Butane Honey Oil, or BHO, is the essential oil from the cannabis plant, extracted using Butane as a solvent. It can be extracted from fresh material or from cured material as a Concrete or an Oleoresin. A concrete or an oleoresin that has been winterized to remove the waxes, lipids, and fats, is known as an Absolute.

Butane Honey Oil extraction refers to the method used to extract the essential oils from cannabis, and there are multiple theories on the best way to accomplish this, as well as what material is best to use.

Perhaps the first question is why use a BHO technique to extract the resins, instead of just boiling the material in alcohol to get the greatest amount of extracted material?

The answer to that is that because butane is relatively non polar, it doesn’t extract the water solubles like chlorophyll and plant alkaloids. Butane produces one of the cleanest extractions, albeit typically at a lower yield than polar alcohol.

Using closed loop extractors, we average slightly more than 20% oil by weight from bud, but as low as 5.7% absolute and as high as 28.1% absolute.

The first wash will usually extract 75 to 80%, leaving the balance for the second after repacking the column. The second extraction will be more sedative and less heady. If you use a hand microscope, you can easily see when the trichome heads are gone and the stalks look like wet fur.

We've only tried a few processes here at the pharm, and used to cover simple flow through columns, and using a thermos bottle, but now cover only closed loop systems, because of the number of brothers and sisters ignoring my caveats to not extract indoors.

We currently use a closed loop system for BHO, and I cover that process on separate threads named The Terpenators, where I will detail building our Mk I through second generation automated systems.

Before we discuss how to extract the essential oils from cannabis, let us talk about the plant material to be used. That immediately brings to mind the qualifying question, "What do you want to use it for?"

Oil that is to be vaporized, is normally treated differently than oil that is used orally or topically, because it doesn't need to be decarboxylated. For cannabis concentrates to be orally and topically active, it does require that the THCA and CBDA be converted to THC and CBD, by a heating or drying process. I will cover that issue under a separate thread on Decarboxylation, so as to not clutter this post.

Terpenes:

Besides the cannabinoids, which are Di-Terpene alcohols and di-alcohols (diol), there are also other terpenes in cannabis essential oils, which add to its smell, flavor, and medicinal entourage effect. Some of these terpenes are highly aromatic alcohols, phenols, ketones, aldehydes, ethers, and esters, which are aromatic because they freely give off molecules at even ambient temperatures.

Heating the plant material or the oil to decarboxylation temperatures will evaporate off most of these smaller aromatic Mono-Terpene and Sesqui-Terpene molecules, before the larger and heavier cannabis Di-Terpenes are affected. Decarboxylated oil is smoother to the taste, but basically tastes like hash, with the floral undertones gone.

Gone also are the medicinal and entourage effects from those terpenes. The price we pay for decarboxylation, so we shouldn't decarboxylate casually, and should first consider the end use before picking the process.

One of our process limitations, is that though non polar, n-butane has slight water solubility. At 20C/68F, it is only 0.0325 percent by vol/vol, but not zero and is still enough to pickup undesirable water solubles. 1 liter, or 1000 ml X 0.0325 = 32.5 ml of water.

With water, comes water solubles, which includes chlorophyll and plant alkaloids, that detract from the taste, so the dance is to maintain the volatile terpenes, while studiously avoiding the water solubles.

Freezing the water is one method that works well, but it is important that the material be dry when it was frozen and that it is not exposed to high humidity while frozen, or ice will form over the trichomes, preventing their extraction.

Another method is to simply remove most of the water. This will produce pristine extractions, but doesn't preserve the terpenes. If the material is to be decarboxylated anyway, that is of little concern, because we will lose them anyway.

We also have the issue of purging out the remaining butane, while preserving the terpenes. Again, there are a number of ways to do that, but I will address only a few of the ways that have worked for us here. Those are light heat, high heat, and thin film vacuum.

So, besides decarboxylation, what are some of the things to consider selecting a process and how should the plant material be prepared?

In our experience, for best flavor and taste, freshest material works best (less than 3 weeks old), whether it is fresh frozen material or dried. Older cured material loses the nuances of the floral undertones and just tastes like hash. That means that the degree of drying and curing is also critical, if your goal is to maintain maximum terpene content.

Oil from buds is tastier than oil from even sugar trim, because most of the terpenes are produced by the buds, and that is where they are the most plentiful. Tasty is usually not a word used to describe oil from fan leaves or stems, though effective may be.

The absolutely most flavorful BHO extract to me personally and to the test panels thus far, is fresh picked buds, that are immediately frozen to tie up the water, and extracted while still frozen. It produces an oil that abounds in whimsical flavors darting about and the word most often used to describe it by panel members, was the word "fresh."

Next most flavorful, from a BHO standpoint, is material that has only been cured 5 to 7 days, and is at the small stem snap stage, where you might jar it if you were curing it to smoke.

Part of the formula is of course the degree and methods used to purge out the remaining butane. While there are a number of ways to do that as well, I will address only a few of the ways that have worked for us here. Those methods are low heat, high heat, and thin film vacuum.

Butane supply:

Lastly, selecting a suitable butane source is a key step, in that all butane sources aren't created equal. n-Butane boiling point (30.2°F -1°C) is a simple alkane, with four carbon atoms linked together in a row, with the remaining possible carbon bonding sites taken up by hydrogen atoms. Iso-Butane is three carbons in a row with the forth carbon attached to the middle carbon in a "T" like conformation. This conformation change also alters the boiling point (10.94°F/ -11.7°C) and also the specificity.

