I don't know about ya'll, but I have been watching CO2 Super Critical Fluid (SFE) with interest and have wanted to sample some cannabis essential oils extracted by that method, but the cost of conventional SFE equipment, is outside the range of most of our finances.

For the rest of ya'll just learning of the process, let's quickly examine what SFE is, by looking at what Wikipedia has to say about it, followed by our kicking off our affordable DIY CO2 extractor design project:

Supercritical carbon dioxide

From Wikipedia, the free encyclopedia

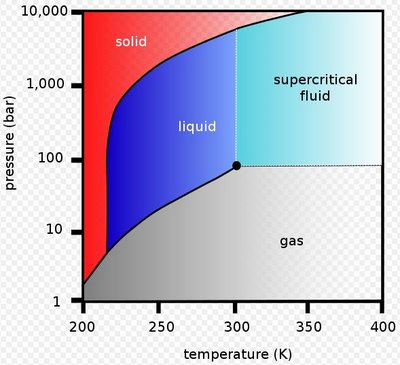

Standard carbon dioxide pressure-temperature phase diagram from Wiki, plus another showing the droopy nose normally not shown on CO@ SCFE charts, but which can be exploited.

Standard carbon dioxide pressure-temperature phase diagram from Wiki, plus another showing the droopy nose normally not shown on CO@ SCFE charts, but which can be exploited.

Supercritical carbon dioxide is a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure.

Carbon dioxide usually behaves as a gas in air at standard temperature and pressure (STP), or as a solid called dry ice when frozen. If the temperature and pressure are both increased from STP to be at or above the critical point for carbon dioxide, it can adopt properties midway between a gas and a liquid. More specifically, it behaves as a supercritical fluid above its critical temperature (31.1 °C) and critical pressure (72.9 atm/7.39 MPa), expanding to fill its container like a gas but with a density like that of a liquid.

Supercritical CO2 is becoming an important commercial and industrial solvent due to its role in chemical extraction in addition to its low toxicity and environmental impact. The relatively low temperature of the process and the stability of CO2 also allows most compounds to be extracted with little damage or denaturing. In addition, the solubility of many extracted compounds in CO2 vary with pressure,[1]permitting selective extractions.

Soooo, in us'n layman's terms, we use plain old CO2, that we have gotten hotter than 31.1C/87.98F, while under at least 1086 pounds per square inch pressure.

In that state, the CO2 becomes a super solvent, which has higher penetration power, and can be fine tuned to focus in on specific constitutes, by varying the pressure, temperature, and by the use of co-solvents like ethanol or hexane.

Fair enough, and easy enough to accomplish several ways! Traditionally a high pressure intensifier pump is used to achieve the required pressures.

Cryo-pumping also works. You start with liquid CO2 or dry ice and heat it in an enclosed space.

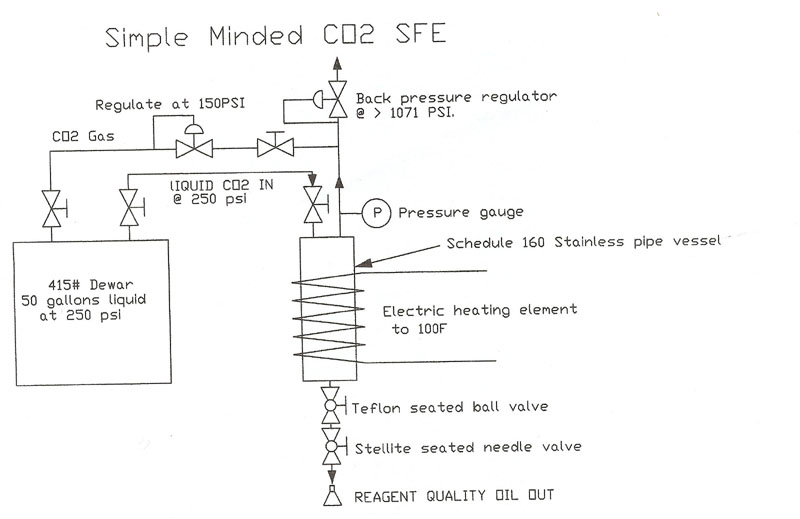

My first conceptual of a system that was semi affordable, was a simple minded system using liquid CO2 and heat to run it at about 1500 PSI. That eliminated the pumps normally used and by using a liquid Dewar with a dip tube, with both a gas head and a liquid tap, the need for any liquid pumps is eliminated as well.

It is designed to use readily available Schedule 180 austenitic stainless pipe and its largest component is small enough to fit in my 7" X 36" lathe. My original plan was to use an existing hydraulic cylinder for my vessel, but alas, carbon steel embrittles excessively at cryogenic temperatures.

My design calls for achieving pressure by simply heating the pipe with available pipe band heaters.

Pressure was controlled using a conventional, though expensive back pressure regulator. Please note the attached conceptual, which reflects my thinking four to five years ago. I put the project on the back burner after reading the SFE CO2 patents for extracting cannabis, and noting that CO2 isn't a very aggressive solvent and the patented processes used significant fluid exchange rates, as well as relatively long spans of time.

