Ever thought of using N-Hexane for extraction or alchemy? At the Skunk Pharm we use an HPLC reagent grade hexane, which we acquire from the local scientific supply store, for a number of things.

Like butane, hexane is a simple alkane, but it has two more carbon atoms and four more hydrogen's, which makes it completely insoluble in water. Pentane, with five carbons in the chain, is the first completely insoluble alkane.

It's longer chain gives it a higher specific gravity and higher boiling point than butane. Hexane boils at 69C/156.2F, versus -0.6C/30.9F for butane, which makes it more difficult to purge.

It can be purged under heat and vacuum using thin film techniques, or simply washed in ethanol, which boils at 78C/172.4F.

Our sensory perception threshold for hexane is 30ppm and OSHA TWA limits for breathing it 8 hours, is 500 ppm, so we can detect its gasoline like taste far below TLV.

Hexane is commonly used to produce pharmaceuticals and even food products, and is not Mother's Milk, but the point is moot, as it is not left in amounts that are toxic.

There is a difference between trace amounts and toxic doses, because poison is in the dosage. Even Oxygen is a toxin at over 75% atmosphere and you are just as dead as from an over dose of any substance.

So what are the facts about hexane? One is that if hexane is present at levels as low as 30ppm, it tastes exactly like gasoline.

Since concern starts at 250 ppm for chronic and nearly continuous exposure, our senses are adequate to protect us from exposure to toxic levels.

So lets see what the governing authorities think about it, while paying attention to how the dosage rates compare to levels less than 30 parts per millionth:

SECTION 11 – TOXICOLOGICAL INFORMATION

CAS# 110-54-3: MN9275000

LD50/LC50:

CAS# 110-54-3:

Draize test, rabbit, eye: 10 mg Mild;

Inhalation, mouse: LC50 = 150000 mg/m3/2H;

Inhalation, rat: LC50 = 48000 ppm/4H;

Inhalation, rat: LC50 = 627000 mg/m3/3M;

Oral, rat: LD50 = 25 gm/kg;

Carcinogenicity:

CAS# 110-54-3: Not listed by ACGIH, IARC, NTP, or CA Prop 65.

Epidemiology: Occupational polyneuropathy has resulted from hexane exposures as low as 500 ppm, but the minimum levels of n-hexane that are neurotoxic in humans haven't been established.

Nearly continuous exposure of animals at 250 ppm has caused neurotoxic effects.

Teratogenicity: No evidence of teratogenicity or embryotoxicity in anmial studies with hexane.

Fetotoxicity has been observed in the presence of maternal toxicity.

Reproductive Effects: Severe testicular damage has been observed in rats exposed to hexane at concentrations which have produced other significant toxicity.

Although sub-neuro toxic doses of its principle toxic metabolite, 2,5-hexanedione, can induce progressive testicular toxicity in rats, there have been no reports of human sterility or other reproductive toxicity associated with n-hexane exposures.

Mutagenicity: Positive results (chromosomal damage in the bone marrow cells) obtained for rats exposed by inhalation to n-hexane.

Neurotoxicity: n-Hexane is a mild irritant and CNS depressant in acute exposure, but its principal effects are damage to the sensory and motor peripheral nerves, particularly in chronic exposure.

Moving to ease of use, because of its insolubility in water, you can soak plant material in hexane without picking up water solubles. I have soaked as long as 12 hours.

Using hexane requires close attention to safety issues, as it is highly flammable and even lower explosive limits than butane when used in an unventilated area.

Hexane's lower explosive limits is 1.2% of atmosphere, and its upper explosive limits are 7.7, as compared to lower limits of 3.3% for ethanol and 1.8% for butane. Except for well ventilated lab conditions, hexane extraction and alchemy is best done outdoors, with a fan blowing away and dispersing the vapors as they are given off.

Pentane and Hexane are the components of light naphtha, or white gasoline, and should be treated with the same care and respect.

Needless to say that it is a no smoking or toking activity, so leave the lighter and smokes out of reach, lest you reach for them automatically.

Besides open flame, static sparks can ignite the fumes, so don't do hexane extractions wearing plastic clothes, especially on cold dry days.

Using glass wear to contain highly flammable liquids carries drop and splash dangers, which I am going to draw your attention to, but confess that I routinely use lab glass wear with flammables in it and that the hexane itself usually comes in a glass jug.

A stainless steel container for the soak portion of the process, could achieve the same effects however, without the same breakage danger.

Ambient temperature is important, and hexane has a relatively high vapor pressure of 151mm Hg @ 25C/77F, so it is important to keep the mixture relatively cool for long soaks or use a vented container to control pressure buildup.

We use hexane for both extraction and cannabis alchemy. Because it is relatively expensive, it is usually more cost effective to do the initial extraction with another less expensive solvent and use a lesser volume of hexane to polish it afterwards.

For extraction we simply fill a jar about 2/3rd full of material that we have broken up to about coarse rolling size, and fill the jar to the 3/4 level with hexane. We shake well, loosen the lid to release the pressure, seal it again, and set aside. We periodically repeat the shake and pressure relief steps, for up to 12 hours.

