light yellow in this case are saved out and evaporated off. DCVC has a few KEY advantages over this but is substantially the same idea. In DCVC if you start with running a column through (say about 100ml at a time) with 10%iso/90% water and (unlike flash chromatography) pull the entire solvent phase through the column (hence the dry column name), then you will only get the part of your extraction soluable is 10/90% iso/water. This is only needed to be done through about 2-3 inches of alumina and is done under vacuum which is opposite of flash chromatography done under pressure. In Flash Chromatography you NEVER let the column go dry or it fails the column. There are orders of magnittude less solvents used in this process compared with Flash Chromatography. So first you run 10%/90% solvent system. Save the fraction seperately. Then make your next solvent gradient at 15%/85%. Then run that through the column until dry and save it seperately. Repeat this in 5% increments until the system is 100% isopropyl alcohol and you will be left with 20 samples. Most can easily be identified by color as the keeper. Note that my system is based on iso/water because it is simple, effective and extremely inexpensive compared to other systems but without a doubt other systems of solvent used as a gradient thusly would likely be more efficient. I use 5% increments as an example. When you are cleaning up really gunky stuff it might be more practical to use 10% increments. YOU MUST START WITH A SUBSTANTIALLY FILTERED extraction to begin with, so a first column run without alumina and just the fine frit filter of a buchner funnel pulled through is HIGHLY recommended at 100% iso as the solvent. Even then, pulling the product through will take horsepower because there will be so much unwanted material it will tend to plug up. Just keep adding solvent until you can pull it all through without a column in place. I have been tasked with helping a producer in Oregon who extracted with isopropyl alcohol to clean his stuff up as well as several various batches over time from others who extract with SCF extraction methods. Hands down DCVC produces purified and seperated results and generally is useful for the ounce size quantities I process and likely much larger quantities.. I have really messed up extracts through a variety of experiments and this method cleans them up to pristine. It works without question and the only product loss will be the polar compounds which will not pass the alumina column. GW explained that activated carbon can clean up extract and he is right, however i have used it extensively in tests and irregardless of how I extract with it the activated carbon will indeed absorb cannabinoids along with the other material. I have tested and it is nearly a one to one ratio by weight what the carbon absorbs - one gram of carbon will absorb one gram of material from your extract. I have gone to using activated carbon pellets only in the vapor stream of my Vapir One vaporizer which is packed with carbon pellets in the chamber that the vapor passes into prior to the breathing tube. Out of all the hundreds of experiments I have done it is clear to me that DCVC will become the standard for pufiying extractions. It is cheap, highly effective, safe, and uses just a Buchner funnel, vacuum pump, and the vessels to collect them in. Even used as a purely filtration method using 70/30 iso to water ratio the filter will catch most of what you do not want as medicine.

Excellent post, we'll definately look into this in the future, sounds quite interesting. Looking forward to your video! As of now we're... pretty much cornered. I've looked into carbon filtration a lot, but this is the first time someone gave an actual number as to what is lost. Thanks! After giving it some more thought, we settled on halting precessing more bud until we can comfortably do more than one quick wash. Instead, we'll wash our current solution with hexane and water, removing chlorophyll and whatever else goes out with it. Some questions that we have... - Should we 'winterize' before washing or that is not necessary? - How much should we reduce the volume of the methanol? We've observed that when evaporating 1 liter of methanol, hash oil starts forming in the last 50ml. We think reducing it 10 to 1 or 2 should be safe. - Do we really need salt in the water? It always tends to leave traces and crystals in the extract... - Roughly how much ethanol would we need per gram of oil in order to purge the hexane at the end? - Despite the dark color of the end product, what do you reckon is the actual THC concentration?

We did a quick wash and it still came out dark. Hm! Clean and nice smelling, but dark.

Dark green or dark amber? How long a quick wash at what temperature? How old the material? GW

Amber black... 4 months old. Below 10 degrees celsius, outdoors, not frozen... 90 seconds wash. The hexane was much brighter, but when we purged, it came out pretty black.

Four month old trim will be significantly darker than fresh trim. How dry is it? GW

I am curious, could this method work using acetone instead of hexanes? Could I use pure acetone to re-dissolve my oil (as I use acetone to extract it from plant material anyways) and then simply salt water-wash that in a separatory funnel to clean it, then evaporate the acetone on a 140F hot plate? Could I just skip the first step of extracting from the plant material and evaporating that off just to re-dissolve in a solvent, and just go straight to salt water washing after the original extract from the plant material is in the acetone?

