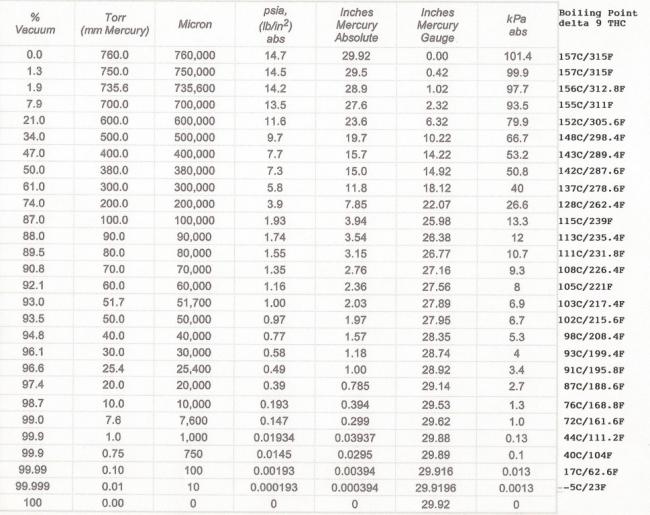

Any ya'll thinking, "hot damn, ah gots mah vacuum chamber and bodaceously big pump, so where do ah go fum heah?" Goooood question, so lets hit on a few key points. There is more to vacuum purging and finishing than just sticking the oil in the chamber, and turning on the pump. Tip # 1 Selecting vacuum levels and pumps. Don't waste money and cannabinoids purchasing a 2 stage vacuum pump. First lets look at what is going on when you place oil in a vacuum chamber and start raising the temperature. The boiling points of compounds are given at a specific elevation, normally sea level. That is because the weight of the atmosphere at sea level is about 14.7 psi, 760, 000 microns or millibars, or 29.92" Hg. The weight of that atmosphere suppresses the boiling point, and if you remove that weight, the compounds boil at lower temperatures. That is a good thing in that it allows us to cold boil away solvents with little heat, but it has its limitations, and one is that the same vacuum also changes the boiling point of the components suspended in the alcohol, that you are hoping to end up with when the alcohol is gone. For instance, here is a chart, complements of Skyhighler, demonstrating what happens when you pull a vacuum on THC. Note that at sea level, Delta 9 THC boils around 157C/315F. Now look at what happens at -29.9196" Hg, where Delta 9 THC is boiling at only minus -5C or 23F. Whoaaaaa! That sorts of flies in the face of the common perception that nothing but a 2 stage vacuum pump will suffice, when most single stages will pull to below 100 microns, which is about -29.916" Hg.

Tip # 2 Install a ball valve between the vacuum chamber and the vacuum pump, so when the pump is turned off, the vacuum line can be closed off, so as to not suck vacuum oil from the pump crank case, into the vacuum chamber.

Better yet, install a cross, with the pump ball valve in the straight through port and a vacuum gauge in one of the side ports, leaving the last port for another ball valve, which will allow backfilling directly from the atmosphere.

We install a filter on this ports ball valve, so as to not vent dust into a fresh extraction.

Tip#3 The brains of the system is the compound pressure gauge, so get a quality unit and calibrate it at the start of the process, as well as periodically check it to see that it is returning to zero.

Bourdon gauges have flat partial circle shaped thin walled tube inside, that opens and closes its diameter under vacuum, and they take a little time to nestle in when new. We like a Just Better M2-250B Refrigerant Compound Gauge ourselves, which has removable front cover, and a calibration screw that allows zero adjustment.

Never try to turn the adjustment screw under pressure, or you will most likely damage the adjustment screw.

Tip#4 Check your pump oil for color, clarity, and level before starting the process and regularly during use, most especially during cold boiling under vacuum.

We prefer a clear, colorless pump oil, so we can see if it is contaminated by looking at it through the oil level view window. You can also note the level, as most have an upper and lower limit indicated.

All slide vane vacuum pumps puke oil and oil vapors out the exhaust and are noisy, so it to make a mess where you set it, unless you add a larger filter on the exhaust.

I just saw a cute conversion, that allowed spinning a Fomoco size oil filter on the exhaust, to contain the mess. If you don't have such an arrangement, might I suggest you use a metal tray under your pump where making a mess is of concern.

If you are using the pump to cold boil, and aren't using an effective cold trap, you must regularly change your oil as the level rises beyond the safe level and begins to puke out the exhaust.

More on cold traps further down.