At the end of the soak, we pour the mixture in a strainer, and press the material to force as much hexane out of the plant material as possible. We then filter through a coffee filter or vacuum filter using a Wattman # 1.

You can do the initial purge of the hexane by simply setting it aside in a pie plate to evaporate, and can speed that up by setting the pie plate in hot water and blowing air over it, if you aren't in a dusty setting.

You can also boil off the hexane in a double boiler, with either hot water or hot oil as the medium in the pot, and can speed that up with vacuum. See attached pictures of thin film vacuum purging, as well as a ghetto rig in a fruit jar:

That brings us back to final purge, and as I noted above, if you don't have vacuum equipment, final purging can also be done by washing in ethanol. Washing is done by re-dissolving the raw HHO in ethanol and boiling the ethanol off. The higher boiling point of the ethanol and the scrubbing action of the alcohol molecules boiling off, will take the remaining hexane molecules with it, while keeping the process temperature below 173F.

Re-dissolving in ethanol also allows the interim step of winterizing, by which you place the ethanol HHO mixture in the freezer for a couple of days until the waxes coagulate and can be filtered out, before evaporating away the alcohol.

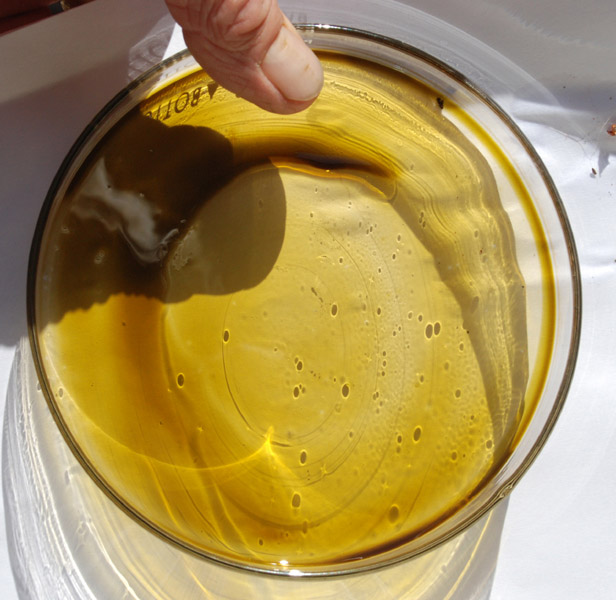

While it can be used for extractions, where hexane really shines, is cannabis alchemy. For instance, you can extract the cannabinoids with ISO, Methanol, or Denatured alcohol and after reducing the volume of the alcohol through evaporation, when it reaches a convenient and economical handling volume, mix it with equal parts of hexane and super saturated salt water.

If you agitate that and place it in a separatory funnel to separate, the hexane will rise to the top with the cannabinoids and the water and alcohol mixture will sink to the bottom, where they can be bled off. See picture of separatory funnel, and check out our page on polishing extracts for more details.

Lastly, we use hexane to isomerize or make cannabis acetate. That involves reflux boiling the hexane cannabis oil mixture in sulfuric acid, or acetic anhydride.

More on that in Joe's Cannabis Acetate thread.

Hi I am just wondering would this be a good process to remove unwanted chlorphyl from a soxhlet extraction I will be extracting using ethanol then winterizing then remove as much ethanol as possible ready to mix with hexane and water Could I polish soxlet extract like this ??

Wtf need more info on a basic process

Can anyone tell me why hexan is even required in all this? What would be the problem with extraction via isopropyl throw the aliquots a into a rotovap to evaporate off 80-90% of the ISO to a point where it's still workable then transfer to the fractional distillation apparatus to distill the rest of the ISO off and then do you fractions at slowing increased temps? All the lipids and chlorophyll should just stay in the round bottom and won't boil off until the last fraction, right? The end use of the product would be for vaping not edibles if that even matters.

In this process it is a required component because the title of the article is about it.

Haha yeah I noticed that after I posted. sorry about that. Not really the right article to be asking. You seem really knowledgable on the subject. is there anyway to contact you directly to ask your opinion on a few things? -nick campbeln2007@hotmail.com

lolz, I was half joking in the response hehe. My contact is my screen name redturtle984 at gmail dot com. Drop me a line anytime.

Azeotrope is easy to look up on the internet, but if true what this person is suggesting is that a ternary azeotrope exists between these substances then is simple to check; if these three do form an azeotrope then distilling them under standard atmosphere will not seperate them. They will come out of the condenser in the same ratios that they boil at, complicating seperation. Isopropyl Alcohol and water form an azeotrope known as rubbing alcohol. If you distill water and isopropyl alcohol then you get both back at the same ratio they were before because they form an azeotrop (constant boiling temp) rather than a non-azeotropic mix in which each component boils off at seperate temps. If the assertion that these three form such a combination is true then in order to use fractional distillation it must be carried out at reduced atmosphere. These are other ways to "break" an azeotrope too. For instance, if you want isopropyl alcohol in a form mostly free of water, you can add salt to the mix. The salt breaks the azeotrope formed between iso and water and the two will seperate into seperate immiscible layers. Try it. Very cool to watch happen. Alcohol goes to top by itself, and salt water settles to bottom. It is a simple way to cheaply obtain relatively pure iso from any grade of rubbing alcohol - just salt out the water.

