Quick Wash Isopropyl, also know as QWISO is one of the techniques that skunk pharm uses to extract oil from mixed leaf for topicals and sometimes buds or trim for vaporization. Here is our technique for producing a pristine oleoresin extraction.

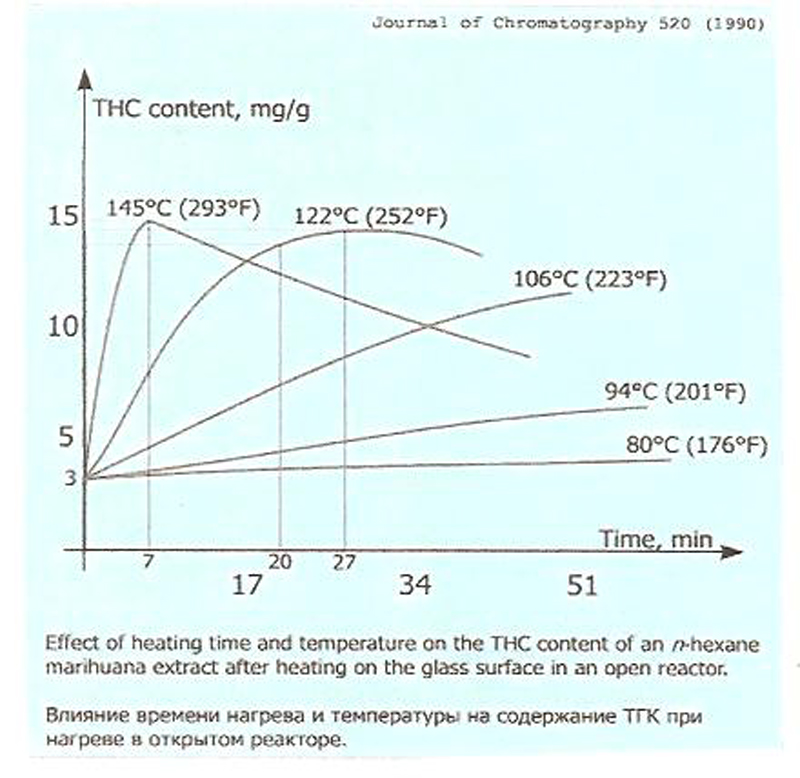

We also decarboxylate our oil for topicals and based on the 122C/252F curve shown in the attached graph, courtesy of Jump.

Note that the boiling point of the terpene ß-caryophyllene is 119C/246.2F, so it is boiled off at that temperature, and its anti-inflammatory, cytoprotective (gastric mucosa), and anti-malarial properties are diminished or lost.

The first question is why use a quick wash technique to extract the resins, instead of long soaks to extract as much resin as possible, or just reflux boiling the material in alcohol to get the greatest amount of extracted material?

The answer to that is that because alcohol is a highly polar solvent that is soluble in water, the latter two techniques also extract the water solubles like chlorophyll and plant alkaloids, as well as the plant waxes and vegetable oil.

Even quick wash does to a lesser degree, but the added steps that we include here minimize pickup even further and we take additional steps to remove the impurities that we do pick up, so that they are not left behind on the skin.

The first wash will usually extract 75 to 80%, leaving the balance for the second. If you use a hand microscope, you can easily see when the trichome heads are gone and the stalks look like wet fur.

A cured material QWISO absolute made from prime bud, is one of the most aromatic and tasty of the extraction and consistently gets high raves from the volunteer test panels, as well as the patients and students when vaporized. Both from an efficacy, as well as a flavor standpoint.

This process is for mixed leaf material however, which includes fan leaves, so it usually isn't all that tasty.

The first step in the process is to get as much water as possible out of the material. Typically material for smoking has been cured to about 15% water content. 15% is a lot of water and the alcohol already has 1% in it, so unless we reduce the water content even further, we will be extracting a lot of water solubles.

We dry our cured material even further by spreading it on a cookie sheet and baking it in a 200F oven until just frangible when rolled between the finger and thumb.

At this point, we have a choice of running the leaf whole, or reducing it in size to improve packing. Leaving it whole will produce a more pristine extraction, with the least amount of chlorophyll pickup, and we do it both ways.

When we make QWISO for vaporizing, or for a show and tell beauty contest, we always leave the leaves whole.

When reducing it in size, while it is still warm from the oven, we force the material through a pasta strainer.

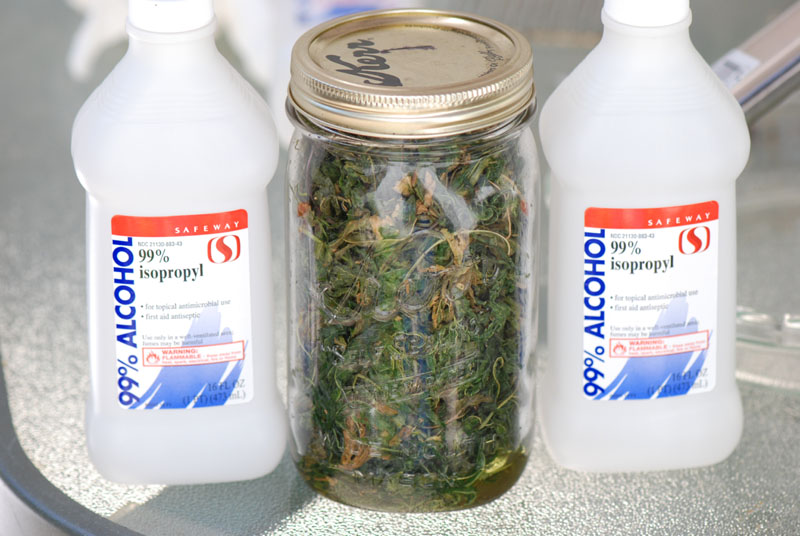

In both cases, we seal the material in a jar while still warm and place in the freezer to tie up any remaining water as ice. We also put the 99% Isopropyl alcohol in the freezer.

