Until 2007 there were no published reports of highly successful methods for culturing Cannabis sativa. Hemp was successfully cultured in China but at a success rate of a mere 85%. Then Ole Miss published “Thidiazuron-induced high-frequency direct shoot organogenesis of Cannabis sativa L.” in The Society for In Vitro Biology which detailed how they achieved a 95% success rate.

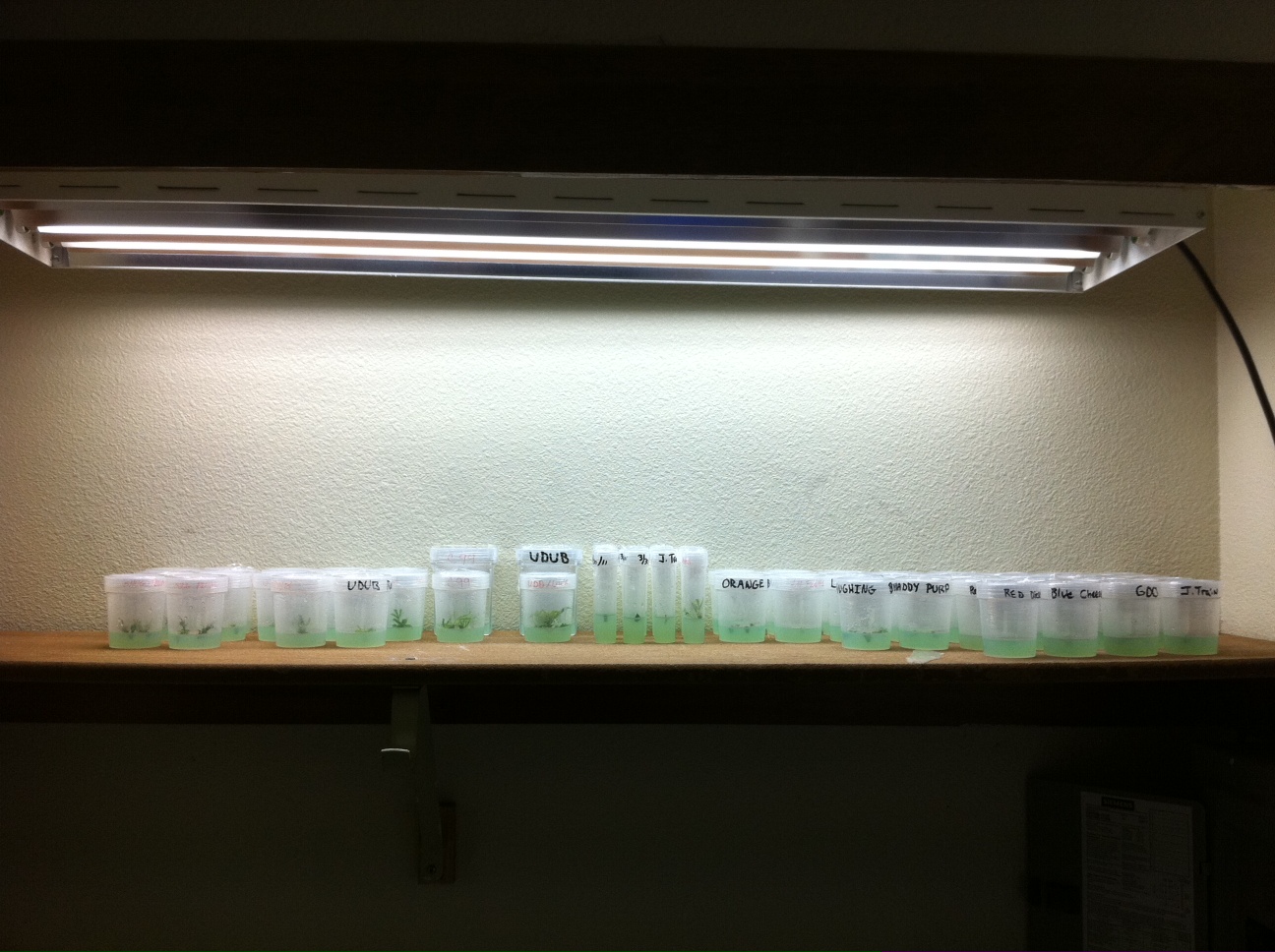

We found this paper and started making the medium. We were able to get great results with the vegetative propagation medium which utilizes hormones TDZ and gibbrellic acid. We used this medium to multiply and expand our library. The rooting medium calls for half strength MS salts and the exchange of hormones to only IBA and with the addition of activated charcoal. We had problems initially with the medium being watery after sterilization but we have since linked the issue to our gelling agent and have moved forward.