I am used to making RSO w 99.8+ isopropyl. Soak time is suggested at only 3 minutes so other non THC compounds dont go into solution, such as waxes, chlorophyll etc. So I'm surprised the soak time for hexane is 12 hours. Thoughts?

I routinely disolve supercritical fluid extracts in isopropyl alcohol as the first step in refining them. At room temperature, unless agitated, the extracts left to soak in iso can still not be dissolved completely in more than an hour. Depending on the xtract it sometimes involves several minutes of vigorous shaking to disolve every last bit. Since the extracts are orders of magnitude easier to disolve because they have already been seperated, I am having amtough time visualizing how just a few minutes soak of plant material can extract the same things out of the plant in such a short time? I have speculated that one thing that makes RSO effective is likely trace residue of iso which in theory is an anesthetic in mammals. Since RSO clearly spells relief for so many I often wonder if there is a synergy between trace amounts of it and other plant constituents. I am absolutely certain that extract refined with iso is far and away better than other processes I use. Generally makes the oil turn red if it is cooked low and slow leading up to a boil. Yum.

That means you need to use a column when you reclaim the solution. If two different compounds boil together than there needs to be a column to cause the ethanol and water to reconsid and not come out in the distallation process. Thanks for that info, I was wondering what was happening.

It's worthy to note that if you are intending to reclaim your hexanes, that they form an azeotrope with ethanol and H2O.

Meaning what Einstein?

That they're coming back in the same ratio unless you separate them in a vacuum to recover JUST the hexane.

I have as a and eye problems can this help me.

Start reading on page 741 in the Granny Storm Crow listings. http://www.letfreedomgrow.com/cmu/GSCListJan2014CONDITIONS.pdf GW

I have learned how to tease out the red color, purify, and control the general makeup of dispensary extract in preparation of running a cryogenic sublimator to attempt to photograph amber and red crystal formations of Delta 9 THC. I use isopropyl alcohol in the process which is fully removed. Isopropyl alcohol can be fatal in doses as little as eight ounces. My whole process prior to evaporation uses a tiny fraction of that dosage and is therefor safe even if exposed. I vape everything I make. The Cherry Red oil is by far the smoothest, fruitiest, and most pleasant body rush and mental focus medicine I have to date used - and I use a LOT. The reality of purifying the med this way is from dispensary to vape the process removes 25% nominal material by weight. Most of what is removed smells and looks just plain gross, but there is some transfer loss which can add up. It makes gleening fun though lolz. https://vimeo.com/171020414

what are you using as a hating unit is that a light bulb

I have several display lights left over from a retail business. These lights are sealed beam and have UV light shields. They are about 35 watts and get very hot but have a rheostat for asjusting brightness/heat. They hold small beakers perfectly and let you see "inside" the product which reveals so much more than unlighted. They are merchant sealed beam UV protected lights meant for display windows.

Where can I find affordable hexane? I'm not-for-profit, so can only afford iso by the gallon. N hexane is exponentially more expensive but I want to try it. Also, than you for the great info!

You are not going to be able to find a really cheap source of hexane that is the grade necessary (in my amateur opinion) for safe purging of the solvent. I believe this is the grade of hex that I used and I got it from Spectrum Chemical - https://www.spectrumchemical.com/OA_HTML/chemical-products_Hexane-HPLC-Grade_HP682.jsp?minisite=10020&respid=22372 I opened an account with them using my company name but they would probably sell to anybody. This version is 95% n-Hexane and the other 5% is a combination of the 3 isomers of pentane. They use really high grade packaging for safe shipping and will ship anywhere (within the US).

Hi graywolf, The first thing I would like to say is thanks for all the amazing information. I really, really appreciate it. I wanted to ask you about hexane extractions. I have a question I was hoping you could answer. It seems like hexane oil extractions can still be very dark after filtering through coffee filters and "removing" the chlorophyll. My thought is that some of the chlorophyll is still present but it doesn't exactly make sense since as far as I can tell hexane won't dissolve water. The samples were dissolved in isopropyl, evaporated then redissolved in hexane. Then it was filtered through coffee filters and some thin wire mesh, removing a large amount of thick green material. After it was dissolved in hexane it was mixed with water and stirred under heat for a while. Then frozen to remove the water and evaporated down. It however still remains quite dark. A few notes, Salt was not added to the water I would appreciate if you have any knowledge of why its still so dark, and any methods that might be available to change that.

in your initial rinse, how long are you letting the material "soak"? Are you doing sub zero rinses? or room temp? In my experience keeping it cold along with precise timing keeps the color for me. I have never experienced any green in my rinses mostly cherry and gold. One thing you might consider is cutting back your soak times. start by cutting them in half and work up hour by hour. this might just help your color problem.