When they have both stabilized at about -32C/0F, we pour the alcohol into the jar of plant material, so that it is at least an inch above the material, and shake it gently for 20 seconds.

At the end of 20 seconds, we dump it through a wire strainer to drain quickly. I use a pasta strainer to catch the bulk of the material, followed by a fine mesh French Chinoise. This allows the material and the alcohol to separate fast.

We set the material aside to dry and refreeze for a second extraction.

Next we filter the alcohol, using either vacuum and a #1 lab filter, filter or a simple coffee filter, depending on the quantity we are processing.

After filtration, there are a couple of directions to go, depend on use. If it is to be used for vaporizing, we may place it on a large surface area dish, like a Pyrex pie plate, and just blow air over it. That reduces it fast, but is not a suitable technique in dusty areas. That can be improved somewhat by placing cheese cloth over the dish and blowing over the top of that.

When the alcohol is visually gone, place the dish on a 140F heat mat, or float it in a hot water dish, until the smell and taste of the Isopropyl is gone, usually around 30 minutes to an hour.

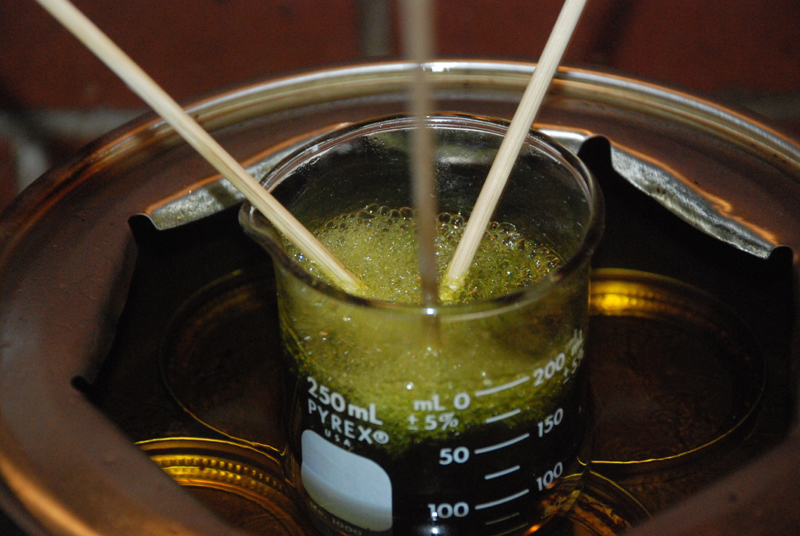

For our use in topical, we place the filtered liquid in a bain marie stainless vessel and place that into an oil bath heated to 121C/250F.

I throw four jar lids in the bottom of my electric fondue pot to suspend the container up off the bottom, to eliminate hot spots and never trust the numbers on the fondue pot dial. Instead, I use a good mercury lab, or a digital thermometer to set the dials. Good temperature control is key to the process.

That means the device that we use to control the oil temperature must have a narrow dead band, so that the temperature control is stable.

We paid about $60 for a Quisinart fondue pot that was designed to heat sensitive sauces like chocolate and has excellent control throughout its temperature range. We scored a second one for $15 at Goodwill, so do shop about.

There are a couple of Revels in our group that are slightly larger and work well, plus cost only about $30, though they have a slightly larger dead band.

Some fry cookers have sensitive enough controls, but many deep fryers designed to primarily run at 375F, lack control sensitivity and have large dead bands at 250F.

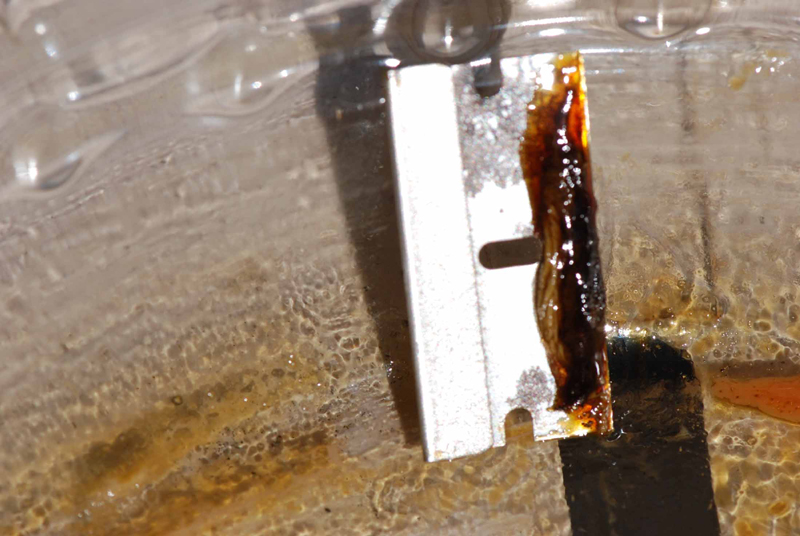

We boil off the alcohol until the liquid is reduced to a pool of oil and all but minor bubbles cease rising at the edges and then pour in at least ten volumes of ethanol and wash out the whole pot by swirling it and washing off any resin stuck to the sides.