I have used acetone in combination with hexane and isopropyl alcohol, as well as used it to great effect in cleaning my hobby lab glass. Acetone is hands down the solvent of choice for cleaning extract and the residue it leaves in a boiling flask. I get acetone from Amazon labelled as "Pure Acetone Nail Polish Remover" by the quart. So I take advantage of a lot of acetone/extract mixes by experimenting with it after I cleaned up my glassware. Isopropyl alcohol always has water in it so that was involved. I have never had any evidence that an acetone/extract mix can be "washed" with water. When in the seperatory funnel in conjunction with hexane and iso I have seen odd seperations happen. Once a distinct yellow layer formed just underneath the hexane. I captured it and it was acetone (smell). I evaporated and purged at high vacuum the yellow layer by itself and the dark hexane layer. The water layer underneath was clear. Only tiny bits of immiscible particules. This is off the question topic, but I will comment I do use acetone to clean up all my glass (I burn extract/solvent inside ceramic dishes so it gets gunky). The resulting black gunk can easily be purified/purged much further until it is deep red (normally). One last thought. I have done a LOT of seperatory funnel work, centrifuge work, filtering, cooking, distillation, and have even oxidized away Volitile components of extract with Hydrogen Peroxide by carefully creating an emulsion of extract at elevated temp with (drop by drop) 35% food grade hydrogen peroxide. The Hydrogen Peroxide treated extract boiled dry of HP is as smooth as silk smoking in a pipe (over fiberglass) but sucks the big weinie in a vaporizor. It has a burnt taste not normally present when vaped above 365F but is sweet below that. With all of the listed items above done as a hobby one thing is very clear - the results are highly variable. What it takes to repeat success is a commitment to observing carefully and closely. Instead of predicting results, it pays to observe the results and learn the "little" things that happen and use "common sense" (taste, touch, smell, look, sound) to figure out how to adjust. Like a chef. Extract can take a VERY long time to decarboxylate. Much longer than is normally attributed to it. So time, temp, state of decarboxylation(therefor boiling point and acidity), residual solvents from extraction, and a littany of other "little" things can and will have a big impact on results. By observing closely it starts get a bit easier to see when an amount of H2O needs to be adjusted, or the temp needs to be changed, or the solvent strategy needs to be adjusted overall. I think this is why there is no simple answer to solvent questions because after all extract itself is solvent heavy (terps) and the ratios of the different solvents will always be a bit different. Have a great New Year!

The light yellow layer mentioned with acetone evaporated into pure thc judging by the slightly sweet chalky flavor and my commitment to solving Einsteins problem with gravity as a constant in any given inertial frame after vaping some.... :)

So, to boil all that down, 1. Just using acetone/salt water is unlikely to work, and 2. I will need a hexane-group solvent or other alcohol to work with acetone/salt water to create various fractional layers. Is this the correct thought process?

My experience with just acetone and water produced nothing useful. As far as the other components the answer is that I have found it to be unrepeatable as to the results. I have seen various layers form but trying to repeat the results is hard. I generally see the best results going from the most non polar solvent (hexane) and proceeding towards the least polar solvent one step at a time in the seperatory funnel. See what happens. There are solvent polarity charts online. I like iso because it falls in just the right niche polarity wise to target the medicine. When you add salt to the mix it is very tough to know how that impacts things. First of all any salt will greatly impact the miscibility of alcohol and water. With iso it actually breaks the azeotrope between water and alcohol, forcing those two into seperate layers by themselves. Even the saturation of the water with salt cannot be predicted very well. I have used salt in my trials but only to get pure isopropyl from rubbing alcohol. Google "salting out water in rubbing alcohol" and there are sites that will explain this. I have not observed salt having any significant impact in my own experiments, but it was cool to see salt crystals form in the extract upon drying. Extract doesnt like salt. Also, when mixing multiple solvents into extract it can be a pain in the rump to purge them out, and forget about recovering the solvents lolz. I strive to recover the $100 per gallon hexane and other spendy solvents but when they are mixed it is just too tough for me to get a clean seperation so usually they get evaporated. Even at the hobby level for me it gets spendy to just evap it all.

When you say acetone/water experience, is this including salt water? I'm led to understand that salt water is about as polar as you can get and should remove chlorophyll, as well as other polar solvent-soluble materials. Just asking as I have not much access to hexane or usable light naphtha, all I have access to are generally acetone, isopropyl alcohol, ethanol alcohol, and water/salt water. What would I do in this case? All help is appreciated, as the chlorophyll is making my medicine give me a headache in place of relieved leg and back pain.

I do not recall any experiments with salt water and acetone. I do not believe that the presence of salt impacts the relationship that water and acetone have. Chlorophyl is not soluble in water. It is carried by it like a boat is not soluble in the stream it. The only thing I have extracted by intense boiling in water is some pinene which is partially miscible in water (no idea about salt water here). I do not extract but from time to time get flower to puff. If your goal is to extract without the chlorophyl then let me suggest that you prepare the leaf as you normally would, except prior to extracting place it in an oven at 300 F until sun baked brown in color. It will be odiferous according to the strain while it bakes but should not smoke or give off much odor when it reaches a dark brown. Bake it at 275F-300F until the cooled product is dark brown and crumbles easily between your fingers. Take a puff and it will knock your socks off lolz. Bigger chunks bake at 275F instead of 300F to avoid burning. I even crumble it finely and whiff it like snuff. Zero nasal irritation and the relief sets in MUCH faster than edible products. This presumes that your goal is to remove the chlorophyl only. It will remove nearly all the odor and "terpene" rush you get too, but the medicine that I am after is THC and that is joyfully intact and as decarboxylated as it can get without further time and heat. From your post I assume you are also after THC. THC is very hard to get to volitize/boil but the rest of the gunk can be removed/destroyed by heat. When heat goes above about 350F and held there then some bad odors and flavors develop in all the strains I have tested this way. I rarely use flower because I do not extract, but this reply is in hopes of helping you out.

Acetone is polar with a dielectric index of about 20.7 and is miscible in all proportions with water. Hexanes dielectric index is closer to 1.3 and for all practical purposes, isn't miscible, so I thinking not. GW

Did anybody realize the pictures show this person with the dab out on the sidewalk with a vacuum or blower... dude that shit has so much dust and dirt in it you are an idiot if you smoke that shit and I'm sorry for the people you sell it to. If you even leave a small amount uncovered in a closed room for a night it will collect dust. Get the picture?