Also, as you are doing the fill, shake and drain process, make sure that you have enough hex in the mix to keep the oil dissolved good. I found that after filling and draining over and over the hex would gradually evaporate and I would have to add some new (~50ml) to the separatory funnel a time or two to keep the process going in the right direction. (the process---> right direction = removing the dark color) REMEMBER! Always use care when handling/opening a container of n-Hexane. The very high vapor pressure of this stuff is a trip and all the agitation increases this property!

fantastic advice. good point man, kudos! I affectionately call that "sprinkling". Hex DOES evap. very fast and you most definite can F*&^ yourself during this process if you are not mindful of time vs evap. when it comes to hex.

Hi, Thanks for the replies guys. Just to be clear I'm hearing that you redissolve the samples in hexane and filter several times. This seems like a prudent idea as any chlorophyll should stay behind in the filtering layers. My question is in large samples around 1/4" thick (6mm) is it always going to look black or should it be transparent. How many times do you repeat the fill shake and drain process? I'd also really like to know the specific compounds that hexane might pick up that isn't a active ingredient or a terpene. I was looking into beta carotene but as far as I can tell only a small amount should exist since pubchem lists only 109mg dissolving in 100ml of hexane. https://pubchem.ncbi.nlm.nih.gov/compound/5280489#section=Melting-Point I've really not much chemistry knowledge but I thought chlorophyll shouldn't dissolve in hexane as well, which again perplexes me why the color remains dark. It may just be sample size. In response to Shivago Joe, the rinses are about -10C from like 5 minutes to as long as 12 hours and they don't exactly look green, the edges look gold but looking directly at the sample all I can gleam is black. Oh and I most definitely agree hexane does evaporate very fast, I would never get near it without a gas mask. As a side note it seems condensing hexane vapors is more than a small challenge due to the unusually high vapor pressure at normal operating temperatures. One possible solution is heating a closed system, but well ..... I don't know if I'll be willing to try that without quite a bit of research first.

This shit is analogous to cooking meth. Yall aren't even getting high from weed at this point. You know every additional chemical added leaves residues that DO NOT vacuum off....

He's solely 23 years previous and he might easily win this week it is just do you want to take 16 to 1 odds on him?

Hello I am wondering if all the extra "rinse" steps are totally needed? I have been using more or less the same procedure but when it comes to evaporating off the white gas, I use minimal heat at forced air(controlled). The art form, for me, is in the last evap. making sure that I don't heat it up to the point where it will burn because we all know how fussy thc can be in this form. Also are the super long rinses a better way to go? I have been doing about up to 2 hours max. and getting two good batches and one "lesser" batch from that initial rinse procedure. Is doing a cleanser rinse with ethanol a vital procedure? I have not been using anything to rinse away the final traces of white gas I have just been purging with minimal heat and "kneeding" the oil with a 2" wide spatula. I hope I have not been slowly killing myself all these years hehe.

The answer is as close as your friendly neighborhood analytical lab to verify your procedure. We found it necessary when we did it. GW