Using a funnel, we pour that liquid into a jar or bottle, seal it, and place that in the freezer. After about 48 hours at -18C/0F, the liquid will lose its clarity and become slightly cloudy, from marginally dissolved inactive ingredients like waxes and lipids flocculating out. There will also be precipitant on the bottom of the container. While this step isn't totally necessary, it makes a cleaner, more pristine oil.

Next, we carefully decant and filter that liquid one more time, leaving a bell clear extract, that is ready to reduce down a final time.

We pour it into a Pyrex beaker or a stainless bain marie container for return to the oil bath and since we have much less material, we use a smaller container to keep film losses low.

When the oil is completely bubble free, we remove it from the oil bath, wipe it off, and weigh it. As we know the tare weights of our containers, we subtract it from our total weight and add the rest of the required ingredients for the topical into the same container, based on the amount of cannabis oil present.

We then set the container back into the oil bath and stir until thoroughly mixed and then remove it from the container using a glass syringe, so as to not leave a streak of material in the vessel. Attached thumbnail(s)

GW

Hey, Skunkpharm! I was wondering if there are any solvents that should not go into a vacuum chamber with silicon gaskets? I have seen people use the vac that I have, but I remember reading somewhere that you have to be careful purging certain solvents as they can degrade the materials in the chamber faster. Any truth to this? I'm using 91-99 ISO and 200 proof ethanol (different runs). Also, thanks for the incredible articles and tutorials here. Finding out about this site has been incredibly helpful in my extracting endeavors.

do you guys sell the vacuum assisted filters mucho grassyass

I read somewhere that it takes 8 minutes for all of the good stuff in the leaves/buds to fully be extracted or absorbed into the alcohol, but that heat helps. Personally, I start off with everything at -32f. After the wash, but before I run the product through a paper coffee filter, I use a metal coffee filter so that what's left is nothing but liquid and trichomes. At this point, would placing the jar of product into a pot of hot/warm water do anything to improve or worsen my product?

I am new to iso extraction . In your article you said if the extract is for vaping , you filter the material after a 20 sec wash into a Pyrex plate, evaporate the alcohol then put it in a water bath at 140 degrees for 30 min to an hour. Is that now ready to vape or is there another step after that?

What is that suggest purge time and temp for 99.9% Iso under full vaccum?

Good day sir I have turbo 500 with copper alembic pot still that I just bought😁 I was wondering if I can reclaim ISO through it without screwing up the very expensive piece of equipment for when I start distilling my own ethanol? Buy giving off flavours etc and kinda just wanted too try it to get use to the piece of equipment. Any thoughts would be great but don't want to risk ruining that expensive piece of equipment Without some advice. Sorry if I posted this in wrong place

I would recommend against Isopropyl recycle because of the explosive peroxides that can form with exposure to UV and oxygen: http://nj.gov/health/eoh/rtkweb/documents/fs/1076.pdf If you look at the Cole Palmer chemical compatibility database at:https://www.coleparmer.com/Chemical-Resistance, you will note that Isopropyl alcohol and copper are only rated as "Good", as opposed to "Excellent", which means there is slight corrosion, or discoloration. GW

I AM KINDA NOT TOO SURE ABOUT PART OF THIS ,I THOUGHT THAT THE OVEN WAS IN THE BEGINNING TO BRING THE MATERIAL UP TO ABOUT 220 , BEFORE YOU DO THE WASH?THEN AFTER 2ND OR 3RD WASH, PLACE THEM IN THE FREEZER ON BLOCK OF ICE FOR 1- 12 HRS,THEN FILTER ONCE MORE POUR OUT THE PRIMO LIQUID ON PARCHMENT PAPER AND START THE PROCESS ON A GRIDDLE AT 125-132 D AND LET ALL BUBBLES SLOWLY COOK OFF THEN LET COOL FOR A BIT TAKE MATERIAL PUT ALL THE GOODS ON PARCHMENT AND DO A FINAL SLOW HEAT TO TRY AND GET ALL THE REST IF NO VACUUM IS HANDY, GW, DOES THAT SOUND LIKE IT WILL WORK OR AM I MISSING SOMETHING? THANK YOU ANY MASTER OR EXPERT ADVISE GW WILL HELP LOL, T.Y.