Synthetic seeds

During our research we also came across another paper published by Ole Miss on synthetic seeds. These same scientists were able to develop a formulation that consistently would regenerate 100% of these synthetic seeds under greenhouse conditions. Impressive statistics, but not an original or groundbreaking discovery; synthetic seeds have been around a while and are underutilized technology.

We have also been tooling around in our spare time with synthetic seeds and have some preliminary observations on their implementation.

- Inconsistent size of capsule; we are looking into a suitable fluid distribution system that can produce a consistent volume in each droplet.

- Irregular shapes; we have found in our research that a surfactant can be added to the hardening bath to break the surface tension, which prevents the droplet from being deformed by the impact.

- Nonconforming product placement; getting the explant into the center of the droplet consistently has been an issue. We are trying different strategies with promising results so far.

- Lead time; this is an obstacle because the incubation time before sowing is 30 days with 75% success rate and 60 days for 100% success rate. In order to be successful explants also need to have come from a specimen already in culture because some varieties don’t take to culture. This could be the medium we are using or genetics we will know more in the future.

This technology has great promise if these obstacles are overcome. We are making headway with an automated capsule making machine design. We will keep you updated as this project progresses. Attached Photos

We now have the beginnings of a plant tissue culture lab and we are working on building back up our strain library. In the meantime check out the hand built laminar flow hood that I designed and built. It had to be built in the lab because there is no way it’s getting through either door. It has a 4’W X 2’T X 2’D workspace. It is made from ¾” melamine board and has a 1200 cfm fan inside. Two high quality pre-filters and a HEPA final filter. I didn’t take any construction pictures because it wasn’t a pretty sight until it was finished. I got my HEPA filter from another pharmer for free and the rest it set me back around $500. The fan was $200 the Lumber around $150 I had to buy a brad nailer for $50 and the tempered glass top with the rounded edge was $80, then all the edge tape and ¾ round plastic to secure the glass, plus sealant’s, caulk and such ate the rest. I will be getting some state paperwork finished up this week and will then start accepting donations of genetics for our reserve. All strains once established and multiplied will be shared free of charge with the local MMJ community. Once we finish the lab and have some more eye candy; we’ll be sure to share.

Joe

.

For anyone interested in getting the paper mentioned in the post, or almost any peer-reviewed paper for that matter, copy and paste the title into the link below. Sci-Hub is a Russian pirate site on Cocos (Keeling) Island that offers access to over 55 million papers for free. I get better results trying to access papers here than from my university library website, which actually provides pretty good access, compared to most universities. 99 + % of what I search for is offered. Copy and paste this title into the link below: Thidiazuron-induced high-frequency direct shoot organogenesis of Cannabis sativa L. http://sci-hub.cc/

Any updates?

Hi, We are a culture media manufacturer and we are looking to manufacture and distribute tissue culture media. We have recently expanded our lab and have the capability of manufacturing 7500 petri-dishes per lot, and would like to know if you would be interested in working with us.

You guys are so inspiring. I finally have got my flow hood and my lab setup. do you guys think you could send me a copy of the paper? cascademtnpainting@gmail.com Much thanks! Cheers!