I leave my refined extract in an uncovered petri dish in my home. Heck, I even get little gnats that land in it. An eyelash or two, inevitably some hair, and always some dust. It turns out that I don't mind or notice a bit. It occurs to me that marijuanna is often grown outdoors as well. As a matter of fact, prior to winterizing I intentionally add dust or sand of some sort to the disolved mix which increases wax removal orders of magnitude better that filtered extract/solvent. Like a boiling chip for boiling, the dust gives the waxes something to precipitate onto. In meterology this is called "condensation particulate" and dust was once added to clouds in an attempt to seed the rain. The real question, putting aside your personal attack, is this; "What data do you have that suggests the dust or debris that might collect in your extract is harmful to human health vs. an advantage to human health? What evidence can you provide that suggests the lungs are not capable of dealing with this? Without testing you cannot know these answers. The extract shown certainly contains terpenes. The MSDS sheets regarding the inhaling of terpenes says do not do it, yet people do it all the time and many believe it benefits them. Do you honestly believe the extracts you obtain do not have dust, eyelashes, bug parts, and every other thing that floats around in our atmosphere? Because brother, I have found when refining dispensary extracts; fitting grease, eye lashes, tiny flies, unidentified dust bits and have added on accident some of ose those things myself. Last month I dropped a hot beaker I was refining on my hardwood floor. I scraped it up and vaped it and honestly couldn't tell the difference at all. Floor dust,doggie hairs, and (yuuuuck) I walk barefoot on my floors...and did not get the cooties, just a little athletes mouth. Do you have data that shows ordinary dust found in every single food product, tobacco, and marijuanna leaf to be more hazardous to human health than the MSDS shows for either pinene or limonene? Have you personally smoked or vaped extract with dust in it? I have. All the time because I don't get overly anal retentive about a drug that grows out of the dirt and dust to begin with, and I leave my refined oil, nearly pure thc and runny at room temp next to my chair. I notice lint in it. I vape it anyway lolz. Besides name calling your post has little data to support your claim that environmental elements found in normal day to day living are hazardous beyond the hazards already present in the product. The far more hazardous thing (verifiable with medical data) to do from a healhwise perspective is to kiss another human or share a joint or pipe. Are people also idiots who do that too? Maybe you could get patent on dust free extract and sell it and get rich - heck if you get rich enough even you might be President some day. Semper Fi Brother.

correction - "condensation nuclei" (it has been decades since my meterology courses in professional pilot school)

I'm pretty sure I get the picture, but question whether you do or not brother/dude/man, as well as your intent in wording your input. Did you actually read the article, or just look at the purdy pictures? A couple of points, and as the first seems to be based on an ASSumption on your part, I will give you the benefit of the doubt and infer it is from ignorance, as opposed to malice. You seem to be blissfully unaware that we don't sell any concentrates to anyone, period. We give away free process information. Secondly, this polishing article on ashtray reclaim was simply to make a point, not suggest a source of dabbing concentrates. Repeating the last two paragraphs of the article for your benefit: "While the black color was gone, slight ashtray undertones could still be tasted, so further refining was necessary with activated charcoal, but we will cover that as a separate subject. I am not suggesting this process for reclaiming ashtrays, but simply to make a point." GW PS: On the valid subject of dust control, a cheese cloth covering will aid in dust control, as will operating in low dust conditions. Here is a link to a DIY evaporator that addresses that issue. https://skunkpharmresearch.com/evaporator-chamber/

For some reason, my alcohol, Hexane and water mixture does not bringing chlorophyll down. After mixing, water goes down, but chlorophyll stays with top layer, with hexane. I use HPLC greate 99% hexane. It's not n, but it is HPLC. Any ideas?

I have done many experiments with hexane, acetone, alcohol, and ethyle acetate as well as water. Hexane has been unpredictable for me in the seperatory funnel in terms of repeatable results. Once, a mix of hexane and acetone and water in my experiment formed a layer underneath the hexane. The hexane layer was dark but the layer underneath was light yellow... At the time I did not think anything of the yellow layer but save everything to study later. The light yellow fluid evaporated down, and then I purged. It was nearly pure THC, sweet chalky flavor and delicious. I tried many times to repeat the process but couldn't get the same thing to happen again. My hunch is that environmental factors like ambient temp, the times of reaction involved, and maybe even a dirty seperatory funnel may have been factors I could not duplicate, and the fraction that I described was only a small percentage of the THC I recovered from the hexane layer so I did not try more than a few times to repeat the idea.

Plus remember that "Hexane" is not the name of a particular chemical but names a group of chemicals with substantially the same characteristics.

Bottom line, all this hexane method. does not really works, am I understand it morrect?

*correct

It is not correct to say that using hexane is not highly effective at recovering thc from any form of extract. Hexane grabs all of the medicine for sure, but the real point of this article is to show one posssible use of it. One article cannot cover the multitude of variability encountered in our pursuit. However the general process is a great tool if you realize that this is not a simple cookbook recipe. The reason is that with a cookbook recipe we can be certain when we add flour, that the flour is as pure as it gets. Same with the eggs and so forth. When I helped a friend yesterday to clean up RSO into THC oil (REALLY messy lolz), we started with a hexane/water wash. At first there was no visible seperation visible which should not be possible, right? Hexane and water do not mix. I reasoned that the RSO had been ethanol extracted soxhlet style, so guess that ethanol was present. I doubled the hexane from 100ml to 200ml total and voila! Seperation with a definate emulsion layer between. Repeated washes from then on got a huge amount of the green out and fats and so forth. I think of water and hexane as two extremes - most polar I have and least. The closer I get to using the extremes the more variable the results will be. This doesnt mean it isn't effective it just means that more understanding is gained with each effort. Patient thinking is key.

