I was in my first semester of Organic chemistry and had recently synthesized aspirin when Graywolf brought THC-O-Acetate to my attention.Our research into Acetate started and we were all very impressed by the outcome of our first reaction.

We have since followed this procedure many times with varied efficiency This variability was caused by and directly proportional to the amount of essential oil in the reaction.The more oil the less efficient the reaction. The maximum amount of oil I use is 20g.

When making aspirin, salicylic acid is the raw material for the reaction, Acetic Anhydride is the conjugate and Sulphuric acid (H2SO4) *is the catalyst.

The similarities between Salicylic acid and THCA are the carboxylic acid groups that direct the acetic anhydride to form an ester with the phenolic hydroxyl (OH). In fresh plant material of cannabis, most cannabinoids are present as their carboxylic acid form, known as acidic cannabinoids [Shoyama, 1975].

Since carboxylic acid and hydroxyl groups are polar and hydrophilic, small amounts of THCA are soluble in water. They can be precipitated at a higher PH and made insoluble at a low PH which can be used to our advantage. See our high purity extraction page for more details.

When THCA is converted to THC-O- Acetate, the polar C-OH becomes C-O-CH2C=O-CH3. The carboxylic acid group is hydrolyzed (forms water) by the heating with the H2SO4 which reacts with excess Anhydride to produce acetic acid which reacts with regular THC at the hydroxyl group to form more THC-O-Acetate.

Simpler than it sounds, this is a highly efficient reaction, when *catalytic volumes of H2SO4 are added and a Molar excess of acetic anhydride is present.

NOTE THIS DISCLAIMER:

Do not attempt this procedure if you are not qualified or without the proper Chemical fume hood and proper personal protection equipment.

Sulfuric acid is highly corrosive, and Acetic anhydride is not only highly corrosive, but as flammable and explosive as gasoline. Not to mention Hexane is highly flammable and explosive! You should read, understand, and have ready a Material Safety Data Sheet (MSDS) for all chemicals you have.

We neither recommend this procedure or accept any responsibility if you elect to try it yourself.

Materials needed:

- Face shield

- Chemical goggles

- Respirator with acid cartridge

- Chemical apron

- Elbow length gloves

- Fume hood

- Heated Stirrer

- Flat Bottom boiling Flask

- Alhin Reflux condenser

- 5 gal bucket of ice water

- Aquarium water pump

- Pasteur pipette's

- Beakers of various sizes

- Graduated cylinders

- Coffee filter and funnel

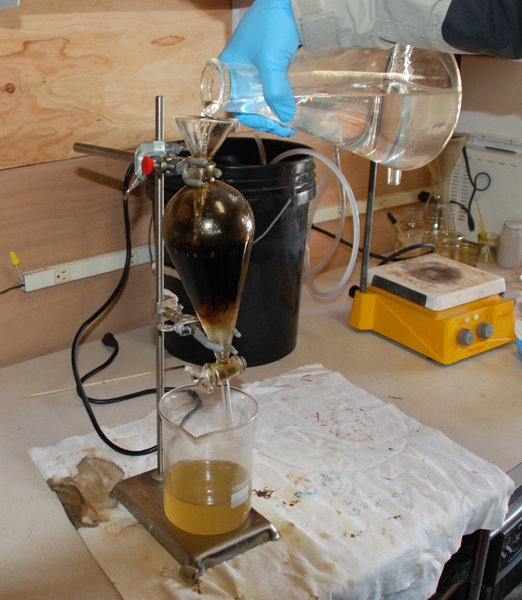

- Glass separatory funnel

Chemicals

- Dry Ice in a foam cooler

- ½ gal 95% Ethyl Alcohol

- ½ gal Denatured alcohol

- Hexane HPLC grade

- 98% Sulphuric acid

- 98% Acetic anhydride (controlled substance)

- 2 gal distilled water

- 200g Kosher salt

- Baking soda

Basic procedure:

- Dry your extract in an oven at 220ºF until thoroughly dry and free of any alcohols.

- Dissolve your extract into an alkane solvent such as hexane (HPLC grade)

- In a flat bottom boiling flask combine extract in a 1:2.5 w/v ratio of oil to acetic anhydride. (1g + 2.5mL).

