Quick Wash Ethanol, also know as QWET is one of the techniques commonly employed to extract oil from cannabis.

Here is skunk pharm’s QWET formula to produce an absolute using a 3 minute quick wash.

As most of our extracted oil goes into oral meds, we also decarboxylate ours. This process is based on the 252F curve shown in the attached graph.

The first question is why use a quick wash technique to extract the resins, instead of long soaks to extract as much resin as possible, or just boiling the material in alcohol to get the greatest amount of extracted material?

The answer to that is that because alcohol is a polar solvent that is soluble in water, the latter two techniques also extract the water solubles like chlorophyll and plant alkaloids, as well as the plant waxes and vegetable oil.

Even quick wash does to a lesser degree, but the added steps that we include here minimize pickup even further and we take additional steps to remove the impurities that we do pick up.

The first wash will usually extract 75 to 80%, leaving the balance for the second. The second extraction will be more sedative and less heady. If you use a hand microscope, you can easily see when the trichome heads are gone and the stalks look like wet fur.

You can also use the material for other extraction methods after it has dried. I have subsequently used BHO after the first QWET wash that yielded 16% oil by weight, and got 5% more pristine oil, or about 21.6% total.

A cured material QWET absolute is one of the most aromatic and tasty of the extraction methods and consistently gets high raves from the volunteer test panels, as well as the patients and students. Both from an efficacy, as well as a flavor standpoint.

The first step in the process is to get as much water as possible out of the material.

A fresh material QWET is possible, but this procedure is specifically for material that has been cured to about 15% water content, which is typical of cured material. 15% is a lot of water and the alcohol already has 5% in it, so unless we reduce the water content even further, we will be extracting a lot of water solubles.

We dry our cured material even further by spreading it on a cookie sheet and baking it in a 200F oven until just frangible when rolled between the finger and thumb.

If the material is prime bud, we break it up loosely by hand and extract from trim as is.

We never, ever, use a blender or coffee grinder to reduce material, because it produces a lot of ultra fine powder that makes it through conventional filters.

Next, while it is still warm, we seal the material in a jar, which we place in the freezer to tie up any remaining water as ice. We also put the 190 proof grain alcohol in the freezer.

When they have both stabilized at about 0ºF, pour the alcohol into the jar of plant material, so that it is at least an inch above the material, and shake it gently a few times to make sure everything is wet. Place back in the freezer.

Remove and gently shake twice more until the material has soaked for 3 minutes, and then dump it through a wire strainer to drain quickly. We set the strainer atop a fine mesh stainless French Chinoise strainer, or a stainless coffee filter can be used. Don't press on the material to extract more, but just let it drain.

Set the material aside to dry for a second extraction. We usually keep the two extractions separate, as they will have different properties, as does the third extraction using water.

After refreezing, the second extraction is done like the first, but when it is drained this time, the material is returned to the jar, which is then refilled with water and set aside.

Filter the extracted liquid.

We use either a #1 lab filter with a vacuum assist, or a simple coffee filter to further filter the solution, depending on the quantity we are processing.

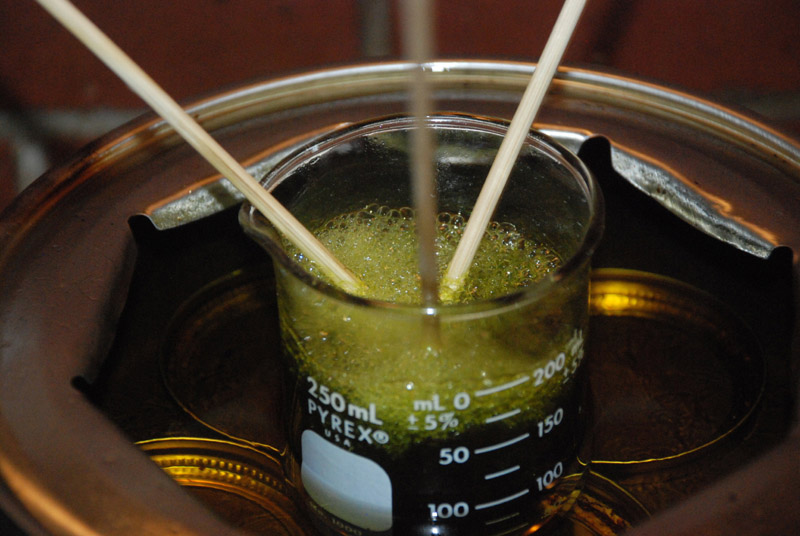

Place that filtered liquid in a suitable container and set that container in an oil bath heated to 250F. We use bain marie and other stainless ware from a restaurant supply or a still, so as to recover the alcohol.