If you are decarboxylating prior to extraction, I would suggest 252F to 293F. Check out the maximum THC results on the curve at https://skunkpharmresearch.com/decarboxylation/ Pouring on the parchment paper with that much alcohol still in it, will ostensibly saturate the parchment paper. I use a casserole dish for the first evaporation, and usually finish it in the same dish. GW

THANKS GW, I HAVE HAD THAT SAME ISSUE WITH THE PAPER LOOSING IT'S ABILITY TO KEEP YOUR GOLD ONT THE PAPER WITHOUT STICKING ,AND IT WILL NOT LET YOU FINISH THE PURGE, IMO, THANKS FOR ALL OF YOU SPEEDY HELP ,AND KEEPING ME FROM MAKING SOME ERRORS. I HAVE BEEN VERY SUCCESSFULL WITH THE BROWNIES THE ONLY PROBLEM IS I USE 4 LBS OF LAND O LAKES ,1 1/2 CUPS OF NATURAL PEANUT BUTTER AND 1 CUP OF EVOO, AND SLOWLY COOK THIS IN LARGE SAUTE PAN FOR HOURS AND I HAVE TRIED IT OTHER WAYS THIS IS POWER FOR SURE THEN I USE THE PRODUCT THAT I MADE IT WITH TO PUT IN WITH THE BROWNIES AND USE 1/3 CUP OF THE BUTTER IN THE MIXING AND USE ENOUGH BUTTER TO COTE THE PAN NICELY,AND HAD SOME VERY LOST TIME FIGURING OUT THE PROPER DOSE, 1/1/2 INCH LONG X1/2 INCH WIDE THEN YOU MUST CUT IN INTO 4 PIECES OR YOU WILL WAKE UP STUMBLING,AND PLAYING PINBALL WITH YOUR FURNITURE,LOL THANKS FOR YOUR ADVICE I TOO AM INTO THE GUMMY S AND CANT HELP TRYING TO MAKE A BATCH, ILL BE CAREFUL, PEACE TT YOU SOON, NEWEYGOOEY

BON APPETITE! GW

HI GW, I AM TRYING TO MAKE THE LIQUID FOR GUMMY S CAN YOU HELP ME MANY VIDEOS ARE LEAVING THAT PART OUT AND I WANT THIS FOR 3RD STAGE LYME'S DISEASE, I CANT NOT HELP HER ,IT'S IN MY KARMA BAG AND I NEED HELP WITH THIS CAN YOU PLEASE HELP ME MAKE THE MMJ JUICE THAT GOES INTO THE JELLO AND GELATIN MIX?? PLEASE ADVISE ASAP, THANK YOU PEACE , MATT

Solly Matt, I checked and none of us know Jack about gummy bear recipes. After ODing a few patients on tasty "betcha can't eat just one" edibles, we stopped researching and making them. GW

I am confused about decarb and temp. If you decarb in the oven and then boil off alcohol until bubbles disappear is this too much heat? Isn't that decarbing twice? Will it ruin the THC?

If the material is already decarboxylated, then the last bubbles to leave will be the solvent. GW

I AM TRYING TO GET AWAY FROM USING BHO AND FROM WHAT I AM UNDERSTANDING THIS QUISO IS NOT USING BHO? IS THAT CORRECT AND YES I HAVE DONE THE BHO METHOD AND HAD SOME GREAT AND IT WAS NOT CLEAR OR LIGHT YELLOW IT WAS USED WITH ONLY bruce banner #3 BUDS ,ALSO USED gdp and the buds were purple dark and it came out the same dark purple, so snobs that think only clear yellow or close to it is better .even though i only use buds no trim,and the terps are yummy.so can i use pure grain alc,150 proof ever clear ? or should i buy the 99% from amazon? and do the wash repeat then remove the alcohol ,and store for cooking gummy candy or vaping? thank you for your time NEWEYGOOEY

Correct, QWET & QWISO are alcohol extraction and don't use butane. 190 proof works better for QWET. You can order it shipped to most places from: East coasters check out, http://www.winechateau.com/ and West coasters, try http://organicalcohol.com/store/ I prefer to use 190 proof ethanol, but if you can't get it, Isopropyl does a good job as well, the purging is just more critical. GW

Would not 200 proof be best as it would reduce pickup of undesirables, or does the water play a part in terpene extraction.

This is a QWISO process, which uses Isopropyl alcohol. It doesn't come in 200 proof, but is readily available in 99% purity, vis a vis the about 95.6% purity of the azeotropic 190 proof ethanol. The water does change the polarity some, and the terpenes do include other atoms like oxygen, so are not polarity neutral. No direct experience finding out, as 99% does a fine job. GW

HEY GW, SORRY ABOUT THE CAPS ARE DUE TO MY POOR VISION,PLEASE TELL ME HOW AND WHEN THE OVEN IS USED INSTEAD OF THE VACUUM?? NEWEYGOOEY

GW, IT'S NEWEYGOOEY AND I WANT TO TRY A SMALL BATCH I CAN ONLY GET 79% OR 90%,ISO COULD YOU PLEASE TELL ME HOW TO USE THE OVEN METHOD,TRYING ABOUT A ZIPPER BLUE DREAM,WOULD IT HURT THIS BATCH IF I HAD TO USE A LITTLE PURE GRAIN ALCOHOL,I THINK ITS 160? 180? PROOF OR SHOULD I USE THE MAJORITY OF PURE GRAIN THEN A BIT OF ISO,TRY TO ANSWER ASAP I WANTED TO TRY IT TONIGHT EITHER WAY THANK YOU FOR SHARING THE KNOWLEDGE , YUMMY

