To perform some of the desirable alchemy with cannabis essential oils, requires some sort of vacuum chamber that you can control the heat and vacuum levels in, as well as see what you are doing.

These are readily available as vacuum desiccators and vacuum ovens, but all are pricey, so how about just building your own?

We already have a glass desiccator with a hot plate inside, and picked up a new used vacuum oven, but alas the temperature controls are ineffective in the low ranges that we operate, so we are in the process of refining its controls.

More on that subject on a separate thread, but this thread is to show how we punted when the vacuum oven capacity that we had counted on, eluded us, with meds to process backlogged.

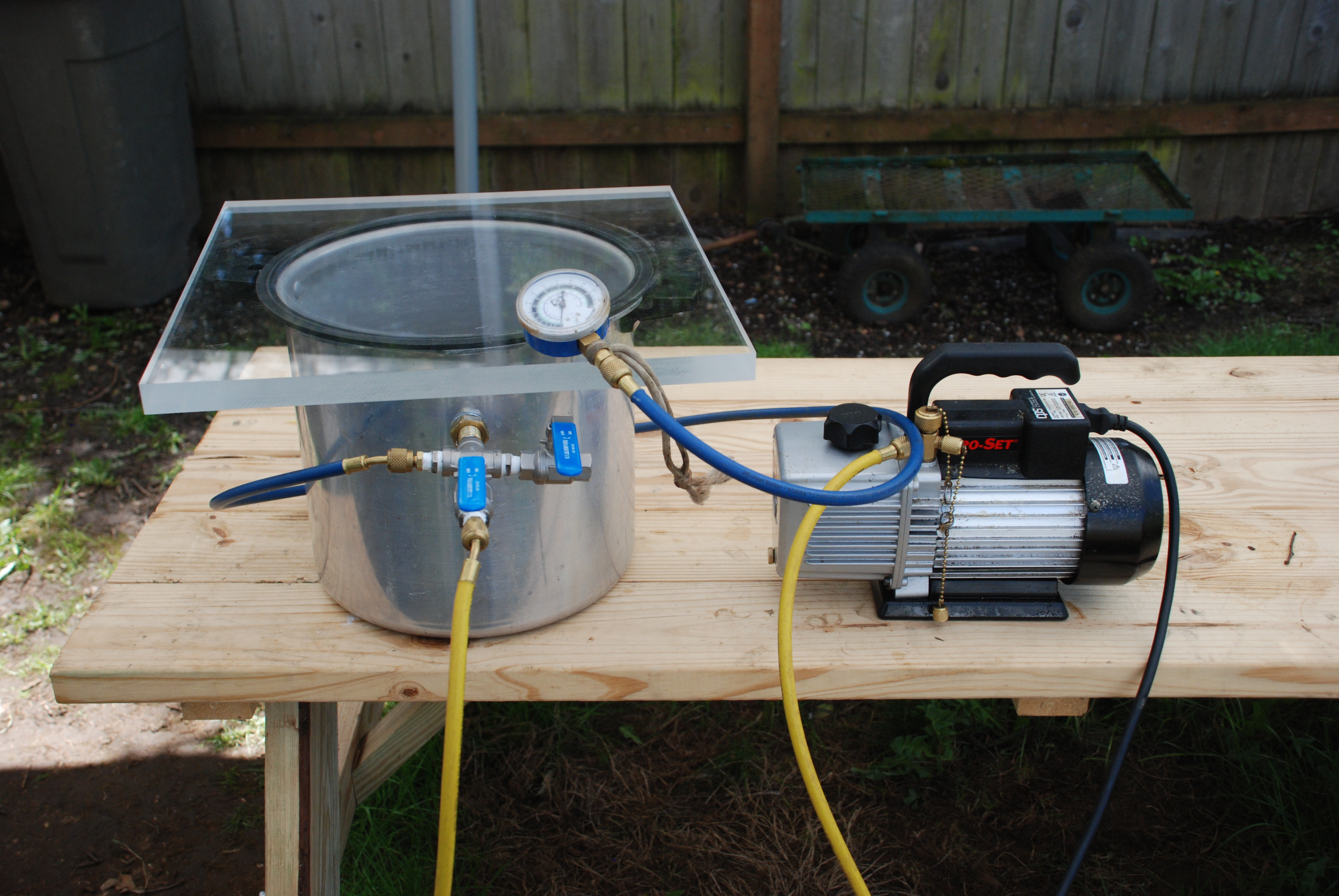

To that end, we used an old 22 quart Mirror pressure cooker that was gifted to us, and after removing the gasket, we tossed the lid.