The simple alkanes all are gaseous at room temperature and atmospheric pressure. They are removed from crude oil before it is further processed, by simple heating. The simplest is Methane, which is only on carbon and four hydrogen atoms, followed by Ethane with two carbons, Propane with three, and Butane with the four.

Pentane is the next simple alkane, the first to be liquid at room temperature and the first to have zero water solubility. From Pentane on, the simple alkanes are named from the Greek alphabet, and are Hexane, Heptane, Octane, etc, on through the light naphthas, oils, waxes, and asphalts.

The formula for all simple alkanes, is the number of carbon atoms times two, plus two, because each carbon atom has four possible bonding sites. A mnemonic device for remembering the first four alkanes, which were named before the Greek system was applied, is Mary Eats Peanut Butter.

After removal from the crude oil, the gases are typically de-sulfurized using steam and a catalytic reactive bed, and fractionally distilled into the four basic gases. As fractional distilling separates the gasses by specific gravity, the principal contaminants in n-Butane at that point, will be Iso-Butane, a branched molecule isomer of n-Butane, as well as n-Propane, and Cyclo-Propane, plus low levels of heavier, longer chain molecules than C-4, and which are often referred to as Mystery Oil.

Neither of the butanes or propanes are particularly toxic at any sort of reasonable levels, nor is C-5 Pentane, but C-6 Hexane is and a third party forensic lab analysis of canned butane reveals the presence of molecules as long as c-18 as contaminates at the parts per billionth level.

We advise pre-distilling your butane to remove any mystery oil, prior to extraction. It is easy to remove from the butane, but hard to remove from the concentrates afterwards. See /vacuum-distilling-butane/

MSDS info:

The following for instance is taken from a typical MSDS sheet for n-Butane. The Rat LD-50 (50% dead) is 658000 mg/m3 4 hours. That is breathing a 65.8% pure butane atmosphere and asphixiating.

Section 11. Toxicological information for n-Butane; Diethyl; Freon 600; Liquefied petroleum gas; LPG; n-C4H10; Butanen; Butani; Methylethylmethane; UN 1011; UN 1075; A-17; Bu-Gas.

Specific effects

Carcinogenic effects No known significant effects or critical hazards.

Mutagenic effects No known significant effects or critical hazards.

Reproduction toxicity No known significant effects or critical hazards.

No specific information is available in our database regarding the other toxic effects of this material to humans.

Chronic effects on humans May cause damage to the following organs: central nervous system (CNS). Other toxic effects on humans

Toxicity data

Butane LC50 Inhalation Vapor

Rat 658000 mg/m3 4 hours

Product/ingredient name Result Species Dose Exposure

Products of degradation: carbon oxides (CO, CO2) and water.

Section 12. Ecological information

Products of degradation :

Environmental fate : Not available.

Environmental hazards : No known significant effects or critical hazards.

Toxicity to the environment : Not available.

Aquatic ecotoxicity Not available.

The MSDS LD-50s on Iso-Butane, Propane, Cyclo-Propane, and oleaginous waxes are as follows:

n-Propane; Dimethylmethane; Freon 290; Liquefied petroleum gas; Lpg; Propylhydride; R 290; C3H8; UN 1075; UN 1978; A-108; Hydrocarbon propellant. LC50 Inhalation Gas: Rat >800000 ppm 15 minutes

Cyclopropnane; Trimethylene; Trimethylene (cyclic); UN 1027; No LD-50 established;

Iso-Butane; 2-methyl-; Trimethylmethane; 1,1-Dimethylethane; 2-Methylpropane; isoC4H10; i-Butane; Isobutane mixtures; UN 1075; UN 1969; R 600a; tert-Butane; A 31;Methylpropane; Propane, 2-methyl-isobutane LC50 Inhalation Vapor Rat 658000 mg/m3 4 hours

Oleaginous Waxes- Paraffin, no notable toxicity or LD-50 available

n-Butane is used for any number of things, so it is processing beyond this point, or sharing storage tanks with other contaminated sources that may create health concerns. While n-Butane is non-toxic enough used as a food propellant, if it is to be used as a stove fuel, it will in most cases have an odorant added for leak detection, as n-Butane has only a very light sweet petroleum odor.

Ethyl Mercap is most often added for that purpose, and is the familiar rotten egg smell is detectable at the astonishing low concentration of under 3 parts per Billionth! Hexane (Gasoline) by comparison, has an odor threshold of around 30 parts per millionth, or about 10,000 times more is required for us to smell mercaptoethanol.

The MSDS for Ethyl Mercaptan shows 4420 ppm/4 hour(s) inhalation-rat LC50; 682 mg/kg oral-rat LD50, with the target organs being the central nervous system. Not super toxic, but tastes and smells of rotten eggs, so that point may be mute.

Butadiene may be added to stove fuel as well, and is of serious concern. While the following typical MSDS example shows relative low toxicity, take a look at the carcinogenic effects.

LD50 Oral Rat 5480 mg/kg -LC50 Inhalation Vapor Rat 285 g/m3 4 hours

LC50 Inhalation Vapor Rat 285000 mg/m3 4 hours

LC50 Inhalation Gas. Rat 128000 ppm 4 hours

Mutagenic effects No known significant effects or critical hazards.

Reproduction toxicity No known significant effects or critical hazards.

No specific information is available in our database regarding the other toxic effects of this material to humans.

CARCINOGENIC EFFECTS: Classified 1 (Proven for humans.) by IARC, 1 (Known to be human carcinogens.) by NTP, + (Proven.) by NIOSH, 1 (Proven for humans.) by European Union. Classified A2 (Suspected for humans.) by ACGIH.