Make sure that the container is sitting on something that suspends it up off the bottom of the oil pot. I throw four jar lids in the bottom of my electric fondue pot and use it for that purpose.

Never trust the numbers on the dial and use a good thermometer to set temperatures. We use either a mercury lab thermometer, or a digital one. Good temperature control is key to the process.

That means the device that you use to control the oil temperature must have a narrow dead band, so that the temperature control is stable.

We paid about $60 for a Quisinart fondue pot that was designed to heat sensitive sauces like chocolate and has excellent control throughout its temperature range. We also have a couple of Revels, that are slightly larger and work well, plus cost only about $30, though they have a slightly larger dead band.

Some fry cookers have sensitive enough controls, but many deep fryers designed to primarily run at 375ºF, lack control sensitivity and have large dead bands at 250ºF.

Either boil or distill off the alcohol until the liquid is reduced to a pool of oil, with no large solvent bubbles.

We suck it out of the container using a 60ml syringe, and then filter it to 0.2 microns using a PTFE syringe filter, but a coffee filter or a #1 lab filter may be used.

Place in a suitable container for return to the oil bath and this time cook it until there are not only no large alcohol bubbles, but the production of small CO2 bubbles along the edge dramatically slows down, even when stirred with a bamboo skewer.

Since you have much less material, a smaller one may be used. At this point we put them in small stainless cups with their tare engraved on their sides or a Pyrex beaker. The smaller container reduces the surface area that will be coated with oil when we cook it down the last time and knowing the cups tare weight allows me to take it directly from the oil bath and place it on a scale after simply wiping the exterior.

Since we know the tare, we then know the extracted weight, and exactly how much other ingredients to add. Once adding those ingredients, we place the cup back in the oil bath, where we stir it until well mixed and then decant into its final container.

Since the added ingredients include things that lower the cannabis oils viscosity, very little is left as a film in that container.

If we plan to use the oil as is, without adding any other ingredients, we extract it from the container using the syringe, or a pipette, so as to not leave a streak of material in the vessel. After we have extracted all that I can using a syringe or pipette, we wash the container and pipette out with hot alcohol, and save the wash for the next run. Nothing is wasted or left behind.

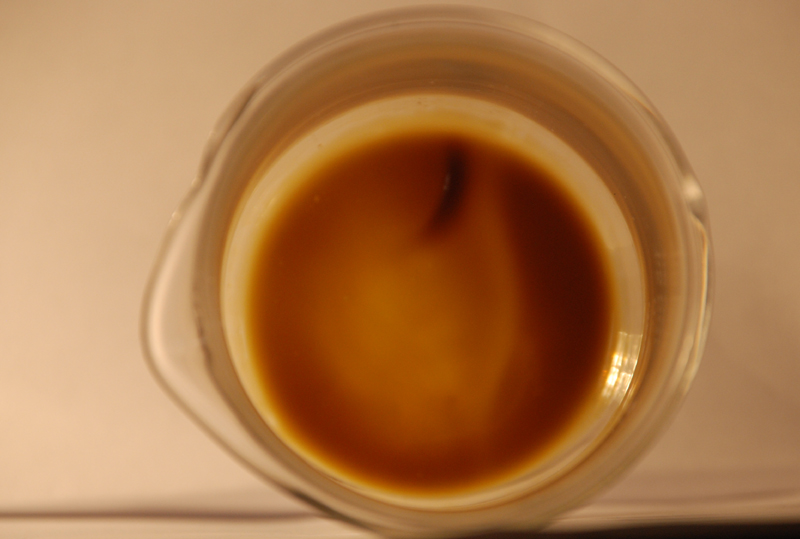

In that vein, as a final step, and for a different product, we strain the water from the plant material, the same way we did the alcohol and cook it off exactly the same way. When the water is cooked off, we redissolve the remaining oleoresin in hot alcohol, and place it in the freezer for a couple of days, before filtering it. This time there will also be red waxy globs of insoluble material collected in the bottom of the jar.

Cook off the alcohol, and it produces an oil that is more sedative that either of the first two extractions.

Attached thumbnail(s)

6-30-13 For all of ya'll living where 190 proof isn't readily available, here are a couple sites that will ship most anywhere,

6-30-13 For all of ya'll living where 190 proof isn't readily available, here are a couple sites that will ship most anywhere,

East coasters check out, http://www.winechateau.com/

West coasters, try http://organicalcohol.com/store/

Hello, Been doing a lot of research as keen to give this a go. I have got a substance already which is called perfumers alcohol, its a mixture of ethanol, isopropyl myristate and propylene glycol. Just was wondering if this would be suitable in this process, has anyone done any experiments using this and if its a bad idea, why? 2 of the products seem to come up quite commonly in various recipes, but not sure about this type of isopropyl and also how they might act together. I am sure will have many more questions when I start out but I am just getting the theory under the belt first! Thanks, any advice much appreciated, this site seemed to have a bit more scientific understanding than anyone else! Aimee

What is a good pressure/temperature to boil off the ethanol using vacuum distillation and a hot water bath?