Tip#5 Test your vacuum pump by itself, before trying to vacuum test the complete system.

You can test your vacuum pump to see what level it will achieve inheaven, but simply attaching a refrigerant hose to the pump and the other one to a vacuum gauge.

Make sure that the cord connecting the pump is heavy enough for the pumps rated amperage and avoid using extension cords.

Don't run multiple motors on the same circuit, because of the high locked rotor amp spike during startup.

Turn on the pump and see how far it pulls down. If it doesn't pull down to its rated capacity at your altitude, check for leaks at each of the hose connection points.

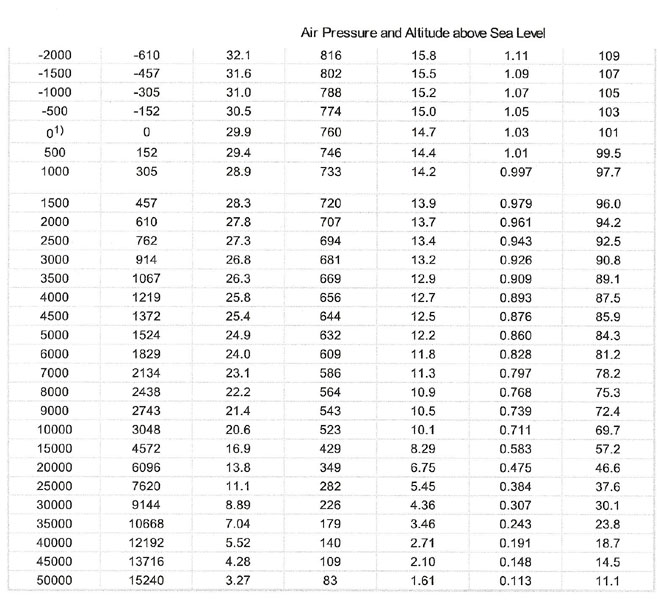

To adjust for altitude, here is a good chart, taken from: http://www.engineeringtoolbox.com/air-altitude-pressure-d_462.html

Tip#6 Vacuum test your complete system by first pumping it down as far as it will pull down, and turning off the pump isolation valve. There should be no pressure loss after at least an hour.

Except for losses due to temperature changes, there shouldn't be any pressure losses overnight. The key point is that the system needs to be hermetically sealed.

Tip#7 To keep the pressure of your chamber within the range that you have selected for optimum results, open the bleed valve and spill air into the pump line.

If you have both a 1/4" and a 1/2" hose connection on your pump, you can install a bleed valve on the unused one, to throttle vacuum at the pump.

Besides acting to limit how low your pump pulls the negative pressure down to, injecting dry air at that point, will help dry out the crank case vapors and slow down crankcase dilution.

Tip#8 Regularly close the ball valve to isolate the vacuum pump, and turn it off to give it a rest.

It isn't necessary to continue to run the pump, once the desired pressure is reached, but it is necessary to regularly start the pump and open the valve to burp it, so as to keep the atmosphere enriched by the cold boiling solvent removed from the chamber.

You can also valve off the chamber and introduce a dry gas through the other vacuum pump port, to act as a ballast to dry out the crankcase. Clearly you can't pull much of a vacuum venting a dry gas into the intake port, but the valved off chamber vacuum loss is tolerable for a few minutes and the pump doesn't care.

Tip#9 Use a cold trap between the vacuum chamber and the pump when cold boiling solvent to recover the solvent for reuse, before it dilutes the vacuum pump oil.

To insure that the solvent is recovered in the cold trap, and not cold boiled away there too, you must control the vacuum pressure at the cold trap, as opposed to the chamber. The lower the cold trap temperature, the more efficient. Besides ice water,antifreeze, dry ice and alcohol, and liquid nitrogen are used in cold traps to achieve desired recovery rates. A trap with more face area to the flow, will decrease velocity and increase transfer time. A trap with the most surface area will transfer the most heat, at the same velocity and temperature.

Tip # 10 When you first pull a vacuum on a liquid, it will out gas the dissolved gasses and may boil explosively and violently, until the gasses are expelled.

To prevent making a mess, throttle the vacuum carefully, while observing the boiling action, until the gasses are expelled and the pool calms down.

Tip # 11 When cold boiling, use a glass sheet or equivalent cover over your boiling pan, so as to not blow specks of oil all over the interior surfaces of your chamber or oven.

Even though it may look like boiling has stopped, it is still sublimating, with occasional explosive bumping.