To compound that, reports from those testing SFE CO2 extractions reported poor taste and effects, so I put CO2 extraction on the back burner to just watch for awhile.

Within the last couple of years several folks have done some interesting work starting with dry ice. The first that I noted was able to maintain high enough pressure in a test tube to keep dry ice from sublimating as it warmed, so as to extract some Limonene from an orange peel.

That led me to question whether super critical pressures were required to extract the essential oils from cannabis that we typically extract with other solvents, and further experiments by others suggests that it is not. Some even report better results at subcritical pressures, especially with the use of co-solvents.

Sub critical extraction presents an interesting twist from a simplicity standpoint, so of course my simple mind immediately envisioned replacing the test tube with a pressure vessel containing dry ice in the bottom, and a basket of material suspended above it. Screw down lid and bring it up to temperature with a pipe clamp heater for pressure.

Flooding is achieved by simply turning it upside down to soak the material and right side up to drain. That step could be repeated back and forth, to soak the material and keep the boundary layers diminished. On setting it upright the final time, we could bleed off the liquid into an expansion chamber and then to atmosphere, leaving behind the oil.

I have decided to build a 2" X 24" prototype, and have acquired two resources on this project that emboldens me. One is the offer from a dear old friend, to allow me the use of his aerospace pressure and vacuum equipment manufacturing facilities for giggles and old times sake.

The other is an agreement with another old friend, who owns a cryogenic equipment manufacturing plant back east and is familiar with SFE.

We have a mutual engineering support agreement in effect, in exchange for my support on one of their projects with a former aerospace customer of mine, who is now their customer as well.

For my support interfacing their equipment with equipment of my own design and manufacture before retirement, they will support me in developing a simple minded DIY SFE system, that hopefully more of us'ns can afford to build, or have built.

So here is my first simple minded conceptual using liquid:

Here is my simple minded conceptual starting with dry ice: OOPs, solly, watch this space!

After working all day on the drawing, my 2002 32 bit Auto Cad program is not able to access my printer on my 64 bit processor, and I'm not smart enough to figure it out, so I have to find a computer hero or heroine first.

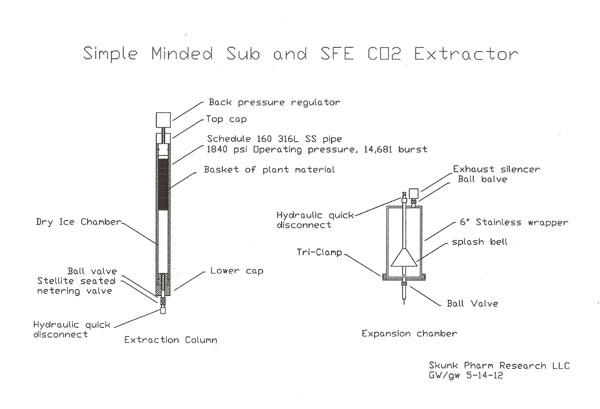

The way my conceptual works, is the bottom of the cylinder is filled with dry ice, on top of which sits a wire basket of plant material. Clamp on band heaters turn the dry ice to liquid, which is circulated and soaked through the material by simply turning the cylinder upside down.

After flipping it about a few times, over an extended soak, the vessel is set upright and attached to the lower expansion chamber via a hydraulic quick disconnect. The liquid is bled off, decompressed, and the oil collected from the decompression vessel via the bottom drain valve, as well as via the detachable bottom.

Lu lu lu lu lu lu lu lu lu lu lu lu lu lu lu!!!!!!!!!!!!!!!!!!!!!!!! Progress!

Well thank the Great Spirit for ex-brother in laws, who can sort out computer problems, so that I can print from virtual mode. Hee, hee, hee, kept him at tossed the sister..........

Here is my simple minded conceptual of how such a dry ice system might work. More detail prints once I have exercised some resources.

After further discussion with another experimenter, I have decided to build the system to operate at 5000 psi and below. Instead of using schedule 160 stainless pipe, I will gun grill a billet of stainless, but will keep the bore at one inch.

Hi ya'll! Been out talking to folks running commercial CO2 SFE units and would like to share some selected excerpts from their letters, to keep their identities confidential:

Hi Graywolf, here is some pics of the unit i have been running for 8+ years. Our whole thing with this unit was to have maximum fractionation capabilities.

The extraction vessel is rated to 10,000psi, and made of stainless!!

We use a basket to hold the material and I'm having a natural cloth bag made that will go into the vessel and hopefully allow me to extract 2x current volume.

There are some great graphs around the net that show the combinations of pressure and temps and the resulting density of co2. In general high pressure (we go up to 10,000psi) works well in combination with high temps (around 100c) and lower pressure around 5000 psi goes well with about 60c.

I tried high pressure and while i need to try again to confirm, there seemed to be some degradation to the overall quality and definitely the fragrance. the yield was higher and its much more efficient requiring less co2.

I already noticed on the bit of extract that i dissolved in ethanol and then winterized and filtered, the flavor is no where near what it was before going in the ethanol. I plan to try and get the waxes out with only co2.