I then drilled a 1/4" pilot hole through the side wall wrapper, about 2.5" below the top flange, followed by a 3/4" bit, to enlarge the hole to fit a 1/4" NPT brass bulkhead fitting.

I then inserted the bulkhead fitting through the side wall from the inside out, installing a gasket on the inside flange, and tightening the nut and lock washer on the outside of the pot.

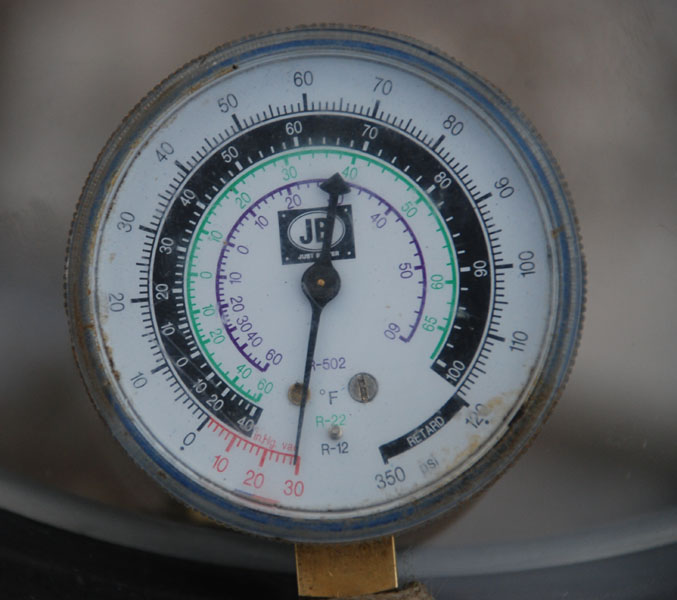

To this I added close nipples, a cross, with two 1/4" ball valves, and two 1/4" MPT to 1/4" flare refrigeration hose fitting. One for the vacuum pump and the other for the vacuum gauge hose.

As it is temporary, and we needed it immediately, we reused the existing gasket, and made a new lid out of a 1" X 16" acrylic plate. At -29.9" Hg gauge, there is about 1/16" lid deflection in the middle, so a thicker plate would be better to reduce high cyclic fatigue.

If it were permanent, we would have a new Viton gasket cut by Paramount, or Gaskets Unlimited and use 1 1/2" polycarbonate, for the lid.

Hee, hee, hee, after telling me that they didn't have any, and after having them cut the 1" acrylic plate, I found a 22" X 29" X 1 1/2" Polycarbonate remnant at Multi Craft Plastics, which I scored for $72. It has one 6" hole in one corner, but that is $2/lb for bullet proof polycarbonate panels, like those used at teller windows. Snicker, snark, snort, more projects to come!

Here are pictures showing how we made and how it turned out. We are able to easily control the temperature with an outside hotplate and reduce the pressure to -29.9 with one of our 6.2 cfm single stage AC vacuum pumps: Vacuum chamber from pressure cooker

Vacuum chamber from pressure cooker

Soooo, how about heat in the 85/115F range, way below what most hot plates and griddles control at?

We've tried several different hot plates, with and without trivets and pads to dissipate heat, and ran across a slick set up forum X, posted by Superly and using two layers of reptile mats to generate the heat, controlled by a simple light dimmer switch.

Hee, hee, hee, works pretty slick! After cutting them to size, I put a towel under them and then put two layers of towel over the top surface, but cut out a big hole in the top layer through which the pot sat, resting on the heating mat.

Here was the test run of Cheese, as well as a picture of the heating provisions and an inlet filter on the makeup air to keep out atmospheric dust!

