The Terpenator Essential Oil Extractor

Our main project and the one closest to completion is our volatile gas (butane) essential oil extraction apparatus. This project started when we realized how expensive large quantities of butane are and how environmentally damaging it is to volatilize that butane into the atmosphere. We began to think of a passive recovery device that anyone could DIY with a little help from a local machine shop.

While that was in the brainstorming phase we learned of a DIY active recovery unit designed and built by FOAF, that made use of a refrigerant recovery pump. He posted it on Overgrow, and subsequently on IC Mag in 2006.

https://www.icmag.com/ic/showthread.php?t=27954

Alas, our first pump had a misclocked valve operator from the factory, and though oil less, some how butane still got to the bearings and washed out some oil into the extract.

We discovered the oil in the essential oil extract using a black light, and by the time we figured why the recovery was so ghastly slow, the seals were toast from running dry.

We were back on the hunt for an oil-less refrigerant recovery pump that was suitable for R-600 (Butane). We found a large scale compressor that is used for liquid to liquid extraction of propane from train cars; which would not be suitable for our needs.

From a fellow researcher who had similar problems with pumps, we learned of the Appion unit that ultimately proved successful. He had about 80 hours on his unit at that point without issue.

After choking a few days over the cost, we purchased the same G-5 model Appion, and we have put a several hundred testing hours on it, with one upper end rebuild. Primarily caused by running the pump under hard vacuum too much of the cycle.

After increasing our systems bottom heat and adding column heat in the final recovery, we have noted little loss of performance on the new rebuild.

We were also able to cut the process time in about half, by having our collection pot sitting in boiling water, while we kept our butane recovery and storage vessel in an ice bath.

Presently the test sled is running ten flood and soak cycles over a 30 minute period, using about 10 column volumes of butane, with full recovery in about 15 minutes. The unit has extracted in excess of 25% essential oil extract Absolute by weight, and averages in excess of 20%. A full cycle has a sample floor to floor time of 45 minutes.

With the 24" column in place, it holds about 240 grams of material, which provides an average production rate of about 80 grams per hour plus raw essential oil extract.

During testing, we noted how boring it was to watch a vacuum gauge and proved that with every new step in a manual process, there is an exponential increase for human error, so our next all stainless steel unit will use explosion proof automatic valves and microprocessor controls. Our new unit will be simple to use even for the most non technical user; load the column, push start and then clean out the collection container and column.

As we have no desire to build more than prototype test sleds ourselves, we sent the conceptual CAD prints out for competitive bid by CNC water jet cutting and machining vendors, as well as an aerospace pressure vessel shop, with ASTME certifications.

Alas, we discovered that with negotiating as an OEM, we can buy the ASTME pressure vessel lower end, cheaper than we can have one made, and even buy columns off the shelf at retail for less than we can have them made using local resources.

As our survival as a company, is more important to us than supporting the local economy in the style to which they have become accustomed, we will modify our designs to reflect that and then start posting the DIY details.

Now that the pressure vessel is a buy out, there is nothing else that isn't buildable in a garage workshop, equipped with a drill press and TIG welder.

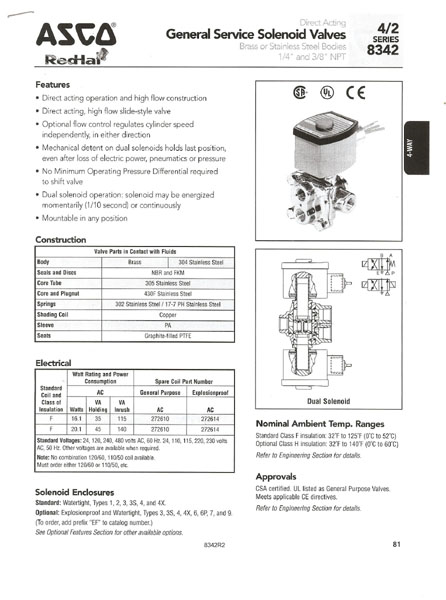

We have taken a deposit from the vender whom has our original test sled leased out, for a fully automated unit, and have ordered the pressure vessel and identified explosion proof automatic Asco valves that will work, but are still reviewing alternatives before placing that order.

The controls is the open question at this point. Our original plan was a PLC micro processor, but after looking at the price for an industrial unit, we are reviewing using simple timers and pressure switches with solid state relays to accomplish the same thing, using a hobbyist microprocessor, or building our own dedicated solid state electronics at about 25% the cost of a PLC with software.

Our mostly retired electronics genius, is pondering the issue on his current vacation in warmer climes, and will begin looking at it seriously on his return. If we end up building our own, we will post an electronics design as well.

We are building this first G-2 prototype ourselves, and I will take pictures as we progress, starting with the modifications of the pressure pot when it arrives.

The unit is designed, so that it can also be fitted with manual valves, and forgo the automation. The current manual test sled works extremely well, so the only advantage to automation, is less stand by labor, and more precise timing of process steps.

We will of course also be trying to beat old process records, whose records continue to improve, and to make loading easier and faster.