MORNING MATT! NOT FULLY UNDERSTANDING THE QUESTION. YOU CAN EXTRACT WITH ALCOHOL CONTAINING MORE WATER, BUT YOU WILL SUBSEQUENTLY HAVE TO REMOVE IT, SO BEST TO USE 99% ISO. HAVE YOU TRIED SAFEWAY PHARMACY, OR AN ELECTRONICS SUPPLY HOUSE, OR A SCIENTIFIC SUPPLY LIKE AMERICAN SCIENTIFIC? 190 PROOF ETHANOL WORKS WELL AND IF IT ISN'T READILY AVAILABLE LOCALLY, YOU CAN HAVE IT SHIPPED TO MOST PLACES. SEE: https://skunkpharmresearch.com/qwet-extraction/ IF THE OVEN PART IS HOW TO USE IT TO PURGE, I SUGGEST EVAPORATING AWAY MOST OF THE ALCOHOL IN A CASSEROLE DISH WITH A CHEESE CLOTH COVER, SITTING ON A 130F HEAT MAT UNTIL THE VISABLE ALCOHOL IS GONE, AND THEN SETTING THAT IN THE OVEN PREHEATED TO 125F. COVER THE DISH WITH A SHEET OF GLASS TO CATCH BUMP SPLATTER AND HEAT UNTIL MOLTEN. START PULLING A VACUUM AND HOLD IT AT ANY VACUUM LEVEL JUST BEFORE IT BOILS FURIOUSLY, UNTIL IT CALMS DOWN AND THEN CONTINUE UNTIL THERE ARE NO SOLVENT BUBBLES AT -29.5" HG. REMOVE AND LET AIR AND COOL. GW

thank you for the tip on electric supply house that's sounds like the best option for me Safeway is not in my state Florida, the question was because i want 99% and i could not find it but as much as i read i should have no problem, thanks for your help,cant lose any treps that important to me. lol

You're welcome! Location, location, location! We don't have any gaters here not in captivity and sun glimpses are a fleeting thing. Do you have Fryes electronics stores there in the mystical land where Sol Rex smiles, and gaters maraud? It is Safeway's pharmacy that carries it here. You might check with other pharmacies there and hospital supply stores as well. GW

Hey skunk pharm can you help me? After a quick wash of 20 to 30 seconds with 99 percent iOS, I strain through cheese cloth and then through two coffee filters and then into a glass pirex pan. I then put on a double boil and monitor the temp to between 140 and 160 degrees Fahrenheit.. Until all alcohol is evaporated off. I then scrape the resin onto parchment paper, from there I set it onto a hair straightener that is set to 300 degrees Fahrenheit Until all the bubbles are almost gone and nothing put oil is left. Would this be a safe product at this point to vape or do you recommend I burge it again?

Tommy, seems like higher temps than you want to expose your materials to, for best product quality 85 F max retains all your flavorful terps etc

Even for purging.... How do you remove all the iOS?

time works under vac helps, but even then a week or so... patience is not just a virtue, it's a key to good consistent results

vac chambers start @ under $100 cheap vac pump can be had from cheap tool places like harbor freight one time is one thing but if you want to do the process repeatedly, or are sharing with others, being safe is even more important

A good point! If you are making it for others, you should have it tested, and that is in fact a requirement where legal and regulated. Vacuum chambers and ovens make achieving acceptable levels easier and faster, so are more suited where any volume or high quality is a requirement. GW

Chasing a thin film using a heat gun until all the solvent bubble cease would typically have the residual Iso below FDA residual standards of 5000 ppm. The great news is that Iso is pungent, so you can still taste it below 10% of that level, and one dab won't kill or maim you, so I suggest trying it and seeing if you can taste residual alcohol. GW

Hi skunkpharm! I love your website and your scientific approach. I followed your technique with a minor adjustment - i use lab grade iso for extraction, 10 sec wash, and when 95-98%of the iso evaporates, i pour 50 ml abs ethanol to replace the solvent and retain the terpenes, and evaporate until a final product. End product was certainly a blaze. I have not gone through the winterization process but i plan to test that out. My question is have you tried different time points, from 10 sec and above, for the iso wash? Will cooling the solvent and plant material using dry ice or liquid nitrogen allow for longer, more clean extractions?

We used various times and picked 20 seconds as a generally safe place to start. We always tweak a process based on what we are observing happening, so you can extend it until the moment of "now", by observation. Freezing the material and using subzero Iso definitely improves your odds of getting a pristine extraction. It will slow down the extraction somewhat, so it takes longer and is more forgiving. GW

Thanks for the reply! Last question - in your personal experience does winterizing changes the rnd product in terms of psychoactive effects?

Pleeeaaase write that book, I'll be ur first buyer!

Wow! great info, thanks so much. I am wondering tho, if I'm making this strictly to be used in topical recipes is it absolutely nessesary to do the second heating to purge out residual ISO? If I'm not planning on ingesting the oil wd it be sufficient to just fam dry n add to my other topical oils? Does a conflict come in down stream somewhere when I'm melting all of the oils together? Any advice wd be greatly appreciated.

As you suspect, a minor amount of residual ISO would not be an issue for a topical. GW

Have u written any books on extraction

Working on one. GW

if I was only planning on eating the end product what is the best way to concentrate, also do you feel the effects from topicals

Starting out with no equipment, and extracting for one person, I would recommend a QWET extraction. A quality extract with low initial investment. https://skunkpharmresearch.com/qwet-extraction/ I don't feel any psychoactive responses to a topical and have only met one person who said that she could. She was an ultra lightweight from a tolerance standpoint, so it is possible. GW GW

Thank you for all the great info! The issue I'm running into lately is the product still tasting like alcohol. After I evaporate the alcohol until the remaining is a molasses-like goo (about 45 minutes on my heat source), l scrape it all into one puddle. After about ten minutes the puddle starts getting little tiny bubbles which gradually turn into larger ones. After about 45 minutes, all the bubbles are gone and the goo is clear. The wax doesn't give me a headache at all, just tastes a bit like the alcohol. I'm not vaping it currently.