GW you know who I am. I have no clue if you hate me or live me and thusly trolled the he'll out of me , I Was told that I may offend by way of which I speak herein, making you feel like I am mocking your own writing style but this is not true in fact could not be more of an incorrect judgment than saying that I am a beautiful woman in my prime with gazongas the size of watermelons yet still perfect in shape and ton hehe. I always write this way always have always will then come to find out more about your business and work in the future of this, I am completely shocked and intrigued by the similarities between us and our own research along with words of choice, and let's not forget the implementation of a few of our own words of wisdom teeth removed from the list of things that are found in a dictionary yet make more sense for the best interpretation of. Only intended to help and support the community and the enterprise of what we love so very dearly I am writing this all out and about to get to my point just wanted to let you know that I am not mad but not sure if I should be or not lol. Yet again I digress in my message and purpose here . The first thing that I would like to say with personal afilliation aside Thank you for everything from you man you are something else to say the least. I truly don't believe that you get nearly enough credit for how gard you have worked to find out al km of this info only to few reply give it out as you know I am of the same mind set( it's fun for me why would I charge people who need help for me to get to play with toys and have fun seems wrong IMO again for the third time i slightly digress. I have a great deal of time experience and knowledge of this I need a good outlet and guidance on what to do with it and where to go next and so on i find a way to get a pseudo Scie Cy way about me but I just plain old don't know how to enterprise and all that junk .I am not looking for a free ride nor free education nor to gain anything else other than the chance to work hard and burn the pages out of books by way of page flipping. I am sure you get the idea of what I have implied here to which i leave you with the best way to express my interest by saying; I would be eternally great full, respectively hard working, overall detailed, responsible, responsive and ultimately be 100% honored if you would allow me to be a predecessor to you. ... I don't want your stuff man I want your mother lobbing brains man who is not jealous of your mind and quality of thinking. To which I think I am finished with my RANT for this post you know where you can contact me at to troll away or possibly a few words met with you and your heart and soul of a sudden I will. .........NOT! Lol I hope you have any idea how much it would mean to me. The fact you trolled Me alone is a dam fine honor sur and I will be off with that RiPieces sincerely Kilo/Kaih Element Setzkorn

Thanks for the good thoughts brother Kilo! I do remember you and am pleased you are doing your own thang and having fun! Not sure what you mean by trolling you, but if that is bad, I assure you I run off at the mouth responding on line, with neither love nor hate involved. It also is never personal, because with everyone using avatars, it is also hard to know with whom I am conversing. You can reach me at graywolf@skunkpharmresearch if you would like to chat. GW

For the Explant media, Are you guys using MSP 09 or MSP 20?

Our lab works very well in the meantime. Go to our FB-page for further information.

nice website, just wondering if doubling up on pressure canners is neccessary for avoiding contamination, if the primary function of the first is to pressure sterilize canned goods?

Outstanding job seriously nicely done Very innovative thinking, keep up the great work I learn so much needed information from you guys

How does one go about sharing genetics? Please email me with details. Thanks

Joe, I'd love a copy of the paper when you get it. My e-mail is markemiles@gmail.com.

Can you detail the agar and media preparation? What type of gelling agent are you using? How much charcoal? Have you used L and M woody media? Does the addition of micros, Macros, vitamins help? Can you detail the transfer process from stage to stage? Thanks for all the insight so far. I'm looking to succeed not experiment. I've got a couple special hybrids I'm hoping to preserve. I've already harvested and am praying for a revert (back under 18hrs). Or tissue culture a node. What about callousing and blending then seperating by cell? I'm working with a group in IL. We need to produce 200,000 plants annually. What would be the easiest way to produce 5000 plants per week?

How is this project going? Can we get an update. I have been cloning using Mother plants with a high success rate but this method just fascinates me. I see the potential. However the one key part for me is the growth medium. I would love to see how you make a batch - any chance?

Dear Joe, Is the flow hood essential or could you get away with just using a pressure cooker? cheers M

You'll need an aseptic transfer area like a still air box or Bunsen burner. But a flow hood is not required.

The article about synthetic seeds that you reference above, is it also written by Lata and entitled "Propagation through alginate encapsulation of axillary buds of Cannabis sativa L. — an important medicinal plant?" just wan to make sure i'm reading the right thing.

I believe so but I don't have it in front of me.

Hi! I am looking for someone who can take a tissue culture ( I guess that is what it is called) and get a clone for me out of a planet that is still growing out in my garden. It has gone thru the veg and grow cycle and is about 8 months old. I have been unsucceful using my cloneator and doing it the old fashion way using medium. It still has branches and buds with leaves on it. It's a strain that I really want to save as I won a cannibis cup (2nd place) here in Oregon with it. Plus, it's my husband favorite and works good for his pain. I am willing to pay to have this done. Please contact me at : Crazycatwoman@charter.net Thanks, Terri Breazeale

Hi Terri! May I suggest you try Joe at joe@skunkpharmresearch.com? He can help you with that problem.

Member asks http://freemygreenpdx.com/index.php?/topic/7910-cloning/?p=73768

This is so cool..

Thank you! I just received my hormones from RPI and was wondering how to go about diluting them. Do I have to dilute the tdz into NAOH and then into ddh20. Also with the iba would I have to dissolve into ethanol then into ddh20? Thanks for all your guys help!