Tattered old wolf, Two Dawns here Bro, I have a project that you need to be involved in ! No chemicals involved ! But it's dark ! I think together we can make it right . Are you up for a challenge ? You will have to come down to Nor Call for a little while Two Dawgs On Dec 13, 2016 8:46 AM, "Skunk Pharm Research LLC" wrote: > redturtle984 commented: "It is not correct to say that using hexane is not > highly effective at recovering thc from any form of extract. Hexane grabs > all of the medicine for sure, but the real point of this article is to show > one posssible use of it. One article cannot cover the m" >

I am sure about others, but for me Hexane is very expensive. So, can I evaporate hexane out, after polishing, for reuse purposes?

Hexane is as easily recovered as Ethanol, using the same techniques. GW

I need help!!********* How or can I at all remove neem oil from my bho? I see stuff on Google in this thread but I can't find it. I have tons of material sprayed with anzamax and I need to know how to remove it. I can't waste this material. Is it safe to smoke?

I have found the following site to be a good source on information on this sort of thing. I surfed the links and discovered that the active ingrediant in neem oil is azadirachtin. Clarified neem oil is food stuff - lipids and fats. Since you are posting on a marijuanna site I assumed of course your concern was neem oil as an insecticide which contains the naturally occuring azadirachtin. Neem oil with azadirachtin has been given to children orally in the Far East for various remedies for a very long time. The report states that at oral doses of 5 - 10 ml (extract is almost precisely 1 gram per ml) that some children begin to display nausea and other icky feelings. yuck. I learned you cannot cook it out. It has extremely low volitility. It appears however that azadirachtin by itself is hydrobolic and miscible in water. Clarified neem oil is said to be hydrophobic. It is the azadirachtine that is reported to have the strong odor. Based on this, my "go to" method of removing the irritant azadirachtin would be to attempt to disolve it in water. Rubbing alcohol that I recomend trying would be a 70% isopropyl alcohol to 30% water ratio. Dissolve the entire batch in just enough rubbing alcohol to make it dissolve. Place that dissolved mixture in front of a fan in an open container so the fan ripples the water. As the mix evaporates off there is typically a milky white seperation of two immiscible layers that develop. Continue the evaporation until complete. The alcohol will disolve into the hydrophobic components of the extract and neem oil present and give the water (which forms an azeotrope with the alcohol) a way to be presented to the hydrobolic component like azadirachtin and alpha pinene. You will be able to easily identify the water miscible (hydrobolic) components versus the oil that we seek. Removal with a pipette or eyedropper. I often remove the water gunk by tossing the dish into my freezer. It is a frost free freezer. This means it is designed to sublimate frozen water into water vapor, skipping the liquid phase. I have my freezer set to max and my thermometer show a temp just under -10 C. The water components freeze and the freezer dries it. The oil becomes hard and taking the dish out, the water left melts first abd pours off easily. Rinse in hot water until cleans. The oil will stick to the dish. Finish by heating the oil on low until the boiling and odor of isopropyl alcohol stops. I immediately place the dish used while still very hot into my vacuum chamber and pull it down until the gauge shows 30" or the pump starts complaining lolz. This will yank out the rest of the isopropyl alcohol and nab some water bubble too likely. It will pop under vacuum when those water pocket burst under the oil so a cover is necessary on the dish. I have zero experience with neem or azadirachtin. I have much experience clarifying extracts in a number of ways. What I just typed is how I would attempt it. Given the extremely low toxicity of the product to humans I personally would not hesitate to vape the oil after I did the above procedure. Unless of course you vaped first and an alien worm with horrible fangs jumped out of your gut immediately after you started hacking violently. I that case, I would switch to ethyl acetate and try again...

oops, here is the site https://pubchem.ncbi.nlm.nih.gov/compound/5281303#section=Top

Hi All, I am having some trouble polishing my extracts with Hexane. I am trying to polish my ISO with hexane. My ISO process is done after I have done other primary extractions, so I am extracting whatever is remaining in the plant. ISO wash done at room temperature, overnight. The resulting RSO concentrate is a dark harsh wax/tar (50% THC). In my attempts to polish with hexane I have done the following: Protocol: Winterize the RSO oil in ethanol and filter out waxes, then distill off the ethanol. Following this I dissolve the winterized oil in n-hexane (Ratio 20 g ISO to 100 ml hexane). Then I add the ISO/hexane solution + 100 ml water to a separatory funnel, I shake and let settle. Bleed off bottom layer (or what I can semi distinguish as the aqueous phase) and replace with clean water. The issues I am having is that I do not get a distinct phase separation between the water, emulsion and hexane layers. You can see a color gradient between the water and the hexane layer but it is impossible to tell where one starts and one ends. Also I have bled off some of the bottom layer and replaced with fresh water, even after 10 additions of fresh water I notice no color change in the system it is still dark and nasty. I have also tried using salt water, also isopropyl instead of water and a blend of isopropyl and water as the aqueous phase. What am I doing wrong, can someone please help!