Tip # 12 Before paying good money for cheaply made vacuum chamber, consider making something of your own like the one shown at:

Watch this space for more!

Whatsapp: +195.464.18238 Open link https://sites.google.com/view/nembutal-pentobarbital-sodiums Buy Xanax bars , Lean syrup , Oxycodone , Adderall , Percocet , Methadone , Ecstasy , Lsd and acid , Actavis Promethazine Cough Syrup , Viagra , Vyvanse , Klonopin , Fentanyl , Rohypnol (Roofies) , Ketamine , Hydrocodone 10/325, MDMA (molly) crystal and pill form , Crack Cocaine , Heroin (white, brown and tar) Weed , Marijuana , Cannabis buy in Switzerland , Germany , Spain , Italy , Strawberry , Sour Diesel , Jack Herer , Durban Poison , Haze, Pineapple Express , Blue Dream , Purple Haze , AK-47 , Grapefruit , White widow , OG Kush , Purple Kush , Black weed , CBD Oil , Hemp oil , Moonrock for sale in Switzerland , Germany , Spain , Italy ,E-mail: danny@ doctor. com https://onlinecannamedshop.com

Precious advice as usual over here! I have read conflicting info on THC boiling point, without having a clear idea on what to trust (http://hightimes.com/grow/what-is-the-real-boiling-point-of-thc/). I'd be curious to know how you guys found out about the 157°C bp for D9-THC at sea lvl Cheers for all the great work!

Good call Buntu! The post needed updating to reflect our own investigation into the disparity between posted boiling points for THC. Check out the new BP calculator. GW

Hey guys, thanks for having such a great resource online for all of us to use. Here's a little contribution that might help. The link is to a chart i just made. It take the boiling points of D9-thc in C under vacuum (in Torr) and puts it on the same axis as the evaporation of ethanol azeotrope. I've also included a line at 23 C as a room temp reference. The slope of the two lines is much the same, and looking at the data points the difference in temperatures falls between 78-84 C I made this to make sure that the lines did not intersect and to operate well above the cold boil point of ethanol without sacrificing any cannabinoids. When i have a bit of time, I will try to update this to reflect terpinoid cold boil temps as well. Enjoy http://www.filehosting.org/file/details/602743/DELTA9%20(1).xlsx

Here's a jpeg of the chart http://www.filehosting.org/file/details/602744/DELTA9chartdark.jpg

http://i.imgur.com/9mWzPxS.jpg

I first would like to thank everyone who has contributed to furthering our knowledge in "world of extracts" especially GW and everyone at skunkpharm! I am thinking of purchasing a Rocker 500 Laboratory vacuum pump, it is piston powered oil-free pump. My thoughts are it is oil-free and has a built in moisture trap so I will not have to worry about all the drawbacks of a single/2 stage "oil" pump. My only concern is it only pulls to 650mm Hg or 25.59 inches Hg max vac. I was wondering if anyone has any experience with purging under lower "loads" like this instead of the ideal -29.5 Hg & 115 F... i was wondering if I could still achieve a "complete" butane purge with thin layers of material and extended vacuum times as this is still producing around a 96% vacuum. Has anyone had material "lab tested" under these conditions. Any feedback is greatly appreciated as I am making this extract for a patient friend of mine who is battling an aggressive form of cancer. I am Using only N-Butane and I want to provide her with the purest form of medicine I can. Thanks again everyone keep up the great work!

oops screwed up the math... So the vacuum capacity can be expressed in percent. standard atmospheric pressure = 760 mmHg = 1013mBar, the max. vacuum of Rocker 500 is at 650mmHg (Torr), so the vacuum capacity in percent is 650/760=85.5% drawing out 650mmHg or 866mBar from the standard atmospheric pressure.

Be careful of the oil free piston pump. It has very poor durability for anything other than clean dry air. You would be better off with a scroll pump, if you want oil free, but the brand matters. Edwards and Leybold are good, Agilent (Varian) not as good.

Is it possible to produce shatter using Hexane? At what temperature would Hexane boiling point be at -29 Hg?