- In an ice and water bath; add 2.5 drops/g oil of 98% H2SO4 slowly down the side of the glass swirling gently after every couple of drops.

NOTE: This is where things can hit the fan! You should have proper PPE including a face shield, chemical resistant apron, and elbow length chemical gloves. This again should be done in a certified fume hood by qualified chemists. If you try this and it goes wrong, it’s not our responsibility.

- Once the solution has cooled place a stir bar in carefully to avoid splashes.

- Put on a stir plate and begin stirring vigorously

- Place a reflux condenser onto the top

- Begin heating until the vapor is being condensed at the second bulb. This takes a bit of adjusting to get to the perfect plate temperature versus condenser water flow.

- Start a timer for 60 min for up to 10g and add 60 min for up to an additional 10g of oil.

- Turn off the hot plate but continue to stir

- When cooled slightly add 1mL (/g oil) of distilled water drop wise against the glass.

- Vapors containing acetic acid will escape from the top. This is normal. DO NOT INHALE VAPORS!

- Pour liquid into a separatory funnel, wash flask clean with hexane and pour into funnel. Wash flask of anything left with 95% non-denatured alcohol pour into funnel.

- Prepare 2 gal of distilled water with 100g kosher salt dissolved in each.

- Once the water can be distinguished from the hexane begin draining the water.

- When you are close to the emulsion layer, stop and add salt water until the funnel is almost full.

- Cap and mix by inverting several times, uncap or the pressure will shoot the lid off.

- You should have a lower water layer an emulsion layer and an upper organic layer.

- Continue washing with salt water until both gallons are empty.

- Drain the organic layer into a clean beaker and place into an oil bath @ 250F until dry.

- Test a small drop of acetate on a watch glass with some baking soda dissolved in water. If it fizzes, re-suspend acetate in hexane and wash with baking soda and water until it stops bubbling. Re-separate water from organic in funnel.

- Dry at 250ºF

- Re-dissolve in 95% Ethanol and place beaker into a shallow, denatured alcohol and dry ice bath for at least 5 min.

- Pour liquid through a coffee filter

- Discard filter and dry the acetate by boiling off the alcohol.

- Wash and dry 2 more times with ethanol

- Enjoy

Attached Photo's

Hi there, SkunkPharm. I want to preface this by saying that I am an inorganic chemist, but I want to try my hand at this procedure, but certain things about it bother me. My primary concern after doing some research is that THC-O-Acetate is said to be water soluble. Is this the case? If it is, am I right in assuming that the saline solution must be absolutely saturated? Secondarily, your setup in figure 1 is a little confusing. The way I understand it is that you have cold water in the bucket with an aquarium pump moving water from the bucket through the reflux condenser and back to the bucket. Is this correct? Third, I wanted to ask some questions about the oil requirements. First of all I am fully aware that the addition of sulfuric acid to the oil will result in CBD being converted to various forms of THC, some of which are not the delta-9 variant. My first question is are any of these other variants detrimental to health/product? Second, how pure must my initial oil be, and what are your tips for increasing purity using ethanol as a primary solvent? do I need to do a secondary extraction with an alkane like hexane to ensure that there are no water soluble impurities like chlorophyll present. Fourth, what are ways this product can be used? Is it able to be used just like a normal THC oil in an oil rig, or being baked into edibles? also Is it stable enough to be stored under normal atmospheric conditions or are there special requirements for storing this chemical? I would really appreciate your input. Given that this experiment has the potential to be very hazardous, I want to make absolutely certain that I know what I am doing every step of the way.

THC O-Acetate RSO If I follow the RSO recipe from extraction to distillation and finish with my oil. Can I let the oil cool and then add acetic anhydride to the oil and distill the acetate. I am thinking this should change the THC to THC O-Acetate. Then wash the product with chemicals and a separatory funnel. My goal is to take THC (oil) and turn it into THC O-Acetate (WATER SOLUBLE) so I can administer as a suppository. The THC O-acetate is water soluble and will pass through the membrane of the sphincter, where the THC (oil) will not pass through the membrane wall as well because it is a fat. Thanks for the help.

I was under the impression that acetic anhydride was used to avoid an equilibrium reaction.