Reptile pad towel insulation

Reptile pad towel insulation Insulation and inlet filter in place

Insulation and inlet filter in place Vacuum purged Cheese Absolute

Vacuum purged Cheese Absolute5-26-13

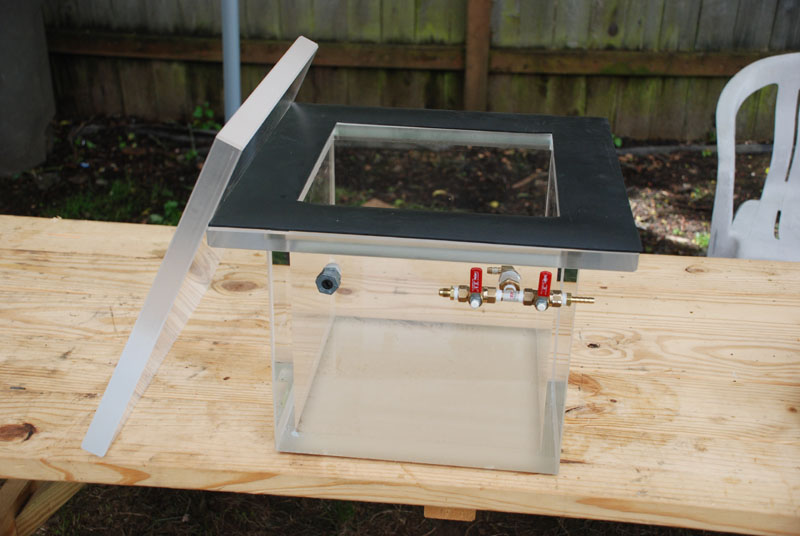

Wowza, speaking of DIY, look at what Steve whomped up out of acrylic panels! Looks purdy enough to use for a jewel display case and sturdy enough to last.  Steve's Vacuum chamber

Steve's Vacuum chamber Steve's vacuum box and lid

Steve's vacuum box and lid

__________________________________________________________________________

8-2-13

The question arose regarding the suitability of a 2" Polycarbonate plate lid on a 20" pot, so I thought that I would share the answer and the math with you:

In summary, it looks to me like a 2" Polycarbonate or a 2" Acrylic plate would work. Stress at the extreme fiber at 450 psi, is a small fraction of the 9,500 psi ultimate tensile strength.

Deflection would only be about .004", so high cyclic fatigue shouldn't be an issue.

Calculating stress at the extreme fiber and deflection of Polycarbonate vacuum chamber lids lids

The formulas for calculating stress at the extreme fiber and deflection for a simply supported flat circular plate from the Thirteenth addition of the Machinery Handbook are as follows:

1.0 Assume:

S= 0.39W

t2

d= 0.221 W R2

Et3

Where:

S = Stress at the extreme fiber

T= Ultimate Tensile of Polycarbonate =9,500 psi

p= Pressure in psi = 14.7 psia atmospheric pressure

W= Total load on plate= p X area = 4618 lbs

t= Plate thickness= 2"

d= Deflection

R= Radius of plate= 1/2Diameter = 10"

E= Modulus of elasticity = 375,000 psi

D= Diameter of pot= 20"

Mechanical properties taken from: http://www.boedeker.com/polyc_p.htm

2.0 Therefore:

d= 0.221 X 4618 lbs X 100 = .034" deflection on a 2" plate

375,000 psi X 8

s= 0.39 X 4618 lbs = 450 psi

4

8-13-13

Here are some more heat mat sources, compliments of Skyhighler, which have greater capabilities that the one above:

Does the type of metal matter in the fittings and the chamber if you are working with ethanol? I don't want to leach any nasties out. Thanks

I bought a universal lid and tried making a chamber with that and a stainless steel stock pot but I think its leaking air from the handle mounts. How should I seal it up? I saw someone use blue rtv silicone on a similar situation but with silicone molding, Will it work with my situation with essential oils?

Hello! Im gonna build my own chamber, but i want to use tempered glass as a lid instead. I'm trying to find a chart or some information on the thickness needed on a tempered glass lid. I like many others cannot begin to thank you enough for all the information you have made available to the people. We are lucky to have you guys around :-)

Glass has a modulus of elasticity close to that of aluminum, or around 10 X 10-6. Just plug that into the deflection and stress formulas at: https://skunkpharmresearch.com/diy-vacuum-purging-chamber/ , using 1,000,000 for E instead of 375,000. GW

Thank you for such an incredibly fast reply :) I have to admit that math isnt my strong suit, i cant say that I understand how to read the formula. But from what I can tell it seems that tempered glass is stronger than polycarbonate.