MUTAGENIC EFFECTS: Classified 2 by European Union.

May cause damage to the following organs: the reproductive system, mucous membranes, upper respiratory tract, skin, eyes, central nervous system (CNS).

Here is another n and Isobutane toxicology division of the Texas Commission on Environmental Quality.

http://www.tceq.texas.gov/assets/public/implementation/tox/dsd/final/butanes.pdf

Of note, is that the FDA has rated n and Isobutane as GRAS, or Generally Recognized As Safe.

https://www.gpo.gov/fdsys/pkg/CFR-2012-title21-vol3/pdf/CFR-2012-title21-vol3-sec184-1165.pdf

Food and Drug Administration, HHS

§ 184.1165 n-Butane and iso-butane.

(a) n-Butane and iso-butane (empirical formula C4H10, CAS Reg. Nos. 106– 97–8 and 75–28–5, respectively) are colorless, flammable gases at normal temperatures and pressures. They are easily liquefied under pressure at room temperature and are stored and shipped in the liquid state.

The butanes are obtained from natural gas by fractionation following absorption in oil, adsorption to surface-active agents, or refrigeration.

(b) The ingredients must be of a purity suitable for their intended use.

(c) In accordance with §184.1(b)(1), these ingredients are used in food with no limitations other than current good manufacturing practice. The affirmation of these ingredients as generally recognized as safe (GRAS) as direct human food ingredients is based upon the following current good manufacturing practice conditions of use:

(1) The ingredients are used as propellants, aerating agents, and gases as defined in § 170.3(o)(25) of this chapter.

(2) The ingredients are used in food at levels not to exceed current good manufacturing practice.

(d) Prior sanctions for these ingredients different from the uses established in this section do not exist or have been waived.

[48 FR 57270, Dec. 29, 1983, as amended at 73 FR 8607, Feb. 14, 2008; 76 FR 59249, Sept. 26, 2011]”

Lighter Butane: n-Butane may also be further refined to increase its purity, or to make it suitable for use in butane lighters. R-600 Refrigerant and Instrument grade n-Butane are examples of higher purity n-Butane suitable for extractions, and are distributed by suppliers like Praxair and Airgas. As those sources are expensive and not usually available to non commercial customers, in support of federal guidelines listing it as a controlled substance used in the manufacture of illegal drugs, some folks use butane made for butane lighters.

Each manufacturers blend is slightly different, with n-Propane usually added as a propellant, because below the freezing temperature of water, butane is a liquid instead of a gas.

They also further refine the n-Butane to remove more of the low level "oleaginous waxes" aka Mystery Oil, which clog the small orifices in expensive butane lighters. This is often shown on lighter butane cans as a number followed by an X. IE: 5X.

Here Madison Avenue has gotten a foot hold, and even 7X butane is available for even more money, though there is no advantage over a good 4X for the purpose of extraction.

One refiner has started labeling the brand names that they produce, Near Zero Impurities, guaranteeing under 50ppm impurities. An independent test showed that they in fact are under 50 ppm, and even under the 15ppm testing cutoff, as were competitors brands not touting near zero impurities.

If using lighter butane, the safest course is to use tried and proven brands, but if forced to improvise, first obtain a MSDS sheet from that specific manufacturer, showing the contents. Reject any containing mercaps or Butadiene.

Ingredients less than 1% need not be shown on the MSDS sheet, unless they present a health risk at the levels present, so they are not all inclusive, but a good place to start.

Here is a link to a study by Skyhighler ranking the different lighter butane brands by residual MO content:

https://www.icmag.com/ic/showpost.php?p=6099306&postcount=28

Safety:

Butane is highly flammable, so let us next talk about safety. First and foremost, always perform the extraction outside in a well ventilated area. Have a fire extinguisher handy, as well as a blanket to roll up in, should the unthinkable happen.

It goes without saying that smoking around a butane extraction is asking for a disaster, but I have literally grabbed the hand of folks starting to light up because they “forgot” where they were at and what they were doing. May I suggest that you leave your lighter and smokes somewhere else when you are doing extractions.

Same with your cell phone!

Wear no synthetic fabrics, including your socks, because static electricity sparks probably ignite more butane unintentionally than bone headed smokers.

We use a fan to disperse the butane rapidly so as to keep it from pooling. Butane is heavier than air and will collect in low spots given its own devices. We use a plastic fan so that no sparks are created by a piece of gravel or other hard material passing through the fan blades.

In dry cold conditions, we add a grounding strap to our cans, so as to not draw static electricity sparks between the can and the column.

See /butane-safety/ for more butane safety detail.

Material Prep:

Material prep will of course depend on the application, so lets cover that subject generally.

Fresh buds should be dry of standing water and cut into small pieces, before being stuffed into a column and placed in a -32C/0F freezer for 48 hours to solidify. Fresh frozen buds produce the most aromatic extraction.

Second best for for maximum terpene retention are buds broken up after 5 to 7 days hanging, or as soon as the small stems break freely. They should be jarred immediately to retain freshness and run as soon as possible to prevent molding.