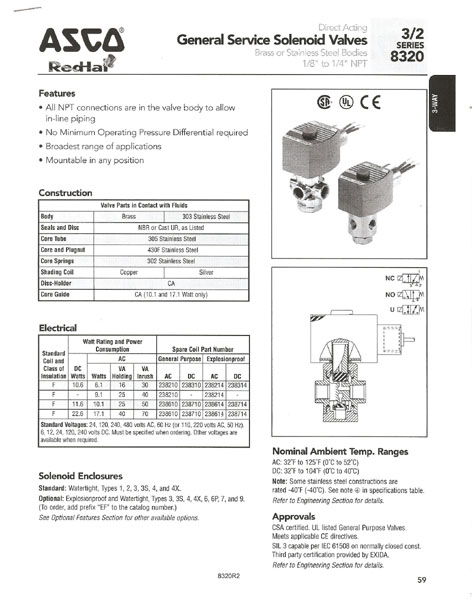

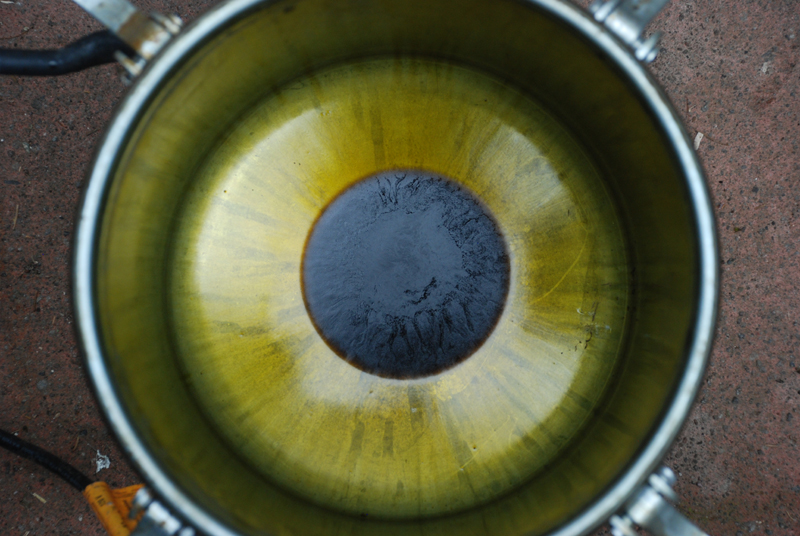

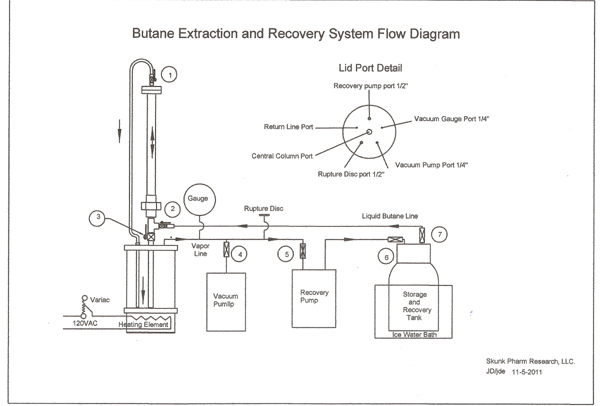

Here is a schematic of how the system operates, as well as a picture of the test sled after shakedown. Follow us to stay up on our latest development’s.

The Terpenator Essential Oil Extractor

Hi ya'll!

I picked up a 2.8 gallon Bink's Model 183S stainless steel ASTME paint pot, rated at 110 psi and am excited to try out some 1 1/2" X 24" stainless tri-clamp columns that I discovered at www.glaciertank.com.

Our target operating pressure is -29.9" Hg vacuum, to +60 psi and according to Glacier, the sanitary pipe spools are capable of several times that pressure. If it works out in field beta testing, I will adapt the Mk I test sled, to the new column, so the lessee has a common column.

The paint pot has a central opening for an agitator, which had a plug with an o-ring seal filling the hole, on my cheaper non agitated model. I dropped that plug off at a machine shop yesterday, along with the loading port lid, for modifications, which will allow me to more or less just screw the whole thing together out of available parts from this point on.

I'll share pictures of those, after I pick them up, but here are some pictures of what we have so far:

3-3-12

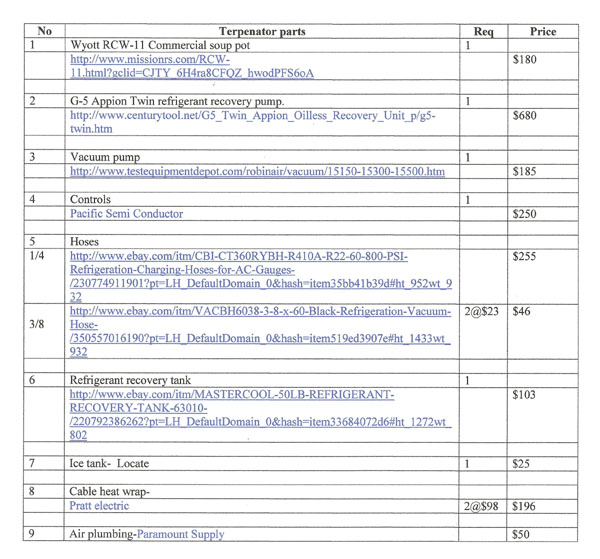

Progress is being made. I developed the process logic and then met with Bob, to discuss controls. My logic assumes three pressure switches and three timers, but we looked at using a single pressure transducer, with a 4 to 20 miliamp output, in concert with three voltage comparitors, but just the transducer was $540, as opposed to $38 each for the double pole adjustable pressure switches.

For timers, we found some premade count down timers which we will modify, and we will have two LCD timer readouts. One adjustable total process timer, 5 minute hard vacuum purge soak time, and one 20 second flood timer.