GW, Thanks for all the REALLY helpful information, you guys must have a great time doing what you do! I was going to use the term “blast” but thought otherwise. My question(s) have to do with cold boiling, purging and recovering as much of the solvents used (Hexane and Ethanol) at room temperature as described below and if this process will work. You have much more experience so we look to the “Master” for his opinion. A friend sent me his “recipe” for HHO. It seems very straightforward and clear process. This process seems slightly safer than boiling under heat since it is performed at “room temperature”, I guess the area is hot since the stated temp is 21c or 80f. If there are any missed steps or critical errors PLEASE ADVISE. Would you please review it as I would like to try it ASAP. Here is the process as explained to me: Materials List: 112g of high grade dry (40% humidity) bud 1 Liter of HPLC Grade Hexane 98%+ 1 liter of 95% Ethyl Alcohol 1cf Vacuum Oven or vacuum chamber (since heat is not required) 1000ml vacuum distillation kit and stand to hold it. 70mm Ceramic Buchner vacuum filter kit and slow 70mm filter paper Vacuum pump, Vacuum gauge(s), Submersible fountain pump (small), air tubing, 5 Gal bucket 20Lb Ice 2 big mason jars with lids gloves, goggles, lab coat, assorted glassware Lots of Isopropyl Alcohol and paper towels to clean up A work Area with plenty of ventilation (OUTSIDE), no source of ignition or flame 1. Grind the material to the consistency of course coffee grounds, remove any sticks and twigs. 2. Soak Material covered in Hexane for 12 hrs in a Stainless or glass container semi-sealed and allowed to release the pressure. I put it in the fridge to minimize evaporation. Mason Jars work fine just don't tighten the top. 3. Vacuum filter the soaked material through “Slow” filter paper (you can cover the top of the filter funnel with clear plastic food wrap and a rubber band which will increase the vacuum pressure as the plastic food wrap is pulled down adding pressure to the material getting more of the liquid out), save liquid. If any solid material is present in the liquid repeat step 3 until there is no vegetable material present. 4. Take the filtered bud material and repeat steps 1 & 2 again, 2 runs should be sufficient if you have enough Hexane left or use the recovered Hexane. If you repeat the process and distill each hexane extraction individually you will see that the first extraction gets about 98% and the second gets very little but one pass doesn't get it all and we would hate to throw away any of the good stuff. 5. WINTERIZATION; Mix filtered Hexane with equal amount of 95% Ethyl Alcohol and Place the filtered liquid in Freezer for 12 hrs and allow the waxes to congeal. You can place it in the freezer in a bath or bag of dry ice to reduce the temperature as much as possible (**do not place dry ice in the liquid) Time and temperature are key so, as cold as you can get it works best (-50) but most freezers give up long before that. It takes time for the waxes to congeal enough to filter them out, that's why the 12 hours. 6. Vacuum filter the liquid again through slow filter paper ** We Freeze our ceramic Buchner filter prior to vacuum filtering the waxes, as they will melt back into the liquid so keep the funnel as cold as possible during this step. Keeping it really cold is really good in this process so colder the better. Allow the waxes after filtration to air dry and they can be used in hand cream or other uses 7. BASIC FRACTAL DISTALLATION: Place the now filtered liquid into a distilling flask of sufficient size and connect to the distilling column with the thermometer in the liquid, it will take a while for it to come up to room temperature (21c 80f). 8. Once the mixture reaches room temperature, Vacuum distill the Hexane off at room temperature (21c) at 22 In. Merc. On my Gauge, either by maintaining the vacuum pressure or the temperature the Hexane should distill off long before the alcohol, if you keep this a constant. This can take awhile depending on the volume. **Measure the distilled Hexane to make sure you got MOST of it. ** I have a 1000ml vacuum distillation kit I bought on Ebay with 2X 1000ml boiling flasks, 1x 300mm Liebert condenser, a few fittings, to which I added a 300mm Graham condenser in series to the Leibert condenser being first in line. I feed chilled water from the bottom to the top of the columns using a small submersible fountain pump in 5 gallon bucket filled with ice and water that recirculates. Place a collection flask just past your vacuum port in an ice bath and turn on the pump to controlled vacuum pressure. Save the re-distilled Hexane to use on the next batch. 9. Once you recover the majority of the Hexane, change to a clean flask and raise the vacuum to pressure 28 In. Merc. And the alcohol should start distillation, this will also remove any lingering Hexane. Recover as much of the alcohol until the oil mixture starts to noticeably thicken. 10. THIN FILM EVAPORATION: Remove the liquid into Pyrex baking pan(s) putting NOT more than ¼ (.25) inch of liquid into the pan, cover with glass flat sheet to prevent it from boiling out of the Pyrex (these can be stacked in the oven, we use 4) and place in vacuum oven (no heat) and apply vacuum SLOWLY to 29 In. Merc. and the balance of the alcohol will boil off. Repeat the filling and purging process if necessary until all the liquid is evaporated and you have a thick oil remaining, if after an hour there is no more alcohol dripping into the cold trap or condenser then all the alcohol has been purged.** Make sure you have a cold trap connected between your oven and pump or connect your oven to the distillation column before pulling a vacuum (this is what is recommend, using the same columns and ice bath to recover any remaining solvent(s) with the distillation apparatus). **Hexane and alcohol will ruin the oil in your vacuum pump and stink up your work area. 11. Test the Oil in the oven, If you can still taste the Hexane after step #10 when smoked, redislove the oil into fresh 190 proof Alcohol and purge in the oven again until the Hexane (Gasoline) taste and alcohol are gone. 12. Never pull a vacuum on the oil mixture higher than 29.8 (at room temperature) or the cannabinoids will start to boil off as well(17c/68f @ 29.9). 29.8 is a lot however and many pumps will not go this far (29.5 max) but will easily get to the pressures necessary to vacuum distill and vacuum purge water or solvents. **Always Increase the vacuum pressure slowly, rapid decompression has the same result as increasing the heat rapidly and can result in the mixture boiling out of control. To stop the boiling simply stop or reduce the vacuum. **Always “lock off” your vacuum pump with a valve as they can “bleed” vacuum oil back up your vacuum tube (liquid or airisol) and into your PURE product when they are shut off and connected to a vacuum. We recovered 22g of pure oil or about 19.6%, no hexane taste, no waxes just clear thick oil. We recover about 97%+ of the solvents also. If you purge and distill reasonably carefully you can easily reuse your solvents. If your alcohol starts to smell like gasoline, there's a lot of Hexane in it, probably just start with fresh as the “gasoline” taste is what you are trying to get rid of, this is a result of incomplete purge of the hexane stage, to fast or too much vacuum pressure, the boiling point of Hexane and Alcohol are quite different and can easily be separated, The amount of Hexane necessary to be able to be detected by smell is small and taste even smaller(>130ppm or less, target is >30ppm or less). This process will yield good high quality Oil if you take your time. The shortcuts through this process are expensive and don't really impact yield or quality very much. Sure, you could add lots of equipment and cost but you will not get much cleaner or better product.

If your serious about making oil get yourself a CO2 extractor. Much cleaner, easier and safer. No toxic petrochemicals used on the process either!!

When you get your finish product I would run it through a reflux still the smooth it off i can create or remove ant taste that way

I acquired Hexane from Grainger and they sent me this HPLC grade material made by Spectrum but it says its only 60% n-Hexane. What is the other 40%? I can't tell from the MSDS.