GW, I ran into something several years ago that would be of interest to you possibly, I have the PDF of this if you don't have it in your library. I was going to send the PDF via this site but it wouldn't stick. Is there an email address? Pak. J. Bot., 41(2): 603-608, 2009. A MICROPROPAGATION SYSTEM FOR CLONING OF HEMP (CANNABIS SATIVA L.) BY SHOOT TIP CULTURE REN WANG1*, LI-SI HE1, BING XIA1, JIN-FENG TONG1, NING LI2 AND FENG PENG1 1Institute of Botany, Jiangsu Province & Chinese Academy of Sciences, (Mem. Sun Yat-Sen); Jiangsu province key laboratory for plant Ex-situ conservation, Nanjing, 210014, P.R. China 2Department of Biology, Hong Kong University of Science and Technology, Clear Water Bay, Hong Kong SAR, P.R. China Abstract This study describes the standardization of an efficient in vitro propagation and hardening procedure for obtaining plantlets from shoot tips of Hemp (Cannabis sativa L.). Hemp seedlings were germinated on half-strength 1/2 MS medium supplemented with 10 g·L-1sucrose, 5.5 g·L-1agar at a pH of 6.8 under light for 16 h per day. MS medium containing 0.2 mg·L-1TDZ, 0.1 mg·L-1NAA supported the maximal auxiliary bud multiplication rate of 3.22 per shoot tip. The proliferated buds were successfully rooted on MS medium supplemented with 0.1 mg·L-1IBA and 0.05 mg·L-1NAA resulting in 85% of the plantlets rooting. The procedure requires a 54 days cycle for the In vitro clonal propagation (14 days for shoot multiplication and 40 days for root induction) which includes 35-42 days for acclimatized plantlet production. Its a scholarly work on how to grow cannabis in vitro. Let me know if you would like me to send it or you could probably bring it up with Google using the above information. At the time of my interest I couldn't find anything like this, it the "recipe" that everyone was looking for at the time.

Hi Ron, thanks for the heads up! That looks like something that Joe will be interested in too, as he is conducting our micropropagation experiments. I would love a copy at graywolf@skunkpharmresearch.com and I will forward Joe a copy, or you can also e-mail Joe attachments directly at joeoakes@skunkpharmresearch.com.

GW by now both you and Joe have the PDF, at the time when I found this I could find nothing like it, would be fun to contact the Chinese scientists and see how much further they have taken this. It apparently is the road map of application that so many people were looking for a couple of years ago.

I look forward to learning more myself! After Joe has had time to absorb the contents, I plan to pick his keen alleged mind! He is consulting in CA land as we speak, but is scheduled to return soon. GW

Looking forward to your inquiring perusal. Hope it helps the cause, medical and otherwise.

Hi there! I would love a copy of that document as well. would you be able to send it to healthygenetics510@gmail.com?

Please email me if you can't find it through Google.

Hi there, I would love a link to that PDF. Could you send it to my email? 😁

So I was trying to place a order at RPI and they want a reference. By chance could I use skunk pharms as a reference? Thank you for all your help!

Sure, you can use Skunk Pharm Research, and Joe says that you can use Oregon Medical Growers as well. GW

Have you had any luck with root formation using Mississippi's formulas?

I would suggest adding per liter: 1) 500mg activated charcoal 2) 0.5mg IBA I realized I had put these in the text but didn't list their concentration in the previous comments with the other ingredients. Maybe that will solve your issues.

Thank you. You guys are too kind at skunkpharms. May I ask what are your thoughts so far on in vetro propagation of cannabacae? Have you successfully brought a plant to full term?

Hi Joe, love all of the things that you're doing here, including your work on synthetic seeds. I would love to get in contact with you to discuss a few minor questions I had. If you could send me an email at info@syntheticsomaticseeds.org. I would love to discuss protocols procedures with synthetic cannabis. Thank you.

Hi Marc. Thanks for the kudos. My email is joeoakes@skunkpharmresearch.com

That's awesome I was looking forward to that issue bc it included a refinement article about polishing extracts and when I went to read it I realized that it was just stuff that I've read on here over the past year or so, GW your truly the most well versed person in extractions it seems, notice how your site was the only one listed that has any information on how to actually extract cannabis. The rest of the sites were basically BHO porn. Keep it up

Thanks for the good thoughts bro! Bon appetite!

Way to go everyone!