I have tested a multitude of solvent/lab techniques to accomplish what you are attempting. I have employed many solvents, including hexane, ethyl acetate, isopropyl alcohol, acetone, light patroleum ether, water, and a litany of polar household cleaners. Here is what I would do with a glob of black tar as you describe. I cannot know if this would work for you because every parameter often gets adjusted "on the fly" as I do my own. This is because every extraction can be different. This method is as safe as any method and I personally consume 100% of all extracts I process. This attests to safety. without seeing the stuff.... 1) It is IMPERATIVE that all traces of hexane or any other solvent be removed. Smell testing is important. Any solvent placed into an oven, as in step 2 will ignite as soon as the vapor reaches its flash point. It will reach that point...I nearly soiled myself once learning about oven doors exploding to the open position... 2) I would transfer what you desribe to an oven safe piece of glass or stainless steel and turn the oven to 275 F. Place the goop into the oven with lid off. Cook at 275 F for one long nap, or until any visible signs of smoke or vapor cease. Light smoking will occur if particulate is present - the goop oil will stop smoking though. Most smokes very little. 3) After nap, I would vape some good oil, then, after cooling I would disolve the goop from the oven in a mix of 70% isopropyl alcohol/30% water (rubbing alcohol). 4) I would pass this mix into 20 ml centrifuge tubes through a lab filter. Filter is "slow" rated for fine crystals. Prior to centrifuge I would place the tubes in my freezer which is set to lowest temp. My lab thermometer goes down to -10 C and it is colder than that. Another vape hit. Another nap. 5) Spin the tubes at 4000 rpm for 20-30 minutes. Pour off mix into seperatory funnel. Really icky goop in bottom of centrifuge tubes actually makes a good skin lotion that immediately softens my skin. 6) The seperatory will reveal at least two layers and in the first stage sometimes a third. Begin adding COLD water in a pippette, about 1ml-5ml at a time to the seperatory funnel. The water will drop through the iso layer and into the bottom layer at first, oulling polar compounds with it. I might have to drain the bottom layer off a frw times as I do this. Adding salt is not productive at all because it iterferes with the water in a way that prevents the water from pulling pinene out of the goop. The water layer will be milk to chalk white. If it is not chalk white, evaporate and oil will be recoverable. Eventually the oil wil seperate from the alcohol in the seperatory funnel as fresh water is added. There are about a hundred variables that might present themselves with your extraction, but the general prodedure above has been employed by myself for a long time. A personal disclaimer; I involve one more step that requires flame to volitize the remaining hydrocarbons out of the extract. I have not included the full details as I have been asked not to discuss this in this site for safety reasons. The final polish essentially burns away the residues of solvents present naturally, like pinene, or the ones I use. I have a fireplace at home, but normally do this on my stove top and I agree with Skunkpharm that a burn danger does exist. I accept the danger in my own kitchen and simplyhave not found a way to finalize the polish without it. Here is a short video of the finished product with no solvents being shown burned off. I hope all this helps. https://vimeo.com/181396690

yo bro! K.I.S.S!

First off ,freeze your alcohol and plant material separately for a good 24 hours ( never wash at room temperature! and put your freezer at the coldest temperature ) Next step is to add your alcohol to your plant material , buds, sugar leaf whatever you are using and place back into the freezer for another 24 hours , during this time shake,or stir occasionally.Step 2: use cheesecloth or bleached free fabric to filter your plant material& alcohol, once this is done place alcohol oil mix back into freezer and discard plant material. Let it sit back into the freezer for another 2-3 hours so sediments will settle and plant waxes, lipids and chlorophyll will coagulate. Step 3: have 6-8 filters , jars &funnels ready, i usually have my alcohol oil mix into 2 liters glass mason jars so i can filter as quick as possible so the waxes, chlorophyll etc..does not dissolve back into the alcohol ( which will happen if the alcohol starts to reach room temperature). Put back into freezer for a couple of hours and repeat 2 more times so you have a good clean product. You can also place out in the sunlight for a few hours to breakdown more chlorophyll before placing into the freezer for the last time. i will guarantee you will end up with a nice amber color oil high quality oil.( depending on your material and type of alcohol you use). DISCLAIMER; I do not condone using this method where as any extracting methods are consider dangerous.

You've picked yourself a challenge brother! I've been waiting for Pharmer Joe to return from over the hill and far away consulting, because he's our brain trust on salvaging babies out of their bath waters, but will pass on a couple thoughts in the interim. The first relates to the adage that you can't make chicken salad out of chicken manure, so the best you can hope for is to make the best out of whatcha got. ISO readily dissolves and holds chlorophyll as a solute, as well as the anthro cyanin color pigments, water, and water solubles. We typically freeze everything and do a subzero quick wash to avoid as much of them as possible, but soaking overnight at ambient, is pretty much guaranteed to extract them all. Especially if the material is preconditioned by some of the other extraction methods. Since you are already involving Hexane in the formula, why not extract with it in the first place? You can soak over night without picking up chlorophyll and extremely low water and water soluble extraction. After removing the hexane, you can winterize with Ethanol to remove the plant waxes, and help purge the remaining hexane. You can remove the C-30 size molecules like the color pigments, using column chromatography, or short path distillation, but I will leave that up to Pharmer Joe, who took his organic chemistry classes this century and is our brain trust on those subjects. GW

Hey Skunkpharm, this post, while interesting, is contradictory and confusing: first you say: "...After it has separated, bleed off the water and emulsion layer...), and then: "...After carefully bleeding off the bottom layer of water, we continue to replace it and repeat the wash process of both the emulsion layer and the hexane solution, until the emulsion layer disappears..." Which is it, and why? Thanks for your efforts.

Hey skunkpharm! I have recently made nearly pure thca powder in my cls by accident. it is 94.5% thca and I was trying to figure out how I may clean it further. Since purity is already so high and it is in crystalline form this should be relatively easy given the correct procedure. I have tried this saline/hexane wash before on some oil few years ago. Was thinking this may be a good experiment but I think the main impurity is oily so would probably migrate to the hexane layer. Any tips or suggestions would be great! Thank you! !