I recently purchased a micron Guage to help me bore exacting as I take notes on what strains prefer what Temps and vacuum levels. I was thinking to attatch it to a fitting that I can put a ball valve on to help me control my exact vacuum levels by throttling back the pump like you suggest. I have a 1/4" port available. Is my thinking correct here or do I need to hook the micron Guage to my 3/8 side that I'm using to pull my oven from? I know I need to hook the ball valve to the 1/4" side I just want to be sure I'm getting an accurate read on things. Thanks for your time

The best way to control your pressure, rather than restricting the inlet of your pump, is to have higher flow rate through your pump. There are a couple of ways to achieve that, but when you are pumping butane, you should be careful of mixing air with the butane in your pump, the number of explosions in the US is ramping up in this business. The feds are beginning to notice. Want to ruin your day, and your year? Have an explosion. Need tips on controlling pressure safely? Send me an email. geneligman@gmail.com

so im looking to buy an entry level vac purge kit i was thinking about getting http://www.ebay.com/itm/like/281522472581?lpid=82 this one i live at 308 ft above sea level would it suffice

That would work, the open question is longevity.

grey wolf was wondering if you can steer me in the right direction i have an ai purge oven just tryin to figure out if im using this thing right or how to use it right the stuff i made comes out nice but not like all the stuff i see how do they get it flat do they just flaten out the bubbles and repurge i dunno maybe you know acouple of links you can point me too im just tryin to give everyone around me the best product i can give them thanks

~In an oven @ 115F & 29.5Hg (relative to where I am), Could you tell me from your experience how long a 1 oz slab spread out over a 8x12 area on parchment usually takes to purge? ~I ask because I it seems like I have massive bubbles that never wanna disappear unless I (obviously) burp the oven, but another quick vacuum and those notorious bubbles are back. ~Is there some strategy I am missing? I appreciate any help you could offer. One Love Btw, With an IRT, I can tell you my oven heats up fairly evenly and is precise.

help my vacuum keeps exhausting a mist and small spurts of oil although ive read in other places that its okay just reassuring myself so i can go to sleep at night

You need a mist filter for your vac, it attaches to the top port, and collects that oil back into your oil chamber, filtering your exhaust. http://www.acrossinternational.com/Dual-Stage-Vacuum-Pump-Exhaust-Oil-Fume-Filter-SMF-010.htm

What micron activates the boiling point of delta 9 thc at sea level at 45 Fahrenheit?

So im completely lost with vacuums. Im in Colorado around six thousand feet and im unable to pull either of my pumps over 24.5 inHG. I thought it was my old pump being weak so I bought an across International 9.5 cfm pump but it won't go any higher than my old one. Does any one have any advice on how I can increase pressure

Think of it this way: your vacuum gauge sees how much atmosphere is lifted off of your chamber. At your high elevation, you have less atmosphere overhead to lift off from the get go. The HIGHER elevation, the LOWER the number you will see on your gauge at full vacuum. Your 24.5" is basically equivalent 30" at sea level. Keep the gauge under 24 and you should be fine.

Vacuum measured with a stand alone dial gage that reads in inches of mercury is actually comparing the pressure in your vacuum chamber against the pressure outside. When you live in a location that has lower pressure outside, you will see a lower reading on the gage, even if you are getting excellent vacuum. Find out what your local atmospheric pressure reading is, and compare it to your vacuum gage. Hint, the barometer you can get from Walmart or Home Depot will tell you the atmospheric pressure. Buy one and use it to compare. If your gage says 24.5 in Hg and your barometer says 24.6 in Hg, then you have good vacuum.

What's your opinion on using induction heating pads with an induction interface plate as a source of low heat? Would the heat transfer consistently and evenly or would I run into issues maintaining low heat? Assuming the heating pad allows for precise control of temperature.

I haven't found anything that holds temperature consistently outside of an oven.

Induction plates have a much finer temperature control than standard resistance heating plates. It would be a good step, but a temperature controlled oven is by far the best.

if you dont plan on washing the bho in everclear or another alcohol and just want to vac purge the residual tane out would a cold trap be needed? and if not does the pump oil get contaminated with butane ? thanks

No trap needed.

How much Co2 do you need? I need to make the Co2 oil into a solid? How? Each batch is different? Shatter will do but do not know how to get their.

Hello and thank you for all the great information. I have a terp 3A and it works great. I am having a ton of issues making shatter / amber glass out of my oil. I live in Denver at 5500ft. My collection pot is in a oil bath at 80 degrees. Best results so far is purging the 3A to 0 instead of -29 at end to leave some butane in the oil. then I go to 80 degree room and vacuum purge for 45 min. i repeat this step 3 times. the final product holds its shape at room temp but gets sticky as soon as you touch it. If I freeze it for a minute it will snap like shatter. Please help!!! Trying to find an end product other than sticky oil or taffy. Thank you and cheers to a successful new year!

iam having the same problem with mk3 in colorado. i believe its my N-tane only, thinking of cracking cans of newport for the iso-butane and propane maybe that will help, iused to get shatter with newport...