I have a question for you. Why do you filter after purging as oppose to winterize and filter before purging in the qwiso methode?

When finishing qwet thin film purging under vac are we talking evap under fan Then purging or using boiled off to purge?

You have choices. You can evaporate in a casserole dish with a fan or sitting on a 130F heat mat to get rid of most of the alcohol and the thin film that is left is processed under vacuum with a lid or sheet of glass to catch the bump splatters. GW

what year would you generally vac purge ethanol at

Thank you GW So I did evaporate in a dish with a fan vacuum purge under heat my target temp was 115f. At some point heat went to 117f purge time was 5 hours. The result. Snap and break shatter😀I did use everclear. So if this was iso ? Just wondering if you'd Use the same temps for both solvents oh yeah this was tasty😁

Can you detail the "final step" in QWET a little better? For example, I have all these questions about the final step: How long do you let the plant material sit in the water, and at what temperature? When you strain out the plant material, do you now discard that material? After filtering the freezer cold alcohol, you say there's red waxy globs at the bottom of the jar. Are these discarded or useful? After cooking off the alcohol, the oil that's left, should it be used as is or combined with other ingredients as the other oils? When you say it's more sedative, do you mean it is more pain relief or more potent body type sensation?

I just added water from the faucet shook it once lightly, and strained it off. The water absorbs the residual alcohol containing some target elements. It also changes the polarity so as to bring along more of the anthro cyanin pigments and is typically a bright red extract, though the color of anthro cyanins are affected by pH. The spent plant material is then discarded. We compost ours. I'm saying that after filtering and removing the water/alcohol, the end result concentrate is an interesting red color from water soluble plant color pigments. As far as usefulness, it recovers target elements, and reduces residual THC in the spent material, which in some locales is regulated for licensed facilities. I was introduced to the phenomenon by Jump 117 from Russia on IC Mag, and think it unique enough to pass on, but typically don't do it where time is of consideration, because getting rid of the water alcohol mixture is lots slower than just alcohol and higher temperatures are involved. A QWET concentrate is essentially (for practical purposes) the same as a winterized BHO from a content and utility standpoint. Both solvents dissolve what is in the trichome heads, and any differences lie in how the solvents were removed, which determines the levels of the remaining mono and sesquiterpenes. When I say "more sedative", I mean that opposed to an energetic and "euphoric head high" typical of THC at the CB-1 receptors in your brain, you experience more "couch lock" sleeepy symptoms, typical of CBN. A good evening medication, but not a good choice first thing in the morning. If it is pain relief that you seek, I suggest extracting a higher CBD strain like Cannatonic, Maui Bubble Gift, Harlequin,.....etc. GW

Hi GW, Can you elaborate on what other ingredients you add and the proportions? sounds like you're adding ingredients proportionate to the extracted oil: "Since we know the tare, we then know the extracted weight, and exactly how much other ingredients to add. Once adding those ingredients, we place the cup back in the oil bath, where we stir it until well mixed and then decant into its final container."

https://skunkpharmresearch.com/holy-anointing-oil-and-holy-shit/ GW

Great write up.! Now how to get me vg/pg to blend with it! ??

One thing I would like to know is the saturation point of ethanol. How material can be 100% extracted per volume of ethanol. I'm just asking for an estimate based on ideal conditions.

great blog! do you have any material or studies on iso toxicity in this type of extraccion in the final product. im a begginer and listen so much versions for this. any info will help. thanks.

I hear you about all the different voices regarding ISO toxicity! We rely on the professionals at FDA, whose job was to set the standards. You will note that they have Propanol 2 as a Class III solvent and the standards that they hold them to. https://www.fda.gov/downloads/drugs/guidances/ucm073395.pdf GW

Yes u can use a still, I have been using an automatic still called a Megahome. Bought it 2 years ago from an on line store, Nutriteam.com. The model I use is made for a making alcohol and essential oils. It is automatic, but needs to be manually stopped before all the ethanol is gone, otherwise it will burn the oil. It recaptures most of the ethanol into a pitcher. What is left can be evaporated using a electric cup warmer or small griddle and a small glass storage container. The 190 ethanol from the liquor store works great. You can also order organic190, and also a 200 proof online. I use extractahol.com. And buy 5 gals at a time to save money.