Nice work! Featured in today's HomemadeTools.net newsletter: http://mailchi.mp/buildthreads/multi-angle-magnetic-saw-guide-portable-boring-machine-all-terrain-track-chair-342573

Hey Good morning GW and skunk Pharmers I have a question so I was doing a vacuum purge with a small ISO wash run i had turned off the vacuum pump to give her a break and fell asleep when I woke up this morning my 1" acrylic lid looked all messed up so I released took it off and yep sure enough the bottom was real Soft lots of spider cracking and made it more of a translucent than transparent it dried up now and isn't soft anymore. Is the lid still safe to use like that? Is there a way to many sand the surface down again so it will be transparent or should I just throw the lid away and fabricate a new one PS thanks for all you guys are doing it has made a huge difference in the quality of life for me and the people around me Keep up the good work

Thanks for the good thoughts! You have two issues at this point, so I would replace the lid. The first is the Isopropyl attack on the surface. Here is a chart showing the chemical resistance of Acrylic. https://www.tapplastics.com/uploads/pdf/acrylite_chem_resist.pdf That could be polished off, but the stress cracks demonstrate eminent failure under load, so better to toss it before it wrecks an otherwise perfectly good day. 1" is relatively thin. How big is your pot? GW

Ok thanks for the info GW I was going to wet sand and than buff it out but with that info and the stress cracks now it's better to be safe and get a new one . My Vac chamber is 6"x6" round stainless so I figured the 1" was ok. I am currently building a Lil' Terp using all the great info on your site thanks again and Keep up the good work 👍🏻

How longdo you purge your wax . and wats the temp. you should have it . and I'm new to this so what should I do .?? Anyone??

How do you get the stress and the deflection on the side panels of the rectangular polycarbonate vacuum chamber? Is there no stress/deflection on the side? I want to make a bigger (20X20X20") vacuum chamber, but I am not sure what thickness the side panels need to be. Same question about the bottom panel. Does the atmospheric load only apply on the top, and not other surfaces? Or would it be the same on every face? I couldn't find any information on it. Any help would be appreciated

If you have a magnetic pressure cooker, or, pan/container that you can use, then I highly recommend it, and; use induction heating. No flame/spark 100°F is the auto low button (you can go lower). Time is programmable as are heat changes at different times. I use it exclusively cause it's so exact & programmable in 5°F increments, stops heating insantly, and only heats where pan is, very cool. I've even put a metal baking pan and then my pyrex water dish for initial purge before vacuuming.

for heat use a reptile warming blanket

Beyond the speed-up of the purge does the vacuum chamber bestow any other benefit? I don't mean the benefit to time-temperature trade-off to thermally-unstable components. I mean is the change in various component's relative vapour pressures (as the temp/pressure is varied) beneficial to the retention of desirable components and removal of undesirable ones?

Graywolf, you are as much a beast as the name implies. Superlative information, creativity, scientific process, and humanitarian striving. Definitely my new favorite site — and one I will refer to extensively as I dip into building an extractor for my business. Thank you for all the data, BlueFox (Nice naming convention, by the way :).

What gauge would you recommend if I only want to pull down to 29.2?

Depends on the design and size. Typically, around 10 gauge is used for the wrapper, but has stiffeners welded to the outside for rigidity. A round cylinder would require less wall thickness, because of the way the stresses are distributed.

t end, we used a old 22 quart Mirror pressure cooker that was gifted to us, and after removing the gasket, we tossed the lid. I then drilled a 1/4″ pilot hole ... ccookerp.wordpress.com

How long will it hold-30 for how many hours my chamber only hold for less than a hour

I am not very sure about the need, I mean, do I have to use one? Like , for the vacuum selaer I use in home, does it really need to be cleaned once a while.So if someone can suggest me which one I should use, the ones from market;or this home made one?

Thanks for all the great info here. Does the pot being made out of either aluminum or stainless steel make any difference, other than stainless steel working on induction cooktops and aluminum not?

How long should I let the butane evaporate off before putting the oil in the vacuum chamber? Do I need to worry about butane contaminating my vacuum pump's oil?