If you want a really good vacuum degas of the butane, then you should consider heating the product while under vacuum, if possible. If you are not getting good enough degas of the butane in 45 minutes, try extending the run. When you get to the pressure at which the butane (and some other light oils) start to vaporize, the pressure will hold steady there until all the liquid is boiled off. This could take a variable amount of time depending on how much butane etc. there is left to vaporize. While you are drawing the vacuum, check to see if the pressure continues to go down slightly over time. If it does, try keeping the vacuum going until the pressure drops much faster. When the source of vapor (the butane) is gone, the pressure should drop faster. This is assuming you are using a vacuum pump.

Hey I was wonderin if when making bho can you over cook and turn the thc into cbn making a more sedative oil. Also, if so, what will happen when put in a vacuum does this temperature and time become smaller too like the boiling point?

Vacuum reduces the temperature at which vaporization of your butane happens. This means that if you draw vacuum, your product will either degas faster at the same temperature, or you can degas in the same time at a lower temperature.

Do you have knowledge of a chart (like the one above showing THC boiling point) for BPs of common solvents (such as ethanol, butane, etc)? All the tables I can find show absolute values and don't have that handy column displaying guage inhg (below atmosphere), which we all use... The best I have found are calculators that lack consistency, even when given more than one temp/pressure variable with which to calibrate the results. Cheers

Some day you will all graduate to absolute pressure. It is far better and easier to understand. The reason there are no charts in gage pressure is because the pressure in the atmosphere outside the gage is different in various locations, and gage pressure is just a comparison of pressure on the inside to the outside. Boiling points follow the laws of physics, which are absolute. You will never find a boiling point chart in inches of Hg.

I vacuum purged for the first time and produced something that looked like crystals/rock candy. What does mean?

Sounds like you made brown sugar or gold dust shatter.

I just vacuum purged for the first time and my end product looked like crystals/sugar. What does that mean?

Sounds like you made brown sugar shatter.

Hey There! Thanks for all the great info on your site! I wanted to add a small modification I use on my vacuum process gear: I added a 1/4" check valve to the line between the ball valve and the vacuum pump. It is not perfect, and one still needs the ball valve to lock in vacuum. However, it is a very inexpensive insurance policy for extracts and vacuum oven cleanliness.

If I evaporate the ethanol naturally first with fan then collect my absolute amber and put it in the chamber and turn it on without heat is this a safe way to cold boil without needing a cold trap, thank you so much grey wolf

That would work. You may pick up some atmospheric moisture, which you will require some heat along with the vacuum to get rid of.

Do other chemicals beside THC also have different boiling points when under vacuum, such as terpenoids and cannabinoids? Also, my pump will only get my chamber to -29.5, sometimes just slightly under. Will this, combined with temperatures between 110-140 f, be capable of purging all of the butane in my oil?

Yes, all boiling points are lowered by vacuum. We like 115F at -29.5" Hg for a fast and complete purge.

At that level vacuum and temperature how many of the terpenoids are kept. Also, I still don't quite understand how elevation effects vacuum. I'm at 600 ft of elevation. Does that mean I can only pull to -24.6 hg?

There is 29.92" Hg or 14.7 pounds of pressure at sea level on everything, because that is what the atmosphere weighs. As you rise in altitude, there is less atmosphere pressing down on you. At 600 feet, there is only 29.3" Hg left, so you have to add .6" Hg to your gauge reading to get an accurate reading of what the oil is seeing.

GW, Hoping this is the right place to ask. I am happily running a MkIII and living at an altitude of 4000 ft. My vacuum pump is rated to 25 microns but of course maxes out at 85 torr due to altitude. I know there are tables that show max vac at various altitudes, etc. However I don't understand how to make the appropriate adjustments for purging temp and vac levels at my altitude. For example: Delta 9 thc boils at 315°F at sea level. I try to keep my purging temp at 90°F. Looks like from the chart that at a vacuum level of 85 torr delta 9 thc would boil at about 234°F. Hence no risk there, correct? What about the more volatile terpines? At what temp and vacuum level would you recommend at my 4000 ft.altitude for purging ethanol after winterizing? Any and all help greatly appreciated.

Your correction factor for 4000 feet is about 4.12" Hg. I like -29.5" Hg, which would read about 25.4" Hg on a gauge at 4000 feet

Thanks for your help. Thought I was on the right track but needed confirmation.