I have two questions. 1 I have been looking into doing this and finding different ways of evaporation. There's a video on YouTube that uses a water distiller which seems like a safer method. Then they use the warming portion of a coffee pot to dissolve the rest of the alcohol Is this a viable option? 2 we are talking ethanol is 190 proof alcohol from liquor store the same thing or do I need to find ethanol because I'm only finding denatured for sale online.

Megahome makes both a water and an alcohol still, either of which will work to remove gross alcohol. Finishing is best done in a thin film under vacuum or mild heat and time. I suggest a casserole dish and silicone heat mat, if you don't have a vacuum chamber. We use 190 proof ethanol from the liquor store. GW

Thanks

Just curious as to why you chose to do two larger pulls? If I recall correctly, doesn't chemistry dictate that larger pulls are less efficient compared to smaller pulls when using the same overall volume?

Are you referring to my doing a gallon at a time? If so, it is mostly related to how much material I have to process. If you are asking why not process half as much twice as long and in one shot, it is because of the non target elements that will start to come along for the ride with more time. GW

Nope, neither actually.. sorry for the ambiguity.. What I was trying to ask is why do you do two pulls with the ethanol an inch over the material instead of say 3 or 4 smaller pulls (using the same total amount of ethanol) for the same time as you would normally

Smaller amounts of ethanol wouldn't cover the material completely, but some folks do pack it in a column and pour through it, rather than soak. We typically don't mix the first and second pulls, because their properties differ. GW GW

GW Thank you for all your healing wisdom. Winter here in the northeast. My first QWET was done with frozen colas and everclear. The rise was done outside in 10 degree f weather. My wife saw it in the jar and said that looks like pee. Golden. I evaporated under a heating pad with a fan. The finished material was a wonderful amber tacky consistancy. I was amazed at the way it worked. Here in NY I'm a MM card holder and have to pay the dispensary $130 for 1 mil. of co2 e juice. My finished product mixed one mil extract with two mil vapeur extract and with .5 mil holy terp flavorless. It was so nice and effective. Better than what i paid 130 for. I've saved $$$$. The final product appears clear amber and vapes clean. Like dispensary e-juice. Was it just beginners luck or is the outside rinse in below freezing temperatures the reason for my sucess? is it possibe the freezing temp during the rinse polish it even more. What do you think? I'm not sure it really needs anymore purging than what I described above. Again GW I've seen you on many sites for years and Im very grateful for all the healing your knowledge and wisdom provide.

Thanks for the good thoughts! Cold is the key as long as the alcohol and plant material are in contact. At subzero temperatures, the frozen water soluble chlorophyll binding proteins hold the Chlorophyll in place, protecting it from the alcohol. Once they make contact, chlorophyll is readily soluble in ethanol and comes along for the ride. I like QWET for extraction because purging is less critical that QWISO and it is slower to extract, so allows a greater margin of error. It also adds a sweet after taste if not fully purged, which some find a pleasant addition and it isn't insalubrious. If you're mixing your own juice, pull the on line .gov toxicology sheet and MSDS to see what all of its properties and its permissible exposure limits are, as well as whether it has been determined to be a carcinogen, mutagen, teratogen, or cause dandruff and bad breath. My favorite book on that subject is Essential Oil Safety, by Tisserand and Young. GW GW

Cooler was just to cool the alcohol and bud. To prevent chlorophyll for dissolving into alcohol. I just lift out the filter, 99% of the alcohol stays in the jar. Takes no time at all. Filtering through the coffee filter takes about ten minutes. I use the 10 minutes to start another soak which I repeat 4X. Starts to get a little green tinge at that point.

Sure. Largely the same as the QWET process. Placed material and 190 ethanol in my home freezer overnite. Then placed everything in a WELL insulated ice chest surrounded by the dry ice. Checked the temperature with electronic thermoniter until it was -35/45 degrees. Used a quart mason jar with a stainless steel cold brewed coffee filter (Amazon) with 2 oz decarbed bud. Filled jar with ethanol to just over top of bud. Shake to mix and placed back in cooler for 10 min. Then poured off ethanol into another mason jar filtering through a coffee filter. Distilled ethanol with a Megahome still for recovery of ethanol (to expensive to just evaporate) and finished removing it with a sm glass tray placed on a electric griddle set to low.

was the dry ice was just used to keep the cooler cold? or did you incorporate some into the alcohol+cannabis tincture while infusing? Also, curious how long did it take to filter thru the stainless coffee filter? thx!