MSDS states that boiling point is 154.4-156.2 °F

Just a follow up if anyone is interested: Tech support at Spectrum said the undefined 35% could be one or a combination of the three pentane isomers. From the information I have gleaned here that containment should be acceptable. If anyone would like the catalog numbers of either the 95% or the 99.5% (95% n-Hex) material I just ordered from Spectrum, let me know. If you have a business name and address (and act like you know what you're talking about) , Spectrum will approve you for ordering lab solvents.

Another follow up to comments about this process: Finally able to successfully finish a polishing operation with n-Hexane. There are some nuances to completing the process in a reasonable amount of time. I had seen a comment made by someone who said they could not distinguish where the line of separation was on the FIRST saltwater wash. This is a common observation on the 1st wash due to the presence of ethanol in the mix and will not be the case on the second and subsequent washes. If you use a slightly larger amount of hexane than advised in this article it will be less difficult to see the line and less emulsion layer will form. You also might have to add hex later in the process due to evaporation. This is my experience but it gets pretty hot where I am working. Also, be careful about NOT getting the salt water TOO saturated. I don't have any specific guidance here but about a pound of kosher salt to a gallon of water was what I used (after having the SUPER saturated water re-crystallize and precipitate out of solution when it was added to the mix) Until I got some of the nuances worked out it took HOURS and GALLONS of water to complete the process so if you don't first succeed...try, try again! Also, if something doesn't seem to work right or it seems like oil is coming through on the separation, no sweat....just take the drained-off liquid and run it through the process again. At the end of the wash you can recover oil residue lost in the process (stuck to walls) very easily by washing all the containers with a small amount of hex. Last but not least...always be careful of thermal shocking glass lab containers. As many times as I have had to be careful I still managed to thermal shock my glass bowl during the final purging process of my second (and almost successful) run and dunked the polished extraction in the canola oil bath in my fryer. Don't add cold (or cool) alcohol to a hot glass bowl!! ps - It took me SEVERAL ethanol scrubs to get rid of the really persistent Hexane taste, so...it is possible, but not easy, to get rid of! Might be easier in a vacuum... Mark

I was wondering if you could just let the hexane evaporate for the final product. Would it ruin the taste, and how would I get it to have a shatter-like consistency?

I have a suggestion, GW. I've been thinking that I could take my pan of hexane extraction with the solution cooked down to about 10% of original volume. Spray a small amount of water into the solution and then freeze the mix. Should be able to filter off any ice then.

You mentioned the cost of the Hexane. The last 55 gallon drum cost me a little over $300.

Hey guys, and everyone else interested in this.thus info is wonderful..i am in school , loving my organic class and have been really interested in of the cannabis alchemy and medicine. I know I am a beginner, and just learning a lot of these techniques, but any recomendations on books or sites to get my feet wet? thus stuff is so cool!

Firstly, if the oil isn't high CBD, what are your isomerizing? Secondly, you didn't furnish lab results of before and after. To show what you are "isomerizing." Thirdly, I know you get your stuff analyzed. I've seen analytical reports of your partners work.

Hmm is anyone else having problems with the images on this blog loading? I'm trying to determine if its a problem on my end or if it's the blog. Any feed-back would be greatly appreciated.

I don't have a problem viewing this thread

Hi SkunkPharma's... Thanks to your efforts, i've been making polished BHO for about 6 months & while is great. i find it lacking in potency. I've been advised that i will get a more psychoactive end product if i extract using RSO method with a product called Shellite (lite naptha, i believe) ... I'm unable to email anonymously so i was wondering if you'd be so kind as to check over the MSDS link -> http://www.recochem.com.au/files/downloads/Shellite_Sep11.pdf & reply to wether it maybe ok to use?? Thanks !!!

Are you decarboxylating (Dropping the carboxyl group from THC to yield THC) your trim prior to initially adding your solvent

Yes, i'm planning on decarbing. My only real concern is wether they put anything in that will remain after decard & hoping someone with relevant knowledge can check the msds for me. Being lite naptha i'm assuming all will boil off under decarb temps but i'd hate assume and be wrong. Thanks in advance!

Hurrah! In the end I got a blog from where I be able to in fact obtain valuable data concerning my study and knowledge.

[…] unsafe and could be toxin. Hexane is used for food and pharmaceuticals. This link shows the specs: Hexane Honey Oil | Skunk Pharm Research LLC it shows you the type that is used. Only you would use the RSO method which is similar to mine. […]

Hello Gray Wolf, I am looking for a way to make the purest cannabis oil for cancer, I remember reading a post by your good self and I think it was the 'freeze everything quick wash hexane' can you verify this? and also point me in the direction of the post? thank you. ps it was not on ommp pay it forward it was on another forum. thanks again, KTD

Never done a quick wash hexane with freezing, so it must have been some other half breed. Hexane doesn't pick up much water, so freezing isn't necessary.

It works really well at 100f. Just be careful of ignition issues with the vapors. Its super flammable and really fumes heavy just under boiling.