Most esterifications I’ve seen utilize an alcohol and carboxylic acid with H2SO4 as a catalyst. Would this reaction work with glacial acetic acid (carbocylic acid) and decarvoxylated thc (alcohol)? The glacial acetic acid is much safer to handle than the anhydride, but likely less reactive. Let me know what you think!

Could you use an already decarboxylated extract to start with?

You rekon 97% acetic anhydride would be suffecient for this reaction?

Yes. GW

I'm a huge fan of all you do here - this is the best cannabis site anywhere with priceless information for anyone wanting to make friends with this magic plant. Thank you all from the bottom of my heart! Concerning the value of the acidic cannabinoids found in fresh flowers and leaf, it was interesting to read the author's information. I've benefitted from this form of the plant for the last 4 years and my experience with this might be of interest to others. I started using leaf in my daily smoothie and it was good, but since the buds are where the action is I started using frozen fresh buds instead. I never juiced any of it since the trichs are sticky and not water soluble so would likely stick to the juicer and/or get discarded with the green "waste" from the juicer. The effects were easily 10X what they were using only leaf, and with typical commercial strains (high THC, low CBD) these smoothies gave me a nice energy lift along with a mood lift as well - all without any feeling of getting high. After a few months using them every day in a smoothie (this first round was all high THC varieties) I suddenly realized when I bend/knelt down to tend my plants, I was able to do this without pain. I'm old....so had made friends with my beginning arthritis as a cost of getting old, along with typical prostate issues. Once I noticed this lessening of arthritis pain (and greatly increased mobility in all my joints) I also realized my lifelong depression had vanished as well. No more St. John's Wort - didn't need it. My prostate issues cleared up, my skin heals noticeably faster and overall I feel 10 years younger. I've been using fresh/frozen buds in smoothies since 2012, and at 62 can get up off the floor without using my hands (hadn't been able to do that for many years) and no longer feel arthritic or depressed. Prostate issues have cleared up as well. For the first couple of years I used it daily (maybe 5-7gm flowers/day), and since then I've cut back to a couple-few times a week. I was baffled at the healing aspect of fresh bud on my arthritis until I read that our cartilage has CB2 receptors, as do many/most of our internal organs. Mystery solved! As exciting as true scientific research on cannabis is these days, I feel if we wait for all the studies to be done we'll lose precious time. The acidic cannabinoids have been labeled "bio-inactive" by many, but if you suffer from any of the above ailments I urge you to try fresh/frozen cannabis buds in your daily smoothies for a while and see what they do for you. And a plus - harvest/freeze 'em and if you change your mind, you can still dry/smoke/extract them without much if any loss of potency from what I've seen. They're darker but no less effective. If you've gotten this far - thank you for your time, and I hope you have as much success as I have eating fresh cannabis. My website has nothing to sell at all and has a bit more info on this subject.

what is the average yield percentage on this method? lets say i have a starting material of 20g @ 80% potency after dewaxing and decabing. thanks!!

isnt that oil the same thing as rick simpson oil???? which is made by first decarbing the bud material (bm) then soaking the bm in 99% isopropyl alcohol and stirring then boiling off the alcohol over a low heat source.... then the oil that is left looks just like the oil u show up there... & it definitly cures cancer..... so whats the difference??? is that more of a pure product? is that why someone would go to all that trouble???

In simple English can someone explain how to make this at home or where to buy such thca tinctures or products? Can you simply grind up marijuana leaves and eat them to consume tcha?

Buy an homogenizer. Mix dry sieve or bubble hash with refined coconut oil, and homogenize with homogenizer. Filter oil from solids. Easier using a vacuum assisted filtration system, as pictured in the article. I've never shopped for THCa tincture, but would start here in Oregon, by calling the dispensaries. We used to make brownies by adding ground plant material, but they tasted greeeeeeeeeeeeeeeeen, and some folks digestive tracks took umbrage. They were of course also not THCa. Extracting with a low polarity oil leaves the green chlorophyll behind, so sidesteps that issue, and if done cold, retains the THC in its acidic THCa form. https://skunkpharmresearch.com/extracting-with-oils-and-fats/ GW

Hello, Love your site, my hat's off to you! Can you suggest how to make a strong THC tincture, for sublingual use..perhaps with VG or pg - without using alcohol, dry ice or fancy lab equipment, Thanks!