I would like to filter ethanol and oil solution through a Bucher funnel/frit disc but am wondering what micron disc would be best? 15-40u 5-15u 2-5u Thanks!

i filter using a 70 micron filter. I use a 10" cone designed for filtering fryer grease https://www.amazon.com/Reusable-Shortening-Filter-Broaster-Pressure/dp/B01DL4A6PU, clarity is good enough for me at that level and fast too, here's an image of some finished concentrate at that filtration: https://twitter.com/CulinarySolvent/status/815144487676760064

I would start with a #1 first, which is around 15 microns, and then filter finer. We've filtered down to 0.2 microns for show and tell bragging rights. Take a look at 1 micron polyester felt sock filters from Dudda Diesel, which are used for biodiesel. GW

Im only getting 1g of concentrate from 10g of bud. Always the same no matter quality and volume e.g 1.4g from 14g of bud. Is this good? Should i be expecting more?

That's low for bud, but in the ballpark for trim. We typically get about 18 to 25% yield, depending on strain and other factors. GW

you can't concentrate what isn't there to begin with...are you sure your starting flower has the THC to begin with? 10% THC is still common and could be the reason for your consistent yield? how long are you letting the alc and cannabis sit combined? and what are you using for solvent 190/200pf? I usually pull 20% yield, using dispensary bud with a measured 23% THC content, i've been doing 10 minute single washes using 190 proof ethanol....

Dont have the luxury of dispensaries in UK. Have gowith whatever i can get. But tried from different sources and my own home grown and always 10% yield. I use 95% proof ethanol and do 3min washes. I dont dry the weed in between washes, and do the second and 3rd washes right after the first. Ive also been using ethanol instead of water for the third wash. Reading your method i may as well just do one 10min wash and see if that bulks out the yield. Before reading this i was rhinking of trying thr 48hr wash, strain and leave for another 48hrs. Dont like the amount of chlorophyl that people are reporting with this long wash though

I've seen strains that low, usually high CBD land race. You can tell when you have it all by inspecting at 100X for intact trichome heads. Only their stalks should be left. GW

USE A ROTOVAPE! :-)

During the stage where the ethanol is being evaporated in the 250F oil bath and the drying step at 200F, it seems like these temperature and duration are high and long enough to be decarboxylating the concentrate. Do these steps potentially run the risk over decarbing even before the last decarbing step when watching for CO2 formation?

The 200F drying step is optional, and some decarboxylation happens both at the 200F dry, as well as the 250F boil off. Those are techniques employed when the material is going to be decarboxylated anyway. If you want to avoid decarboxylation don't oven dry it first, and vacuum off the alcohol at lower temperatures. GW

I have the same question and would like to add to it. When I use the qwet extract for baking edibles, I heat the extract to a liquid consistency and then pour into butter or oil and mix for 15-20 min, both of which are done at roughly 180 degrees. Then they are baked at 12-20 minutes at 300-325 degrees. Wouldn't these steps also decarb and therefor OVER decarb and degrade the THC in the final product?

Here's another supplier of organic 190 and 200 pure ethanol. Available in 1 & 5 gal (much cheaper) I have ordered from them and they are helpful and competent. http://www.extractohol.com/ethyl-alcohol

We currently offer 190 Proof Grain Alcohol for sale online for your solvent needs! We offer the finest and purest quality Ethanol safe for human consumption. Visit us online at www.EthanolExtraction.com to place your order today! Enter coupon code 20off17 for 20% off your purchase!!

I have been using this process for 2-3 years. This past fall I used dry ice to cool the alcohol and bud down to 30-40 degrees below zero. I was able to do 4 runs of 2oz for ten minutes each in a quart mason jar with no visible green. On run five there was some "green" creeping in. Mixed all runs together, filtered with coffee filter and used a 1 gal distiller to reclaim most of the organic 190 ethanol. Didn't notice any perceptible increase in yield compared to previous runs. But I did not have the time to compare different methods with this harvest. Yield was about 4-5g per oz of bud (from auto flower plants)

could you describe the process

Hello GW and the Skunkfarm team! I am starting to run RSO for patients and was wondering about maximum cannabinoid saturation in the ethanol...how much dry cannabis can a gallon of ethanol handle? Or more accurately, how many milligrams of cannabinoids can a gallon of solvent take? I have been told the standard amount is 1 gallon per pound of flower all the way up to 2 gallons per pound. Any chance you guys have tried maxing the solvent out on washes? And maybe have the results to share? Or maybe just a rough estimate on maximum numbers? It seems like you could wash material in a closed loop type system, cycling the ethanol through the column, packed with several pound software material. The only question is, how much material and how many gallons of solvent would be "too much"? Thanks for all the info, it has helped many of my patients and myself as well!