I also dropped by Paramount Plumbing Supply and looked at the ball valves with operators, which I will need to automate this unit. For both size, cost, and explosion proof qualities, I have elected to go with pneumatics, and the operators are still so big and heavy that I will have to build a metal frame to support them. Hopefully I have enough structural aluminum in my haunted garage to do so without adding much weight.

Here is the logic sheet.

Butane Recycle System Logic

|

NO |

DEVICES |

CYCLES |

||||||||

|

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

||

|

Event driver |

1.0 |

1.1 |

1.11 |

1.15 |

*2/3LOOP |

1.14 |

1.12 |

1.11 |

1.16 |

|

|

1.0 |

Turn on power |

X |

X |

X |

X |

X |

X |

X |

X |

X |

| 1.1 | Momentary start button | O | X | X | X |

X |

X | X | X | O |

| 1.2 | Vacuum pump valve NC | O | X | O | O | O | X | O | O | |

| 1.3 | Ref. recovery valve NC | O | X | X | X | X | O | O | O | |

| 1.4 | Lower isolation valve NC | O | X | O | O | X | X | X | O | |

| 1.5 | Upper vent valve NC | O | X | X | O | X | X | X | O | |

| 1.6 | Butane control valve NC | O | O | X | O | O | O | O | O | |

| 1.7 | Vacuum pump on/off | O | X | O | O | O | X | O | O | |

| 1.8 | Ref pump on/off | O | O | X | X | X | O | O | O | |

| 1.9 | Hot water pot on/off | X | X | X | X | X | X | X | X | |

| 1.10 | Column heat on/off | O | O | O | O | X | X | X | O | |

| 1.11 | Vacuum switch -29.2Hg | O | X | O | O | O | X | O | O | |

| 1.12 | Vacuum switch -22" Hg | O | O | O | O | X | O | O | O | |

| 1.13 | Vacuum switch -10" Hg | O | O | X | X | O | O | O | O | |

| 1.14 | 15 minute timer | O | X | X | X | X | O | O | O | O |

| 1.15 | 20 second flood timer | O | O | X | O | O | O | O | O | |

| 1.16 | 5 minute timer | O | O | O | O | O | O | O | X | O |

*Once in the 2/3 loop, 1.13 becomes the driver, instead of 1.11, as on the first cycle.

To initiate, turn on power and push momentary start button.

X in a column is ON

O in a column is Off

X in a column is the event that ends the cycle and initiates the next.

3-11-2012

More progress! The lessee who is operating my pumped test sled, and who ordered a full blown automated system, has continued to refine the process and has not only bumped the record yield to over 25% Absolute, but has determined that four flood cycles are all that is required.

She now has the total floor to floor cycle time down to about 28 minutes. That processes about 480 grams of material an hour, for a yield of around 120 grams of BHO Absolute. That would compare to around 130 grams of raw BHO oleoresin, before winterization.

She also no longer tries to recover 100% of the butane, but instead stops the recovery when the recovery vessel reaches -22 mm/hg, and turns on the hard vacuum pump to pump 29.9 mm/hg, which pumps off about 57 cu/in/.00095m3 of gaseous butane to atmosphere per cycle, or about $0.076 worth.

Electrical costs are about 3.3 KW per hour, at $0.09, or $0.045 per cycle.

Total operating cost, less labor and periodic pump maintenance, is $0.18/hr, or about $0.0015 gram.

We have noticed that our recycled butane is starting to pick up water, so I will add a dryer. Fortuitously, I was able to pick up a R-12 Robaire refrigerant recovery and recycle system off E-Bay cheeep, and will rob the filtration and dryer system off of it.

That includes a circulation pump, a dryer, and a water detector, which can be circulating the butane in the recovery tank through the dryer and returning it, while we are doing other things. It has been used to recover automotive refrigerant, so I will completely rebuild it and replace the hoses and dryer element to avoid cross contamination.

UPDATES ON PROGRESS

Well, progress is going slower than planned, with illness rearing its ugly head amongst usn's cadre of graying, hoary moss covered retired machinists.

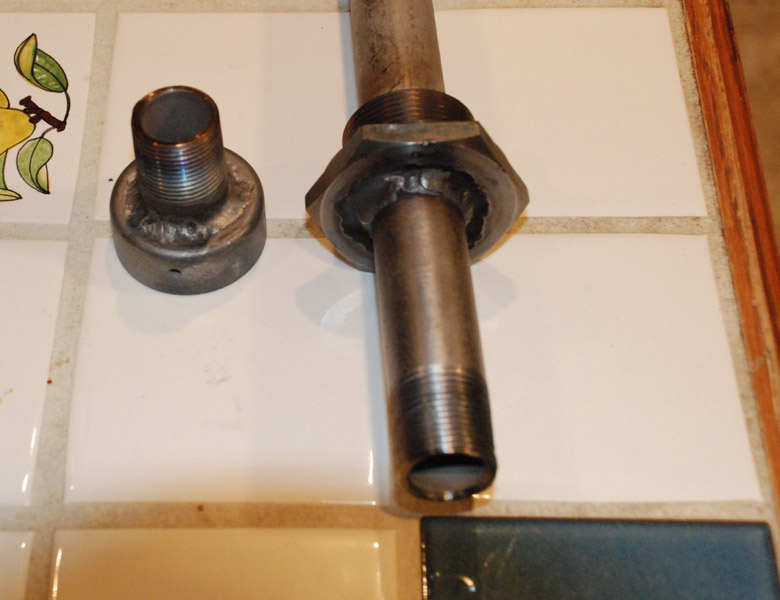

Here is the only two pieces in the basic system, that require machining or welding, and you can see how easy they are to make. They still need to be cleaned and polished, but the attached pictures show what they look like immediately after fabrication.