I cant see any advantage to using either hexane or ethanol or a mixture as a co solvent?? the compounds are easily soluble in co2 and usually those types of things will help to extract more polar compounds such as chlorophyll. It all depends on what your goals are? maybe he is using that mixture to help fractionate out the waxes??

I can do a small run next week using those co- solvents and report back if i see anything magic or some beautiful separation. maybe he is just some chemical engineer using a method that was used for another project and he is trying to apply it there?

It seems really counterproductive to use co solvents and contaminate a great extract... maybe he can only do really low pressure and he requires the co solvent to help the efficiency??

I found material with a moisture content of around 10% to be fine. I don't know what the implications of a slight amount of carbonic acid could mean?

I have heard it can make oils rancid, but have run vegetable oils at 10+% moisture and had them test very low in peroxide values in respect to oxidation and rancidity. I do not see any problems with around 10% moisture, the water sometimes comes out with the extract and is sitting on top and the few mls there can be poured off.

And from yet another hero!

I. Extraction was performed by sub and supercritical CO2:

Subcritical (liquid): 10-12 ºC @ 65-70 bar for approximately 6 hrs.

Supercritical (liqid/gas): 40-45 ºC @ 230 bar for approximately 4 hrs.

II. Separation of fats and sugars, by winterization, chromatography and high speed centrifugation.

This part was very critical in the purification schema and required analysis of both the anaylate and precipitate.

III. Purification, at this point one has two options, Flash Chromatography or Wiped Film Evaporation (Short-path)

I performed both, and in both techniques, one can obtain purities in the range of 95-99% total THC (?9, ?8 and ?6) with the purity of ?9 ranging anywhere from 78-98% depending on the parameters set.

One last comment, probably the most important..... absolutely no petroleum derived hydrocarbon solvent was used. Except for the small amounts used for LC/MS analysis. This was my driving force to see if it could actually be pulled off.

12-21-12

We are moving this project from research to active experimentation in our FY 2013, now that the shack and Terpenators projects are a fait accompli. What I did in FY 2012, was simply research and develop resources.

It was good that I did, as further research put things in better perspective.

While I determined that my simple minded CO2 SCFE system would work, it raises a bigger germane question of why is this trip necessary, given how effective BHO and some of the other extraction methods are. Why spend the money for this more expensive fish trap, if we already have the fish?

The answer lies in that what CO2 SFE extraction shines at, is selective extraction. By fine tuning the pressure and temperature, as well as using co-solvents, specific components may be extracted, while leaving behind everything else.

That is of less value when discussing cannabis essential oil extraction, in that it has been determined that it is the entourage effects of all the terpenes present, including the diterpene cannabinoids, that are responsible for its medicinal properties. That however doesn't mean that we can't specifically focus on that list of terpenes.

The other thing that my research made clear, and that is using one vessel to process the material and raise the pressure in, would result in extractions along the entire temperature/pressure curve. Woops, no selectivity there, but easily solved by bringing the liquid CO2 or dry ice up to a higher temperature and pressure in a separate vessel, and then equalizing it with the one containing the plant material! Easy, but the system complexity grows.

One of the interesting things that my research turned up during tete a tetes with brothers owning and operating commercial CO2 SCFE's, and bumblers like myself whomping up DYI ghetto extraction equipment, is the wide range of processes that different operators have achieved a modicum of success at.

One operator simply took the valve out of a CO2 bottle and filled it with plant material and dry ice, before replacing the valve and heating the tank to SCFE ranges. He then inverted the tank and vented the CO2 into a catch container, where it left cannabis essential oils behind.

He claimed his best success using co-solvents at ~5500 psi and that his product was superior to all competing, but alas, I was never able to sample it and his spamming got him banned from the forums where we shared information.

Commercial SCFE operators report successful sub critical products as low as 350psi, and another at 850psi, but I haven't been able to sample their successes, to confirm my own opinion of product quality. There in lies the rub of course, as there is no common measurement and each creator loves his creation.

Fortune has ostensibly smiled on us however, in that two of the operators that I have been conversing with, have agreed to work more closely with us and to supply confirmation samples. Hee, hee, hee.................................

Even simpler DIY SCFE C02 6-2-13

Hee, hee, hee, you have to admire simplicity. Here is the system by jyndustriez which I mentioned, that simply puts the plant material in an off the shelf CO2 tank, and floods it with liquid C02 from a second off the shelf tank, before heating to achieve super critical state.

More information on how he accomplishes that at http://jyndustriez.blogspot.com/, but here are some pictures he has shared:

8-25-2013

Progress! We got to play with a donated SCFE CO2 extraction sample and were able to heat it under vacuum and observe the effects.

As received, the sample was in a "wax" hydrate form, and was not aromatic. The flavor was mild, and the effects were good.

As it was a small sample, I was unable to winterize it to remove the waxes, but I was able to heat it to 115F, under vacuum, and observe what happened.

The sample out gassed significant CO2, even though at 115F decarboxylation was minimal, and never quite turned clear, due to the high wax content, but that isn't unique, as BHO extracts are improved by wax removal as well.