Hey all, I have a few questions and doubts. 1. Can I use "Dehydrated Alcohol" for oil extraction ? Please see picture below, I got 2 bottles from a Science lab supply. There is no mention of percentage or proof. It says Ethanol b.p. Just made in India by Bengal Chemical and Pharmaceutical Ltd. Kinda scared, what if I go blind or just die instantly, worse painfully slowly. https://forum.grasscity.com/attachments/img_20161017_143833-jpg.2201763/ This Extraction is strictly for my father (stage 4 lung ca.). 2. Is it safe for for consumption? The guy at the shop told me it was safe as long it was not drunk neat. As if... Sorry folks but we don't have EverClear or other good solvents. No Amazon or eBay either :( yes that's the Third World. The last time I used Isopropyl 96%, I hear it's not as good as Ethanol. So there you go, any help will be much appreciated. If there are any Nepali folks reading this your suggestions and input would help even more. Thanks :judge:

Sorry Pavitra, I couldn't open the site without joining, so couldn't see the pictures. If you will provide more information on the manufacturer and brand name, I will see if I can dig up more information. You can get ethanol to about an azeotropic 95.6% just using a compound refluxing still, and that is considered 190 proof. To get rid of the last 4.4% water requires either a vacuum still and/or a drying agent. The suitability of the ethanol can depend on what that drying agent was. If they are representing it as pharmaceutical grade 200 proof, it is most likely OK, but I'm unsure of how much attention the country of India is paying to standards compliance. If that doesn't work out, are you anywhere where you can buy or build your own compound refluxing still, so as to produce your own 190 proof ethanol? GW

Thank you for getting back :) I called up the manufacturing company (http://bengalchemicals.co.in/contact/) this morning, was a complete waste of time and money. The industry has stopped production :( and the fellow i spoke to had no idea where it was denatured or un-denatured or as a matter of fact anything. So there in lies my fear, and as far as standards compliance & application in India - many doubts. I have lived half my life there. Here is the link Dehydrated Alcohol (Ethanol b.p) i got yesterday, https://www.dropbox.com/s/d2es9mkqoeyw1zd/IMG_20161017_143833.jpg?dl=0 I have extracted oil using Isopropyl only a couple of times before so i would consider myself new at this, i am more at my learning and listening phase at the moment. Any suggestions and help i am ready to soak. About the compund reflux still, i have no idea what it might be, but i sure do want to produce my own 190! :) Thanks. pd

USP, EP, and BP grades are ostensibly not denatured and are fit for human consumption. ACS reagent grades are denatured and not fit for human consumption. Ostensibly it is suitable, but as you've noted, because of where it was made, quality control is an unknown. GW

https://skunkpharmresearch.com/enabler-alcohol-fractionating-still/ GW

Thank you for getting back. Here is the photo link of the Ethanol b.p (dehydrated alcohol) doesn't say much but please have a look, https://www.dropbox.com/s/d2es9mkqoeyw1zd/IMG_20161017_143833.jpg?dl=0 I called up the manufacturing company at Calcutta this morning, said that the have stopped production of the item. When i inquired about the Ethanol, fellow, he seemed very lost and vague, basically he had no idea. Denatured - Undenatured - grain - synthetic??? no idea. Waste of time and money. About the standard compliance in India it gets very dodgy, i have lived half my life there to know. Hence, more doubts. Also called up the supply shop to reconfirm if so one knew it was safe to use that but no help :( But they said the have Absolute Alcohol, cost more and ther are other additive in the content :( think i will drop by the shop and have look. Are there any specfic chem i should be aware of? About your Compound Refluxing Still, yes i would like to produce my own 190 if i can't get my hands on readymade stuff - why not. I have only made ISO a couple of times earlier so i would consider my self new at this but i am quick and keen learner so i am all ears and eyes at the moment. I think i can DYI one too, under your guidance master shifu :)

I live in Colorado and can buy ever clear for ~$40 for 1.75 L. It must be illegal in some states

"To get rid of the last 4.4% water requires either a vacuum still and/or a drying agent. The suitability of the ethanol can depend on what that drying agent was." Why is it considered bad to have 4.4% water in the final product...