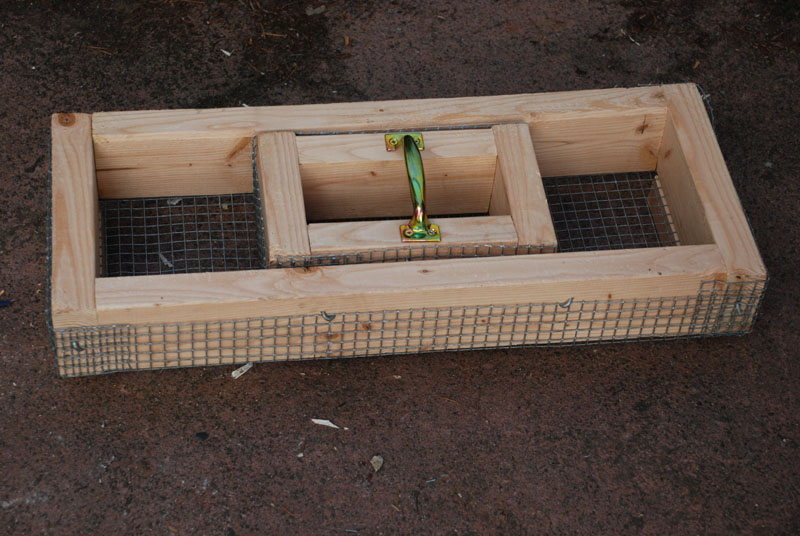

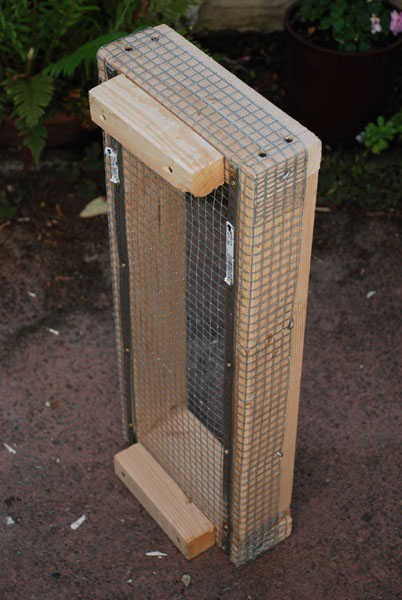

When extracting dried buds for vaporization, or bragging rights, the material is broken up just loosely enough to extract, but not enough to expose excessive broken cell boundaries. That can be done by hand, or with a nugget buster. Here is an example of a nug buster design that I scored off Roll It Up forum, but alas I can't remember the author: The wire cloth can be obtained from Howard Wire at http://howardwire.com/square_mesh.html

Buds for decarboxylation and most pristine appearance, should be placed on a cookie sheet and baked in a 94C/200F oven until just frangible, when rolled between the finger and thumb. They can then be ground or scrubbed through a pasta strainer to remove the sticks and stems. Or ground up and should be jarred after grinding, to keep moisture pickup low.

The material shouldn't be bone dry as it will become too frangible, nor should a coffee grinder be used, because of the fines that it produces, that have to be subsequently removed.

We also dry our trim and leaves until frangible as above and scrub it through a pasta strainer, using a leather gloved hand and firm pressure, so as to minimize the amount of fine particles generated.

Another more commercial version is a cement mixer and dry ice chunks to break up the material for extraction.

So now that we have covered some of the basics, lets move on to the different processes:

Simple Flow Through Column:

Simple flow thorough columns are sometimes used in a technique called open blasting, and we once had a section covering that technique, we have elected to remove it because of the number of brothers and sisters blowing themselves and others up blasting indoors, despite our dire warnings and instructions to the contrary.

It is always the few, that ruin things for the us'n masses, but their actions paint us all with the same brush in the public eye. If you have no alternative to open blasting, you can find ample instructions elsewhere on how to do so.

Purging:

Butane is relatively easy to purge from cannabis oleoresins or concretes, as it has a boiling point of around -.5C/31.5F, or right about the freezing point of water. Given enough time just sitting around, it will purge below our 5000 ppm smell sensory threshold, and even our far more acute sense of taste, either of which is a small percentage of the 658, 000 ppm, that the MSDS LD-50 tells us it took to asphyxiate 50% of the test rats in 4 hours.

We can speed up that purge, by using a dish with a large surface area, relative to the depth of the pool of oil. Usually small extractions, so as to keep the depth thin, are the easiest to purge.

Air movement over the surface speeds up evaporation, by whisking away the saturated boundary layer and providing the extra energy for the molecules of butane to escape the surface of the oil. Care must be exercised here, as any dust or lint in the air will end up in the oil, so usually a cheese cloth or similar porous cover is placed over it, before blowing over the top with a fan.

We can also speed it up with the application of heat. Any heat will speed up the evaporation, and one line of thought is to keep the heat low and around 60C/140F, using a hot pad after the hot water bath. A typical purge might take an hour and provides maximum terpene retention.

When adding bottom heat, you can also add a loose fitting lid, which will speed up the purging and keep out lint and dust.

For a faster purge, the temperature can be raised to above the melting point of the cannabis essential oils, or around 82C/180F, to give the butane molecules maximum mobility.

Instead of heat, vacuum may be applied to speed up the purge process. That is the process that we use when we wish to maintain the cannabinoids in their carboxcylic acid forms.