On the surface however, the wax content seemed high, compared to our typical BHO extraction, so I look forward to a large enough sample to winterize and determine just how much.

Here is a starting and ending photo, demonstrating the ending wax content.

To add to our excitement, last week we got a guided tour of Eden Labs during our recent business trip to Seattle! What fun!!!

Patrick, one of Eden Lab's bright new sales consultants, attended one of our BHO classes and subsequently invited us for a tour, so how could we resist, hee, hee, hee, snicker, snark, snort..................?

Always a pleasure to see how the pros from Dover do things, and I do likes the way they detail a package.

We lucked out in finding the original creator available and got our guided tour from Fritz himself. Besides his latest creation, we got to see not only his original test sled, but some of the R&D that may make great strides someday, when Fritz can find enough time to finish them, between current product demands..........

Their latest all stainless creation was in final assembly and testing, and was capable of extracting not only with subcritical and Super critical C02, but also with refrigerants like butane and propane.

It was appointed well, and used pneumatic intensifiers both for the hydrocarbon pump, as well as the SCFE CO2 pump.

It also sported a unique closure system, which simply spins close and that greatly simplifies loading, as compared to a 12 bolt flange with a torque wrench.

The vessel itself uses a Schedule 160 stainless core, but adds water jackets, so as to permit the use of a commercial heater/chiller for temperature control.

The unit that we looked at, had a $60K base price, plus the price of the hydrocarbon extraction capabilities. Not cheap, and more complicated that most folks should attempt at home, but if you need a machine capable of a quality extract, in commercial quantities, you will need to step up to a system of this caliber, which includes pumps to cycle the C02, and C02 recycle to recover it afterwards.

Fritz did note that one of the things on his list of thangs he is juggling, is a smaller lab sized unit, which fills the market window for a smaller unit that doesn't recycle. Looking forward to see what comes up there!

From a process perspective, Fritz shared that the aromatic extractions are best done at low pressures and as the pressure goes up, so does the rate of chlorophyll extraction. Based on his and other input, I will focus on the range from 800 psi to 3500 psi. While I've heard operating parameters up to 9500 psi, the lower ranges sound more believable.

As unbelievable as it may sound, ah think sometimes operators shuck me, cause they are trying to protect process secrets and lead me astray.

10-27-13

Lu lu lu lu lu lu lu lu lu lu lu lu lu lu lu!!!!!!!!!!!!!!!!!!!!!!! The Great Spirit smiled and JYNdustriez loaned us a CO2 extraction setup and will show us how to use it, when he visits to watch Dr. Fischedick's lecture on 11-2.

I've also located a local brother with an Eden Lab machine, who is amenable to experimentation, so things are heating up in the area of CO2 extraction at Skunk Pharm Research. We will have machines from both ends of the price scale to experiment with.

Sound CO2 has also extended us an invitation to visit, and they run Apeks equipment, soooo even though our CO2 project was slow getting in motion this year, it looks like it is finishing with a bang.

1-31-14

Hee, hee, hee, check out JYN's latest link on DIY SCFE CO2 http://jyndustriezllc.com/diy-co2-extraction-crumble-wax-shatter/

