As ventilation is an important part of indoor growing, here are a few principles to consider in your designs.

When you move air through a duct, it rubs on the side of the duct and through friction builds up resistance to the flow. The rougher the duct, the more friction and resistance.

This resistance to the flow of the air is called static pressure. Not only does friction in the duct produce static pressure, but every shape transaction, elbow, branch, and filter also adds static pressure, so if you add them all up in the system, you have total back pressure.

Designing a system to minimize these pressure losses in the system is a good first step, but after that is done a fan must be selected that will move the CFM that you require, at the total static pressure of the system. All fans are not created equal, so let's look at some differences.

Axle Flow Fans:

Fans with a simple propeller on the shaft of a motor, will move the most air for the least horsepower, but will produce almost no static pressure. When you see their CFM rating it is usually given in free air.

When confronted with backpressure, the fan blades simply stall out, and flow is lost.

Centrifugal Fans:

Centrifugal fans require more horsepower to move the same amount of free air, but they will operate at elevated static pressures. Vacuum cleaners are a good example of a centrifugal pressure blower, that uses an impeller shaped like a paddle wheel, instead of an air foil. They are noisy, due to the siren effect, but produce the highest pressures.

Squirrel cage fans are the most common forms of centrifugal fans, because they operate at moderate static pressure, and depending on the impeller design, are relatively quiet in operation.

The modified inline centrifugal fans typically used in indoor grows, has the squirrel cage mounted on the end of the shaft, with the air drawn in the front, and forced out its outer diameter, through a force cone, to the inline discharge port.

This design is effective for its designed purpose, but won't support high static pressures, so system design is important.

It varies by design, but for instance a 4” Vortec fan produces about 2” of Water column static pressure and a 6” about 2.28”.

A cubic inch of water weighs .0361 pounds per cubic inch, so 2.28” WC equates to about .082 pounds per square inch. Not very much until you put it over a large area, and then for instance a 6’8” X 30” door has 196.8 pounds of pressure pressing against it.

Fan Laws:

In heaven, the amount of air a specific fan design will put out is directly proportional to its RPM. A fan that puts out 100 cfm at 1000 rpm would put out 120 cfm at 1200 rpm. Here on Earth, it does so on a predictable curve that approximates those numbers, until the curve falls off from losses.

The additional horsepower necessary to achieve the 20% increase however, is equal to the cube of the increase, or 72.8% increase in horsepower and amperage draw.

In addition, increases in static pressure draw additional horsepower at the rate of the square of the increase. A 20% increase in static pressure would therefore draw an extra 44% horsepower.

What that means of course is that the penalties for not designing a clean low backpressure system are severe, so it behooves us to pay close attention.

Duct Design:

The larger the duct for a given flow, the lower the static pressure and the smoother the duct walls, the less resistance to flow and the lower the static pressure.

The straighter the duct and least amount of fittings and transitions, the lower the static pressure.

Anytime there is turbulence in a duct or the air speeds up or slows down, it raises static pressure.

That means that to keep the air moving uniformly, when you pull branches off the main duct, you must reduce the main duct size where it continues, so that its cross sectional area plus the cross sectional area of the branch equal the cross sectional area of the original main duct or is as close as one can come to it using standard ducting sizes.

Area 1 = Area 2 + Area 3. And Velocity 1 = Velocity 2 = Velocity 3

Most ventilation designers use programs or ventilation slide rules, but the way I calculate the sizes on a simple calculator is as follows:

Duct diameter in inches squared X .7854 equals the duct area in square inches.

.7854 X Diameter squared (D2)

For a transition duct size, duct Diameter 1 plus duct Diameter 2 = the area of the main duct.

Area 1 = Area 2 + Area 3. And Velocity 1 = Velocity 2 = Velocity 3

Examples:

Assume:

Main duct is 8"

Secondary branch is 4" diameter.

Therefore:

8 X 8 X .7854 = 50.3 square inches

4 X 4 X .7854 =12.6 square inches

50.3 in/sq - 12.6 in/sq = 37.7 sq/in

37.7 = 48 in/sq

.7854

Square root of 48 in/sq = 7" main duct continuing after the 4" drop.

Going the other way, lets say that we have two 6" ducts and wish to compute the size of the main duct after they are combined.

6” X 6” X .7854= 28.27 square inches of cross sectional area.

2 X 28.27 square inches = area of main duct or 56.55 square inches.

56.55 divided by .7854= 72

The square root of 72 = 8.49 “, or the desired main trunk size.

Fitting design:

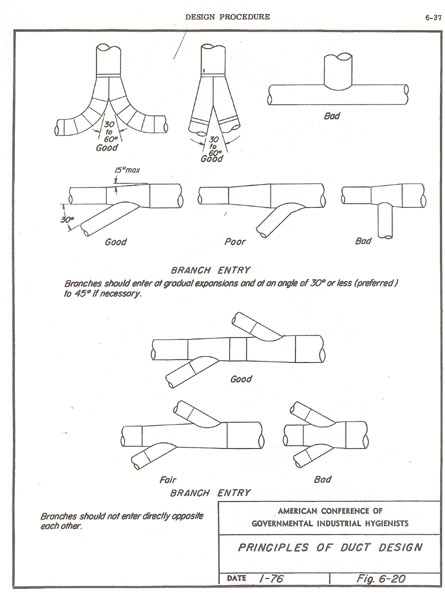

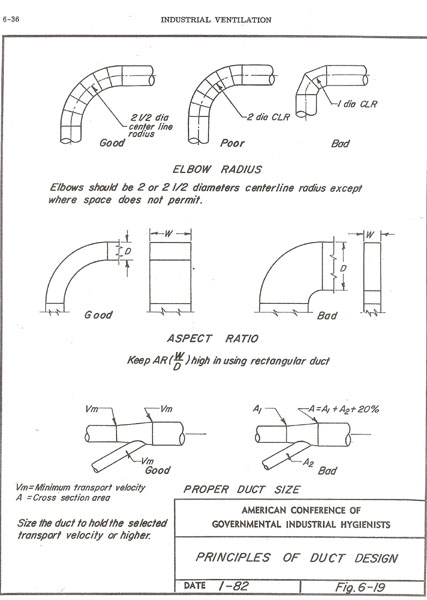

As noted above, every change in the duct adds static pressure, so the design of fittings has a significant impact on static pressure.

The following two attachments from Industrial Ventilation, by the American Conference of Governmental Industrial Hygienist, show proper fitting design:

GW

GW

All Hail George for doing his part in Paying it forward! and I think maggie and lolas paw prints should be clear coated on permanently!

Way to go george!! ITs good to see skunk pharm getting back what they work so hard to put into the community... :)

NICE!!! Way to go George! Glad to see Skunk Pharm being taken care of....

Hats off to George at george@alpineinc.org for helping our friends at the Skunk Pharm Research LLC. Only right that those floors should be pristine. Everything else in there is. And I am proud to receive all my medicine through http://www.specializedformulations.com Specialized Formulations.LL located conveniently in Portland, Oregon Also remember to add your "Likes" to the Skunk Pharm's Facebook page found here. https://www.facebook.com/SkunkPharm EDDIEKIRK Owner Operator of OMMP Pay IT Forward

Thanks for the good thoughts Kirk!