We use 190 proof 95.6% azeotropic EtOH typically produced in a compound refluxing still, for a couple of reasons, the question of vacuum or drying agent being one. Since we typically subsequently remove the 4.4% water in a vacuum oven or chamber, it isn't a question of water in the end product, but the effect of the water on polarity and what is extracted. In that regard, we've found that 95.6% does an adequate job, regardless what those changes are. If it is a question of water in the end product, it depends on the end use of the concentrate. Brothers and sisters vaporizing concentrate with water in it, will experience popping and sputtering on the hot nail. Oral ingestion, not so much........... GW

Hi, About how many times could i re-use the same alcohol once I've extracted into it, filtered it and used it again with fresh material, before it would become too saturated to work? Thanks

If you are referring to the same ratios of material and alcohol used in this article, we are still stuck with the variable of how enriched the material is. The material used in the article for one 3 minute soak was prime and as you can see is rife with solute. It would probably be pushing it to extract one more batch. GW

Thanks a lot for sharing your knowledge and taking time to reply, I very much appreciate it :)

Could you explain the 3rd wash with water, Im a little confused. You say "for a different product" what exactly is this, ...cbd? I looked online and cant seem to find any info on this topic using water. I followed the direction and made it, its currently in the freezer. I need a more seditive oil due to cannabis oil being to strong for my treatment. 1 gram is the recommended daily dose for fighting cancer, but this is such a strong dose its hard to handle. More info on the water product would be greatly appreciated. Thank you.

The third wash captures the cannabinoids in the alcohol soaked into the plant material, among other things. An interesting red waxy product, that I've never run through the gas chromatograph to see what all is in it. Jump 117, of Moscow fame and glory, turned me on to it, and it does contain cannabinoids, based on its psycho-activity. GW

hi greywolf ! its nick again ... i'M a little bit confused about following your tutorial using my t500 distiller . My questions are : should i decarb buds prior to distillation ? following you instructions and distill ? or should i decard when oil is distilled and i'm finishing it in a cup warmer ? checking the bubbles ? i've read that you said its easier to manage the decarb when it's oil than when it's buds in the oven. for a top notch decarb high potent Thc what would you suggest as temp and time in the oven . Decarb in mason jar or pyrex , tight seal ou aluminum covered foil ? thanks in advance

I'm having a problem picking up too much chlorophyll and other polar solvents. We're using twitter trimmings, think cut grass in a lawnmower, and due to volume, don't have room in freezers to do this all at 0C. We are able to bake material at 200F to get all the most inure, and after the ethanol soak, I run it through a #1 filter with lab assist. However, my previous purge product looks almost jet black. Ideally I'd like to look a little prettier. I'm using a magnetic stiring hotplate while double boiling in oil, so my Temps shouldn't be a problem. I have noticed that until all the ethanol has evaporated my Temps won't get past 76C. After the ethanol is gone, I can bring Temps too 100C to cook off the remaining water.

Ethanol is polar, and has a love affair with chlorophyll, because of the magnesium atom in its chain. Soaking material at ambient temperatures will typically pick up large quantities of it. Freezing it ties up the water soluble chlorophyll binding proteins, so the alcohol can't as readily reach it. Material that has been run through a rotary bladed trimmer, have more crushed cells bleeding their water and alcohol soluble contents into the extraction. You would pick up less chlorophyll using a non polar solvent. Rotary bladed trimmers typically clog, unless lubricated with vegetable oil, which contaminates the extraction and difficult to remove. GW

Thanks for the wonderful info, GW. I'm still curious as to the necessity (and ratios) of using hot water to remove the last of the alcohol from finished product. Thanks in advance. Scott

Thanks for getting back to me. What I washed the material in cold water first with some sort of scorn to stop the crystals from being washed away. Would this pull out most of the chlorophyll? Then I could really dehydrate and proceed normally.

Hey. Thanks for this awesome instructional! Could you clarify what are the "added ingredients" that lower the viscosity etc...?

Are you referring to: https://skunkpharmresearch.com/holy-anointing-oil-and-holy-shit/

Here's the full article (the original link is only to the Abstract): http://www.ouramazingworld.org/uploads/4/3/8/6/43860587/bradford2016.pdf

[…] a fantastic description of the alcohol extraction process (QWET) check out https://skunkpharmresearch.com/qwet-extraction/ Skunkpharm.com is incredible and a great resource I encourage you to explore their […]

Mr Wolf, I want to prepare QWET oil for skin application (I'll be mixing it with some grape seed oil which i've read helps it to penetrate the skin). If I do not decarb the plant matter prior to extraction, is there a difference in the amount of cannabinoids extracted? i.e., does decarboxilation have any effect on the solubility of the cannabinous in chilled ethanol? Or, can I just run the QWET extraction, and then decarb later in the event that I end up wanting to ingest it orally. I realise that it may be beyond the scope of this page / site to discuss the pros and cons of decarbed vs non-decarbed for skin application, but any info or links would be appreciated.

Decarboxylation does not have any effect on the solubility of cannabinoids in ethanol, chilled or otherwise. You can effectively decarb before, during, or after the extraction.