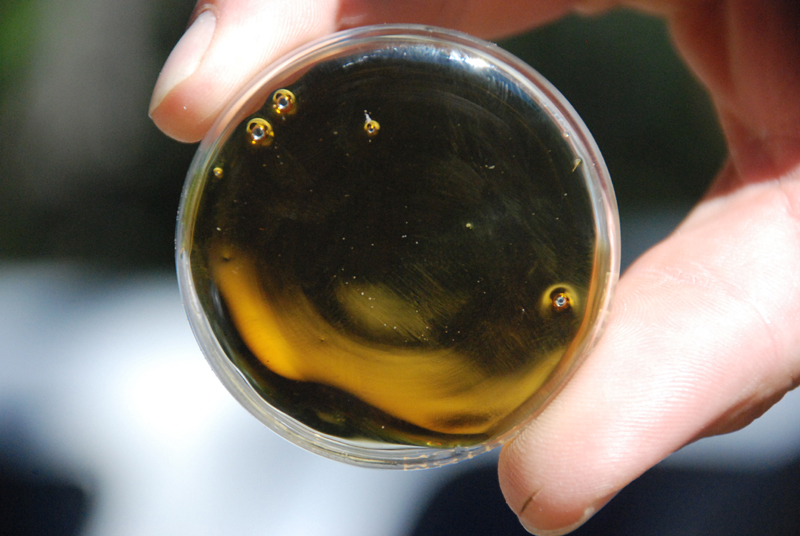

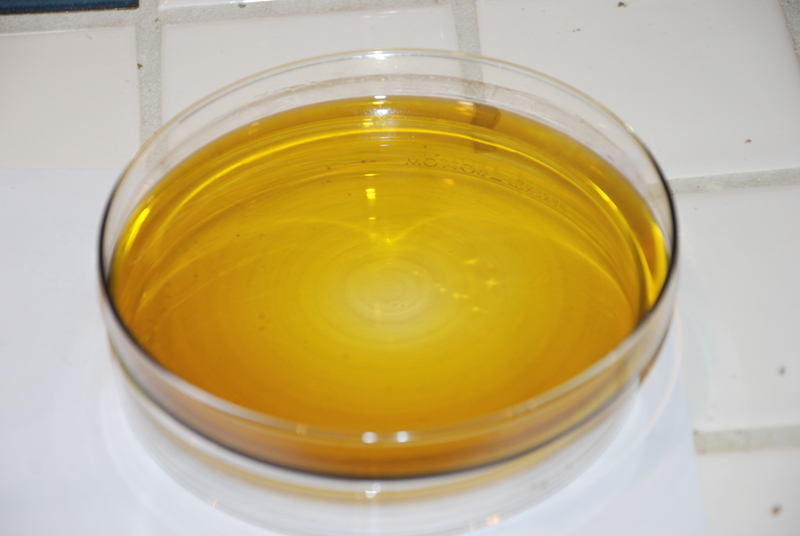

In thin film vacuum purging, we place about an 3/16" of the oil in a 6" Pyrex Petri dish, and place that in a vacuum chamber, which also contains a hot plate. That allows us to manipulate both the temperature and atmospheric pressure, so that we can achieve boiling at very low, or even ambient temperatures.

While we use 180F to vacuum purge a raw oleoresin, adding heat isn't necessary when thin film vacuum purging raw oleoresins redissolved in ethanol. The alcohol will boil away under 28.5"Hg at ambient temperatures, as will the water that is left behind, even without adding any heat.

Vacuum ovens are the most popular way to purge anything more than a few grams of personal stash. This is a subject in and of itself and is covered in depth on our Purging in a Vacuum Oven page.

For our oral and topical meds, we exclusively used the bain marie collection vessel, and simply wiped the water off the outside, following the hot water purge, and set it in an electric fondue pot full of hot 121C/250F Canola oil.

The residual butane will boil off first, exiting in larger, multi sized bubbles, followed by the smaller equally sized CO2 bubbles from decarboxylation.

Depending on the use, we remove it from the hot oil when the bubble activity suddenly slacks dramatically off, indicating the 70% peak of the decarboxylation curve, or when it becomes quiescent, if we are looking for maximum sedative effect.

Hot oil Pots:

We use electric fondue pots for decarboxylation and I prefer the Quisinart, for their sensitive controls and narrow dead band. We also have a couple of Rivals, which work well too, but whose controls aren't as sensitive.

Some fry cookers may have sensitive enough controls, but most are designed to primarily run at 375F, and lack control sensitivity, as well as have a large dead band at 250F.

It is important to make sure that the container is sitting on something that suspends it up off the bottom of the oil pot, to eliminate direct transfer hotspots. We keep several jar lid rings in the bottom of our electric fondue pots for that purpose.

We never trust any controls however, and use a good mercury lab thermometer, a digital, or an infra red optical pyrometer to establish and control temperatures.

Air stills such as the MegaHome essential oil or water distiller work great for purging or decarbing without the mess of a fondue pot. They also allow you to recapture the alcohol from a winterization step as well.

Thermos extraction:

Thermos extraction is an open extraction technique allowing an extended soak period at atmospheric pressure.

Because it is an open extraction process, and because of how many brothers and sisters are blowing themselves and others up, ignoring the warnings and open blasting indoors, we have removed instructions from this site.

CBD

Whatsapp: +195.464.18238 Open link https://sites.google.com/view/nembutal-pentobarbital-sodiums Buy Xanax bars , Lean syrup , Oxycodone , Adderall , Percocet , Methadone , Ecstasy , Lsd and acid , Actavis Promethazine Cough Syrup , Viagra , Vyvanse , Klonopin , Fentanyl , Rohypnol (Roofies) , Ketamine , Hydrocodone 10/325, MDMA (molly) crystal and pill form , Crack Cocaine , Heroin (white, brown and tar) Weed , Marijuana , Cannabis buy in Switzerland , Germany , Spain , Italy , Strawberry , Sour Diesel , Jack Herer , Durban Poison , Haze, Pineapple Express , Blue Dream , Purple Haze , AK-47 , Grapefruit , White widow , OG Kush , Purple Kush , Black weed , CBD Oil , Hemp oil , Moonrock for sale in Switzerland , Germany , Spain , Italy ,E-mail: danny@ doctor. com https://onlinecannamedshop.com

i forgot to mention its for vape oil but do you recomend i just test the wax first or vape oil