Here is one techique that can remove any impurities soluable in water - specifically alpha pinene. In the video I am processing extract into a more refined product which I vape happily, and the video starts as the centrifuge of the isopropyl alcohol and extract mix are finish slinning the waxes out. I remove the liquid with a vac chamber but how do hou keep that sample from decarbing? My extract begins to decarb noticably with very little heat. At room temp it is constantly decarbing judging by the experiments with time lapse photos up close to see it. I would love to see photos! The process you see in the bid was copied from an old patent on removing alpha pinene from citrus oil meant for human consumption. In that patent they mention the same kind of azeotropic behavior shown here when using hexane and water as well as the primary patent application that soecified isopropyl alcohol at 91%. The video demonstrates my modification in that I force a separation at a 50% mix of water to iso. There are details to this too tme consummkng but I can tell you this process has been used by me for some time. It works for cleaning extract up. Hope it helps. https://vimeo.com/172564716

I really like what you guys are doing. In my humble opinion, you are doing it absolutely right. I'm pretty much retired these days ... maybe considering a bit of a comeback ... who knows? If I can ever help in any way, let me know. D. Gold

I got your book. Loved the question part at the bavk also, very educational. Would have a question for you.

The web says PAM is water soluable. This new vid I made this morning boils the extract and also makes the water a bit murky. Does this help? https://vimeo.com/166726729

I'm wondering if it will be possible to remove pam cooking spray from a run of bho. The Pam was used to lubricate the blades on an automatic trimmer and contaminated the trim used for this particular extraction. If anyone has any knowledge of how this problem can be fixed, it would be greatly appreciated.

I have a half pound of green wax, Maui Waui, it's orange when looked at in the light. I think it was moonshine derived but not finished. I have some Everclear. I wanted to know the best way to clean the 8 oz of green wax. Can I put it in a jar of Eveclear in the sun for 2-3 hours, then rubberband 2-3 coffee filters on the jar and filter out the green Everclear? Should I use non ionized salt? Also wanted to polish BHO with Everclear. Will this work? What is the best way? May do it with an ounce or a pound, advice on both quanties would be great.

Do you have an email graywolf? I'm looking for an older link you posted to terps you bought off line.

I've been fighting with this process and I'm trying to figure out exactly what I'm doing wrong or still need to do. I started with a bunch of old green oil that was made with older auto trim material so it picked up a ton of chlorophyll. I saturated the oil in ethanol, ran it through a vacuum assisted filter using a watman 1 filter, pulled out a ton of gunk, then dumped hexane and saturated salt water into the seperatory funnel as instructed, poured out the water and ethanol mixture, using the funnel, saving the hexane and terpine mixture that was the dark color on top, just like the picutres, and I have been running salt water though allllll day and the color isn't getting any lighter. I wish I could post pictures, but what it looks like, is a perfectly clear big thick layer on bottom (of salt water) and a gunky, kinda fatty layer in the middle (I'm assuming this is the emulsion layer though I'm not entirely sure what that means because it wasn't explained) and then the dark hexane mixture up top. I strain off the salt water and gunky middle layer. I saw that middle layer getting thinner and thinner and harder to see each time, as I felt like I got more out of it. To try and make that layer easier to see and remove I have tried heating up the salt water, and cooling it down. It seems like the colder I got the salt water, the more of that gunk I was able to pull out each time. But I've run a ton of washes through it and I'm still getting a gunk layer (only when cold) but the color of the hexane mixture isn't getting lighter or more yellow at all. Any feedback would be hugely appreciated as I have about 3 and a half liters of extremely concentrated oil dissolved in ethanol that I'd like to keep running. Just feel like I may be doing something wrong....

There are limits to what you can wash out with brine and if you have a lot of chlorophyll, it isn’t really water soluble, but washes away in micelles, so it doesn’t come out easily. Anthrocyanin plant pigments are one of the prime culprits, and are about a ~C-30 molecule, in the same range as chlorophyll and plant waxes. Easiest to avoid extracting them in the first place by using subzero extraction techniques, but iff’n you are stuck with a bunch, you aren’t dead in the water. Pharmer Joe has successfully removed them using column chromatography, and with a Kugelrohr, Pharmgold Terp Trommel molecular still, as well as filtering through mixes of rare earths and clays. I just scanned through the site and it doesn’t look like Joe ever published his chromatography results, so I’ll publish something using a picture of his samples, to explain the issues with color and other non-targeted elements. GW

So am I missing it or did you not publish something using pictures of his samples?

Hey did you ever figure it out?

So I am working on extracting some lovely compounds from plant matter... only problem is I left it in alcohol for several days longer than expected. At this point, I have concentrated it down to a very potent, yet very dark matter. I have redissolved it into fresh ISO and have it in the freezer separating from a saline water infusion. My question here is can I use this method above to further remove the chlorophyl with white gas.. specifically Coleman camp fuel? I know it has other elements in it... but will these evaporate over time with winterization, or is it too dangerous to even try this method?