dc weed for sale jeeter pre rolls for sale in DC dried mushrooms for sale in DC cannabis concentrate for sale in DC cbd gummies for sale in DC buy stiiizy pods online in DC jungle boys pack weed for sale CA cookies berner for sale california runtz cans for sale in dc buy thc vape cartridges online buy marijuana strains online, marijuana for sale in Washington dc wham strain | buy shroom bars online | mushroom chocolate bars for sale in washington dc | whole melt extracts live resin disposables buy shroom gummies for sale in washington dc buy shroom bars online | mushroom chocolate bars for sale in washington dc FRIENDLY FARMS PREROLLS FOR SALE California USA, Buy Friendly Farms Carts online delivery cbd thc gummies dc, cbd thc gummies for sale in DC buy buddah bear carts online, buy buddah bear shatter online, buy buddah bear badder online buddahbear bar 1.1 grams for sale buddah bear carts for sale buddah bear lil lit stix 2.5 grams for sale california buddah bear shatter 1.1 grams for sale california buddarbear badder 1.1 grams for sale california vegan dark chocolate psychedelic chocolate bar unicorn cake dream bars near me unicorn cake dream bars trippy treats chocolate bar for sale online best shroom bars tre house magic mushroom chocolate thunder clouds milk chocolate magic mushroom edibles temple teleport sample pack 20 pieces of magic mushroom tea chocolate choconaut scooby snacks temple magic mushroom tea bags silo jubes microdose psilocybin mushroom gummies edibles shafaa penis envy magic mushrooms dark chocolate bar edibles shafaa penis envy hazelnut milk chocolate bar edibles shafaa evolve magic mushroom microdosing gummy bears seremoni psilocybin mushroom chocolate marshmallows edibles seremoni psilocybin chocolate bar edibles orange golden teacher mushrooms psilocybin mushroom bar 3.5g psilo mart magic mushroom chocolate bar best shroom bar usa polka dot mushroom chocolate for sale online penis envy psychedelic chocolate bar one up mushroom chocolate bar one up mushroom bars neau tropics chocolate bar for sale online mr mushies chocolate bar moons psilocybin gummies edibles 3000mg mmelt magic mushroom chocolate bar 6g mantra chocolate bars for sale buy mantra chocolate bars magic mushies chocolate bar for sale online buy shroom bars infinite rx shroom infused large heart gummies edibles 4000mg fusion mushroom bars for sale buy fusion mushroom bars online fun guy chocolate bar for sale buy fun guy chocolate bar exodus amanita chocolate bars 1500mg enokia micro dosing mushroom chocolate 37.5mg easy peazy mushroom chocolate dream mushroom bars wholesale buy dream mushroom bars doce mushroom chocolate for sale online buy shroom bars online diamond shruumz mushroom microdose chocolate bars deja vu dream bar for sale buy deja vu dream bar online dean deluca mushroom chocolate caramel chocolate psychedelic chocolate bar buzz killer trip stopping capsules better u bars for sale online where to buy better u bars online amazonian psychedelic chocolate bar alice mushroom chocolates for sale online One up Mushroom Chocolate Bar For Sale in DMV online delivery | shroom bars Polka Dot mushroom Chocolate for sale in DMV | Buy Polka Dot shroom bars in Washington, DC Better U Bars for sale online delivery | shroom bars Fun Guy Chocolate Bar for sale in Maryland | shroom bars Trippy Treats Chocolate Bar for sale in Maryland online delivery | shroom bars mr mushies chocolate bar for sale in Maryland online delivery | shroom bars buy gummies for sale in Maryland buy dmt for sale in Maryland buy ketamine for sale in Maryland buy lsd for sale in Maryland buy marijuana online Maryland | marijuana for sale in Maryland buy mdma for sale in Maryland buy mushroom microdose for sale in Maryland buy mushroom spores for sale in Maryland buy neau tropics for sale in Maryland buy pentobarbital sodium for sale in Maryland buy psilocybin cubensis for sale in Maryland buy shrooms edibles for sale in Maryland buy stiiizy pods for sale in Maryland buy toad venom for sale in Maryland buy OZEMPIC injection online | ozempic for weightloss | ozempic for diabetes buy 1G Shatter Wax Cannabis Concentrate for sale in Maryland buy V-mod Square Battery for sale in Maryland Buy DMT Crystals for sale in DMV USA online delivery Buy One Up Mushroom Gummies for sale DMV | Shroom Gummies Buy Faded Fruits Gummies for sale in Maryland Online Delivery | Shroom Gummies where to buy Alien Labs 3.5 gram jars for sale in Maryland Buy Stiiizy Starter Kit for sale in Maryland online delivery Buy Bufo Alvarius Toad Venom online in Maryland Best Place to Buy Pentobarbital Injection Online in Washington DC Best place to buy Nembutal powder online In Washington DC mushrooms in dc apple fritter leafly lsd tabs for sale magic kingdom shroom bar tryp gummies trans envy magic mushrooms puffla gummies mantra chocolate bars for sale in dc mr mushies bar for sale in dc limoncello strain allbud neau tropics dmt for sale in dmv yeti shrooms shrooms dc near me neau tropics gummies chocolate mushrooms dc faded fruits gummies near me club car golf carts for sale yamaha golf carts for sale e z go golf carts for sale 2024 ezgo golf cart for sale 2018 yamaha drive golf cart for sale 2022 yamaha drive for sale 2023 yamaha gas golf cart for sale 2007 yamaha golf cart for sale 2019 club car tempo for sale 2023 club car onward for sale 2007 club car precedent for sale buy 5 meo dmt cart online San Francisco buy 5 meo dmt cartridge and battery 5ml for sale in San Francisco buy 5 meo dmt for sale in san francisco 5 bromo dmt for sale in San Francisco buy 4 aco dmt for sale in San Francisco buy 4 mec drug for sale in San Francisco buy dmt 5ml purecybin for sale online buy pure dmt nn dimethyltryptamine online 4 aco dmt microdose for sale in san francisco dmt crystal for sale in san francisco changa dmt for sale in San Francisco, buy changa dmt online in california dc mushrooms delivery, psilocybin for sale in DC buy psilocybin cubensis for sale in Washington dc buy mushroom chocolate bars for sale dc buy stiiizy pods for sale in dc buy dmt for sale in dc buy psilocybin tea online in dc buy lsd for sale in dc buy mushroom spores online in dc buy mdma for sale in dc buy mimosa hostilis for sale in dc buy shroom gummies for sale in washington dc buy hybrid weed for sale in washington dc buy exotic weed strains for sale in dc buy ozempic for weight loss in dc buy dmt for sale in san francisco dmt 1ml purecybin 700mg dmt buy dmt for sale in san francisco buy psilocybin cubensis for sale in san francisco stiiizy pods for sale in san francisco buy stiiizy pods sf buy mdma for sale for sale in san francisco buy ketamine for sale in san francisco Buy marijuana online in San Francisco | Marijuana for sale San Francisco buy shroom edibles for sale in san francisco buy lsd for sale in san francisco buy mushroom microdose for sale in San Francisco buy ar 15 rifles ar 10 ak47 for sale firearms for sale buy ar upper for sale buy handgun semi auto for sale buy primers for sale buy reloaded brass for sale buy semi auto rifles for sale buy springfield handgun semi auto online remington rifles for sale buy kimber pistols revolvers online kel tec semi auto rifles for sale henry rifles for sale henry shotguns for sale cz usa rifles for sale cz usa pistols for sale buy pistols revolvers century arms canik online buy browning lever action online buy browning bolt action rifles online cz 75 pcr custom 9mm pistol by cz custom for sale cz 75 semi compact bull shadow 9mm for sale cz 75 shadow tac ii 9mm for sale buy ammo online, ammo for sale buy winchester handgun ammo online buy winchester rifle ammo online buy winchester rimfire ammo online buy winchester shotgun ammo online buy vova 6g shroom gummies online mantra bars for sale | buy mantra chocolate bars online buy whole-melt extracts carts wholesale online buy sluggers juiced joints online buy polka dot mushroom chocolate online buy polka dot mushroom gummies online buy poppy sage gummy bears online buy quality drip carts online buy quality fire cart online buy fryd donuts 2g online buy quality fryd extrax 2g disposable online buy devour gummy online buy devour high crawlers online buy choices lab disposable online astrobar chocolate bar for sale in california astrobar chocolate bar for sale in california silo jubes microdose psilocybin mushroom gummies edibles best shrooms dc mushrooms for sale in Seattle buy quality marijuana for sale buy Best Bourbon Whiskeys for sale