45 min is not long enough even with vacuum. Try spreading it in a thin film 1/16-1/8" and placing it on a seedling heat mat for two or three days. GW

I'm having problem with my qwiso. The end result look really nice but every time I light it there is black smoke. Even if I boil it before consumption there is always that black crap at the beginning. Are you guys able to obtain results without black stuff at all? I used 99% iso , made the extraction outside (-11celsius). Filtered with strainer , 25 micron bag and coffee filter. Pyrex dish for 24 hours with a fan. Do you guys do something else?

Isopropyl burns clean and doesn't leave deposits. The Terpenes are flammable and cannabis essential oil gives off black soot when burned. I don't recommend burning cannabis products in any form, because of the free radicals and carcinogenic byproducts of pyrolysis. Have you tried vaporizing that concentrate to see how it is? That is how I recommend you use it. GW

I AM HAVING A PROBLEM FINDING ALCOHOL THAT IS MORE THEN 91% UNLESS ITS PURE GRAIN 150PROOF?? ANY IDEAS

We can get 99% Iso at Safeway locally, as well as the local electronics store for cleaning circuit boards. I typically use 95.6%/190 proof ethanol from the liquor store, but you can also get it shipped directly to you at: East coasters check out, http://www.winechateau.com/ West coasters, try http://organicalcohol.com/store/ GW

I have been making qwiso shatter for a while now. Following these instructions nearly to a T. My problem lately has been the fact that I have been unable to make shatter anymore. Since it turns to a sugar wax. I looks great, and lasts longer. I am just bothered, because I'm not sure why this keeps happening. I also looked into the boiling point of caryophyllene to find the boiling point to be slightly higher. We may have already debunked that.

I discussed this with Pharmer Joe, since he has been working extensively with THCa crystallization, and he opines that your THCa level of purity has increased to the point it is nucleating. GW

So then should decarboxylation remedy this issue?

Ummm, could you elaborate? GW

Ya, referring to Pharmer Joe's thought that perhaps THCa neucleation has occurred. Would decarboxylation reverse this so the end product is more "shatter" like?

Can you explain the purpose of reheating after the ISO evaporated?Cant I just scrap the residue left behind and use that oil?

Even though it may appear that all the ISO is gone, there is still more left in the concentrate than is permitted by FDA residual solvent standards for ISO. ISO attacks the central nervous system, as well as the auditory nerves in excess. GW

Thanks for the quick response. So can you validate if this process will work? Take the pyrex dish after alcohol evaporated and place on an electric griddle on 200 degrees, low heat, until the oils have warmed and turned liquid again. Will that get rid of the rest of the alcohol? Id use what you just posted, but I got totally lost at some point.

In a word, no! If you put the alcohol mixture in a bain marie type container, and set it in 250F hot oil, the alcohol will leave and then the carboxyl group, in the form of CO2 bubbles. By the time you are decarboxylated, you are typically below FDA residual solvent standards for ISO. GW

Is the 140F heat mat/water bath for 30/60 mins not supposed to be the last step for product that's to be vaporized or dabbed? or are you saying it needs further purging?

[…] QWISO Extraction with Isopropyl | Skunk Pharm … – https://mobile.twitter.com/pancakespoons/status/763020983783399427/photo/1 This is a photo of extract dissolved first in isopropyl alcohol, then tap water is added … […]

Hi all, i had a run of BB#3, hat got neglected at harvest, not my fault , i ran all buds and got plenty that came out great for a newb, the other was blue kripple and was dark but with a light under it ccould see thru. Is it too late to use my mini blender and some IPA TO GET THE KINDA GREEN FLAVOR out by blending it with IPA? Filter it put in freezer 24-48 hrs and r evaporate on siclacone mat? To improve the flav? IT is already strong. So can this work ANY HELP T.Y.

please help me get the responses to my question's, i am not the best on a computer and also 100% disabled so this is all new to me. thank you

[…] QWISO Extraction with Isopropyl | Skunk Pharm … – Isopropyl Alcohol is based on the simple Alkane Propane atom, … THC, cbn, liquid … QWISO Extraction with Isopropyl | Skunk Pharm Research LLC … […]

https://mobile.twitter.com/pancakespoons/status/763020983783399427/photo/1 This is a photo of extract dissolved first in isopropyl alcohol, then tap water is added slowly until the nearly pure essential oil rolls out of the mix like a worm. Small amounts of oil are left entrained in the white iso/water/terpene/wax layer. That layer is drained and frozen to recover trace amounts, and the oil "worm" is boiled in water then frozen. The water as ice is easily removed and a vacuum chamber procedure used to remove all water. Isopropyl alcohol is listed as being fatal to humans in doses as little as eight ounces. This process normally takes an ounce or so of iso for each batch of a few grams as shown. Iso is widely used in pharmecutical processes because of the inherent historical safety - only cases of extreme suicide attempts account for serious poisonings and those are pretty rare because of the pain involved in attempting this. In my process the iso is completely evaporated under vacuum. Trace amounts of isopropyl alcohol are easily detectable by smelling hot extract. The nose knows!