I use freezing hexane for extraction. During the winter. Produces very clean extract.

Thanks GW.

Hello :-) Is N-Hexane 95% CP grade (not HPLC) is good enough ? Thank you Gil

Should be.

[…] It comes up here, scroll to the last photos you'll see a preparatory funnel. http://skunkpharmresearch.com/hexane...n-and-alchemy/ The hole thing smells of concentrated hydrosol so I dunno the slime from the water. What I do know […]

[…] easy to find, pay attention to what type to use. There are MANY great tips on this site ! Enjoy. Hexane Honey Oil | Skunk Pharm Research LLC […]

hexane gas, ozone is destroyed by giving. Thanks.

Hexane isn't a fluorocarbon or a green house gas. http://activhealth.com.sg/research-papers/epo-hexane-extraction-and-the-environment

Petrol products fumes eat away at the ozone layer because we're so happy to burn them in our I.C.E's. Don't blow your supply up and the ozone layer should be fine.

Whoever said "stay off the net. for info & learn from a homie is full of it" . Awesome info !!! I've been using Rick Simpson method with Acetone (100% pure-allegedly) & (ISO 99.8). Used Acetone for a couple of months because couldn't find 99.8 ISO right away. I've been researching better methods and found many but never explained in detail with the knowledge and pics of this site (Props to you guys for giving up your skill sets !!!).. I've been dosing for 1 1/2 years with ISO 7/8th of the time. Heck, it took me all that time to learn how to dose the correct way using cannabis concentrated oil (without becoming euphoric taking larger doses for med purposes (although that can be a good thing)! Cooked with the rice cooker (modified the tip over feature) and finishing with a plate warmer. I have now replaced the rice cooker with an induction portable cooktop (temp control is much more adjustable). Looking back from my 1st batch to now, its came a long way...lol. I've gotten my oil down fairly well but always looking for improvement. I'm old school in age and remember toke'n "hash oil" (black) and 'honey oil' back in the early 70's and always preferred honey oil for its cleaner look, smell and taste. Looks like I've found it here. It might seem I've progressed slow, but, learning to grow @ the same time and all the set up time plus $, but, I've had my best check up in 25 yrs (4 heart attacks). Wished I would of found info this good when I started. Just love the way you guys explain things (I'm far from a lab tech, but, not afraid to jump in and give it a go, using safety of course) from chem stats converting it into layman terminology. I'm absolutely STOKED with your site. It is so refreshing to get great intell. THANK YOU SO MUCH !!! Getting back to more learning. When I first logged in to the site it said if I would like to donate for the cause...where did it go...lol. G/B

Acetone? It must be some horrible goop. That shit picks up huge amounts of chlorophyll, like 5x what ISO (just a guess).

First off You guys rock for your awesome contributions! Secondly, I was wondering if someone could help me understand the differences in hexane VS hexanes? Can hexanes be used in place of n-hexane? I see it contains 50ppm sulfur amongst other things. Also, I remember reading some of your stuff that suggests older material that has had time to naturally decarboxylate may lean on the sappy side. Have you any new findings on being able to get a higher viscosity in the end, preferably crumble? And lastly, does a 2:3 bho to hexane ratio sound about right? Like 4g bho to 6g/8.6ml hexane, and if so dose that conversion work all the way up to a couple oz’s? Whats the most you'd recommend running in a L separator funnel? Thank You all for your time and knowledge!

There are a lot of 6 carbon chain hydrocarbons, some of which aren't nice. I would stay with HPLC grade n-Hexane or better, unless you have a MSDS spelling out exactly what those hexanes are and have looked them up. I've been told that you can eventually get a decarboxylated oil to wax up, but I haven't tried. I haven't ever determined a ration for Hexane extraction, I just fill the jar 2/3 to 3/4 full of material and fill it the rest of the way with hexane, leaving about an inch for shake room.

The hexane/ brine wash we tried turned out to be a failure. Our variables that could be throwing it off are using acs reagent grade hexanes as to hexane and the time and amount of washes needed to desired consistence. Should the wash take days of multiple washes? It is the bottom layer of water let out after 10min or so of separation time to get the 3 layers? appreciate any insights into the process you see we could be missing.

Hexanes should work too. The wash and separation take maybe five minutes each and you wash until the lower water layer stays clear. Usually six or so times.

Hello, I'm new here so I hope it's okay to jump right in. I have a question regarding grades of Hexane. Is a technical grade suitable to use as a solvent? I purchased a 5 gallon can of tech grade a while back for extraction, Univar being the manufacturer. The cost is about the same as 99% ISO at $125.00 for the can. But seeing that you use a reagent grade it got me to thinking that the tech grade solvent may not be purified enough to safely use? I remember Rick Simpson saying that he would buy light Naphtha ( which is called Hexane in the states I believe ) by the drum from a petroleum supplier. I imagine that would be lesser than a reagent grade to be affordable... I've learned a ton from this site and thanks for all that you do, Tom

It should have a cert of analysis with the tolerance's for each of the contaminates. Its up to you what you are comfortable using as a solvent and possibly ingesting. Just make educated decision's when taking

Check the cert of analysis for unacceptable contaminates. Neither are "food grade" so its really a matter of what you are willing to tolerate if left behind. Both grades are definitely a step in the right direction compared to Namptha. Refined Namptha in the state's is pet ether.