[…] THC Acetate | Skunk Pharm Research LLC – So with all the hassle and risk, was the end result worth it? THC O acetate is legal in the USA as it is unscheduled Last time I checked, which is just about 10 … […]

So with all the hassle and risk, was the end result worth it? THC O acetate is legal in the USA as it is unscheduled Last time I checked, which is just about 10 minutes ago...

THC is most certainly illegal at the federal level, and is subject to the Federal Analog act, which constitutes any analogous or drugs of similar psychoactive effects-- the penalties, which are that of the drug it is analogous too. It is an incredibly vague bill, however it covers a whole swath of chemicals because of it.

If you want the acidic cannabinoids: take a crude extract mix throughly with a water/alcohol solution containing sodium bicarbonate (baking soda) at pH ~9, then add water and oil (vegetable oil should work fine). Mix throughly and let the layers separate, the salts of the acids should be in the water layer (on the bottom). You will have to play around with this to get optimum results. The water/alcohol can then be removed by evaporation, preferably via a rotary evaporator at high vacuum (use a diaphragm pump for this instead of oil pump or you'll risk destroying your pump to water). As sodium salts the acidic cannabinoids will not decarboxylate, however they will still oxidize so they should be stored under nitrogen or used quickly.

Analysis for the THCA solution: http://www.catscientific.com/wp-content/uploads/THCA-Analysis-8-5-15.pdf Analysis for the CBDA solution: http://www.catscientific.com/wp-content/uploads/CBDA-Solution-Analysis.pdf

I can't see the results, maybe it's because I'm on mobile? Is it an image?

Nope, I think the results were missed out.

After this process do all of your oil runs come out basically the same? In strength affect and flavor does it still vary strain to strain? How many milligrams of acetate would you say is an appropriate dose? Would you recommend against making oral capsules? I am looking for a way to take a controlled dose that is the same every time with out having to vaporize the oil. My thoughts were to maybe mix the acetate oil with some food oil and put it in a capsule but I read you saying there are down sides to ingesting acetate. As you seem to be very experienced in this I would ask your recommendation on how I should administer my oil. I am also wondering how many doses I would be able to get out of a gram of oil. Thanks for your time

what fun to see folks doing organic synthesis in the shed. this was a fun substance to make in the basement lab back in the 70's when we did not have the high yielding strains of today. After a prosperous med chem career with big pharma I may look at all this natural product isolation and derivatization again. Do you have a TLC system to monitor the reaction and products? and ever try a spray reagent like FeCl3 that reacts with phenols to check out the reaction? So what I think I would like to try is the synthesis of the acetate of the THCA for a direct aspirin adduct. It will require some finness due to the molecule being so prone to decarboxylation. An old man likes to feel no pain.

http://tipskesehatan.website

It's spam.

i like

How to turn it into a powder form

very nice info , for other article search here http://ringmusic.co

Very close to (or maybe is) a THCA-Ester, something that the Feds fear (potency, easy conversion to effective tablet form). The FDA even authored a paper on more or less this process, available on Medline. For the legal questions, the Feds have a new criminal statute that looks at intent rather than a specifically listed compound. Nasty stuff, that! The safety here is medical necessity and compassionate care, but they might forget that with an ester compound. Really interesting work. Cheers -Hugh

I love this stuff......& since currently I have access to 92% pure THC sans terpins I believe this stuff will be quite popular in the next 5 years. Its not even specifically scheduled on a federal or state level Outlaw life...... For life ;)