Ohmmmmmmmmmmmmmmmmm!!!!!!!!!!1

Please be aware that 25 microns is the same as 25 millitorr, which is 0.025 torr. You can't actually read the base pressure of your pump on the gage that you are using. It is too small. The difference between 25 mtorr and 100mtorr is less than the difference between 29.0 in Hg and 29.5 in Hg.

@tony, i just left a comment on the other version of this page (vacuum "purging" and processing tips) regarding this problem, its called backstreaming not to sure what allows this to enter the chamber itself but its caused by the vapor pressure point of the specific pump oil being used and during this vapor point the oil atomizes and has the potential to contaminate. Other than forline trapd there is not a lot of info on how the pump itself can keep this from happening, other than in my opinion from using a high quality pump that can be rebuilt if this oil breakthrugh happens ill i know its not the best of help but i certainly have concerns about this aswell and had to go to the right place to ask these? S

A ball valve between the pump and the chamber is required anytime you shut the pump off with the chamber under vacuum. Close the valve before shutting off the pump, and start the pump before opening the valve when the chamber is under vacuum. A further safeguard, is a cold trap between the pump and the chamber. Even if you forget the valve, or the power fails, the cold trap will contain the aspirated pump oil.

You could get an oil free pump. No backstreaming. Expensive though. You are correct that there is no way to keep the pump from backstreaming its oil, when it is pumping at ultimate pressure. However, if you keep a nice flow of air going through the pump, it will prevent backstreaming. Want specific information on backstreaming, email me. geneligman@gmail.com

Just purchased a 5 gallon vac chamber. Am using same pump as before with a 2 gal chamber getting a 37+draw.With the 5 gal chamber only get to ~15 mm hg. I know something is going on but I'm feeling stupid now but can't figure it out Thanks for any suggestions Steve

Speaking in inches of Mercury, there are only 29.92" Hg in one atmosphere, so if yours was reading 37, your gauge is out of calibration. 15" Hg is way too high for the change in chamber size, so it sounds like you have a leak. Speaking in MM Hg, of which there are 760 in one atmosphere, 15 mm Hg is low enough.

Correct, a mm of Hg is the same as a Torr. 760 mm Hg/atmosphere -- 760 Torr/atmosphere. If your pressure is an absolute reading, then 15 mm Hg is 15 torr, which is about 0.6 in Hg absolute, or 29.3 in Hg gage (at sea level). If your pressure is in gage pressure, or -15 mm Hg, then you have very poor vacuum. The size of your chamber matters in that it will take longer to pump out. What matters even more is vacuum leaks. A larger chamber might have more potential leaks. Leaks are a killer of vacuum. A tiny leak can cause a big problem with vacuum reading.

GW hey brother. In class you mentioned a Haskel pneumatic recovery pump but I can't find any info on those. Their site gives me a redirect and on ebay I am clueless as to what I am looking at. Is there a particular model number you could recommend to someone who has a mega badass air compressor at their disposal? Thankyou my friend -b

http://www.haskel.com/Haskel/en/Products/Pneumatic-Pumps/Refrigerant-Pumps

Hey I keep getting exhaust smoke in my chamber every time I start to pull a vac..we were using it for a while yesterday then all of a sudden it does that and cant seem to figure out why. I just changed the oil thinking that would do it, but unfortunately not. Im scared lol. Pleeease help me. Thanks man

What is in the chamber that could be vaporized into a mist under vacuum?

It was some shatter about 90% done. So I just put em in everclear while I tried to figure out the problem. But it even did with nothing in the chamber. So I left the exhaust cap off and ran the pump without anything else connected, like they say to do upon first setup. Right now it seems to be ok, I'm about to pull one of the jars out the freezer now. Hopefully I'm in the clear now. Any further thoughts tho? Thanks a bunch sir, always a pleasure..even tho I only hit ya up when I have a problem lol.

Not sure what ya got there bro. Glad it seems to have gone away.

whats a good pump i could get? thanks

Application and signup instructions at:http://skunkpharmresearch.com/skunk-pharm-research-classes/

im asking about a pump. i can't take the class right now. thank you tho

Several good ones out there. We've gotten several years of flawless service from our CPS VP6S 6.2cfm single stage rotary vane pump.

Suggestion on affordable cold trap? The unit that comes from my oven manufacturer (AI) is $3300.