The center plug in the pressure pot lid was bored for an easy slip fit on a 3/4" 1.050" OD Schedule 40 316SS pipe, with 10.5" sticking out the bottom of the plug and 3.5" sticking out the top. This is where the valves and column attach.

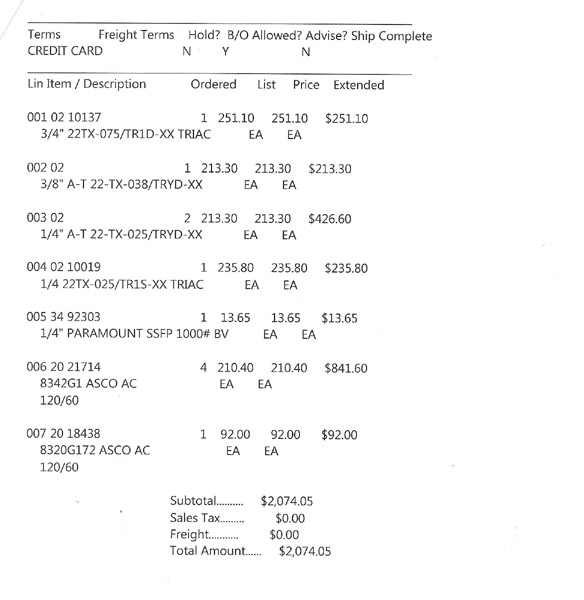

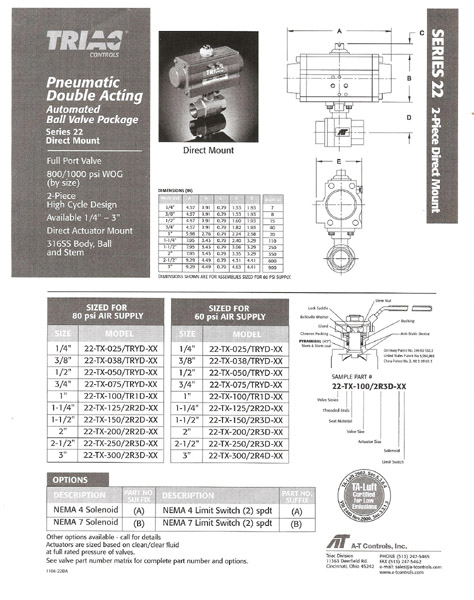

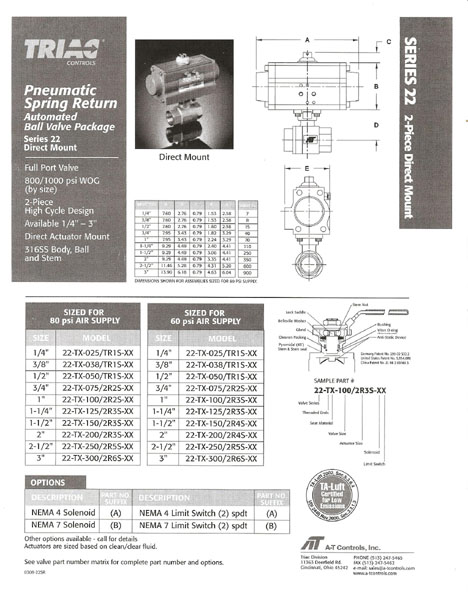

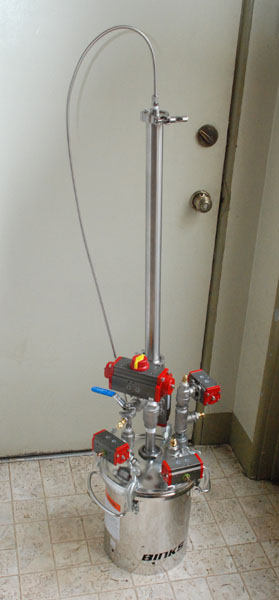

The paint port lid was also modified by cutting off the wrench boss and boring for the same 3/4" pipe. This will be for the control valves and pressure switches. We decided on pneumatic operators on full port stainless ball valves. All are air to open or close, except the butane supply valve, which is a normally closed, spring return valve for safety. The three and four way Asco solenoid valves for the air, will allow us to separate the electrical functions from the extraction area, for explosion proof protection. Here is a picture of the valves that I've ordered and the prices. Keep in mind that manual valves can be used at significantly less cost.

4-11-12 Lu lu lu lu lu lu lu lu lu lu lu!!!!!!!!!!!!!!! The pneumatic operated valves arrived and I installed them. Here is the Mk II assembled and ready to roll. The electronics are scheduled for smoke test this week end, so we are close to beta testing.

4-11-12 Lu lu lu lu lu lu lu lu lu lu lu!!!!!!!!!!!!!!! The pneumatic operated valves arrived and I installed them. Here is the Mk II assembled and ready to roll. The electronics are scheduled for smoke test this week end, so we are close to beta testing.