This is information about supercritical CO2 extraction equipment (https://kdlabequipment.com/supercritical-extraction-equipment/CO2-Supercritical-Extraction.html). Interested friends can find out.

Hello do you still sell your machine? Please let me know, my email is icurart@gmail.com

Interested

I would love information. And prices. Thank you Troy

Brian, I am brand new to this but very much interested in your process. Can you reach out to me?

Would be very interested in more info. masapothecary@gmail.com

Hello, Can you provide me with information and pricing on your machine?

brian like to knowm more about your system your useing

Very nice,i know also other site!!! http://www.nethair.com.br

I do not want to sound presumptuous, but my proprietary machine is awesome. It is cheaper and more efficient than any other manufacturers' that I have come across. We can vary the size of the extraction vessel and pumps, but my current rig holds approximately 2-4 lbs. I can do ten runs a day by myself. It takes 1.5 minutes to get supercritical and start cranking. Its fully automated, except for filling the extraction vessel with herb, and connecting the co2 bottle. It will run any pressure between 1000psi and 5000psi. It is a laboratory grade piece of equipment. I sell, lease and rent the machines.

Would be interesting to gain more info on your invention, so we could talk details.

Link? GW

Details on what makes it unique? GW

Can I see pictures and how much to rent

Can you please send me an email with details on your equipment including price to purchase and price to rent? thanks- ifttt505@gmail.com

Hello, Very interested. Please email me more info with regards to purchase. lilsdelaney@gmail.com Thank you!!!

Hi Brian, please contact me on it.milos@gmail.com. I would like to learn more and talk business.Thanks.

I also would like info on your machines i need a couple please send info to oneime69@yahoo.com

interested as well, please send info to clinch.matt@yahoo.com

I read your post and is intriguing, I want to learn more about your system as I am in the market for a small entry level system 1-2 lbs please? Or I can build with plans and resources...

APEKS i 2000, Apeks i 1500 20L, Infinity 10L w/ 2nd BPV, and EDEN 5L available for daily, weekly, monthly, or long term rentals. Lab spec trailers available for qualified customers. We also have all the post processing equip you need for you concentrates. Next day delivery is available in the Northwest, West Coast, and CO. email: matt@extractionstore.com

I would like to thnkx for the efforts you’ve put in writing this site. I’m hoping the same high-grade site post from you in the upcoming as well. In fact your creative writing abilities has inspired me to get my own blog now. Really the blogging is spreading its wings rapidly. Your write up is a great example of it.

Interesting but a little out of date

Do you know of a do it yourself system more up to date? We stopped exploring passive extraction, once we understood its limitations, and so haven't kept track of bright new innovations that contradict that position. I've seen developments in small SCFI CO2 units using pumps that are of note, but are not DIY. GW

I am no longer certain the place you are getting your info, however great topic. I must spend a while studying much more or understanding more. Thank you for fantastic information I used to be on the lookout for this info for my mission.

What is the best CO2 machine made

I think that depends on "best for what"? There's the usual Apeks, Waters, etc machines but I recently read about new startup in California that seems to be doing innovative things with high-pressure machines (up to 5,000 psi): Applied Extracts (www.appliedextracts.com). Can't hurt to talk to them I guess.

I can give you some good information. matthias@paradigmsupercritical.com

Does anyone have experience running an Infinity Supercritical extractor? There's one posted on eBay for $59k for a 10L. I'm shopping for used, or refurbished, co2 extractor(s) and this is one of the few machines I located thats not an Apeks of Eden. matt@duxlabs.com

The information here gives me a good start for my research on this subject. What I am looking at isquality of product is being produced both as a consumer and a possible business model. In my opinion a good diagnosis starts with good product, that's how we get quality.