With the set-up ypur friend steve made out of the leftover acrylic, did he also use the same hardware, like the brass bulkhead fitting, with his set up? Also i was wondering where could i get just a negative pressure gauge? All i can find in hardware stores are air control manifold gauges... i saw that break bleeders have a negative pressure but i dont want to spend 30$ on the system when i only need the gauge

Search for "differential pressure" gauges.

[…] certain kind of gaskets, etc. that work and don't dry out or leak or anything like that. rnrnDIY Vacuum Purging Chamber | Skunk Pharm Research LLCrn rnrn rnrn rnrn rnrn rn rn rn rn […]

HI I SELL $5,000 dollar VACUUM PUMPS used for $500.00 Pumps are an ALCATEL 2021I 2 STAGE ROTARY VANE 14CFM They are in good Used Condition and Fully Tested before Sale. I also Sell INTAKE AND EXHAUIST FILTERS for this PUMP. STYLEENTERPRISES@YAHOO.COM I do not Ship Them ERIC

Where are you located Eric?

Did Eric ever get back to you?

cant reach your address hit me back please at FIERO8420021@YAHOO.COM

The old rubber gasket from the pressure cooker, from what I read in the article. The vacuum will hold the seal tight.

What did you place on the lining of the top to hold suction?

How do you recommend heating the receiver in your mkiii set up to produce shatter

Hi , I'm running a mkIII and a cascade tek oven. My shatters have tested amazing ,zero solvents detected.But presentation is what I am having a problem with. Here in van bubbles of ANY kind are not good. any tips on getting the small fizzy bubbles out? Thanks Peace

I'm guessing I posted this question in wrong thread sorry to all

The small fizzy bubbles are CO2 from decarboxylation. If you run the puddle high enough for them to escape, or at around 115F at -29.5" Hg, they shouldn't be an issue. You could also decarboxylate the oil and eliminate them, but it wouldn't be stiff anymore.

Something that I'm not seeing discussed much here, or anywhere in fact, is over-purging. Is there even really such a thing? I've built my vac chamber, and I have been following all the guidelines mentioned here with close attention to detail. What I'm finding, though, is that if I leave a concrete or oleoresin in my chamber overnight, it begins to darken and get sticky again. It even happens when I use lower head/vacuum. I've heard of people vacuuming their extracts for up to 16 days, but I don't see how they end up with anything but roofing tar after that long of a purge. Can anyone explain what is happening here?

What temperatures are you keeping your oleoresin at in the chamber? I keep mind 95-110, and don't have troubles with stability. Any hotter, and I may have the problems you describe, however.

Thanks for the response. I have been running at 115f, as recommended here, and I use an infrared thermometer to verify. I've tried as low as 108f, but perhaps I need to try even lower. Do you run your vacuum any different when running at lower temps? I have a very accurate digital vacrometer and I am careful to go no more than 29.8"hg (adjusted for altitude).

Ok I did a new run. 100f, 29.2"hg (adjusted) for about 11 hours. I got similar negative results, but possibly not quite as bad. To give you a little more info, it starts as a dry look around the edge of my puddle, and then the entire thing begins to become cloudy. Again, I'm monitoring temperature and vacuum very carefully, my input material is high quality and thoroughly dried. My puddles are very thin, under 1/8".

Just found your site. It extremely useful and informative, thanks! I realize this thread is a little old but I noticed in the comments, folks are having issues with heating. Hopefully this is useful: Have you ever though about an inexpensive PID temp controller, thermocouple and solid state relay for you heating control? They can be had for 30-40 bucks. I use them in several projects. They are inexpensive, readily available and the best part--- they learn the system they are in and make accurate temp adjustment fairly quickly.

You mentioned if it were a permant setup you would use polycarbonate over acrylic for the lid, is this strictly because of strength and retention properties or is there the risk that the acrylic material could start to seep into my product after prolonged use?

Strength

In a recent search on eBay this gadget for purging turned up HEATED-ULTRASONIC-VACUUM-CHAMBER-EXTRACTOR-DEGASSING-BHO-PURGE-SHATTER-WAX-120F Basically someone added a polycarbonate lid with gasket, valves and vacuum gauge to a heated ultrasonic jewelry cleaner. The guy is claiming this is the newest method for purging BHO and can lower purge times to 1 hour. . . I like the precise digital control on the heater 90-140 Degrees - It has a timer as well. The ultrasonic transducer under the stainless tray vibrates at either 20,000 times a second or 40K It does seem like the vibrations would help "Shake" the butane bubbles out of the extract since it's so thick. . . but I've been unable to find any info on people purging with one of these. . . Has anyone used one of these things? Do you think this would speed up the purging process? Have you ever used an Ultrasonic device in your BHO purging?