I recommend against using Coleman camp fuel, because of what is in it, and how much harder it is to purge than just Pentane or even Hexane. Some even contains a dye. Coleman's MSDS identifies it as light naphtha with a boiling point above 100F, so check out a typical light naphtha MSDS also attached. http://www.coleman.com/uploadedFiles/Content/Customer_Support/Safety/lantern.pdf http://www.collectioncare.org/MSDS/naphthamsds.pdf GW

Question regarding Ethanol purging: If an extraction auto-budders on me, I tend to use an ethanol wash with Klean Xtract. My first step is adding roughly 60g of BHO to around 24 oz of Klean Xtract. Second, I let the substance dissolve around 80 degrees, with some agitation. Once dissolved, I place the mixture in a 0 degree freezer for 48 - 72 hours. After the fats and waxes have separated, I use a Whatman #1 Lab filter, accompanied with an unbleached coffee filter. and a vacuum assisted buchner funnel. Once the fats are extracted an separated, I let the extracted solvent evaporate around 90-95 degrees fahrenheit. Once the extraction has a syrupy consistency, I use a vacuum chamber to purge off the remaining alcohol, and this is where things get complicated. I notice the first pull down to -29.5Hg lets the extraction boil off very rapidly, then slows to a crawl. After I notice no bubbles forming (15min - 1 hr), I pressurize the chamber and pull a second purge. One thing I notice is it takes quite a long time for bubbling to become visible. After a day or 2 in the oven (around 95 degrees F) I consider it evaporated. When smoked or vaporized it has a wonderful taste, and also looks beautiful. I just cannot manage to get it to become a shatter consistency. Its also a thick honey texture, which is kind of a pain to work with. If I can be told a more effective way to evaporate the Ethanol, or even better a method of producing a hard shatter consistency with strictly ethanol? It would be a huge help to my career, thanks! QUICK READ: How can one obtain a shatter consistency with an ethanol wash/winterize, if not what is the best way to evaporate Ethanol? Is it possible to reverse the auto buddering process?

The question assumes a lot. Shatter consistency is caused imo by impurities in the extract. How do I know? I have successfully purged to nearly pure so many grams of extract that my cupboards are overflowing with tiny plastic pucks and their lids lolz - AND I cleaned them out already!!! hehe. Here is how to easily purge the extract of all sorts of nasty stuff you didn't know was in there.... This process assumes from personal experience two things: 1) that a vaporizer, no matter the style, does not convert THC-A to the THC-YUMMY form that the body can use to speak with the animals and, 2) THC does not significantly break down with the application of extreme heat so long as oxygen to oxidize the THC is present. I am absolutely certain, from personal experience that these two things are true. Here is a very short version of what I do to make my Pristine Oregon Pharmers World Class extract into a product that is vaguely fruity, makes DENSE foggy vapor, has zero, nil, no, and absolutely zed respiratory irritation even when held in a long time. And the resulting mind change from this product is absolutely the most premium experience a regular extract user can enjoy. Step One: SAFETY FIRST - remember, if you build a fire for a man you will keep him warm for a day, if you set that man on fire, he will be warm the rest of his life... Step Two: I load my raw extract into a ceramic cigarette. I stuff it in there real tight. I use a rod in the lip end to plug the cigarette and to hold it comforatbly from the heat. Step Three: My trusty lighter is held just off the end of the cigarette and both are held over a smooth cool glass surface. BE CAREFUL Step Four: I light the lighter and slowly allow the exrtact to run into the flame and drip down through the flame onto the glass. Boy Howdy!!!! the first trip through the flame it is quite a light show. It sputters and pops and crackles something fierce. After it is lit I turn the cigarette up so anything fluid drips out and I let the icky part flame off. The flame gets intense. The smoke is horrible so I don't believe any THC is left at this point. It has all dropped down to the glass. Step Five: repeats several times. I use a metal pick to lift the extract up off the glass and drip it down through the flame several times until it no longer sputters and pops when I do so. Generally the whole process is about 15 minutes or less. What is left of the plate is black, and runny at room temp. I noted above how it inhales. I am positively certain that the product is fully decarboxylated and my oh my is it potent. It runs smooth and pure at this point and doesn't snicker or pop when dropped through a flame (Bix). I have heated extract in the oven at 300 F in a glass container. It takes a LONG time for the decarboxylation to occur doing this judging visually. But, vaping the extract baked liked this turned me on to the fact I wasn't inhaling fully converted THC. The mind change is unmistakable. I handle the oil using a medicine feeder for rodents I got at Petco. It's a syringe that wont hurt a mouse lolz! A rice grain size vaped into my Vapir 1 bag fills the bag twice with a dense foggy cool sweet orgasmic vapor. I better go...the Vapir is getting cold. Remember, FINISH YOUR EXTRACT!!!! CHILDREN IN INDIA ARE GOING WITHOUT!!!

so long as oxygen isn't present (typo)

Can neem oil be removed from butane extracted bho?

How can I clean up my wax if I bought it from a friend and it looks like poop soup and very hard to work with?

dissolve it in rubbing alcohol completely. Let the mix settle for a few minutes then stir in non-iodized salt so it is a layer about a 1/4 thick or so on the bottom of the vessel (small tube or jar). Set aside and come back in 1/2 hour. The mix will clearly seperate into multiple layers. The layer that is amber and clear is the good stuff. The rest feels toxic when inhaled. I use a medicine dropper to remove the amber layer. Use a fan to evaporate off the alcohol (about 15 minutes) then place the almost dry extract on some cooking paper. Place this paper on a preheated cookie sheet (250F) and it will bubble briskly for several minutes. Remove when brisk bubbling is over. Place in freezer. Poof - extremely concentrated THC that vapes with zero irritation in the lungs and no hacking choking and so forth and.....it is the most potent form I have used. Extremely potent this way, likely owing to the possibility of DEEP lung inhalations without coughing. Good luck.

Are you using 70% ISO, thus taking advantage of the containment of water to dissolve the salt? ...or not?