No, we are experimenting with building our own and pumping antifreeze through it from a freezer. You might consider something similar http://skunkpharmresearch.com/1845-2/

How long does cold purging take? Today is my first time trying it and it seems to be taking forever. I have about 32oz of everclear and oil mixed and have had it under vacuum for awhile with little results. Currently the vacuum is at 1375 microns, no boiling or motion in the oil. The oil bubbled and boiled at first, then settled down. The level in the oil container has dropped, I think, but not by much. At this rate I'm guessing this will take days. I'm using an hvac vac pump, MT69 cooler, the terp. tank to catch the alcohol, and a JB digital micron gauge. I'm not heating the vac. chamber or oil, didn't think I should? I'll give an update before bed if I'm still at it. Thank you.

Cold purging isn't fast. It usually takes all day, or overnight.

The last picture in the mk III section shows a collection pot full of fluff. Was that product just extracted or just purged?

That was purged in the Terpenator at low temperature.

That's what I thought but the description of the picture says extracted. Thanks for clarifying.

GW - We have a few more questions for you. We have been running pretty successfully lately, getting our column weights up to ~130 g and our yield up around 14%, but we'd like to do better. (1) What is the best procedure, in terms of safety, yield and quality, for a multiple column extraction into the same recovery pot? So far we've done 4-column extractions and gotten out 60 g or so of BHO, at 13-14%. (2) I am seeing BHO slowly seeping/bubbling out of a couple of my connections. Does this indicate I have a leak? Will the BHO actually act to seal up the leak? What do you suggest to do about this? (3) How do you clean your rubber gaskets in between extractions? Do you clean out your entire spool between extractions? (With IPA)? Do you also clean off the top of the recovery pot? Any tips? Thanks for all the help! ~spooneyluv

The down tubes extending into the collection pot are about 1.5" off the bottom, so when the extracted oil passes that level, it starts to blow stuff around and make it messy to clean afterwards. You can gauge where that is, by the yield of the material that you are running. Multiple tube runs take longer to purge, as the pool deepens. Tighten the connections and if necessary, rewrap them with Teflon tape. They won't heal on their own. We clean the Viton gaskets with denatured or Isopropyl alcohol and use both for general cleanup.

Thanks so much for all the information, it has been invaluable. We had a few random questions before running the MkIII: (1) What is the essential purpose of the coffee filters? Do they filter out contaminants that the metal mesh does not? Would a tighter screen mesh accomplish the same thing? Do the coffee filters limit the flow of butane? Have you tried using more or fewer coffee filters? (2) Can you describe the process for the initial butane filling of the (empty) recovery tank? Do you just fill it with many cans of butane using the side tapper? (3) Does the side tapper introduce a spark risk to the system (metal-on-metal when you puncture the can)? (4) You mentioned the possible addition of a low-T heat wrap around the column. What is the purpose of this? What temps do you run it at? Is it a custom made piece, or can I find it somewhere? (5) Is there a cleaning process you recommend for the inside of the MkIII before getting started? Thanks so much, we really appreciate your site and all your hard work!

The coffee filters do the filtration, the screens just hold them in place. They are about 25 micron and have depth as well wadded up, while a single 25 micron screen might get clogged. We normally use two filters at either end, but have used more. Two or more work. If you are doing an initial fill on a 50# refrigerant tank, first let out the nitrogen fill the tank comes with and pull a hard vacuum on it using an AC vacuum pump. Hook up the Mk IIIA as if you were going to run with it, and pull a hard vacuum on it as well. Close all of the valves but the recovery pump valve and turn the pump on. Disconnect the hose from the vacuum pump and hook it to the can tapper. Place a can in the can tapper, near the bottom, with the hose on the bottom and the seam of the can fading upward. Puncture the can with the tapper, and open the vacuum pump valve on the Mk IIIA, to allow the butane to be drawn into the collection tank, where the recovery pump will transfer it to the 50# refrigerant recovery tank. When you puncture the can and open the valve, the gauge will go from -29.92" Hg, to 10 or twenty pounds of pressure, but will be again pulled down again by the recovery pump. Each time the gauge reads zero, close the valve and replace the empty can with a full one, before opening the valve again. After you have transferred all the butane to the tank, remove the hoses and cool it down in an ice bath to below 30F. When it is chilled, open the blue vapor valve and burp off the non condensable atmosphere that got pumped in. We only put about two cases in the tank at a time and the tapper is non sparking. We heat wrapped the Mk II to speed up final recovery, when the columns will coat with ice. It is pipe heat tape from Pratt Electric. I boil my Terpenators out with hot soapy water and then wipe out with denatured alcohol before running and then run a dummy load the first time, which I discard. You can inspect the unit and the extract using a black light, to detect the light blue fluorescence of petrochemicals.