OK apollogies - after reading the replies I think I have worked it out - basically ISO/QUISO extract is perfectly safe to vape in an e-cig but not to use in a tincture or eat?

Hello and thank you all so much for your tireless work. I have a question on this - I thought I had read in another post on here that you should use ethanol not ISO (rubbing alcohol?) because there were nasties in it that would not evaporate (although it might have been about producing RSO oil for oral consumption – but what’s the difference? If it’s not safe to eat surely it’s not safe to vape? (I will be vaping it in an e-cigarette as explained below) I would love to be able to use ISO because I can’t get everclear or any other foodgrade ethanol higher than max 40% ABV /80 proof vodka. (I cant even get it imported into my country!) The isopropanol I have says "external use only" (i.e. topical – definitely not food grade etanol) I am planning to use kief so the quantity of ISO needed should be fairly miniscule compared to using bud or trim so presumably toxins or impurities would be minimal? - will it matter? Is there actually anything in the ISO I need to worry about? The extract will be for use in e- liquids/e-cigarettes /penvapes with a PG/VG mix of 20/80 with some PEG-400,300,200 (EJ-mix) to keep the oil runny enough. Will this be OK/safe with ISO or do I need food grade ethanol? Also I have read it is necessary to decarb the extract for full effect in an e-cig - can I just put the final oil in the oven to decarb it in extract form (and would this help get rid of any impurities?) – or do I have to decarb the kief before the wash? Sorry for all the questions – I’ve been working on getting Food grade everclear or similar but it just isnt going to happen so looking at ISO as next cleanest option. Thanks in advance for any help M

Qwiso is said to not be safe to eat because it had been rinsed with ipa which is extremely toxic to humans, if evaporated properly I don't see why you couldn't just decarb it but I'm not an expert, find out before you do and eBay or Amazon sell 99% cheap they ship global

Can you reuse reclaimed ISO please. I have a small air still which reclaims 70-80%. Thanks

Can form peroxides with distillation and react with aluminum, to form explosive mixtures, sooooo we don't. It is relatively cheap as well, compared to highly taxed Ethanol. Check handling and storage at: http://nj.gov/health/eoh/rtkweb/documents/fs/1076.pdf GW

Ahoi there Grey Wolf/Skunk Phrmers, I'd really appreciate a little clarification regarding PTFE / Oil Slick Sheets and QWISO use, as despite a lot of reading I can't find a satisfactory answer. I see that PTFE is generally listed as resistant to iso alcohol (apart from one comment online saying it becomes temporarily translucent on contact - I can't confirm, and do doubt this), so I presume it would be ok to line a collection vessel with PTFE sheet to avoid scraping up the QWISO after evap. Now, I read that Oil Slick PTFE Sheets are of a woven material, and some people have issues with seepage through the weave. I also think Oil Slick only recommend their use with butane, not iso, but I can't see why from a chemical reactivity point of view. Are all PTFE sheets woven, or can 'solid' foldable sheets be aquired to your knowledge? Lastly, I wish to thank you for the information presented on this site, it has been invaluable in learning how to produce high strength tinctures for sub-lingual use by my wife who suffers with MS - she says this medication has been life changing. Many thanks!!!

Ahoy Sylva! I'd think, if you are concerned about quality and purity, adding unknown variables is counter-productive, in general. More pourous materials are going to be more likely to leech contaminants into solvents. Personally, I have no plans to work with anything but stainless and pyrex with extract thats still holding any significant amounts of any solvent. To me, the price of getting a contaminant into your product is far too HIGH to risk, especially just to save a little time scraping... Feeling that way, these questions of; "how much risk is there" and "what types of contaminants" and "what is the actual possibility" become secondary to deciding to not let it be a factor at all.

Oil Slick Sheet (which is simply PTFE sheeting), is resistant to 2-propanol and will cause no problems as a vessel liner. Unless you damage the surface (by piercing or folding to excess), it will not leak. I will personally attest to this, having used some for this purpose.

so did a quick wash 91 percent iso with an oz of good and when i hit it on my rig it leaves a waxy ashy residue and it dosnt look like there is much reclaim in the rig either whats going on never seen this before its almost like it is smoking like risen after already burning weed ????

I suggest trying to find and use 99% or higher Isopropyl. With 91% Iso you can't be positive all of the leftovers are water without looking at the manufacturer's MSDS sheets online. Safeway used to have 99% but I haven't seen it on the shelves lately. Maybe ask at the pharmacy counter. Fry's also has 99.9% anhydrous IPA. If asked what it's for, talk about optics and lens cleaning without water residue.

I have QWISO washed several dry-ice screened old kief runs and have have good success w this. {Better than 50% returns on tan/blonde/better kiefs with a dry powdery crumble residue left in the coffee filter which had no effect when later "tested" in a few ways after thorough drying and all "musty" smell component was removed from the resulting extract} I have not done flowers/vegetation but am preparing to do so and going the extra steps to chill it and the 99% first. I'm wondering about the after-washed vegetation. Is this "safe" to then compost and recycle eventually back into my bio-cycle of gardening... ? Is there tocxic residue from isopropyl alcohol which would not break down and be detrimental to future soil mixes?