Hi im looking to start a small legit company based on thc wax private label products. but i wanted to do simple test with some collaborators what do i need to buy for the small scale test

Thanks for the info. I just bought an extraction machine from https://www.wilberline.com. Hopefully, your guide will help me get the best results. Cheers

Hello, I want to start by thanking you all for this website, and all the info. herein. And saying that I just purchased this Extractor, and have not used it yet. So please bear with me, I am a carpenter, not a scientist, and this is sounding pretty scientific, the more i read. OK, I have a BHOgart closed loop extractor. I also have a, Robinair Cool Tech 34288 Air conditioning recharging system. Now in case you are not familiar with the Robinair AC. machine, it appears to have all the components of a closed loop Extractor in that, it has a Vacuum Pump, Recovery Pump, scale to weigh your material, filter dryer, condenser, Gauges for high and low pressure, Manifold, and the hoses to hook it all up. Google the make and model for all the info on, Robinair 34288. To the untrained eye, it would appear that you could simply hook up the hoses and turn it on. my question to you is, Can I evacuate the R-134a refrigerant from the AC recharging system, and replace it with butane? then hook low pressure hose to the top of the Extractor. And hook the high pressure hose to my collection chamber and pull an extraction? Thank You, and I look forward to talking Extractions with you Rick

[…] several ways to make dabs without butane or solventless wax. Butane and other hydrocarbon extractions require lots of equipment to do it right and can be quite […]

[…] Today, the most popular method for making dabs is butane extraction. […]

You did a mistake. 0.035% water content in 1000 ml equals to only 0.35 milliliters not 35 ml !

Good eye! My error was using % symbol vis a vis vol/vol. GW

How often does skunk pharms test for resdiual solvents? Do you have any results on here? I cant find them Are butane extracts currently legal in oregon?

Butane extracts are currently legal in Oregon and have been for over a decade. Recently the rules were changed to require a licensed extraction lab, and for material going to the public, to be tested by a certified lab. How often we check for residual solvents on our own GC, depends on what experiments we are running and what we are researching. We are a public information company, that doesn't supply any concentrates to the cannabis market place, but Eloquent Solution and Pharmer Joe both run their own companies supplying extraction and processing services to the cannabis marketplace, and 100% of the batches going out are tested for content, residual solvent, mold, and pesticide by a certified third party lab, as required by OR law. Here is a link to a typical report: https://skunkpharmresearch.files.wordpress.com/2012/03/residual-solvent-scan.pdf. GW

Thats nice to hear. It would be nicer to see the shared public information more strongly urge the importance of testing every batch. So many just rely on this tech and assume there stuff is ok. I work at a testing facility with micologist biologist organic chemist and a psycian on staff. Im none of these, just a student. But Famous last words of a guy dropping off a dirty sample "Oh i know its clean i use the same tech as this company thats been doing it for like 5 years and there stuff is clean so mine has to be"

With legalization comes regulation, and I've watched the quality of the concentrates available to the public through "legal" sources improve dramatically with testing. For instance, I can remember being a judge in a major national concentrate cup, and having a surprising number of the paid entries fall out when tested for residual solvents, prior to regulations making testing mandatory. What was perhaps more revealing, was an expose of the number of samples failing for pesticide residue and mold and most revealing how much difference there was in the analysis of the same material by competing labs. Enough so of the later, for regulation to appear governing cannabis labs. A clear case for knowing the history of your material, pre-distilling the butane to pro actively remove the heavier, harder to post-purge hydrocarbons, and a controlled process, as well as picking your lab carefully. Here is a typical residual solvent scan. https://skunkpharmresearch.files.wordpress.com/2012/03/residual-solvent.pdf GW

Yes. If only the do it yourselfer followed such strict guidelines. Or at least washed their hands. Had a guy recenlty with 90ppm acetone in his product. Come to find out he was cleaning with it and not washing his hands or rinsing his equipment. We have found many of our clients were suprised to learn how difficult it is to completly remove butane. And cuticle wax. We are privy to clinical study that is not on google search.We have seen many give it up and seek other methods.Coming state regulation is going to require 0 residual solvents in this class. Unfortunatley this failed extract only ends up on the street. No dispensary can sell it.

Might you share the clinical studies not available to the rest of us? A tricky slope, because we've seen acetone called out in material that was never anywhere near acetone, but was contaminated by the lab procedure. GW

Thats a scarry test result. Average 80 ppm ? What solvents were used for extraction?

Ummm, what 80 ppm average do you speak of? GW

Clinical studies are not shared publicly on google. There often tens of thousnds of pages. Our office spends thousands a year subscribing to medical journals and clinical reports Honestly you would have to be a dr to be able to read them. Dont waste your money.lol We also work witg state and federal law enforcment. They all say cannabis will never be legal until they get all its dirivitives under control. Such as bho. Its a major health concern. Butane is harming the integrity of cannabis as a medicine and a recreational drug

I didn't expect a Google link, but the name of the study and author, so we can use our resources to look it up. It requires a doctor to read or understand them, and yet you have and do? What is your doctorate in? Looks like your Ironlabs.com address is a software company, vesus Ironlabratories.com which is the cannabis lab. Which one can I reach you at? GW

Sounds like you need to fire that test facility.lol Acetone from a hardware store is loaded with impurities that will show up as residuals. Histological grade is all that should be used in a lab. I was amazed to learn how easily cross contamination can occur days weeks or months after exposure. but thats what they all say. " but i dont even use _____, dont even have it in my work area." Remember that time you wore that shirt to Sorry i read your test you posted incorrecly. When our test say n/d that just means it hasnt been determined yet. Residual test take a long time. Every one of 64 possible contamanates has to be screened for individually. Like i said i am not a doctor or a scientist but i work with some great ones Nice work, Keep up the good testing!