Thank you for the quick response. Is the 50# tank required or would a 30# tank, or something even smaller, work as well?

Something smaller will work, but it is faster with a 50# tank, because there is more wall area to condense incoming hot butane against.

Where did you get the fitting that goes from the air compressor tube to the 1 1/2" column?

I used a 1 1/2" end cap, with a 1/4" NPT port in it, into which I screwed a 1/4" X close nipple, a 1/4" ball valve, and a 1/4" NPT to quick disconnect fitting. I got them all at Paramount Supply and if you are talking about the quick disconnect, they also have them at Ace Hardware.

I was also curious about the use of an air compressor near the setup. The owner's manual for the compressor we purchased explicitly states: "Do not operate the Compressor in explosive atmospheres, such as in the presence of flammable liquids, gases or dust.Compressor motors produce sparks which may ignite the dust or fumes." How do you operate it safely? Thanks!

We don't do open butane extraction near our compressor, or even operate a closed circuit Terpenator near it for the reasons mentioned. Unless it is an explosion proof motor and controls, it will ignite butane.

I was wondering your recommendation on using Teflon tape or pipe thread compound sealant on all of the connections? We have an HVAC guy who adamently opposes using teflon on these types of high precision connections on refrigerant lines. He says teflon is used for simple, low-precision gas lines only. Any advice here? Thanks!

As a refrigeration guy, he may not be attuned to food quality requirements for thread sealants, so I would continue to use yellow Teflon tape until he showed you the MSDS sheet for the sealant of his choice and it says it is suitable for food service.

we are having a bit of a leak issue with the mark 3.our pump quickly pumps the system is down to 29.5 inches, but after we valve of the pump, the system loses vacuum rather quickly in a matter of minutes. we have teflon taped the non-flare connections and that made a big improvement (before teflon the system lost vacuum in seconds). But now we are not sure what the leaky culprit is. We think it may be a male-male coupling that we could not unscrew to teflon it. But it may be something else like one of the 5 buna gaskets. Have you had a lot of leak issues? Is the any treatment for the gaskets such as vacuum grease you recommend? What is a good way to test for leaks? Do you use teflon on the flared connections too? How robust should the vacuum be before we can operate? Thanks so much for all the tips.

We test for leaks by putting 100/150 psi air pressure in the Mk IIIA and sticking it in a water bath to produce bubbles.

What's up been reading for hours GrayWolf I need tot ale ur class but till then , Would u recommend a drying oven from Across int.? looking at the v2 model cums with 9.5 cfm dual stage pump from what I read dual stage is not needed please would love feedback

The Across International oven that I used, worked well with a ~1" granite shelf in it to stabilize temperatures. A single stage pump is more than adequate, and even it will pull down far enough to boil away the cannabinoids at room temperature.

So I can order all the pieces from the various sites listed and the parts come pre-cut or would I have to have them machined to fit together before I can send them to be welded? Very nice device and pretty much half the cost of the tamisium.

This is showing up on the Vacuum Equipment and Process Tips comment section Brandon, so I'm confused. What device do you covet building?

Sorry about tht, when I leave a reply I jumps me all over, it might be cause I'm using a tablet. But that last comment I was talking about the lil terp, I'm pretty sure somewhere in the passage it says I'll need a machinist.

You need a machinist and a welder to make the Lil Terp.

For the little terp, instead of getting the 6"x12" sanitary spool would it be easier to just get two 6x6 spools if one had the money? To get rid of the need of cutting the 12x12 spool into to 6x6 spools

That will work fine. The Lil Terp was designed and built when only the 6" X 12" spool was available at an affordable price.

You think if I sent them (glacialtanks) that list of the materials from their site they would be able to help find a lot of the parts? I'm pretty sure they changed the majority of the codes for looking up the parts and couple of the parts aren't in stock.

What would you like to build?

Moody machine, is this Located in province rhode island, and if so do I just message them about the tank bottom blanks? They didn't have a shopping cart and just a paragraph on the products page.

The lil terp

Glacier Tanks can supply the parts if you call them by their generic names, even if they have changed the part numbers. You can also get updated numbers at http://www.glaciertanks.com/Products-TriClamp_Products.html What has changed though, since I made the Lil Terp, is that you can now get a 6" X 6" sanitary spool and by using an end cap and clamp, you can make a removable bottom. Moody machine can do the machining for you, or get Curt to do it, and can be reached at 503-544-4644.