Isopropyl alcohol is an isomer of Propyl alcohol. Isopropyl Alcohol is based on the simple Alkane Propane atom, with the addition of one oxygen atom in the middle of the chain. If the oxygen atom were at the end, instead of the middle, it would be Propanol, or Propyl Alcohol, instead of Iso-Propyl. That means that there is nothing there but carbon, hydrogen, and oxygen, so that is all that is left behind, usually in the form of CO2 and H2O vapors. If you spread it in a thin layer in the sun/weather, the bulk of the alcohol will ostensibly leave relatively fast, allowing the Aspergillus and other composting molds to take over. You might also consider a tumbling composting barrel to speed up larger batches, by regularly aerating it. GW

Hi, You say the terpene ß-caryophyllene boils off at 246f, whats the best way to do an extraction If I wanted to keep this in?

@EXACTLY 245 degrees...

Short path distillation would ostensibly be the easiest. GW

is it possible for me to use AVB instead of green bud

AVB???

already vaped bud

Yes but it tastes terrible.

Hi there I am a UK resident working on making (obvs. not industrially, UK law does not permit such things for the time being...) a canna extract for use in an ecig. Thanks to this great site I know the whole process but have a question: I have in my possession a bundle (36 oz or thereabouts) of dreadful hash (sputnik or Moroccan, as it is known in the UK, hard resin for those not used to the UK slang) which tastes as though it has been soaked in petrol/ diesel. It is my intention to grate the ghastly ganja, wash with ISO (99.9% lab grade), mix the ISO extract with Hexane (also lab grade), wash with salt water until clear, winterise and purge the Hex with Ethanol (99% denatured with 1% MEK(boiling point very close to that of ethanol)) then disolve the hopefully nice and clean extract in EJMix and dilute to strength with PG/VG. Are there any glaring reasons why this shouldn't produce just as potent an extract as if I was using the finest uncut god's-own hash direct from skilled and aged artisan producers? I am sure the yield will be less, it is the potency and efficacy of the end product I am concerned with, as the dope was absurdly cheap. I am planning a test run on an ounce or so before I go big time. I'll let you know how it goes.

No reasons at all that won't work - good luck with the results

Except that he's talking about using denatured alcohol which contains things you definitely don't want in your final product. Also, if there is a contaminate in the hash, ie: diesel fuel from being crammed next to the leaky gas tank of the car it was smuggled in etc, that contamination will be ten fold in the finished concentrate. Just good for thought. If you don't care about your own health then by all means go for it. I personally think it would horribly unethical if you plan to sell or give it away to anyone else.

I am new to this and I'm trying to find the right path. I started out cooking bud straight into coconut oil at 160 for 12 hours after decarboxylating at 240 for an hour. I was making lotion with a little bit of bees wax. It would knock you out but I like to be active not stuck. So I learned more about temps, THC, cbn, liquid sunflower lecithin and caps and tried less oil to bud ratio and made pills.. It was nice but had to take about 4 or 5 "00" to really hit you and my goal is for a 1 all day pill if possible. I don't care about medical use just trying to give an astronaut a high five. Then I found RSO which seemed pretty promising. I never use more than a 7 of high grade. Always the best I can get. So I was a little nervous about decarboxylating after extraction so I did it before in a oven at 225 for an hour. The RSO was dark and paste like and was way better than before. I made another attempt and tried the decarb after but couldn't figure out what the carb bubbles look like so since it was a good Amber color I kept it to smoke by spreading on blunts and joints. It wasn't good for dab though. So I did a long search and I stumbled across QWISO and found out how filthy RSO is for smoking anyway. So now my next attempt is QWISO. I've seen many methods on wash times and have a good idea what to do. Now the questions. If I let air dry with a fan, do I wait till all alcohol is gone before I scrape it up and decarb? Do I still add a few drops of water to help evaporate if I'm not using heat? After evaporation do I need heat to purge into shatter? Can I make shatter then melt it down to make the pills with coconut oil? Can anyone put a link to pictures or a video showing the decarboxylation process with concentrate? I will be making a batch of shatter for smoke and another batch for the pills. Hope someone can help. Thanks..

Shatter is the original carboxylic acid form, and once decarboxylated, will no longer be brittle at room temperature. To keep it in carboxylic acid form, purge in a very thin film using low heat. For decarboxylated material, the decarbing will remove the last bits of alcohol. We like 250F and watch the fizzy bubbles. The solution won't reach 250F until the 82.5°C (180.5°F) boiling point Isopropyl and included water has quit boiling, and those bubbles are typically larger and more randomly sized than the CO2 bubbles from decarboxylation. I wouldn't add more water. You will have absorbed water from the atmosphere and the plant material. As far as heat, the raw oleo-resin forms a skin with a high enough surface tension that the remaining solvent has difficulty escaping. Adding heat serves to lower the surface tension and to excite the solvent molecules into greater activity, and if also combined with vacuum, so as to require less heat and time, can reliably produce a QWISO of shatter consistency, and below FDA pharmaceutical standards for retained solvent. It is faster and requires less heat if you purge it in a very thin film, and in a very thin film without vacuum, was how we did it in the hoary days of yore, before discovering how much easier and reliable it is using a vacuum. GW

How much of the fizz should I let disappear before taking it off if I want a really good head high instead of getting couch lock?

Also, will adding the coconut oil and liquid sunflower lecithin be enough to make it bioavailable?

[…] QWISO Extraction with Isopropyl | Skunk Pharm Research LLC. […]

Do you have to purge the oil