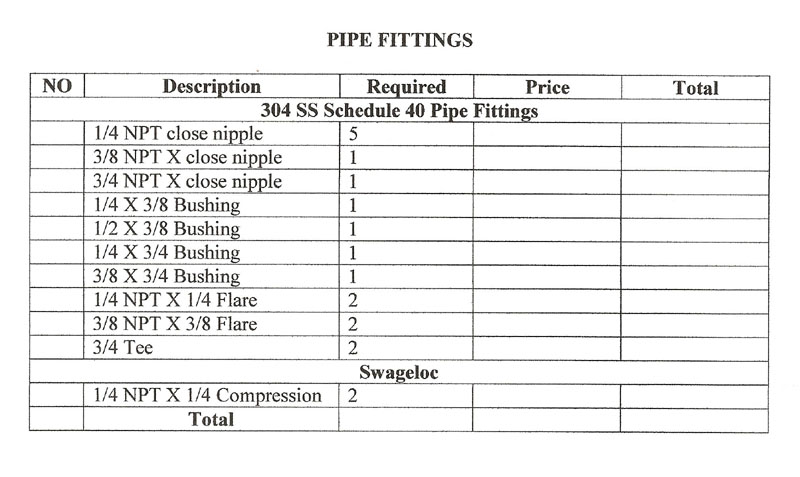

Here is a list of additional parts:

Here is a list of additional parts:

Progress on controls!

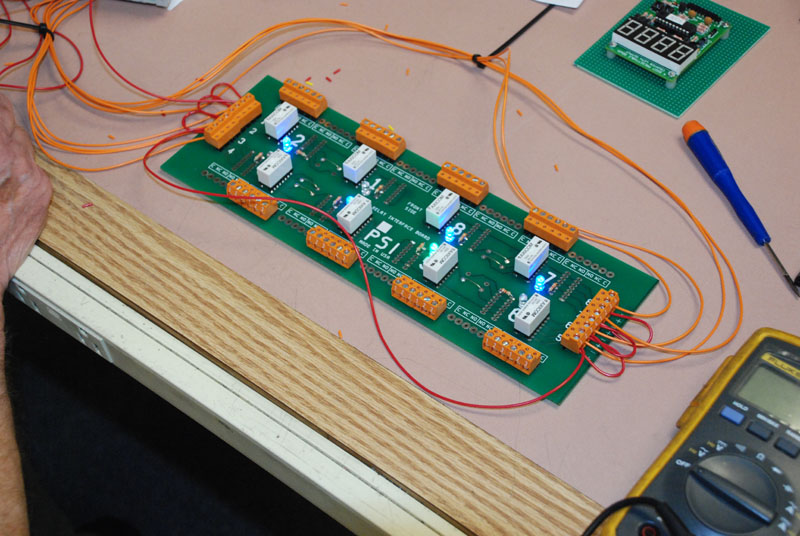

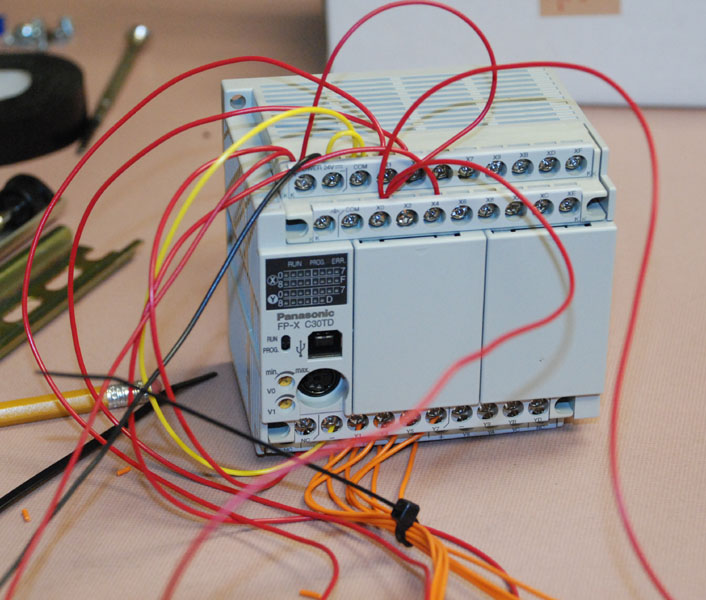

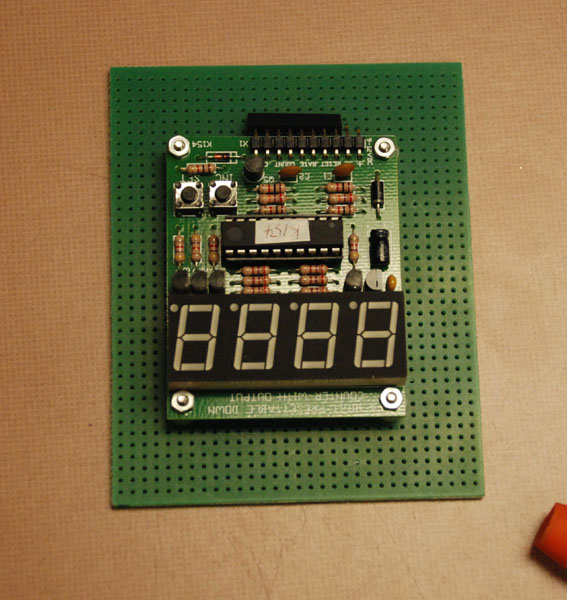

For ya'll that have been waiting with baity breath for what our resident electronics genius came up with, Bob picked a Panasonic FP -X C30-TD PLC (~$300) for the task. Because of some of the loads involved, Bob also built a relay panel, using an existing standard PSI elevator PC board, and a cycle timer display built from a count down timer kit. The heavier 2 hp and 1/2 hp motor loads, as well as the 1200 watt soup pot loads will be controlled using Crydom solid state relays. Here are some pictures of it being smoke tested before installing it in the 12" X 12" Hoffman enclosure.