Hi, naptha is NOT hexane. It is petroleum distillate which means that while it does likely contain hexane (and, more exactly, hexanes) it also contains other hydrocarbons (paraffins, olefins, napthenes/aromatics.) These compounds are more toxic and have higher boiling points. Naptha should absolutely not be used. The higher the grade hexane you can get the better, likely anything that is in hexanes or non-HPLC grade hexane is similarly low boiling and should be removed with an appropriate amount of washing/purging--but you get what you pay for.

Which Naphtha? Light or heavy? Light Naphtha boils lower than the bp of water. Heavy can have a bp of over 150 c. Heavy will have those higher bp compounds, waxes etc. I would agree to avoid the heavy one. Commonly called VM&P Naphtha. If you wish to completely avoid petrochemicals, don't forget butane is one of those.

Hi GW, I may be in the wrong place for this post so I apologise in advance. I'm new to this procedure of making oil and am just totally confused as to what I need to do. I'm located in Ireland so getting equipment and solvents is very difficult here so I'm limited in what I can get my hands on. After reading this entire post and the different methods used can I ask if hexane can be used in this method:https://www.facebook.com/?_rdr#!/334801926611457/timeline/story?ut=3&hash=7180875461232508646&wstart=0&wend=1378018799&pagefilter=1&ustart&__user=100003697020689 Would following these steps produce a decent oil? Is there anything different that you would do here or wouldn't do. I was curious as to why the bud and alcohol is frozen, is this nessacery. The distiller I can get is the same as in the video but it's rated at 800watt, would that heat it up to much. Sorry for all the questions but I just want to do it right first time. Cheers

You can do a hexane extraction without freezing the material or chilling the hexane, because hexane is non polar and mostly insoluble in water. It will do a good job, but I would be leery of using that distiller without knowing more about how its electrical components are set up. Hexane boils at 68-69C/155-156F, so no problems with the boiling range, but it is as flammable as gasoline, so the vapors are highly explosive. We distill off hexane in the lab using a simple boiling flask and water cooled condenser, which might be a safer way.

Thanks for the reply GW. In other comments in this thread people talk about using the hexane to do the extraction and then letting a fan blow over it until it evaporates, is it ready to be ingested after that or would sitting it on a hotplate on a low setting for a few hours be needed.

A hexane extraction is harder than butane or ethanol to purge below sensory threshold, and at the very least, the pool needs to stay liquid so that the remaining solvent molecules can escape. Without vacuum, we typically have to redissolve in ethanol a couple of times and evaporate away the ethanol, to purge the remaining hexane.

This is correct. Redissolving in a nontoxic solvent like ethanol (everclear or other high % spirit, you don't want to add water) several times, stirring, and evaporating will remove residual solvent. You'll also lose volatile flavor components of the oil but so it goes, thats why something like supercritical CO2 is preferred to a traditional solvent extraction.

Tis true that extracting the volatile monoterpenes is easy with any number of solvents, but holding on to them during purge becomes more problematic the higher the boiling point of the solvent being used. Butane only has four carbons in the chain, while hexanes have six, so the Van der Waal forces and boiling point will be higher. One of the issues with the monoterpenes, is that they are alcohols, ethers, aldehydes, ketones, esters, and carboxylic acids themselves, with very high vapor pressures. It is because of this high vapor pressure at even ambient temperatures and far below their boiling points, that they can fill a room with molecules that collide with your noses. That is how skunky weed stinks up a room or car, even double bagged. The same heat that drives off the solvent, does doubly so with the monoterpenes. Hexane also extracts non polar waxes, we typically also winterize it using ethanol, so it gets a double whammy from a solvent evaporation standpoint, and tastes primarily of sesquiterpenes and the diterpene cannabinoids. That is one of the reasons that we use hexane for alchemy, but not for extractions other than in class as a demonstration. It

GW, You mentioned using a boiling flask and an condenser to reclaim the hexane. I plan on going this route and was wondering what size flask and condenser should I buy? Also, what would you recommend as far as a heater? I typically make batches of oil from 1/4 to 1lb of dry starting material. Just want to get this right the first time so I have to only order once! Thanks Tom

We don't do much volume or huge batches, so we use a one liter flat bottom boiling flask, with a 24/40 taper on a stirring hotplate. You could also use a hot oil bath or sand bath or heating mantle to eliminate hot spots. We use a distillation elbow, with a 24/40 taper, and a Allihn or Graham, or Liebig condenser with the same taper, to reclaim the hexane and circulate coolant from a five gallon pail of ice water.

Well as we spoke, I can't get hex to make a wax in the vac oven, but can with butane. O well I like hex better. ? temp will hex need under vac to be well purged let say 28 on the vac gage. How could I send u pics of my rig. I love my vac funnel and watman #1 filter speeds things up XXX fast. Thanks yours MADFARMER

115F will work for hexane too. You just need the puddle fluid enough for the bubbles to escape under vacuum.