Great to see you get the recognition for your good work. We need good science based. Info as new technics evolve. I see you as providing the gold standard when it comes to concentrates and medical uses of cann. And providing the safety warning to keep these technics from becoming a distraction from their many uses. RR

I saw that too and said Woooooooooooooooooooooooooooooo!

Stoked to see you guys in there. Always sharing your info with others. HSAO is working great! Looking forward to my next class there. Hoping to get ES out on the slopes next year. Peace

Any news on the somatic embryogenesis (synthetic seeds)? Also are you using direct somatic embryogenesis or indirect somatic embryogenesis? Thanks!

We aren't using embryonic masses. We have experimented with encapsulating Nodal segments. The production of suitable beads is what we are currently working on. The next step is to identify suitable explants for materials testing. This project is getting more time this summer and I hope to publish preliminary results in the fall. Joe

Thanks High Times for another great pick of resources. Be sure and add your “Likes” too the Skunk Pharm’s Face Book page. https://www.facebook.com/SkunkPharm

[...] that eliminate the need for male plants ? http://www.medicinalgenomics.com/wp-...etic-Seeds.pdf http://skunkpharmresearch.com/tissue-culture/ Reply With [...]

cool, GW. I have already found and read the mentioned paper from Ole Miss. I will shoot Joe an email with all my questions tomorrow. In 2011 I visited the Hempstalk in Portland and made an interview with Paul Stanford, who is the organizier of this event. It would be a pleasure for me to come back to Portland and visit you operation as it seems that you all are very ambitous guys with a lot of knowledge. Thanks again, that you share your knowledge with the community.

Cool, look forward to a tete a tete over tea and crumpets.

hi guys, this is amazing blog. I´m a legal hemp clone producer in Austria. we produce about 10.000 clones per week, why we decided to set up an labratory for tissue culture. Because of that I´m interested in exchange of knowledge (but i think you have much more than we). I would be delighted if you could shoot me an email

Hi Alexander! Joe is our tissue culture brain trust, so I sent the two of you an e-mail making the connection. Peace, GW

Alexander, did you see me when I presented cannabis tissue culture at FF in Vienna, Prague, and Spannabis? I left plants there after I visited. How is the lab going?

In researching tissue culture, I found this reference http://www.biotech.iastate.edu/lab_protocols/AV_Micropropagation.html about potential ways to shift desirable traits between two different plants. Is this possible to translate over to cannabis? Thank you kindly!

They have applied it to cannabis. The last time I checked they had not regenerated a plant but, did get cells to make an exogenous marker to confirm transgene expression. Its been rumored that the cartels have modified cannabis that grows back after being hacked down. Hard to say whether or not someone is doing it underground without a DNA sample.

There is a really good PDF document titled "The Biotechnology of Cannabis sativa" authored by someone named Sam R. Zwenger. He goes into detail on applied techniques for gene manipulation of Cannabis through propagating callus cultures and infecting them with Agrobacterium tumefaciens with modified plasmid vectors that can transfer the desired gene. I believe by the pictures contained in the document that he successfully created a transgenic cultivar of Cannabis sativa that expresses the GFP gene. Interesting stuff for sure.

Biotechnology is very exciting. I haven't seen any confirmation of regeneration of transgenic cannabis plants. Its fairly easy to get genes in but very challenging to get stabilized integration into the genome. Also I haven't seen anything published in scientific journal's indicating successful regeneration of transgenic hemp. Which leads me to believe that the author hasn't either. Otherwise transgenic THC free hemp would be everywhere.

Where did you buy your tissue culture chemicals? I just got a laminar flow hood and I'm looking for a good source for media materials. Thanks for sharing your work so far. Also what concentrations worked best for you?

I get my MS media from Research Products International. All the rest I get from Caisson labs. You can get everything from caisson but RPI has free shipping and sometimes better prices. Agar 7-9 g/L Sugar 30 g/L 1X MS Media TDZ 0.11 ug/L PPM 750 uL/L Rooting Agar 5-7 g/L 1/2X MS Media Sugar 15 g/L

Oh wow. This is the most concise post about this protocol I have ever seen. Thanks for that. So, rooting uses no hormones?

Rooting uses IBA.

What's IBA?

Indole butric Acid

Try planttc.com. The MULTKIT and MULTKIT-TDZ formulae are the most popular prepared media for cannabis. Email for cheaper shipping quotes.