All of this is definitely illegal on the federal level. I do not mean to rain upon your parades. Cannabinoid Freedom Fighters certainly are my people. They are welcome in my castle any time. If you look hard you will see that I am correct. Even Cannabidiol is a controlled substance. Some know this,Others do not. the problem is that the federal and even state laws are so technical in their language that only those gifted with the ability of scrutinizing word meanings and legal definitions can really say so with any accuracy. I have made a point to study the language of the federal laws. This might seem subjective, but I assure you that language is everything and that even with no legal definition to be found for a specific word, one is still able to define legal relevance from even vague and nonspecific legal wording. I do not want to give any examples as they would only fuel something I do not want to fuel. Just know a good Prosecutor will find plenty of ammunition if he looks. He will likely need a chemist. I only know these things because I eat,sleep and shit in the world of chemistry. There is a difference in being able to read chemistry and do chemistry. Not everything is simple read and do. Do not let the internet fool you. The reason why you have go through legal channels for all this is not because Uncle Sam is cool. It has to do with safety. I realize this whole forum is one giant safety meeting. I do have to say that I have not observed one thing or anyone on here that even remotely done by a chemist. You basic training in organic chemistry is lacking. I see very basic chemistry training at best. You forgot some stuff in the acetate ester synth. Just saying. You also lack all the proper equipment to perform what you are doing. Suck it up and get a chemistry degree. Save your pennies, find someone with chemistry experience and then tackle your dream. Also get a really good fucking lawyer. Your going to need it. Even then you will still need the DEA permits. Prohibition ends soon, but it is not over. Do not push it. It might wreck all the hard work everyone has put into subverting the system. Regards The King of Hemp

Does this product cross any legal lines that the conventional extraction techniques do not? Is the federal monitoring of the chemicals a big concern?

I would encourage you to run it by your own attorney for the answer to that. We've used less than a liter of acetic anhydride in the last four years, and have only made it for medical purposes, so not sure what would happen under adult recreational, or if someone started using large quantities. It is also used to synthesize Heroin, so is indeed on the watch list.

Depends have you ever had over, 5 agencies raid before?

Have you tried using butane as your alkane solvent instead? My organic chemistry classes would suggest that it would work, however butane is generally more volatile....I guess my concern is safety...Any thoughts?

Hello, You are speaking of converting THC to THC-acetate by using the side-product acidic acid. Could the THC-acetate also be made without using the acidic anhydride, by reacting THC and acidic acid with sulphuric acid as catalyst? I'm very curious if it could be done without the need of acidic anhydride, because it is hard to get and most people don't like being closely monitored ;) Kind regards from the Netherlands

Theoretically Acetic Acid can cause the esterification of THCA but this esterification reaction is far less favorable as it is reversible - you now have H2O in the equation and the presence of water will lead to hydrolysis of the THC-O-Acetate back to THCA. ....your yield is going to be low and probably not worth the trouble!....but if you are that curious give her the old college try!

Oh and if you do decide to try it expect the reaction to be much much slower than with acetic anhydride....just a tip!

Just curious, but isnt CBD its own analog? You mention CBD converting to THC, but as I understand CBD is created from its own synthase, using Cannabigerlolic Acid as its catalyst.

Without looking into my notes, I believe CBD losses a propyl at some point and isomerizes to delta-9 ("Potency", 1970s? see 'isomerization')

I tgought it was CBN that isomerizes into THC

If a strong acid gets added to CBD it is converted to THC, which is what happens when the acidic anhydride gets added to the oil mixture. THC can turn to CBN under different conditions, but that usually only happens by extensive heating, UV-light or being in contact with oxygen for a long time.

How is the water solubility of THC-O-Acetate, any better than THC(A)? Comparable to THC-O-Phosphate?

Is acetic acid able to be used instead of the acetic anhydrous?

I have breast tumor and lump and I heard that THC is a cancer cure.I want to buy some if you have.Thanks!

Officer, there is nothing for sale here! This is a non profit information based community. Ask your government for help. Good luck with your lump!

What is the dry ice in the cooler used for? Is it for the ice water bath or the condenser?

[…] Anyone can Google isomerizing weed Or better yet http://skunkpharmresearch.com/thc-acetate/ This has pics!! And I think the person may have done it before Reply With […]

Yup, we have.

I don't know if its the more i read the more stupid i feel? or the smarter i am getting? this is a lot of info to absorb. I think i need a safety brake.

Stay safe out there!

[…] It is worthwhile to acetalize using sulfuric and acetic anhydride, which you might check out athttp://skunkpharmresearch.com/thc-acetate/ Originally Posted by nocturnalreef Thank you first of for actually understanding and […]

I don’t even know the way I ended up here, but I assumed this post used to be great. I don't recognize who you are but definitely you're going to a famous blogger when you are not already ;) Cheers!

where the hell do i buy a pump for this i got everything but a pump to keep the condenser cool

Aquarium pump with high flow rate.