Both THC and THCa are readily soluble in ethanol. I always decarb later, because I can watch the CO2 bubbles produced, to tell more precisely where I am in the process. GW

Thanks very much for the quick response

Hi , first of all thank a lot for your help and infos grey wolf ! My mother as diagnosed with pancreas cancer .. 3cm tumor without metastasis . So i've been reading a lot about RSO and can oil . A lot of people pointed me here for more technicals tips. But i have some questions and it will clear my mind if you could answer them. I would like to make some oil with QWET extraction ... i can have acces to a triple grain alcool a 93 % and to a a Still spirit turbo 500. Will i have good results with a 93% grain alcool ? i know about the decarbo and winterisation ( thanks to you ) but it would really help me to know if i can produce a good and effective can oil with this. Do i absolutely need a everclear style of grain alcohol ? ( 95% ) is it better a grain alcool a 93% or iso ? i'm a little bit confused Thank you a lot nick

Sorry to hear about your mom Nick! It will extract just fine. It is getting rid of the extra water that takes its toll on the mono and sesquiterpenes, as well as converting more THC to CBN. While going from 95 to 93% is only 2%, it actually represents a 40% increase in water content. If you have access to a turbo 500 still, I would personally take advantage of it. I'm not a doctor, but when I asked Dr Melamede (https://www.youtube.com/watch?v=KMxiuyLZluE) whether he felt that "Clear Concentrates" (Diterpenoid fraction) would be more effective as a base for cancer medication, he replied that he thought "Whole Extracts" (Cannabis Essential Oil) were more effective. Given the choice between food grade 93% Ethanol and 99% Isopropanol, I would still choose food grade Ethanol for extracting concentrates to be used in medication. Some of the folks using the meds already have compromised immune systems, and our bodies have greater tolerance for Ethanol residuals. GW

Thank you so much for you answer ! yeah that's bad for my mum but i'm trying to ease his life , maybe more time and maybe why not stabilize her .. who knows i am going to follow your QWET protocol but with the 93% ethanol and the Turbo still 500 .. hoping i ll have great results ! very interesting video by the way .. this man seems passioned with helping people with cannabis .. this is great i'm just asking because i'm not sure .. what is the difference with cannabis oil we get with the Qwet amd a cannabis essential oil ? i've read some tecnics about essential oil but i'm not an expert. Thank for you time and you answer greywolf nick

look at meth use going down in weed friendly states https://www.dea.gov/resource-center/meth-lab-maps.shtml

Howdy GW, I have a question for ya about 200 proof non-denatured ethanol...I have sourced a food grade 200 proof alcohol outa California willing to ship to my doorstep at a ridiculous price. I have always used 190 proof everclear along with a cryo freezer to run extractions below -70 Celcius with excellent results. However...my returns are always on the low side (around 14% at best) even after letting the material soak overnight at low temp. I pull zero chlorophyll even with these long saturation times but my returns remain low. I'd like to pick up some 200 proof and see if it improves returns, but won't the alcohol at 200 proof grab moisture outa the air the minute I pop the lid on the container? Is 200 proof actually necessary to see better returns or would I be wasting my $ as the proof immediately lowers to around 190. After I have filtered the alcohol from the material, I use a 1 gallon still to reclaim my solvent...I was told the best I could see through distillation would be 190 proof if I was to run the used alcohol a few times to raise the proof back up. So. After my long winded intro, the question remains...Is 200 proof food grade ethanol worth the price? And will it remain at 200 proof once used in extractions? As always thanks for your experience and time! -Matt

I average 20% return (decarbed plant into concentrated oil) using 190 proof grain alcohol. For every 1 oz of quality bud I expect to get 6 grams of sticky dab-able oil. The quality of your starting material is the driving factor to increase yield, not eliminating the 5% of water in your solvent. I've done both room temp quick washes and dry ice 20 minute soaks with equal results using 95% ethanol. 200 proof will begin to grab moisture out of the air, but it will take some time to reach it's comfortable azetrope of 95.35% https://en.wikipedia.org/wiki/Azeotrope under normal conditions. Regarding redistilling to reclaim your solvent: your setup, the timing on when you take your heart cut, and the speed you push liquid through your system will all affect the final proof you collect. You mention multiple runs to get back to 190pf, how much time do you spend recollecting the solvent?

Does the oil separate from the alcohol like a vinegrette or does all the alcohol need to be extracted for the serum?

The oil is in solution with the alcohol. GW

the alcohol isn't extracted, more evaporated (or boiled) off. I use a box fan and a HEPA filter to cold evaporate away the alcohol in my tincture to produce a sticky oil. here's my setup: https://www.youtube.com/watch?v=kYyszRo_0ow