The ranks of labs thinned some when the labs producing the lowest cannabinoid numbers and kicking out contaminated lots dropped out, because all the customers went to the labs that gave them the best results. The next fall out was when certification requirements reared its ugly head. That part is still sorting itself out. We have our own GC, which we use for our own tracking purposes, but without fail use an outside lab who also has a HPLC and a MS after both of them, for important analysis. Once I learned how to run our GC, as well as what the variables are, and saw how much variation I can get sample to sample, I knew enough to know some things are best left to the professionals with all the high priced toys. ND on our reports means None Detected, or Measured value below Limit of Qualification. It doesn't necessarily mean zero, in this case just typically at least in the Parts Per Billionth range. GW

I’m really impressed with your writing talents and also with the format in your weblog. Keep up the nice high quality writing, it;2²s rare to see a nice blog like this one today.

How many lbs. of butane should I be using with a 12" base and a 2.5lb column in an active closed loop system. I can charge and recover simultaneously. I just got a 50lb tank and I don't want to over do it.

so much nonsense posted here. I posted BHO in 1998 and been sorry ever since, greed takes over for safety

Could you be more specific regarding the nonsense? What is wrong, and what is the correct answer? Calling the input nonsense, and alluding to greed as a motive on a free public information site, with no supporting data, says loads more about you than the site. If you have something useful to add, please do. If not, you waste all of our time. GW

@Keith, ya the harder the better in my opinion. it should help some. ya u can email me @stephennichols90@gmail.com

@stephen hi I wanted if I can emailed you about some questions .

@stephen my vacume oven pump purges it at -29 to -30 . I left it today at my hosue wither fan and windows open I won't be back for 8 hours you think this will help . How can I hard it up at this point where it sticky and gooey I just want it to get hard . Thanks I appreciated it

@Keith Kawano, try raising ur temp from 96 to 110. the consistency could be a couple things TBH, size of screen you used, how you blasted, etc. don't exceed 120 though. and your vac needs to be -25 or better if u really want to clear up your extract. every 2 hours for the first 6hrs try fresh air flushes as well. GL and happy blasting :D

I have some material that I blasted bho but it really oily and sticky from good fresh trim . I have a vacum oven from across international I put in there at 96.0 it still gooey and killing and sticky I wonder what I have to do from here maybe it moist in the wax ?! . I want it to get hard like wax or shatter at this point I have it drying in my house with a fan. Any help from this point on

put it ethanol, wait till the white stuff is on top, pour this part off. discard it, its the wax,wax will come out then dry the remainder it in vac oven and it will become rock candy.

Thanks for the reply. Completely agree with your assessment. It is the prohibitive cost of scCO2. I've managed to produce a SuperCritical CO2 Oil Extraction Unit costing $1,150. I don't think scCO2 extraction device can get lower in cost than that. Go to KICKSTARTER.com Search: "SuperCritical"

Why butane? Why not SuperCritical CO2 ?

true. ill have to think about switching. when I finally did buy a system quite a while ago, I was stuck in my ways and went with butane. :l On Wed, Jun 1, 2016 at 11:40 PM, Skunk Pharm Research LLC wrote: > Philip Wolf commented: "Why butane? Why not SuperCritical CO2 ?" >

to start with supercritical CO2 is a lousy solvent and only drive the oil out by pressure. leaving the good parts behind, did I mention it is also a danger? pressures run way to high.

Nonsense. Supercritical CO2 is a great solvent. You can actually modulate the polarity by manipulating the pressure. Lower pressure ScCO2 extraction are less polar and higher pressure extractions become more polar. Only people who don't understand the science behind the technology think it sucks. Kinda hard to justify spending over $100k on an extractor when you have no clue what you are doing or how to method develop.

You could summarize it by saying it is more difficult and costly to produce the range of products that the market demands with SCFE CO2, both from an equipment purchase and operating stand point, as well as labor costs and skill level required to produce things like aromatic shatters GW

Hi I'm going to use a oven with purge can you tell me what is the best temp for muffing and the next 48 hours .

dayum, 48 hours. try this, scrape your oil onto your slick, try not to over spread, then put on hot plate 125f-130f for 2-3 minutes, until bubbles start to rise and dissipate slightly. next put it into your purge without a vac, set on hot plate for 15 minutes or so, constant checking temp, should b around 110-115 in purge chamber. Once ur temp is reached in purge, pull a full vac, let sit on hot plate, or at 110-115 in purge oven for 20-30 minutes. Vent oven and open/pull lid off chamber venting for bout 30 seconds, re checking temp, re pull a full vac and let sit for another 20-30. Most strains of mine will fully purge within 2-3 "burping's" with a 2-3 hour "air dry" after as well, peeling oil off slick and putting on appropriate slick. for snap-pull snap quality. :D On Wed, Jun 1, 2016 at 10:06 PM, Skunk Pharm Research LLC wrote: > Keith commented: "Hi I'm going to use a oven with purge can you tell me > what is the best temp for muffing and the next 48 hours ." >

if I were you I would ignore that advice as it will make you product oxidise faster.

This is a more industrial solution but head on over to www.rootsciences.com for a closer look at BHO extraction short path evaporators.