Haven't heard of it.

Im very interested in construction a chamber pot like steves. Can you help me out with a link or intruction. What thickness of product what adhesive or anchors to use making something like this. I would be very greatful of you time do so.

Unfortunately no

This may be a dumb question but I've always had a difficult time pulling a vacuum that was 29.5 or so. I did some research and found that at my 3000 foot altitude I can only pull 26.8 lbs. Am I interpreting this correctly? I've got into the habit of listening to the sound of the vacuum pump and using it as my max vacuum. Also, I'm using a Mk3 with 2x24" columns and would like to increase their size. What would you recommend?

26.8 inHg or inches of mercurcy, not lbs.

Won't a flame kill of the residual butane when smoking?

It would cause the vapor to be polluted due to combustion of residual petrochemicals .

Hey GW! I built a similar set up (except we use a sous vide water bath for our heat source :), and it has produced oil with less than 25ppm residual butane. (Woot!). My question is: I noticed that your chart states that THC boils at super low temps while under high vacuum. Are we boiling off the good stuff when we pull a -29+ vacuum?? Thanks, dope cook P.S. you guys are my role models! sending love from Seattle.

Wanted to add more detail: Using a harbor freight vacuum rated at 22.5 microns. I cook my oil at around 110-114F. A recent batch of honeycomb was tested: 60% THCA and 8% activated. <25ppm butane. I cooked it at 110 under full vacuum (29+, my gauge tops out... but like i said, pump is rated at 22.5 microns http://www.harborfreight.com/3-cfm-two-stage-vacuum-pump-61176.html) http://analytical360.com/m/concentrates/174447

Hee, hee, hee, looks like a good choice for a heat source! Where the boiling point really start to plunge is after about -29.89 Hg. I tell everyone -29.5, because it is hard to see .89 on an analog gauge.

I read on one of your posts that glass has the same elasticity of aluminum does that mean if i were to use a aluminum pot as a base(w/ a polycarbonate top) that it would possibly implode on full vacuum? i heard someone say it would be fine at 29...also how bad is an implosion there isnt much information on the internet about it and the only video i saw was with a unfit chamber made of glass & tape

specs are: 3gallon tank height 9 1/4in and diameter of 9 7/8in with 1/2in polycarbonate top

Depends on how heavy the pot is. What I said is that glass and aluminum have close to the same modulus of elasticity, which means that if you simply supported the same size beam of each on both ends and set the same weight in the center, the two beams would deflect close to the same amount. When the two beams reached their limits however, the glass would exceed its ultimate tensile and break, while the aluminum would bend.

1

Hi, thanks for all the great info GW was looking into ambient heat for the chamber and was wondering what you thought of Seedling Heat Mats vs the reptile mats you guys used! and will an aluminum pressure canner be okay for the base without implosion? and would using 3x 1/2 inch polycarbonate fastened together be strong enough for the lid or should i search for a thicker polycarbonate? finally would you contact cement the gasket to the polycarbonate or aluminum pot? Thanks in advance for your time!

Depends on the specs on the heat mat. Briskheat and Omega both make a killer silicone rubber heat mat that works stellar. Probably. What diameter and how thick is the canner wall and bottom? They would have to be attached to one another, so that they acted as a single beam' I would rough up the aluminum and stick it to it. The polycarbonate will be flexing.

Thanks for the info on the heating mats! Do you prefer either mat to your mcgyvered reptile pads and do they provide a more consistent temp? Couldn't find exact specs on the wall thickness of the pot but its this 16 qt presto on walmart, even called their customer service w/ no luck. (http://tinyurl.com/kvkalwe) in regards to attaching the multiple pc sheets which would you recommend between a screw and nuts tightening the pieces together on each of the four corners of the lid, or using an epoxide? i also found this third method maybe you could help enlighten me if this is a viable option. (http://www.ehow.com/how_5686551_glue-polycarbonate-sheet.html) Thanks again for all your help!