Congratulations on your purchase! First, don't over tighten anything and don't pack the tube. Make sure what you run is 100% dry. I typically run one tube of high quality stuff without decarbing to get the terpenes while running at 1100-1500 psi 45c. Then 3-4 runs of decarbed material to get all your psychoactives. You're most potent extract are going to be after decarbing (baking at 250 degrees for 45min) and then running your ground up material in a full but not packed tube At 3200 psi and 60c or 3600psi and 55c you'll get almost pure THC-A jelly. Now, you'll want to winterize with alcohol to remove the wax and lipids. I've also heard from another Super C user that you can skip the winterization process by using a centrifuge.

Since decarboxylated material shouldn't have any THC-a left over, wouldn't the jelly ostensibly be in the phenolic diterpenoid state? IE: THC delta 8 and 9.

Howdy, do you want to know Chinese Supercritical CO2 Extraction Machine? This is Richie from Shanghai, we manufacture such machine and have customer base in Amercia. If you have interest, feel free to contact me at sales@bettermachinery.com or by Whatsapp/Skype/Wechat (ID is +8615921680965). Also weblink on Alibaba for your checking: http://www.alibaba.com/product-detail/Supercritical-CO2-Hemp-Oil-Extraction-Machine_60485920557.html?s=p

Good morning Richie! I infer you haven't read or spam policy, so would like to draw your attention to it, published Nov 15, 2016 on our front page. We welcome resource information for our readership, but this isn't a sales platform, so I sent all of your duplicates of this post to the spam locker. Do you have any links for the readers to checkout as an interim step, to better understand the scope of your offerings? GW

Hello im looking for Co2 extractor. Im based in europe. im looking for a machine with a minimum capacity of 3+ liter vessel. looking forward to hearing from you!

Just got my 1 litre machine up and running. What temps, pressures and flow rates is anyone using to maximize yields?

[…] and the pressure requirements to put it in this form is one of the reasons Co2 extraction systems are usually so costly. People choose to learn how to make wax dabs without butane of this type usually because Co2 […]

Do you have to dry your plants first or can thy be ran fresh? Some one once told me you could extract without drying first, wondering if true. ty

I've never tried to process fresh material SCFE CO2, so will have to leave that question open to readers who both have the equipment and that experience. You can extract fresh material using non polar solvents, by freezing it first and chilling the solvent to subzero temperatures. GW

Fresh material would not work. We must make sure the moisture content is less than 10%.

I think you'll get about a shot of weed soda loaded with THC if you extract at 3200 PsI 60c. Please let me know how it goes!

Dear sir Ask about the most extraction way of cannabis oil that effective in extraction all compinent , high productivity & economical As i have a big project with government here in egypt Also if you provide these machine please send me quotation of different capacities line Thanks

Hossam, please feel free to contact me and send me your e-mail address and I can send you more info about Revolutionary, high production units. We can custom build any size unit to suit your production needs. Thanks in advance. chris@paradigmsupercritical.com paradigmsupercritical.com 1-760-614-5892

My firm recently moved to a large space with 5,000 ft. unused at the time. We are ready to purchase 2-3 different CO2 extractors to complement our Apeks system. If anyone is ready to sell an extractor(new, used, or refurbished) please contact me at quackextracts@gmail.com. Thanks

Skunk Pharm Research provides information as a public service, but sells no equipment. To your question, the lowest cost per gram to extract quality meds in volume that I've found, is closed loop butane extraction. Sales@pharmgold.com is the company now building the WolfWurx Mk IVC and VC designs by Graywolf. What we found with our passive SCFE CO2 extraction, is that it extracted over the whole heating/pressure curve, so we lacked precise pressure control. CO2 is a small molecule, so it requires a lot of flow to extract effectively. Without pumps to recycle existing CO2, more than our passive system volume. Our passive test sled lacked the ability to recover the different fractions on decompression, which active systems make effective use of. An experienced SCFE CO2 consultant, not employed by a specific equipment supplier, whom can elaborate on those issues chapter and verse is Paddy at: scfepatrick@gmail.com GW

Hello, im currently managing a lab that uses an eden labs LLC custom built 3 exstraction chamber co2 supercritical machine, in southern California. We need help refining to a finished product, we have a large industry rotoary evaporator and much more equipment. Im seeking an individual to help us train myself and a few other lab techs in the refining process for a handsome reward/possible % share holder or both. Please contact me asap if intetested 909-534-7274

Hello, My name is Raquel Ernemann and work for Feyecon in The Netherlands. We have been working over 10 years on cannabinoids and plus 20 years on supercritical CO2 with 10 different spin-offs. We are selling our pilot scale quipment 100L, with two extractors and two separators, automated (one person is needed to run), and fully comissioned for the extraction of cannbinoids (CBD/THC). Anyone interested?

i been looking for one you don't show the price in your website email me please moshedri@walla.co.il

Hello van you tell me more about your extractor pilot machine. As well as pictures. Thank you