Care to have a conversation about SuperCritical CO2 Trying to get the word out about Kickstarter Kickstarter.com , search "SuperCritical" Thanks

Great info. Being a chemistry Nazi - I gotta say .... gasoline is 8 , OCTANE. On the gas-pumps you see an octane rating. Still, wonderful writing. Whatcha thinking about SuperCritical CO2 ?? Please go to Kickstarter.com, search "supercritical" Can I get a tabletop scCO2 apparatus into your hands in exchange for getting the word out??

Actually, I believe the octane rating scale uses trimethylpentane (a.k.a. isohectane)as the standard for 100 octane. Many of these isomers have names that don't exactly reflect the number of carbon atoms, functional groups sometimes considered independent of main chain structure. Good article, gracias.

[…] BHO Extraction | Skunk Pharm Research LLC – Butane Honey Oil, or BHO, is the essential oil from the cannabis plant, extracted using Butane as a solvent. It can be extracted from fresh material or from cured … […]

Lifted elite extracts on Instagram is how I see him. All one word

I have a friend in humbolt mendo area who makes them for cheap I think 1100 for a basic one pounder

do they have a website or ad up?

From your experience and with hindsight, do you think a 6"x6" spool is enough collection chamber for a first extractor? Would getting a 6" by 10 or 12" collection chamber be worthwhile in versatility for the slightly higher cost?

for a complete extraction use a 1 to 1 ratio on size

Very good information can you let your butane evaporate naturally when it's in your collection plate

We do not advocate for methods outside of a properly designed closed loop system.

You can evaporate without heat, but it will form ice at the edge of the pool and add water to the mix.

Well, I fell right into it! Thinking I could make a closed-loop system better and at less cost from on-line parts... I now have a couple of great designs for awesome Cadillacs that are way too rich for me to drive as my first BHO Ride! Soooo... back to the drawing board. I'm thinking to do the simplest system off a 6x6" sleeve chamber and 1.5" column. and just workin with it to get going. My Question Is: There is a great buy on a 10 Litre Stainless flask I found and am wondering if havng extra volume would work for or against me in a passive-recovery environment to use an over-sized recovery tank (that I would want to run with only a litre or so of solvent). I can't decide if, beyond the obvious need for more ice/cooling etc, the effects would give me more pulling power or less...

(...I did mean cheaper than the $1700 base-model systems that extractor companies are offering for sale...)

I have a design that's around $1100 from auction parts that's got more options than the $1700 base line models most companies are making. So I met my goal, but the bottom line is still so much more than what GW spent with the Lil Terp project, Im not as sure now one can get a system together from pre-fab parts for a decent value. Being daunted by the machining and welding aspects of having a system made like the MKIII or Lil Terp, I feel it was time well-spent for the educational aspects but I am still not ready to purchase parts. I assumed eBay auctions would be cheaper than sites like glaciertanks, but already see in comparing just a few parts a significantly better value at Glacier.

In re-reading my post I realize I didn't clearly state my intent, to try to build my own system from pre-fab parts for less than the commercial units starting at $1700. In no way did I or would I purposely infer that I thought I could do better than whats been presented on this site for less money, which would be rude and I may unintentionally have left open the perception that I meant that in my opening remark... My apologies for my vague language choices.

Check out best value vacs, they have a lot of choices at fair prices. Also, their kit packages come fully tested. As well as good customer service, they were willing to work on the price when I bought a kit with a few add ons. Def worth calling if u decide to place an order. Hope this helps, happy new year and happy extracting =D

"Best Value Vacs" do indeed have some good values to be had, especially the dewaxers (jacketed spools which have a 3" jacket clearance instead of 1" like most others). However, their $1450 intro 1# model is VERY basic their $1850 is where I see they start a sight glass as standard, but have gone back to a 6"x6" chamber and recovery tank. Add to that everything is offered in single-pin clamps... (I'm thinking about running a dewaxer filled with heavy media and wanting to fasten the collection tank and at least 1/2 the column with high-pressure fittings for safety). I have looked a lot at Best Value and agree with you about them having fair prices.

Holy specific. I currently use passive closed loop extract method, Best value vacs, but plan to upgrade to active soon. Have been messing with extract since 09 here in Michigan. Only until just recently have i had tremendous results. I appreciate all the insight. U offer the kind of knowledge most people would pay for. Thank you #GrowDirt

Is it safe to blast fresh frozen flower in a closed loop system?? Will the water mess with the vaccum pressure?

Yes you can safely extract fresh frozen flowers in a closed loop system, using subzero butane, so that water pickup is low. Extracting cold and recovering with minimal recovery pot heat produces different vacuum pressures, as well as recovery times, versus running at ambient or with a hot recovery pot, so the answer is probably yes.

Great piece and great explaining in a simple manor. Chemistry is good.

Public service announcement.......... i currently made some oil/wax concentrate with the 91% iso method. I used mostly seeds and stems. The turn out was amazing but the only issue i have is that the oil/wax concentrate is really runny, like a watery substance. Are there any helpful hints to try to solidify my watery like concentrate?.... ive tried to freeze it and it wont freeze. Please help

You still have a bunch of iso in your oil, let it sit out for a few days, judging that you don't have a vaccum oven since you used seeds and stems to make your oil use low heat with a fan for a long time and it will solidify, if you went too high of a purge temp then you are stuck with that

Thank you for this entry level tutorial. I found it to be very informative and extremely well written. A real pleasure to read.

If you take dried coconut, not from a bag it has additives. Grind coconut and material to a fine powder. Put this in your butane extraction device. This produces an edible that will stay in a liquid form. The process binds the oils together and makes a potent cocktail. Try it you will like it.

Sry im late, but this--what is this alchemy?