70% iso and 30% water is what the label says. Rubbing alcohol is the label. Deadly poison if you drink it. A couple bucks at the Chevron mart. Rubbing alcohol cannot be separated by distillation - the water and alcohol won't separate that way. It can however, be fractionalized by adding salt. The separation is obvious to a sighted person. There is a very small amount of salt left in the extract, because when I chew it the salt is detectable. Pleasant tasting frankly. Extract washed this way dispenses with the mediciney "Metholatum" taste. No matter the strain it always seems to taste fruity and pleasant. Salting alcohol is well known. Google has tons of stuff on it. What is not known is how effectively the separation of the extract components are when the extract is disolved in rubbing alcohol prior to salting it. The different chemical weights and properties seem to make them separate into distinct layers as the iso/water mix resolve into different layers (water on bottom). The waxes left over, by the way, work GREAT as a skin softener. They melt right in and are very pleasant to the touch, though they are highly irritating to the eyeball so washing hands is a good idea after rubbing it in. Finally, if you really want to see the separation, obtain a glass tube. Test tubes would work but I got mine at Petco down the street. The section for Gerbils and Hamsters has syring type eyedroppers for feeding medicine and test tube size tubes with rubber stoppers and a hole in them for watering the rodents. less than two busks and the have a clip to hold them vertically. Perfect for separations like this.

Could I potentially do this to a fresh extract as well to wash for chlorophyll so I don't have to work with hexane at all? I'm highly allergic to fossil fuel based solvents (makes me break out from eczema, hereditary from my father), and am using this for a food grade extraction so salt in the mix is not an issue. I'm also allergic to chlorophyll so I'm trying to kill two birds with one stone and stick to alcohols which I react much better to. I'd add 3 parts distilled water to 7 parts Isopropanol from my material wash and just follow the same process for salting the water out once i'm done, repeating until I have to use the refractory index of the two fluids to tell them apart and look for that visible layer yea?

I'm curious about the answer also.

I will post another way to "clean up" goopy wax or shatter. I already posted a very simple way to do this, however I am a stoner. This means my ability to be patient and wait only exist when I am stoned....lolz. So waiting for the rubbing alcohol to evaporate or not having any rubbing alcohol present, I will tell you another sure fire way to "clean up" small amounts of wax and shatter; I use a small glass square that I took out of a picture frame. The picture was my ex-spouse. I lit the picture on fire and warmed myself. This step isn't essential, but it did seem to help. I take the glass which is cool to the touch and dab my goop (wax or shatter or scrapings) onto the glass which is held horizontal. Then I use either a battery power hot iron for wood burning craft, or a light to puddle the goop with heat so it is completely liquid and bubbling. Then I quickly turn the glass to vertical, and the part of the puddle that is "runniest" flows down a short distance as a "drip". When held to the light the drip part of what remains is clear and amber. The "splat" part that held to the cool glass and did not run down when tipped is almost opaque and looks grainy like wax in a honey jar at the top. The bottom drip is scraped off and vaped - nearly zero irritation and yum yum yummy. Vaping the "splat" is an experience in hacking and choking. I have found that when holding a flame to bubble the puddle the bubbles will mostly stop after short time and the puddle "settles down". Experience has proven to me that this is the moment to stop heating it and put turn it up for the drip to form. Otherwise the drip is a bit milky with wax and harsh. The amber, by the way, becomes pretty tough in consistency. I better wrap it up now....I have a bag that is just waiting for some vapor. Sweet amber dreams.

What would happen if you put an oil extract through a reverse osmosis system? Thanks for your time

You end up with Sisomso oil. ;)

Reverse Osmosis is sort of like pumping a solution through a blotter paper straw. The flow keeps the filter membrane swept clean as it passes through, so the flow concentrates and the clean stuff weeps through to the outside. Simple filtration, even at that micron level, takes stuff out of suspension, but not out of solution. Micro filtration is the same thing, but uses a larger pore size, so might not clog as fast and I've installed industrial plate and frame micro-filtration plants down to 0.2 microns. They worked well for our purpose, and we cleaned them when they clogged, by alternating a hot aqueous NaOH solution and a HNO3 solution, to break organic bonds. GW

Hi I am having a great deal of difficulty acquiring non-denatured alcohol for the scrubbing of the hexane, what other solvents can be used to get rid of the last of the hexane, or is using denatured alcohol (denatured with MEK boiling point 79.6 C) ok? Thanks

You can make nearly pure iso propyl alcohol for pennies by salting down rubbing alcohol. I have done this many times. The water and alcohol separate and with care there will be no salt in the iso. I suggest if you try to read up on it first. My results came by googling "salting down alcohol". It is interesting to note that rubbing alcohol, being a mix of pure water and iso, cannot be fractionalized through evaporation. By googling, I learned (contrary to my vast knowledge beforehand lolz) that some things, like iso and water, cannot be separated by distillation. Salting down is a method of fractionalization for this solution. I also note that salt, iso, water, oxygen, heat, cold, sand, dust, and aspirin all share a common trait; in sufficient quantities they will all kill us. Perhaps tongue in cheek, but I am more or less making fun of the paranoia we have in using chemicals with tech names, when in fact we ourselves are just a bunch of chemicals. For iso, it takes (I am told) 15 grams of iso to really cause hurt most sane persons wouldn't want. This is VASTLY more than our senses will detect, and is also VASTLY more than most bodies will ingest before violently regurgitating. I do not take lightly the handling of chemicals, but I will not either toss away opportunity to improve my existence because of fear. No fear. No shame. We were right all along. Rock on Oregon. Go Ducks!

Thanks for the reply, but when I mentioned 'denatured alcohol' I meant ethanol, not IPA, incidentally, I got 99.9% IPA off ebay, nice and easy, nice and cheap. Ethanol however, is a very different story, being as I am in the UK and Everclear is not on sale here (nor do we have a limey equivalent).