Hi! So, if i'm not mistake, it was your topic on forum about "XEvil + XRumer 16.0"? Seems it' really revolutional program, that video-review is amazing! Solve a lot of captcha just in 0.01 second without any mistake at most... Incredible. Do you know where I can download XEvil program? Maybe you can share? Thank you! :)

Wrong half breed! GW

Hi. So, if i'm not mistake, it was your topic on forum about "XEvil + XRumer 16.0"? Seems it' really fantastic program, that review video is amazing! Solve Facebook captcha just in 0.01 second without any mistake at most... Incredible. Do you know where I can download XEvil OCR? Maybe you can share? Thank you! :)

Solly, not Moi if you are referring to Graywolf! Might you elaborate? GW

Look over-nice measure ingredients

Hello everybody! Do you like when new users are registering on this forum? Hope that answer is "yeah" :) I just stopped to say hi!

Hello Steve!

Welcome everybody! Just stopped by to say hi! I'm reading this board for long time and now it's great time for register account. Hope we'll have great time together!

Hi Steve!

[…] The Mk IA & automated Mk II Terpenator BHO Extractor … – The Terpenator Essential Oil Extractor. Our main project and the one closest to completion is our volatile gas (butane) essential oil extraction apparatus. […]

Great article, thank you. I have long wondered who complete decarboxylation is when smoking dried plant material, so I found this particularly interesting: "Furthermore, lab analysis of this decarboxylation reaction provides estimates that smoking cannabis yields approximately a 30% conversion of THCA to active THC." I've been playing around for close to a decade with extended dry aging in jars monitored with humidistats. I've come to the conclusion that peak potency is reached at around six to eight months from harvest. I've taken to making my hash oil (cold isopropyl extraction) at month eight for best potency. Since the chlorophyll has mostly broken down at this point, I can do longer soak times than is usually recommended.

Hello! Here is Paul. I am fresh on this forum! Greetings from Warsaw

Morning Paul! GW

I noticed the testing info in here and thought it may be somewhat appropriate to ask in here if you could provide any help with Abs/Conc. data to help me build the calibration tables for my new and 1st spectrometer, sm1100 case anyone's interested, I can only find molar absorbtion and wavelengths, any help???

Given that there were about 10000mg THCA in kief (rough estimate for 33g of 200micron), how much was captured in the final solution and did you test or weigh the filtrate?

Yes, we had an analysis done for a CBDA solution, including a flower analysis..... https://skunkpharmresearch.files.wordpress.com/2016/01/cbda-flower-analysis-1.pdf https://skunkpharmresearch.files.wordpress.com/2016/01/cbda-solution-analysis-1.pdf

Here's the THCA solution analysis for the filtered solution, 25 grams of kief dissolved in 500ml of liquid coconut oil..... http://www.catscientific.com/wp-content/uploads/THCA-Analysis-8-5-15.pdf

Excellent information. Did I understand correctly? IF injesting a juiced form of fresh plant material your metabolites will not show a positive on the drug tests currently being used? You did not comment directly on this aspect, I realize. This would be a plus for those in industry ( e.g.. railroaders) who are subject to testing. Getting the benefits without impairment is a major plus. I was forced to use anti-inflammatories (for osteo-arthritis) while on the job and my stomach is compromised. This type of insight has huge implications for the workplace. Thanks for a well written and documented piece.

Hi Blake: While the fresh cannabis plant contains more THCA than THC, it DOES contain some THC, which can convert into the form that most drug tests screen for after ingestion. Whether it is in an amount detectable by these tests depends both on the sensitivity of the test, and the frequency and dose of the ingestion of the fresh plant. More research is needed. In the meantime, I'd recommend that consumers of the fresh leaf juice or cold extractions experiment with home urine testing kits. Dr. Kate

Wowza is right! Thank you very much SPR and Dr. Kate. So much gratitude towards you all.

Great article Dr. Kate, I can't say, "thank you," enough from all medical and non medical folks. Skunkpharm, you are such great and wonderful people, much love and keep up the great work! Woot Woot

Thanks for the good thoughts brother MM! I agree wholeheartedly and continue to be impressed with the masterful quality of her work! We at Skunk Pharm Research feel privileged to have enjoyed her professional insight on many of our own projects, as well as to be able to post her work! GW

Thank you for all the great information. I have recently done some experiments with extraction processes, and found that using a dry ice extraction first to produce hash, then using a BHO or alcohol extraction to process the hash works great, especially if you have fairly large amounts of trim to start with. I typically see about 15-20% by weight of hash compared to the trim (small buds mostly). A closed loop BHO (the only sane method in my opinion) will yield about 50% by weight going from hash to wax.

http://apptopfan.com/

power tools by

Требуются рабочие в Русский поселок в таиланде по различным специальностям, а так же обслуживающий персонал. Поселок Baan Dusit Pattaya (в поселке более 750 домов, про поселок можно почитать подробнее если наберете в интернете domvtae). есть различные варианты на продажу домов 1-но и 2-ух этажные, готовые, строящиеся, а так же можно заказать строительство по вашим пожеланиям от 3 млн и до 50 млн, есть варианты аренды различных домов в поселке от 1 000 и до 20 000 в сутки. Все цены указаны в батах. На территории охраняемого поселка очень хорошая инфраструктура.