Hello Michael, Can you please send me your email address? Thank you, Raquel

Please send me prices and other info ,thanks larryreeves9@gmail.com

Hi Raquel, we are a hemp growing company who manufacture CBD in the UK. If it has not been sold yet then please email me your details at rob_kinghan@yahoo.co.uk

Hi Raquel, Is the Co2 Extraction machine still available? I live near to Weesp (Almere) and i'm interested. Can we keep in touch for pictures, prices, delivery etc.? Looking forward to your reply. Joram E-mail: info@beneficiumlifecare.com

Raquel- Send me your ask for the equipment if it is still available. ibmillercbr@gmail.com Thanks in advance,

Pre shopping for my extraction lab doing my due diligence for all of the lab equipment I'm going to need Whitney price list

Give me a call, I'd love to tell you about our systems or help you in making a decision on a system. A lot to choose from and I can at least give you some additional input on what is on the market. 1-866-262-5678 paradigmsupercritical.com

We have sold the Waters SFE100

We have a Waters SFE100 Super Critical Fluid Extractor purchased new in 2011 and never used.It includes a new Accel Chiller. Original cost over $65K, will take the first $20K offered!

Hey Im interested in learning more!

Julie, Please call or email me to discuss. sales@usedbottlingmachinery.com (616) 643-8028

Price listed in incorrect..should read $25K

Still available?

I am very interested in the apeks and waters systems as I have been slowly peicing together a diy system for years now. Please let me kno if these machines r still available and what kind of terms are on the table.

Any way this is still available??

It sold a year ago. We have several pre-owned C02 extractors for sale. We currently have Apeks, Infinity, and Eden machines available, including 2 "new" Apeks machines that have never been set-up, an Eden with <100 hours of run time, and an Infinity with <50 hours. Prices start at $40k. We also offer leases and short-term rentals. Email me if you'd like more info. matt@extractionstore.com

Hi Matt, please contact me with details what equipment is available and at what price. You can reach me at it.milos@gmail.com

We have a slightly used (less than a year old) Waters SFE 2X5 co2 extraction system for sale. Perfect condition, and with service agreement. Email kydavid@gmail.com for more information. Thanks

How much for the machine?

Mike, if you are still looking for SCFE Unit contact me. Our units outperform anything on market of similar size and most companies 20liter units at a fraction of the cost. Plus they produce a final product on par with hydrocarbon extraction in both potency and flavors. Without having to winterize.

Chris which manufacturer is the one you are mentioning? Would be interested in more info.

Karen, I work with Paradigm Supercritical Innovations. You can contact me at chris@paradigmsupercritical.com

hi mate , can u give me some details , love to get my hands on one of them ,,

Hey there contact me at matthias.crandall@paradigmsupercritical.com if Chris didn't get back to you.

I am very interested in the apeks and waters systems as I have been slowly peicing together a diy system for years now. Please let me kno if these machines r still available and what kind of terms are on the table.

I am looking for a CO2 extraction machine in Boston, MA area or a DIY method to build my own as I currently make my own RSO for cancer treatment (with success I might add) and would prefer to do CO2 extraction instead as buying it form dispensary is extremely expensive plus I can control the dosing and levels of various cannabinoids needed for my RSO mix as I currently do using Rick Simpson's method. Please email me at jtdowgiert@gmail.com

Hi Joe, If you're still looking into a CO2 extractor, or a partner for extraction services, please contact us at info@highpurityextractions.com. We offer extraction services and rentals of our equipment. http://www.highpurityextractions.com

Good morning Kate! I infer you haven’t read or spam policy, so would like to draw your attention to it, published Nov 15, 2016 on our front page. We welcome resource information for our readership, but this isn’t a sales platform, so I sent all of your duplicates of this post to the spam locker. Thanks for sharing your links for the readers to better understand the scope of your offerings? GW

I cannot split with you, what I can do is rent you my extractor and my time to show you how not to break it. I can run between 2 and five pounds. If you'd be interested message me back.

you can email me @ mikecmt4@juno.com, thanks

looking to extract about 40lbs, without buying a machine is there somebody that will do it for percentage of end product?

Yes - NE Botanical. www.nebotanical.com

I still check from time to time. My co2 machine is kicking ass. If someone can tell me how to upload pics, then I would love to share them all with you.

What is the name of your machine? Maybe post a like if you bought it. thx

Is there any way I can get directions, parts list, and schematics to build a good reliable safe system because I really don't have $36,000 to spend on the systems that r for sale these days. I don't think I would spend it if I had it. But this method sounds promising. If any body can give me any info it would b greatly appreciated. Email me @ Jgard73@gmail.com

Not that I'm aware of. A reader many have a lead on such a prize. GW

Can you turn the co2 extracted liquid to shatter?

We can with a lot of our stuff.

Why would I do CO2 if I have to dewax and purge anyways?

You don't have to on our systems.

What system is that?

Our PSICO2 extraction systems. They isolate the cannabinoids from the CO2 leaving impurities behind, so it's not like the other traditional Botanical oil extractors on the market. visit us @ paradigmsupercritical.com