[b]Its a revolution of captchas bypassing:[/b] [b]XRumer 12.0.12[/b] automatycally recognize most difficult ReCaptchas during: + registering, + posting, + publishing, + profiles autofilling (with avatars also) + personal messaging, etc.! [b][color=red]"Super-difficult ReCaptcha"?! Lol, its not a problem now![/color][/b] Botmaster Labs (c) creates a new revolutional technology of Google's JavaScript processing [img]http://s020.radikal.ru/i700/1505/a0/41c2354407ae.gif[/img] [b][color=red]"ReCaptcha like a House-number"?! New russian technologies make it not a problem too ;-)[/color][/b] [img]http://s019.radikal.ru/i630/1505/34/95aa7a1abe5e.jpg[/img] Also, in [b]XRumer 12.0.12[/b] significantly improved work with such engines as: [i]+ XenForo + Discuz + PhpBB (latest versions) + MyBB + VBulletin + Drupal + a lot of guestbooks[/i] [b](at all, XRumer works with more than 150 different engines)[/b] + a lot of improvements of another antibot processing (textcaptchas like "What is last name of Bob?", CloudFlare, StopForumSpam, etc.) [b](at all, XRumer know more than 500 types of graphical captchas and more than 200.000 types of textcaptchas)[/b] --- With purchasing [b]XRumer 12.0.12 Elite[/b] you will get [b][color=green]ABSOLUTELY FOR FREE[/color][/b]: [b]1. SocPlugin[/b] XRumer's tool for working (messaging/inviting/liking/promoting/autofilling) of [b]Facebook[/b] and several other Soc.Networks with captcha bypassing (unique: [b]no any service needed to captchas recognition and bypassing![/b]) [b]2. BlogsPlugin[/b] New XRumer's tool for autoblogging. Free beta version. Mass registration of account on the: [i]+ Wordpress + Blogger + Livejournal + Tumblr + Bloglines + Netvibes[/i] Need more info? Just Google for [b]"XRumer 12.0.12"[/b] :-)

GW, I love this site. Best place on the Web to receive a free education. One thing I can not seem to understand is the use of a recovery pump such as the appion g5. These pumps and lines are not food grade and have been shown to contaminate. Am I missing something? I'm looking for a suitable recovery pump for the rask...rated for flammable gases and using food grade parts. Any thoughts?

Nevremind I have found a suitable pump...and I believe since the original post some time ago you have changed the pumps you use as well.

GW, your thoughts on the CPS-TS21? Does it pump, Flammable refrigerant, YES!

GW, I have a design feature, I would like to discuss with you. I have seen a few addy's for you. Which is the best? Thanks. Can send drawings.

Question. Why would you install a ignition source,(electric heating coil), when Thermal conduction(hot water bath) would work? Why install a component, that may lead to catastrophic failure/explosion for the novice or the not thinking tech? Glacier Tanks, are Building for me a sealed jacketed, water bath. Will be able to circulate water at any temp, against 98% of collection vessel. Plus, no hot spots! ........just a thought.

[…] rn rn rn rn rn rn rn rn rn rn rn rn rnrn rn more expensive one: rnThe Mk IA & automated Mk II Terpenator BHO Extractor | Skunk Pharm Research LLCrnrnrnLess expensive one: Lil’ Terp Passive BHO Extractor | Skunk Pharm Research […]

How long do you recommended to purge at full vacuum before pulling the product?

Hello friends, good article and nice arguments commented at this place, I am actually enjoying by these.

The Bink's paint pot, what model goes to 120/psi in the 2 gallon stainless range? Is the Bink's 183S-200 right? The manual says its rated at 110/psi max. Thanks!

We used the 2.8 gallon 183S stainless pot, which is rated at 110psi and I corrected the incorrect blog number. Normal operating pressure is under 50 psi, so it is within its certified range. EDITED:

Is that just the latest and greatest upgrade? In your blog you mentioned this comment: "I picked up a 2 1/2 gallon Bink’s stainless ASTME paint pot, rated at 120 psi" Was that an older prototype that had issues and needed to be doubled or something? Thanks!

Sorry, my error. Old age and too many things and too much time. I had to go dig out the records to see what the correct numbers are. We used the 2.8 gallon 183S stainless pot, which is rated at 110psi and I corrected the incorrect blog number. Normal operating pressure is under 50 psi, and I've never seen one over 80 psi in extreme conditions, so it is well within its certified range. We did have a problem with the bottom drain leaking on the first one that we bought, and the plug was galled in place, so we couldn't tighten it or remove it. Binks immediately replaced the tank, but you might make sure that you can remove that plug before you leave the store, so that you can tighten it as necessary using Neverseize to prevent galling.

I have a bhogart 2.5 system which appears to be the exact same as the terpenator. I am having issues understanding this thing. I cant even seem to get the vac pump going right to get the air out and load butane. Frustrated and willing to pay $100 for someone local in Portland to come over for a couple hours and show me from start to finish how to use this thing so I can stop starring at it and actually use it.

Could you post an email addy where someone could contact you that has experience. Skunkpharm is unavailable currently.

they got a video breakdown on facebook on how to setup and operate

What if you want to make your own BHO and reclaim your butane, but don’t have the money to assemble a Terpenator? See: http://skunkpharmresearch.com/projects/ That's how I came to this page. So am I understanding this correct? I need to purchase a paint pot, fit it with hand operated valves,a recovery tank, and order the parts for a column. Then I will have a cheaper version of the lil terp? BTW...Thank You! I have successfully been pulling bho extractions and winterizing with all your helpfull info.

The Mk I, II, and III are Terpenators, not a Lil Terp. They all use recovery pumps, while the Lil Terp uses heat and cold. Check http://skunkpharmresearch.com/passive-butane-extractor-and-reclaimer/ for how to build a Lil Terp.

I do not know if it's just me or if perhaps everyone else experiencing problems with your blog. It seems like some of the text in your content are running off the screen. Can someone else please provide feedback and let me know if this is happening to them as well? This may be a issue with my web browser because I've had this happen before. Cheers

No other reports bro, but thanks for the heads up!

hey gw - so i've been suspecting my system is losing butane from somewhere, as for the past few weeks i seem to have to add a can of butane for every column i run, i.e. i added 3 cases of lucienne to a fresh recovery tank and ran about 30 columns before needing to add more. added 2more cases, ran about 20-25 columns and ran out, then added 1 case and got about 10 columns before running out again. my actual terpenator has a very small leak at the top compression fitting, but not enough to lose that much butane. i never smelled butane leaking from anywhere until today when i was adding more butane to the system, i could smell some coming off of the front of the appion; also, the air that was blowing from there was hot, which it usually is not. does this sound like it needs the rebuild kit, or a different issue? the appion has also seemed to run a little louder/more rough in thes past few weeks as well. thanks!

I use 100 psi air pressure and soapy water on our systems to detect leaks. To test to see if the Appion needs to be rebuilt, close the discharge valve and open the intake valve before turning on. It should pump up to around 500 psi pressure and then shut off. It should also hold that pressure without cycling.

Yep, it needs a rebuild - Thanks. Do you know if they carry the kit at rsd?

Don't know. I got mine at http://www.centurytool.net/G5_Twin_Appion_Oilless_Recovery_Unit_p/g5-twin.htm

When some one searches for his required thing, therefore he/she wants to be available that in detail, thus that thing is maintained over here.

I'm not sure I follow. Could you explain further?

hey grey wolf hope all is well. So i have 4 extractors going like double kindness and they are ripping it up. had some problems with sappy extracts but that issue has resolved itself. today the appion g5 five started knocking a little and then started making all kinds of crazy noise so i shut it off. i saw the rebuild kit at century tools for $230 . i guess i should disassemble and see what needs to be replaced. i presume these motors are like a four stroke dirtbike motor. Valves, piston, cylinder etc

Knocking may be a different issue. The $230 rebuild kit is just valves and seals for the upper end. It is a dirt simple system, with the two piston rods moving back and forth and poppet valves maintaining the vacuum.

after some investigation it was discovered the gearbox crapped out . $105 from century tool. yeah the pump rips. where can i get some safety head/ruptures discs for this system. it seems like a good safety feature thanks for the help

http://www.zookdisk.com/

What is a rupture disc and how would it be used with this system?

A rupture disc is a metal disc that bursts at a given pressure, used in lieu of a pressure relief valve, because the system sees both pressure and vacuum. It is a safety device to guard against over pressurization to the point of something breaking. The weakest point on the Terpenators is the lid, which is rated at 120 PSI on the Mk IA &Mk II's, and 150 psi on the Mk IIIA. To be rated at 150 PSI means that the failure is somewhere three X of that pressure. The valves are rated at 1000 psi and the hoses at 800 psi, with a 3000 psi burst. They typically operate under 50 psi. I only added the rupture disc to the Mk II, because it is automated and has no one there to monitor the pressure gauge. If it ruptures, it vents the butane outside of the building that houses the exhaust cabinet that the system runs in, so that there is never a combustible level of butane in the cabinet or building. They can also be a bad thing, in that you have to change them regularly, or the constant oil canning from both vacuum and pressure, results in high cyclic fatigue.

More pumps designed for R-600 or flammable refrigerants.. With fail safes to possibly consider in future models?. . . http://catalog.vtechonline.com/item/refrigerant-supply-systems/stems-accessorial-equipment-for-refrigerant-supp-2/ptg?& http://www.vtechonline.com/vtech-hydrocarbon-refrigerants-r600-r290-charging-systems.html

Thanks for the heads up bro! I asked them for engineering specifications sheets, so we can see some performance data. Of specific interest, is transfer rates of vapor and lowest vaccum levels achievable.

any way we could see some more pics of the product it makes?can you make shadder?

It will make anything from carboxylic acid shatter, to partially decarboxylated oil, depending on how hot you run the hot water bath. It takes about 75F to just keep up with the refrigeration of boiling butane under vacuum, but you can cut the time in at least half, by running the pot up to 212F. I sent you two pictures to your address, one showing raw oleoresin shatter and one thin film AA shatter. Both extracted using a Terpenator. GW

Does running your collection pot that hot have any effect on the terps or color?

You need to use a desiccant filter dryer when reclaiming vapor, you want to get one of the larger sized ones with a sight glass after it that indicates moisture content so you know when to swap it out, you can build a refillable one with a 12" tri clamp spool with appropriately sized npt adapter ends and npt to flare fittings. If you elect to build your own refillable / reusable filter fill it with combination of watcom filters at the ends and activated alumina beads followed by activated charcoal and zeolite, just make sure to have at least a few layers of 5 micron filter paper packing between layers and before inlets and outlets ifyou build your own filter, this will prevent water pickup from the material your processing, it also is beneficial to use a hygrometer to insure your material is as dry as possible before processing if you want shatter / thick sap consistency,.. Honey comb is what happens if you don't get all the butane out, you need to thin film purge it between 115 and 145f and preferably have a sight glass on your evap / vacuum back off chamber .